home

About company

Directory

Colored circle

Rods made of non-ferrous metals and alloys (copper, aluminum, bronze, brass) are straight sections with a uniform cross-section throughout: circle, square or regular hexagon. Rods of small diameters can be supplied in the form of coils of free or ordered winding; rods of large diameters are supplied in measured or unmeasured lengths, the dimensions of which are established by the relevant standards.

Bronze circle (bar): GOCT 1628-78, GOCT 6511-60, GOCT 10025-78

High anti-corrosion properties and resistance to mechanical stress are the main factors influencing the demand for bronze rods. It is used for the manufacture of consumable parts for machines and mechanisms that operate on friction: antifriction elements, bushings, bearing shells, worm gear rims, etc.

Bronze bar classification:

- according to the material of manufacture: from alloys that do not contain tin (GOCT 1628-78), from tin-zinc alloys (GOCT 6511-60), from tin-phosphorus alloys (GOCT 10025-78).

- by production method: rolled (G), cold-deformed (D), pressed (P).

- Shape: round, hexagonal, square.

The greatest demand is for the wheel produced according to the technical specifications of GOCT 1628-78 from tin-free bronze grades BrAMts9-2, BrAZh9-4, BrAZHN10-4-4, BrAShMts10-3-1.5, BrKMts3-1.

According to the requirements of GOST 1628-78, bronze rods are divided according to manufacturing accuracy into rods:

- increased accuracy (P);

- high accuracy (B);

- normal accuracy (N).

The size range is established by the nominal diameter: for a bar with a round cross-section it coincides with the diameter of the circle, for a hexagon and square it is the diameter of the inscribed circle (the distance between opposite/parallel edges). The minimum diameter is 5 mm, the maximum is 160 mm, and the following assortment step is established as a standard: 0.5 mm, 1 mm, 5 mm and 10 mm.

The unmeasured length of the rod is set in the range from 0.5 to 4 meters (depending on the nominal diameter), and drawn rod with a diameter of less than 14 mm can be supplied in coils.

The theoretical weight is calculated for bronze grade BrAMts9-2 with a density of 7.6 g/cm³>

| Nominal diameter, mm | Weight 1 m/linear. in kg for bronze BrAMts9-2 | Nominal diameter, mm | Weight 1 m/linear. in kg for bronze BrAMts9-2 | ||||

| Circle | Square | Hexagon | Circle | Square | Hexagon | ||

| 5,0 | 0,149 | 0,198 | 0,165 | 30 | 5,37 | 6,84 | 5,92 |

| 5,5 | 0,18 | 0,23 | 0,199 | 40 | 9,55 | — | — |

| 6,0 | 0,215 | 0,274 | 0,237 | 50 | 14,92 | — | — |

| 6,5 | 0,252 | 0,321 | 0,278 | 60 | 21,49 | — | — |

| 7,0 | 0,298 | 0,372 | 0,322 | 70 | 29,25 | — | — |

| 7,5 | 0,33 | — | — | 75 | 33,3 | — | — |

| 8,0 | 0,382 | 0,486 | 0,421 | 80 | 38,2 | — | — |

| 8,5 | 0,43 | — | — | 85 | 43,13 | — | — |

| 9,0 | 0,483 | — | — | 90 | 48,35 | — | — |

| 9,5 | 0,539 | — | — | 95 | 53,87 | — | — |

| 10 | 0,597 | 0,76 | 0,658 | 100 | 59,69 | — | — |

| 11 | 0,72 | 0,92 | 0,796 | 110 | 72,23 | — | — |

| 12 | 0,86 | 1,094 | 0,948 | 120 | 85,95 | — | — |

| 13 | 1,01 | — | — | 130 | 100,88 | — | — |

| 15 | 1,34 | — | — | 140 | 116,99 | — | — |

| 20 | 2,39 | 3,04 | 2,633 | 150 | 134,3 | — | — |

| 25 | 3,73 | 4,75 | 4,114 | 160 | 152,81 | — | — |

Calculation of the weight of a bronze bar

Home -> Directory -> Calculation of the weight of a bronze barTo calculate the weight of this type of non-ferrous metal product such as a bronze rod, it is customary to take the theoretical mass of the bronze rod, which is per 1 linear meter of it, as a unit of measurement. The group prepared a table of weights for rods made of bronze brands: BrAZh9-4, BrOTsS 5-5-5, BrAMts9-2, BrAZHN10-4-4, BrKMts3-1, BrB2, BrOF6.5-1.15 - with a diameter from 10 to 300 mm.

