Assessing the extent to which it is necessary to manufacture a homemade electric tile cutter

If in order to efficiently perform a small amount of tile laying work there is a need for an electric tool, then after reading the recommendations below, you can make such a tile cutter with your own hands.

Before you start making a homemade electric tile cutter, you should critically evaluate your design and installation abilities and capabilities, since even minor errors in the manufacture of such a device can lead to injury.

If you don’t have confidence in your abilities, then you should at least entrust the assembly of this tool to an experienced performer; ideally, you should rent a factory-made electric tile cutter.

Making a tile cutting table

To smoothly feed the tiles under the rotating disk of the grinder, the table surface must be flat and smooth. In addition, for reliable fastening of the angle grinder, the material of the tabletop must be durable. Therefore, the optimal solution would be to manufacture a rigid steel table frame from corners or rectangular profiles with electric welded joints. Then, according to the size of the frame, you need to make and mount a table cover from sheet steel 5-6 mm thick with a slot made with a milling cutter to match the thickness of the grinder disk with a margin of 2-3 mm.

For safety reasons, the grinder disk should NOT protrude more than half its radius from the slot above the table surface.

From below, pieces of a rectangular steel profile measuring 40 x 60 mm or a steel strip 4-5 mm thick are welded onto the table cover in continuation with slits or parallel to it, to which the Grinder will later be attached.

Making an editing table with your own hands

On the tile cutter table, you should install a movable bar parallel to the cutting disk for strictly linear feeding of the tiles under the cutting edge. To do this, to the left of the disk (if you look at the cutting edge), perpendicular to it, you need to make two parallel slots at a distance of the length of the bar between each other, along which the ends of the guide bar will move, secured in the desired position with a bolt-nut through the slot.

READ Storage of Cutting Discs for Grinders

Advantages of a tile cutter

| An electric tile cutter is quite an expensive device, and if you are not a professional tiler and are doing simple repairs, then buying it is not justified | If we make a tile cutter with our own hands, then we need to use an appropriate disk. In order to prevent the appearance of dust during tile cutting work, it is necessary to equip the tool with a special container of water. In most cases, it is attached under the disc. During the work period, the disk from the bottom side is dipped into water and washes away dirt and dust. This ensures the most accurate tile cutting work. |

The advantages of an electric tile cutter made from an angle grinder include:

- Possibility of sawing durable porcelain stoneware and stone;

- The fastest possible processing of large volumes of material;

- Ensuring the possibility of the most even cut;

- Reduced wear rate when compared to hand tools.

Due to the presence of a large number of advantages, the grinder is widely used as a tile cutter among many builders. How to make a tile cutter from a grinder can be seen in the video.

How to make a tool

You can assemble a tile cutter with your own hands quite quickly; for this you will need a regular set of construction tools.

In order to make a tile cutter from a grinder with your own hands, you must first understand the features of this tool. It can be used to cut all types of tiles. Thanks to this tool, the highest quality tile cuts are made.

To carry out cutting, it is necessary to install a diamond or corundum disk on the tool. They must be securely attached to the tool.

| One of the options is a sawing table and an angle grinder attached to the bottom of this table | It is possible to make an electric tile cutter with your own hands, which can be installed on a workbench or table. This will provide convenience while cutting tiles. Thanks to this design, the most even cutting line will be ensured. |

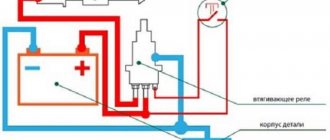

| Another option could be to assemble a structure, as in this diagram |

|

Many people ask how to make a tile cutter with your own hands? For this purpose, it is necessary to correctly install the angle grinder, which is equipped with an appropriate disk. If the method of horizontal fastening of the angle grinder is used, then it is necessary to ensure a strict vertical position of the working disk. When cutting tiles, you must ensure that they are positioned perpendicular to the cutting tool. The process of cutting the disc in this case is carried out with outstretched arms.

What tool can you work with?

You can assemble a homemade tile cutter, but this is not always required, because the process of assembling it will take you quite a lot of time and will also require a certain tool. For example, to make a strong frame, you cannot do without a welding machine, which already imposes certain difficulties.

When working with ceramic tiles, you need to understand that cutting them cannot be avoided

Therefore, to begin with, we will tell you what you can work with when laying tiles without having expensive equipment, and what you still cannot do without.