| — | 0,597 | — | 0,665 | 0,644 | 0,691 | ||

| 10,5 | — | — | — | — | — | 0,710 | — |

| 11,0 | — | — | 0,722 | — | 0,805 | 0,779 | 0,836 |

| 11,5 | — | — | — | — | — | 0,851 | — |

| 12,0 | — | — | 0,859 | — | 0,957 | 0,927 | 0,995 |

| 13,0 | — | — | 1,008 | — | 1,124 | 1,088 | 1,167 |

| 14,0 | — | — | 1,169 | — | 1,303 | 1,262 | 1,354 |

| 15,0 | — | — | 1,342 | — | 1,496 | 1,448 | 1,554 |

| 16,0 | 1,507 | — | 1,527 | 1,547 | 1,702 | 1,648 | 1,768 |

| 17,0 | 1,701 | — | 1,724 | 1,747 | 1,922 | 1,860 | 1,996 |

| 18,0 | 1,908 | — | 1,933 | 1,958 | 2,154 | 2,086 | 2,238 |

| 19,0 | — | — | 2,154 | — | 2,400 | 2,324 | 2,494 |

| 20,0 | 2,355 | — | 2,386 | 2,418 | 2,660 | 2,575 | 2,763 |

| 21,0 | 2,596 | — | 2,631 | 2,666 | 2,932 | 2,839 | 3,046 |

| 22,0 | 2,850 | — | 2,888 | 2,926 | 3,218 | 3,116 | 3,343 |

| 23,0 | 3,114 | — | 3,156 | 3,198 | 3,517 | 3,405 | 3,654 |

| 24,0 | 3,391 | — | 3,436 | 3,482 | 3,830 | 3,708 | 3,979 |

| 25,0 | 3,680 | — | 3,729 | 3,778 | 4,156 | 4,023 | 4,318 |

| 26,0 | 3,980 | — | 4,033 | 4,086 | 4,495 | 4,351 | 4,670 |

| 27,0 | 4,292 | — | 4,349 | 4,406 | 4,847 | 4,693 | 5,036 |

| 28,0 | 4,616 | — | 4,677 | 4,739 | 5,213 | 5,047 | 5,416 |

| 30,0 | 5,299 | 6,217 | 5,369 | 5,440 | 5,984 | 5,793 | 6,217 |

| 32,0 | 6,029 | 7,074 | 6,109 | 6,190 | 6,809 | 6,591 | 7,074 |

| 35,0 | 7,212 | 8,462 | 7,308 | 7,405 | 8,145 | 7,885 | 8,462 |

| 36,0 | 7,630 | 8,953 | 7,732 | 7,834 | 8,617 | 8,342 | 8,953 |

| 38,0 | 8,502 | 9,975 | 8,615 | 8,728 | 9,601 | 9,295 | 9,975 |

| 40,0 | 9,420 | 11,053 | 9,546 | 9,671 | 10.638 | 10,299 | 11,053 |

| 42,0 | 10,386 | 12,186 | 10,524 | 10,662 | 11,729 | 11,355 | 12,186 |

| 45,0 | 11,922 | 13,989 | 12,081 | 12,240 | 13,464 | 13,035 | 13,989 |

| 48,0 | 13,565 | 15,916 | 13,746 | 13,927 | 15,319 | 14,831 | 15,916 |

| 50,0 | 14,719 | 17,270 | 14,915 | 15,111 | 16,622 | 16,093 | 17,270 |

| 55,0 | 17,810 | 20,897 | 18,047 | 18,285 | 20,113 | 19,472 | 20,897 |

| 60,0 | 21,195 | 24,869 | 21,478 | 21,760 | 23,936 | 23,173 | 24,869 |

| 65,0 | 24,875 | 29,186 | 25,206 | 25,538 | 28,092 | 27,196 | 29,186 |

| 70,0 | 28,849 | 33,849 | 29,233 | 29,618 | 32,580 | 31,541 | 33,849 |

| 75,0 | 33,117 | 38,858 | 33,559 | 34,000 | 37,400 | 36,208 | 38,858 |

| 80,0 | 37,680 | 44,211 | 38,182 | 38,685 | 42,553 | 41,197 | 44,211 |

| 85,0 | 42,537 | 49,910 | 43,104 | 43,672 | 48,039 | 46,507 | 49,910 |

| 90,0 | 47,689 | 55,955 | 48,325 | 48,960 | 53,856 | 52,140 | 55,955 |

| 95,0 | 53.135 | 62,345 | 53,843 | 54,552 | 60,007 | 58,094 | 62,345 |

| 100,0 | 58,875 | 69,080 | 59,660 | 60,445 | 66,490 | 64,370 | 69,080 |

| 108,0 | 68,672 | 80,575 | 69,587 | 70,503 | 77,553 | 80,575 | |

| 110,0 | 71,239 | 83,587 | 72,189 | 73,138 | 80,452 | 83,587 | |

| 120,0 | 84,780 | 99,475 | 85,910 | 87,041 | 95,745 | ||

| 130,0 | 99,499 | 116,745 | 100,825 | 102,152 | 112,367 | ||

| 140,0 | 115,395 | 135,397 | 116,934 | 118,472 | 130,319 | ||

| 150,0 | 132,469 | 155,430 | 132,235 | 136,001 | 149,601 | ||

| 160,0 | 150,720 | 176,845 | 152,730 | 154,739 | 170,213 | ||

| 170,0 | 170,149 | 199,641 | 172,417 | 174,686 | 192,155 | ||

| 180,0 | 190,755 | 223,819 | 193,298 | 195,842 | 215,426 | ||

| 190,0 | 212,539 | 249,379 | 215,373 | 218,206 | 240,027 | ||

| 200,0 | 235,500 | 276,320 | 238,640 | 241,780 | 265,958 | ||

| 210,0 | 259,639 | 304,643 | 263,101 | 266,562 | 293,219 | ||

| 220,0 | 284,955 | 334,347 | 288,754 | 292,554 | 321,809 | ||

| 240,0 | 339,120 | 397,901 | 343,642 | 348,163 | 382,980 | ||

| 250,0 | 367,969 | 431,750 | 372,875 | 377,781 | 415,559 | ||

| 260,0 | 397,995 | 466,981 | 403,302 | 408,608 | 449,469 | ||

| 280,0 | 461,580 | 541,587 | 467,734 | 473,889 | 521,278 | ||

| 300,0 | 529,875 | 621,720 | 536,940 | 544,005 | 598,406 |

To simplify the process of calculating the weight of non-ferrous metal products, our specialists have prepared a rolled metal calculator. You can use it by clicking on the “Weight Calculator” or by following the link.

Aluminum circle (rod)

High electrical conductivity, malleability, ductility, anti-corrosion qualities and low specific gravity of aluminum determine the scope of use of aluminum circles (rods): electrical engineering, microelectronics, production of hardware for various purposes, aviation and aerospace industries.

Aluminum circles are produced by pressing from aluminum and its alloys of the following grades: AD0, AD1, AD, AK6, AK8, AMts, AMtsS, AMg6, AD31, AD33, AK4, AK4-1, AD35, AB, D1, D16, V95, 1915, 1925, AMg2, AMg3, AMg5 in accordance with the range and technical conditions defined by GOCT 21488-97.

According to the standard, aluminum rods of round, square and hexagonal sections are available in the following sizes:

- aluminum circle diameters - from 8 to 400 mm, nominal rod diameters with square and hexagonal cross-sections - from 8 to 200 mm;

- unmeasured length of rods ranging from 0.5 to 6 m (depending on the size of the nominal diameter), and rods with a diameter of less than 15 mm can be supplied in coils.