- One of the simplest devices is a classic glass cutter . It only works with thin ceramic wall tiles. Alternatively, you can use it, but there is a more interesting and convenient solution for the same money.

Glass cutter can be used to cut tiles

Types of manual glass cutters

Glass cutter for cutting tiles- This metal pencil or pobedit scriber perfectly cuts through the glazed surface of ceramic tiles. In addition to it, you need a good metal guide (ruler) and a device for breaking tiles.

Metal scriber with pobedit tip - Tile breaking tongs included in the kit with previous tools. They easily and conveniently split the tiles along the line made.

Tile breaking tongs

Scheme for cutting tiles using a glass cutter, a match and tongs

Even if you can put together a homemade tile cutter, laying tiles is almost impossible without an electric abrasive cutter.

- Firstly, when passing through window and door openings at the corners, it is necessary to make L-shaped cuts.

- Secondly, today in bathrooms they install sockets, hoods and other equipment, for which holes need to be made in the tiles. You can do them with a grinder or use an electric drill with crown attachments for ceramics.

- Thirdly, today porcelain tiles are mostly laid on the floor, and cutting it with a manual tile cutter, even a professional one, is very difficult.

When laying tiles, you can’t do without an electric abrasive cutting machine.

Homemade electric tile cutter

You can make a tile cutter yourself from a grinder. This is a complex process, but the result is a very practical tool.

An angle grinder is often used to cut tiles, but it is difficult for it to achieve an even cut, and it also generates a lot of dust, making work uncomfortable.

The proposed version of the tool eliminates the above disadvantages. Even a person who does not have special skills and technical knowledge can make it.

Required:

- Bulgarian. You must use a fully functional tool.

- Metal plates. Their thickness should be 5mm, and the plate size should be about 150x60mm.

- Metal ring. Its width should be 20mm, the internal diameter should coincide with the diameter of the flange on the angle grinder. It can be made by cutting off a part of the pipe with the required parameters.

- Textolite sheet measuring 300x200mm and about 30mm thick. This will subsequently become the base of the device.

- Four 10mm nuts, three 10mm bolts, self-tapping screws of the appropriate size.

- Tools for processing metal elements.

- Drill and set of metal drills.

- Welding machine.

What is needed to make a homemade tool?

An electrical device is much more expensive to manufacture than a mechanical one, but it is more convenient to work with, and the quality of cutting tiles will be much higher. To make it you will need the following:

- table or workbench

- grinder with diamond blade;

- metal platform;

- two steel pipes;

- fasteners;

- clamps.

You can save on equipment if you buy a cheap cutting element, but this is not recommended, since the quality of the cut and productivity of work depend on it.

Choosing an electric motor for a tile cutter

To make a tile cutter with your own hands using an independent electric motor, you need to select and install a gearbox to be able to manually set the required disk rotation speed. Technically, this is not easy to do, so another solution is common - using a small grinder (a grinder for discs with a diameter of 115-125 mm) with the option of manually adjusting the rotation speed.

Electric motor for tile cutter

Necessary materials

If you don’t know how to make a tile cutter from a grinder with your own hands, then you can use a vertical tool mount. In this case, it is necessary to ensure that the surface of the table and the upper part of the gearbox are located on the same plane. There may be deviations of several millimeters. The cutting element of the grinder in relation to the table surface should be located at an angle of 90 degrees.

In order to make an electric water-cooled tile cutter with your own hands, you need to use the appropriate tools.

Most often this procedure is performed using:

- Metal sheet;

- Bulgarians;

- Clamps, the diameter of which is from 0.8 to 1 centimeter;

- Nuts and locknuts.

You can make a tile cutter with your own hands if you have a grinder at hand. With this tool it will be quite easy to make cuts.

Types of homemade tile cutters

Depending on the design features, these devices are divided into 2 types:

- mechanical;

- electric.

The mechanical one is a platform on which the tiles will be fixed and cut. Usually for this purpose they take a thick board with a flat surface. Guides and a cutting element are attached to it, which is usually a glass cutter and replace the cutting head with a blade. You can see a homemade mechanical tool in the figure below:

Performing a manual tile cutter

List of required materials:

Scheme of using a manual tile cutter.

- durable board;

- 4 corners made of steel 20*20;

- 2 steel corners 40*40;

- 2 bearings;

- a shaft that fits the bearings (about 5 cm);

- steel pipe corresponding to the diameter of the shaft (approximately 2 cm);

- strips of durable rubber;

- electric welding.

Assembling a manual tile cutter is done as follows: small corners are welded to the outer part of the large corner so that the bearing can easily move between them. This is half of the main part of the tile cutter. The other part is performed symmetrically to the first. Next, you need to mount the cutting component of the tool. For these purposes, a handle and a holder for the cutting part, which can be a standard glass cutter or other pointed component coated with diamond, must be welded to a steel tube.

This design is put on the shaft, and its edges are pressed into the bearing bushings. The cutting device is retracted to its initial position. It will also be necessary to secure the ends of the load-bearing corners using electric welding. At the same time, it is necessary to check the movement of the cutting part along the gap left between the supporting angles. If there is no vibration and the passage is carried out with ease, then the main part of the tile cutter is done correctly.

Scheme for cutting tiles with a glass cutter.

All that remains is to glue the rubber strips to the bottom and remove the chamfers from them. When the glue dries, you will need to secure this part to the wood base.

There can be a variety of design options. It is important that the metal part moves easily in a vertical position and there are no deviations along the horizon line. The simplest device consists of standard door hinges, which are attached to two parts of a tile cutter. The disadvantage of this design is that it will not allow cutting material of varying thicknesses. It is advisable to use hinge designs that are height adjustable. The homemade tool is ready!

We make the tile cutter ourselves

As you already understand, the most popular solution will be a manual tile cutter. It is its design that we have covered in more detail than the others, and it is this that we will try to assemble with our own hands. In this case, the master will make a tile cutter that is capable of cutting 120 cm tiles. You can make a more compact version.

Table. Step-by-step instructions for making a manual tile cutter.

Photos, stepsDescription

| Step 1. Preparing materials | To work, we will need 4 rectangular pipes with a cross section of 50*30 cm, metal plates, steel angles, a pin, bolts, bearings, etc. |

| Step 2. Blanks for the guide | The rail guide will consist of two pipes 130 cm long. We cut them using a grinder, having previously marked the rectangular pipes on four sides with a pencil and a square. Cutting is also done on each side separately to ensure everything is as straight as possible. |

| Step 3. Sanding the rails | We select the side of the pipe with the least rounding and grind it so that nothing interferes, with the same grinder or drill, installing the appropriate attachment. This will be the inner part of the guide in which the carriage will move. Advice! We recommend processing the pipe from all sides at once so that your work is beautiful from an aesthetic point of view. |

| Step 4. Making the bed | For the frame you will also need two pipes, which we cut to the same size and grind. We install a metal strip between them, which will serve as a break, and weld it all together. First, we grab the parts from the ends, after which we turn the element over and go point by point along the entire length. |

| Step 5. Connecting the bed with the slide | The next stage includes several points at once. 1. A stud is welded to the frame at the ends. 2. A slide is made - two pipes are connected so that there is a gap of 4.5 mm between them. 3. Nuts are welded to the guide at the top and bottom, in which the threads are drilled. You can replace them with plates with holes. 4. The structure is assembled in such a way that another, independent one is placed between the nuts, with the help of which the height of the slide will be adjusted. 5. A lock nut is installed to clearly fix the guide in one position. |

| Step 6. Making bushings for bearings | Our carriage will be made of a 4 mm stainless steel sheet, to which a cutting wheel will be attached. The carriage will run due to bearings, the axis of which will be the bolts. The bolts in the bearings are loose, so we make an intermediate sleeve from ordinary nuts, grinding off all the edges with a grinder. For this we use a fixed drill and a bolt clamped in its chuck. Everything is very simple and done quickly. |

| Step 7. Assembling the guide | We first assemble the moving element. It is assembled in the following sequence: bolt; sleeve; bearing; two adapter nuts, between which the carriage will then be clamped; sleeve; bearing; screw. |

| Step 8. All parts for assembling the carriage | The base of the carriage in the photo is on the left. A part is cut out of a piece of stainless steel, to which a nut is welded on top, and holes for moving parts are drilled at the bottom. |

| Step 9. Start assembling the carriage | The cutting wheel on a bearing is mounted between two brackets, after which everything is bolted together. |

| Step 10. Connecting elements into one system | Install the cutting wheel on the carriage. The far mount (large bolt) is the mechanical part that we pre-assembled before. Interesting! Please note that the wheel can be installed in two positions. |