Theoretical weight of a normal precision round aluminum bar for aluminum with a density of 2.7 g/cm³

| Nominal diameter, mm | Weight 1 m, kg | Nominal diameter, mm | Weight 1 m, kg | Nominal diameter, mm | Weight 1 m, kg | Nominal diameter, mm | Weight 1 m, kg |

| 8 | 0,126 | 35 | 2,52 | 80 | 13,3 | 180 | 68,1 |

| 10 | 0,2 | 40 | 3,31 | 90 | 16,9 | 200 | 84,0 |

| 12 | 0,288 | 45 | 4,2 | 100 | 20,9 | 250 | 131,5 |

| 14 | 0,395 | 50 | 5,2 | 110 | 25,3 | 300 | 189,3 |

| 16 | 0,519 | 55 | 6,27 | 120 | 30,2 | 350 | 256,8 |

| 18 | 0,66 | 60 | 7,48 | 130 | 35,4 | 400 | 334,3 |

| 20 | 0,813 | 65 | 8,79 | 140 | 41,1 | ||

| 25 | 1,28 | 70 | 10,2 | 150 | 47,2 | ||

| 30 | 1,86 | 75 | 11,7 | 160 | 53,7 |

According to GOCT 21488-97, aluminum circles are classified according to the following parameters:

- By manufacturing class: normal (no designation), increased (P) and high (H) accuracy;

- By type of heat treatment:

- hardened, naturally (T) or artificially aged (TI);

- annealed (M);

- without heat treatment (not indicated).

Copper circle (rod)

In terms of electrical and thermal conductivity, copper is in second place after silver, due to which the copper circle (rod) is indispensable in the production of electrically conductive circuits and elements of heat exchange equipment. For the manufacture of copper rods according to GOCT 1535-2006, copper grades M, M1, M1f, M2, M1r, M2r, M3r are used. According to manufacturing technology, a copper circle is divided into drawn (the cross-section can be either a circle or a regular polygon) and pressed (only round in cross-section).

The nominal diameters and theoretical weight of a linear meter are established by the GOCT 1535-2006 assortment (tabular data are given for drawn rods):

Theoretical weight calculated for copper with a density of 8.9 g/cm³

| Nominal diameter, mm | Weight 1 m/linear. in kg, copper rod | Nominal diameter, mm | Weight 1 m/linear. in kg, copper rod | ||||

| Circle | Square | Hexagon | Circle | Square | Hexagon | ||

| 3,0 | 0,063 | — | — | 16 | 1,79 | — | — |

| 3,5 | 0,086 | — | — | 17 | 2,02 | 2,57 | 2,23 |

| 4,0 | 0,110 | — | — | 18 | 2,27 | — | — |

| 4,5 | 0,140 | — | — | 19 | 2,52 | 3,21 | 2,78 |

| 5,0 | 0,170 | 0,23 | 0,19 | 20 | 2,8 | — | — |

| 5,5 | 0,21 | 0,27 | 0,23 | 21 | 3,08 | — | — |

| 6,0 | 0,25 | 0,32 | 0,28 | 22 | 3,38 | 4,31 | 3,74 |

| 7,0 | 0,34 | 0,44 | 0,38 | 24 | 4,02 | 5,13 | 4,44 |

| 8,0 | 0,45 | 0,57 | 0,49 | 25 | 4,37 | — | — |

| 9,0 | 0,57 | 0,72 | 0,62 | 27 | 5,09 | 6,49 | 5,62 |

| 10 | 0,7 | 0,89 | 0,77 | 28 | 5,48 | — | — |

| 11 | 0,85 | 1,08 | 0,93 | 30 | 6,29 | 8,01 | 6,94 |

| 12 | 1,01 | 1,28 | 1,11 | 32 | — | 9,11 | 7,54 |

| 13 | 1,18 | 1,5 | 1,29 | 40 | 11,18 | — | — |

| 14 | 1,37 | 1,74 | 1,51 | 45 | 14,16 | — | — |

| 15 | 1,57 | — | — | 50 | 17,48 | 22,23 | 19,5 |

The length (unmeasured) of a copper rod can be from 0.5 to 5 meters, depending on the size of the nominal diameter. By agreement with the buyer, the manufacturer can supply drawn rods of any section with a nominal diameter of up to 18 mm in coils, and the weight of one coil should not exceed 140 kg.