| Step 11. Fixing the separator | We fasten the last structural element – the separator. Let us remind you that we use it to break the tile when pressed. Advice! Photos show detailed assembly for better visibility. You will have to do it right away on the machine itself, otherwise you won’t be able to push the carriage inside. |

| Step 12. Finished tile cutter | Let's add the finishing touches to our design: · attach a handle - in the example, the master used a piece of polypropylene pipe; · glue pieces of foamed heat insulator as a soft base of the frame; · install a clamp on the carriage above the rails so that it does not slip. By the way, bearings could also be placed on top for better sliding. |

The work of making such a tile cutter is not easy and requires the performer to have certain turner skills, but if you have all this, as well as free time, you can make a very high-quality working tool. Such a handsome man has, perhaps, only one drawback - he will be very heavy.

Making a mechanical tile cutter with your own hands

A manual tile cutter is a safe tool and does not require connection to an electrical outlet. These two factors ensure the popularity of this model. In addition, due to its relatively light weight, such a tool is easy to transport and you don’t have to spend a lot of money on its production.

Manufacturing of a moving element

At the next stage, it will be necessary to make a slider that will move back and forth along the entire length of the base.

To make a movable base, we need two pieces of metal corner. We arrange them as shown in the photo below and weld them together.

Additional upgrade

The tool can be supplemented with a dust collector. To do this, a groove about 4 cm wide and 1 cm deep is made from the bottom side of the textolite base. It starts next to the edge of the cutting wheel and ends on the opposite side of the base, a few centimeters before the edge. A hole with a diameter of 3–4 cm is drilled in this place. A metal plate with a hole is attached to it using screws on top, to which an adapter 4–5 cm long, cut from a metal pipe, is welded. The diameter of the pipe is equal to the internal diameter of the vacuum cleaner air duct, which is put on the adapter. Now, when you turn on the vacuum cleaner, all dust will be sucked out from the work area.

You can make a simple guide device for a tile cutter, thanks to which the accuracy and quality of the resulting cut will increase significantly. For this, a metal plaster rule of the required length is used. It is secured to the tile using clamps (double-sided construction tape will also work) at the required distance to the cutting line. Resting against the smooth edge of the rule, the tile cutter moves along it and makes a perfectly straight cut.

Making a tile cutting table

In order for the ceramics to flow smoothly under the disc, you need to make a smooth tabletop. In addition, it must be strong enough to securely secure the cutting tool. Therefore, experts advise using a rigid steel frame made of corners to make the tabletop. All parts must be connected by electric welding. Then we adjust the tabletop to the finished frame. A sheet of steel 0.5-0.6 cm high is suitable for this. Make a slot on it for the saw blade with an excess of 0.2-0.3 cm.

Note! To protect yourself when working, mount the angle grinder so that its disk does not protrude more than halfway from the slot.

Under the tabletop, in continuation of the gap or parallel to it, you need to weld a steel profile measuring 0.4 * 0.6 cm or a steel strip 0.4-0.5 cm thick. A grinder will be attached to them later.

On the fixture table, install the moving bar parallel to the grinder to directly feed the tiles under the disc. To do this, to the left of the grinder, perpendicular to it, make 2 parallel slits at a distance of the length of the bar between each other. HP will move along them. Its ends will be secured with bolt nuts through the slot.

Installing an angle grinder

You can attach the grinder to the bottom of the tabletop in different ways. Make sure that the fastening is rigid and strong. This is important because otherwise, when cutting tiles, the grinder may jam in the slots of the countertop. Also, when installing the saw, consider the possibility of:

- operate the on/off buttons;

- adjust the grinder rotation speed;

- change disk.

To prevent the bolt from turning out, a Grover spring washer is placed under its head.

Grover's washer

Also, to this connection, the tile cutter is attached to the tabletop with clamps made of strip steel, made according to the table drawing. To lay between the “body” of the file and the table, wooden blocks are used. Grooves should be made in them according to the shape of the grinder.

How to cool a homemade tile cutter

Factory electric tile cutters have a water cooling system. Its design is influenced by the location of the grinder, that is, it can be above or below the table. Making an electric water-cooled tile cutter of this type at home is extremely difficult and pointless. To cool a diamond blade, a simple air blow is enough.

It is also important to remember that you cannot use an angle grinder if the humidity level is more than 85 percent. Based on this, it can be assumed that the file cannot be wetted.

Manufacturing

From metal plates you need to cut:

- Three parts measuring 40x45mm. One short side needs to be ground off to form a semicircle, so that after installation is completed, the corners will not interfere with the rocker arm rotating around its axis. A ø10mm hole must be drilled in the center of each element;

- One piece measuring 40x100mm, which will become the lower part of the mechanism. It needs to be bolted to the PCB base. For fastening, you need to drill two holes ø10mm;

- One - 40x80mm, acting as the upper part of the mechanism;

- One piece with an L-shaped irregular shape that will become a lever. You will need to attach a grinder to the long side. The other side must be placed on the central axis through the hole made.

Manufacturing process:

- Make a clamp from a metal ring that will be installed on the support flange. To do this, you need to remove part of the circle (approximately 10mm). Weld one 10mm nut to the outer diameter of the ring at both ends of the removed part so that a bolt can be screwed into them. When tightening the bolt, the ring should compress.

- Next, the resulting clamp must be welded to the edge of the long part of the L-shaped element.

- Metal blanks must be placed on the central axis from a 10mm bolt, tightened with a nut and welded so that the mechanism lever can rotate around its axis.

- Screw the rocker device to the PCB plate through the holes in the bottom of the mechanism.

- Equip the support flange on the angle grinder with a clamp, choosing the most convenient location. Tighten the clamp and secure the tool. The sawing disc should not touch the edge of the PCB.

- A protective shield needs to be installed on top, which must be secured by welding.

- A small hook or loop must be welded to the top of the device. Attach a spring to this part, the compressed length of which is about 50mm. It must be tensioned so that the driven tool is positioned so that the bottom of the cutting wheel is higher than the base.

- The other end of the spring must be hooked to the hole in a small corner, which must first be fixed on the textolite plate with a screw.

The electric tile cutter is ready. They need to cut by moving the device along the marking line.

Cutting tiles with a homemade tile cutter is not so easy, but at the same time it is not that difficult. The main thing is to have a “steady” hand and a “sharp” eye.

Of course, it cannot be compared with a professional tool, but if you wish, you can perform the necessary work with such a device.

Tips for using the tool

A tile cutter from an angle grinder is an easy-to-use tool, but, as with any electrical equipment, the following safety rules should be followed when working with it.

- It is necessary to cut the tiles away from you, without creating too much pressure.

- It is recommended to start cutting from the outside of the tile.

- If you need to cut tiles, it is better to fix them with special pliers. This will allow you to do the job better.

- It is strictly forbidden to operate the tool while intoxicated or after taking antihistamines, as this may cause injury.

- If you have never worked with such equipment before, then before you start cutting tiles, it is recommended to practice a little so as not to inadvertently spoil it.

- In order for the cutting line to be perfectly straight, you need to draw a straight line on the tile with a simple pencil.

- When cutting tiles, you must wear safety glasses to prevent dust or small chips from getting into your eyes.

If you live with small children, then you need to store electric tools in a room to which they do not have access.

additional information

When installing an angle grinder, there is no need to lay a metal sheet over the entire surface of the table. It will be enough just to cover a corner of the working surface with it, which will ensure maximum cutting accuracy. Also, a metal corner will ensure high accuracy of tile cutting.

Using a grinder, you can make an automatic tile cutter with your own hands, a photo of which can be found on our website. Unlike manual models, when using this tool, microcracks may appear on the tiles. When using a tile cutter from a grinder, you can avoid such troubles.

| Ceramic tiles can be easily trimmed without expensive tools |

|

After this, cutting is done using a grinder. When installing the tool, everything must be done to ensure its stability. This will guarantee convenience during the work. Any craftsman can make a tile cutter from a grinder with his own hands. To do this, you just need to have the appropriate tools. To cut tiles, it is best to use a high-power grinder. This will ensure high quality of the cut, as well as the absence of chips in the tile cutting line. Before carrying out work, it is necessary to take unnecessary or defective tiles and make a test cut. This will allow you to evaluate the quality of the grinder’s work.

However, you can purchase a low-budget tile cutter like this and not waste time assembling your own

Bottom line

A tile cutter is a very necessary thing for arranging home comfort. If you doubt that you can do it yourself, it is better to rent the device or use the services of a specialist.