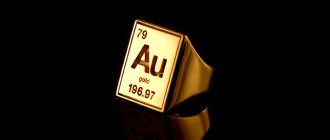

Density of metals and alloys

Home — Documentation — Density of metals

Using the table of densities of metals and alloys, you can calculate the weight of the required length of the product you have chosen. This is necessary in cases where the entire assortment is calculated in length in the estimate, and sales are carried out by weight. Also, knowing the specific density of metals from the table, you can calculate the weight of the structure by summing the mass of each element included in its composition. The need for such a calculation arises when selecting transport for transporting a given structure. The density of metals in the table allows you to calculate the density of an alloy, the composition of which is known as a percentage. Knowing the mass and material of any part, it is possible to calculate its volume.

| Group name | Name of material, brand | ρ | TO |

| PURE METALS | |||

| Pure metals | Aluminum | 2,7 | 0,34 |

| Beryllium | 1,84 | 0,23 | |

| Vanadium | 6,5-7,1 | 0,83-0,90 | |

| Bismuth | 9,8 | 1,24 | |

| Tungsten | 19,3 | 2,45 | |

| Gallium | 5,91 | 0,75 | |

| Hafnium | 13,09 | 1,66 | |

| Germanium | 5,33 | 0,68 | |

| Gold | 19,32 | 2,45 | |

| Indium | 7,36 | 0,93 | |

| Iridium | 22,4 | 2,84 | |

| Cadmium | 8,64 | 1,10 | |

| Cobalt | 8,9 | 1,13 | |

| Silicon | 2,55 | 0,32 | |

| Lithium | 0,53 | 0,07 | |

| Magnesium | 1,74 | 0,22 | |

| Copper | 8,94 | 1,14 | |

| Molybdenum | 10,3 | 1,31 | |

| Manganese | 7,2-7,4 | 0,91-0,94 | |

| Sodium | 0,97 | 0,12 | |

| Nickel | 8,9 | 1,13 | |

| Tin | 7,3 | 0,93 | |

| Palladium | 12,0 | 1,52 | |

| Platinum | 21,2-21,5 | 2,69-2,73 | |

| Rhenium | 21,0 | 2,67 | |

| Rhodium | 12,48 | 1,58 | |

| Mercury | 13,6 | 1,73 | |

| Rubidium | 1,52 | 0,19 | |

| Ruthenium | 12,45 | 1,58 | |

| Lead | 11,37 | 1,44 | |

| Silver | 10,5 | 1,33 | |

| Waist | 11,85 | 1,50 | |

| Tantalum | 16,6 | 2,11 | |

| Tellurium | 6,25 | 0,79 | |

| Titanium | 4,5 | 0,57 | |

| Chromium | 7,14 | 0,91 | |

| Zinc | 7,13 | 0,91 | |

| Zirconium | 6,53 | 0,82 | |

| ALLOYS FROM NON-FERROUS METALS | |||

| Aluminum casting alloys | AL1 | 2,75 | 0,35 |

| AL2 | 2,65 | 0,34 | |

| AL3 | 2,70 | 0,34 | |

| AL4 | 2,65 | 0,34 | |

| AL5 | 2,68 | 0,34 | |

| AL7 | 2,80 | 0,36 | |

| AL8 | 2,55 | 0,32 | |

| AL9 (AK7ch) | 2,66 | 0,34 | |