Sources

- https://zonaplitki.ru/instrument/elektricheskij-plitkorez-svoimi-rukami.html

- https://yaplitka.ru/plitkorez-svoimi-rukami.html

- https://handmade-expert.info/plitkorez-svoimi-rukami/

- https://tehnika.expert/dlya-remonta/bolgarka/kak-sdelat-plitkorez-svoimi-rukami.html

- https://DoctorPol.ru/nap-pokrytiya/plitochka/stanok-rezki-dlya-plitki.html

- https://laminatepol.ru/28443-plitkoreza-svoimi-rukami.html

- https://TehnoPanorama.ru/instrumenty/plitkorez-svoimi-rukami.html

Electric tile cutter

Why not take a simpler route and make an electric tile cutter?

The main thing here is to take into account all the rules that were announced earlier. It is advisable to make an electric tile cutter based on a grinder, since it is this that provides the number of revolutions necessary for cutting. Any other motor will require an appropriate gearbox, which will allow it to achieve 4500 - 6000 rpm. Both the grinder and the electric motor are rigidly fixed under the tabletop so that the exit of the cutting edge does not exceed half the thickness of the tile.

For ease of cutting, a metal corner must be secured to the tabletop parallel to the grinder disk. By moving the tile along the corner, you can get a perfectly even cut. When working on such a device, the user will need respiratory and eye protection, since pieces of tile can be very dangerous if they unexpectedly break off. It is worth remembering that an electric tile cutter also requires certain operating skills and knowledge of the basics of working with electrical equipment.

Making a tile cutter from a grinder

The need for such equipment arises when cladding work is to be carried out. For this purpose, you can use a grinder, having previously taken care of a corundum or diamond cutting disc. But the main problem will be reliable fastening.

Scheme of vertical mounting of an angle grinder.

You can create a tile cutter by specially securing the grinder. It is adapted to a table or workbench. This way the work is much more convenient, because... there is no need to guide the grinder. In addition, holding the tile is much more comfortable than holding a tool. This design will also contribute to a smoother cut line, and the likelihood of the tile breaking is much lower.

The grinder can be attached to the surface using a horizontal or vertical method, but taking into account that the cutting part rotates on the tile.

- Horizontal mounting. In this case, the grinder is installed in such a way that the working disk is positioned strictly vertically. During cutting, you should ensure that the working tile has a perpendicular direction relative to the plane of the grinder's cutting disc. At the same time, the cutting element should not catch on the table surface. If you install a tile cutter-grinder in this position, then you must immediately be prepared for the fact that the entire process will take place with outstretched arms, that is, you will constantly have to hold the elements being cut suspended, which is extremely difficult physically. Especially if there are large volumes of cutting to be done.

- Vertical mount. To use this method, two points must be observed:

The grinder's cutting disc should be positioned strictly perpendicular to the table surface.

- the upper part of the grinder gearbox must be located level with the table surface or lower by a maximum of 1-2 mm;

- the location of the cutting element (disc) and the table surface together should be equal to 90°.

In order to create a tile cutter with your own hands, you should choose the right tools and components:

- grinder;

- metal sheet 0.4-5 cm;

- clamps with a diameter of 0.8-1 cm;

- nuts and locknuts.

Making a tile cutter from a grinder with your own hands: instructions

When everything you need has been prepared, the drawings have been found, and you are ready to start working, one of the main points comes - following the work algorithm for making a homemade cutter for ceramic tiles.

Instructions:

- Prepare your work surface. Most often, a table is used for it. Its surface must be perfectly flat and smooth for the electric cutter to do its job as expected - without overlaps or uneven cuts.

- Place a sheet of metal on a horizontal smooth surface. It will serve as the basis for the tile cutter. At the time of installation and fastening of the sheet, there must be a hole in it for the cutting disk.

- The grinder disc must be secured to the work surface. This is done using clamps prepared in advance. Craftsmen recommend placing the clamps in rubber tubes for longer service.

This entire structure is secured with nuts and locknuts. If desired, you can make a small addition and improve the tool. This can be done to quickly remove ceramic chips.

The improvement itself is quite simple to make. It is necessary to secure the vacuum cleaner tube under the cutting disc. In this case, with the simultaneous operation of both the vacuum cleaner and the grinder disk, all the crumbs will immediately flow into the garbage receptacle.

In addition, the obtained drawings of a tile cutter may be needed in order to repair a broken tool.

Making your own tile cutter

When there is a large amount of work to be done with ceramic products, you can make a tile cutter from a grinder with your own hands. The most practical homemade device that can be made from an angle grinder is electric.

The tool itself should be mounted on the machine so that the working disk is located vertically or horizontally. You can choose any plane - the main thing is that it is convenient to work with the tiles. It is necessary to provide stops for the tiles so that they do not move when cutting.

A table is suitable for the role of a machine. You can use existing ones or make them from metal corners. For the working surface, a sheet of metal divided in the middle into two parts is suitable. A chute should be installed along the dividing line for the movement of the working circle. It is recommended to do it in such a way that it is possible to fill with water. This will help reduce the amount of dust and will cool the disk, thereby extending its service life.

Some craftsmen use an electric motor to mount a device for cutting tiles. But making a tile cutter from an angle grinder is much easier and more profitable, since this tool picks up speed on its own, and you will have to select a gearbox for the electric motor.

In order to cut tiles at home, it is not necessary to purchase a special device. All you need is a grinder, a head on your shoulders and some available materials.

9338 0

It is difficult to imagine laying ceramic tiles without a tile cutter, manual or electric. The choice of tool depends on the amount of work that the master has to perform. For tiling small areas at home, it is enough to have a hand tool; professional craftsmen prefer an electric tile cutter, which increases productivity and performs better tile cutting with a high-speed rotating disk equipped with water cooling.

Home craftsmen who know how to handle a manual tile cutter, having seen the results of using an electric machine by a professional finisher, in order to improve their skills, strive to acquire and master this tool, which is more advanced and productive. The optimal solution to this issue is to purchase a factory-made electric tile cutter. But a high-quality and durable tool is expensive, and a machine at an affordable price quickly wears out and fails.

Making a tile cutter from a grinder with your own hands: instructions

When everything you need has been prepared, the drawings have been found, and you are ready to start working, one of the main points comes - following the work algorithm for making a homemade cutter for ceramic tiles.

- Prepare your work surface. Most often, a table is used for it. Its surface must be perfectly flat and smooth for the electric cutter to do its job as expected - without overlaps or uneven cuts.

- Place a sheet of metal on a horizontal smooth surface. It will serve as the basis for the tile cutter. At the time of installation and fastening of the sheet, there must be a hole in it for the cutting disk.

- The grinder disc must be secured to the work surface. This is done using clamps prepared in advance. Craftsmen recommend placing the clamps in rubber tubes for longer service.

This entire structure is secured with nuts and locknuts. If desired, you can make a small addition and improve the tool. This can be done to quickly remove ceramic chips.

An old grinder is perfect for making a tile cutter.

Such an addition will save time on cleaning, in addition, in this case, practically no crumbs that are dangerous for inhalation will get into the air.

The improvement itself is quite simple to make. It is necessary to secure the vacuum cleaner tube under the cutting disc. In this case, with the simultaneous operation of both the vacuum cleaner and the grinder disk, all the crumbs will immediately flow into the garbage receptacle.

In addition, the obtained drawings of a tile cutter may be needed in order to repair a broken tool.

Making a power tool

First of all, it is necessary to determine how the grinder will be positioned when cutting tiles.

Bulgarian

Option 1

The tiles are fed along a plank under a grinder strictly fixed under the table.

Advantages of a tile cutter made from a grinder:

- this technical solution is the simplest, since it involves reliable fastening of the cutting disk from the bottom of the tabletop and installation of a guide rail (NR) with the possibility of its adjustment;

- You can place a bucket of water under the table, which will catch some dust and cool the disk.

Disadvantages of the tool:

- a lot of dust, since such a tile cutter cuts ceramics throughout its entire thickness and cannot make a small cut;

- inconvenient adjustment of the grinder due to its location under the tabletop.

Option 2

The fixed tiles are cut with a grinder, which is attached to the top of the tabletop to straight sled rails.

Advantages of the device:

- less dust is generated, since you can simply cut the ceramics and not perform through cutting;

- accessible adjustment by tool.

Disadvantages of the tool:

- it is very difficult to make such a tile cutter without certain skills;

- you need to additionally manually process the cut surface of the tile so that it is divided into parts.

If we compare these two tools, the first one will be easier to make at home. Therefore, next we will describe how to do it.