| AL11 (AK7TS9) | 2,94 | 0,37 | |

| AL13 (AMg5K) | 2,60 | 0,33 | |

| AL19 (AM5) | 2,78 | 0,35 | |

| AL21 | 2,83 | 0,36 | |

| AL22 (AMg11) | 2,50 | 0,32 | |

| AL24 (AC4Mg) | 2,74 | 0,35 | |

| AL25 | 2,72 | 0,35 | |

| Tin and lead babbits | B88 | 7,35 | 0,93 |

| B83 | 7,38 | 0,94 | |

| B83S | 7,40 | 0,94 | |

| BN | 9,50 | 1,21 | |

| B16 | 9,29 | 1,18 | |

| BS6 | 10,05 | 1,29 | |

| Tin-free bronzes, foundry | BrAmts9-2L | 7,6 | 0,97 |

| BrAZH9-4L | 7,6 | 0,97 | |

| BrAMZH10-4-4L | 7,6 | 0,97 | |

| BrS30 | 9,4 | 1,19 | |

| Tin-free bronzes, pressure-processed | BrA5 | 8,2 | 1,04 |

| BrA7 | 7,8 | 0,99 | |

| BrAmts9-2 | 7,6 | 0,97 | |

| BrAZH9-4 | 7,6 | 0,97 | |

| BrAZhMts10-3-1.5 | 7,5 | 0,95 | |

| BrAZHN10-4-4 | 7,5 | 0,95 | |

| BrB2 | 8,2 | 1,04 | |

| BrBNT1.7 | 8,2 | 1,04 | |

| BrBNT1.9 | 8,2 | 1,04 | |

| BrKMts3-1 | 8,4 | 1,07 | |

| BrKN1-3 | 8,6 | 1,09 | |

| BrMts5 | 8,6 | 1,09 | |

| Bronze tin deformable | BrOF8-0.3 | 8,6 | 1,09 |

| BrOF7-0.2 | 8,6 | 1,09 | |

| BrOF6.5-0.4 | 8,7 | 1,11 | |

| BrOF6.5-0.15 | 8,8 | 1,12 | |

| BrOF4-0.25 | 8,9 | 1,13 | |

| BrOTs4-3 | 8,8 | 1,12 | |

| BrOTsS4-4-2.5 | 8,9 | 1,13 | |

| BrOTsS4-4-4 | 9,1 | 1,16 | |

| Bronze tin castings | BrO3TS7S5N1 | 8,84 | 1,12 |

| BrO3Ts12S5 | 8,69 | 1,10 | |

| BrO5TS5S5 | 8,84 | 1,12 | |

| BrO4Ts4S17 | 9,0 | 1,14 | |

| BrO4TS7S5 | 8,70 | 1,10 | |

| Beryllium bronzes | BrB2 | 8,2 | 1,04 |

| BrBNT1.9 | 8,2 | 1,04 | |

| BrBNT1.7 | 8,2 | 1,04 | |

| Copper-zinc alloys (brass) foundry | LTs16K4 | 8,3 | 1,05 |

| LTs14K3S3 | 8,6 | 1,09 | |

| LTs23A6Zh3Mts2 | 8,5 | 1,08 | |

| LC30A3 | 8,5 | 1,08 | |

| LTs38Mts2S2 | 8,5 | 1,08 | |

| LTs40S | 8,5 | 1,08 | |

| LS40d | 8,5 | 1,08 | |

| LTs37Mts2S2K | 8,5 | 1,08 | |

| LTs40Mts3ZH | 8,5 | 1,08 | |

| Copper-zinc alloys (brass), pressure-processed | L96 | 8,85 | 1,12 |

| L90 | 8,78 | 1,12 | |

| L85 | 8,75 | 1,11 | |

| L80 | 8,66 | 1,10 | |

| L70 | 8,61 | 1,09 | |

| L68 | 8,60 | 1,09 | |

| L63 | 8,44 | 1,07 | |

| L60 | 8,40 | 1,07 | |

| LA77-2 | 8,60 | 1,09 | |

| LAZ60-1-1 | 8,20 | 1,04 | |

| LAN59-3-2 | 8,40 | 1,07 | |

| LZhMts59-1-1 | 8,50 | 1,08 | |

| LN65-5 | 8,60 | 1,09 | |

| LMts58-2 | 8,40 | 1,07 | |

| LMtsA57-3-1 | 8,10 | 1,03 | |

| Pressed and drawn brass rods | L60, L63 | 8,40 | 1,07 |

| LS59-1 | 8,45 | 1,07 | |

| LZhS58-1-1 | 8,45 | 1,07 | |

| LS63-3, LMts58-2 | 8,50 | 1,08 | |

| LZhMts59-1-1 | 8,50 | 1,08 | |

| LAZ60-1-1 | 8,20 | 1,04 | |

| Magnesium alloys foundry | Ml3 | 1,78 | 0,23 |

| ML4 | 1,83 | 0,23 | |

| Ml5 | 1,81 | 0,23 | |

| Ml6 | 1,76 | 0,22 | |

| Ml10 | 1,78 | 0,23 | |

| Ml11 | 1,80 | 0,23 | |

| Ml12 | 1,81 | 0,23 | |

| Magnesium alloys wrought | MA1 | 1,76 | 0,22 |

| MA2 | 1,78 | 0,23 | |

| MA2-1 | 1,79 | 0,23 | |

| MA5 | 1,82 | 0,23 | |

| MA8 | 1,78 | 0,23 | |

| MA14 | 1,80 | 0,23 | |

| Pressure-processed copper-nickel alloys | Kopel MNMts43-0.5 | 8,9 | 1,13 |

| Constantan MNMts40-1.5 | 8,9 | 1,13 | |

| Cupronickel MnZhMts30-1-1 | 8,9 | 1,13 | |

| Alloy MNZh5-1 | 8,7 | 1,11 | |

| Cupronickel MH19 | 8,9 | 1,13 | |

| Alloy TB MN16 | 9,02 | 1,15 | |

| Nickel silver MNTs15-20 | 8,7 | 1,11 | |

| Kunial A MNA13-3 | 8,5 | 1,08 | |

| Kunial B MNA6-1.5 | 8,7 | 1,11 | |

| Manganin MNMts3-12 | 8,4 | 1,07 | |

| Nickel alloys | NK 0.2 | 8,9 | 1,13 |

| NMTs2.5 | 8,9 | 1,13 | |

| NMTs5 | 8,8 | 1,12 | |

| Alumel NMtsAK2-2-1 | 8,5 | 1,08 | |

| Chromel T HX9.5 | 8,7 | 1,11 | |

| Monel NMZHMts28-2.5-1.5 | 8,8 | 1,12 | |

| Anti-friction zinc alloys | TsAM 9-1.5L | 6,2 | 0,79 |

| TsAM 9-1.5 | 6,2 | 0,79 | |

| TsAM 10-5L | 6,3 | 0,80 | |

| TsAM 10-5 | 6,3 | 0,80 | |

| STEEL, SHAVINGS, CAST IRON | |||

| Stainless steel | 04Х18Н10 | 7,90 | 1,00 |

| 08Х13 | 7,70 | 0,98 | |

| 08Х17Т | 7,70 | 0,98 | |

| 08Х20Н14С2 | 7,70 | 0,98 | |

| 08Х18Н10 | 7,90 | 1,00 | |

| 08Х18Н10Т | 7,90 | 1,00 | |

| 08Х18Н12Т | 7,95 | 1,01 | |

| 08Х17Н15М3Т | 8,10 | 1,03 | |

| 08Х22Н6Т | 7,60 | 0,97 | |

| 08Х18Н12Б | 7,90 | 1,00 | |

| 10Х17Н13М2Т | 8,00 | 1,02 | |

| 10Х23Н18 | 7,95 | 1,01 | |

| 12Х13 | 7,70 | 0,98 | |

| 12Х17 | 7,70 | 0,98 | |

| 12Х18Н10Т | 7,90 | 1,01 | |

| 12Х18Н12Т | 7,90 | 1,00 | |

| 12Х18Н9 | 7,90 | 1,00 | |

| 15Х25Т | 7,60 | 0,97 | |

| Structural steel | Structural steel | 7,85 | 1,0 |

| Steel casting | Steel casting | 7,80 | 0,99 |

| High-speed steel with tungsten content, % | 5 | 8,10 | 1,03 |

| 10 | 8,35 | 1,06 | |

| 15 | 8,60 | 1,09 | |

| 18 | 8,90 | 1,13 | |

| Chips (t/m3) | aluminum fine crushed | 0,70 | |

| steel (small loach) | 0,55 | ||

| steel (large loach) | 0,25 | ||

| cast iron | 2,00 | ||

| Cast iron | grey | 7,0-7,2 | 0,89-0,91 |

| malleable and high strength | 7,2-7,4 | 0,91-0,94 | |

| antifriction | 7,4-7,6 | 0,94-0,97 | |