To obtain the exact values of the theoretical weight of steel pipes of round, rectangular, square cross-section, use the GOST pipe weight table.

To obtain the exact values of the theoretical weight of steel pipes of round, rectangular, square cross-section, use the GOST pipe weight table.

- GOST 8639-82 — Square steel pipes

- GOST 8645-82 — Rectangular steel pipes

- GOST 10704-91 — Electric-welded longitudinal pipes

Pipe calculator

| Cost per ton with price per meter of pipe, ₽: | But |

| The price of a meter of pipe at the cost of a ton, ₽: | But |

| Total weight of 6 m of pipe, kg: | But |

| Total length 1000 kg. pipes, m.: | But |

| Name | Pipe Calculator (Round) |

| Requirements | Javascript |

| OS | Windows, Android, OSX, Linux |

| Category | Business, Education |

| Price |

Install the widget on the site

Formula and calculation methods

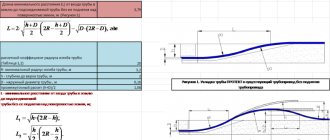

The weight of pipes made of various metals (steel pipes, stainless steel, copper, etc.) is calculated based on the data available in the GOST and TU reference books. The weight of a meter of pipe, the range of which is not included in the directories available on the website, is calculated online using the formula m = Pi * ro * S * (D - S) * L; Pi is a mathematical constant that expresses the ratio of the circumference of a circle to its diameter, equal to

3.14; ro is the density of the metal from which the round pipe is made in kg/m³; To calculate the specific gravity of 1 linear meter of pipe (m), it is necessary to indicate the dimensions of the pipe profile: diameter D in mm, as well as the thickness of the metal from which the pipe is made (wall thickness S) and length L (default 1 m). The calculation of the theoretical weight of a rectangular profile pipe is carried out similarly to a round one, with the exception of the part of the formula for determining the cross-sectional area.

How to calculate the price of 1 pipe 159 mm

In order to calculate the price of 1 steel pipe 159, you need to know the cost of a ton of rolled steel (see prices for electric-welded pipes 159 mm and seamless pipes 159 mm on the APEX METAL website), the weight of 1 meter and the length of the pipe.

Let's determine the cost of rolled steel according to GOST 8732 with a wall thickness of 6 mm, made of steel 20. As of December 2022, the cost of 159x6 pipe is 118,990 rubles per ton (or 118.99 rubles per kg).

Let's say the required pipe length is 6 meters, then the price of 1 pipe is:

- 22.64 x 6 x 118.99 = 16,164 rubles/piece, where 22.64 kg is the weight of 1 meter of pipe 159x6

Weight tables for 1 meter of round pipes of various metals and alloys according to all available GOSTs and TUs

| Pipe name and dimensions | Diameter, mm | Wall thickness, mm | Pipe meter weight | Meters per ton | Density, kg/m³ | Standard |

| Pipe 57x3 | 57 | 3 | 4.0000 kg. | 250 m. | 7850 | GOST 10704-91 |

| Pipe 57x3.5 | 57 | 3.5 | 4.6200 kg. | 216.5 m. | 7850 | GOST 10704-91 |

| Pipe 57x4 | 57 | 4 | 5.2300 kg. | 191.2 m. | 7850 | GOST 10707-80 |

| Pipe 76x3.5 | 76 | 3.5 | 6.2600 kg. | 159.7 m. | 7850 | GOST 10704-91 |

| Pipe 89x3.5 | 89 | 3.5 | 7.3800 kg. | 135.5 m. | 7850 | GOST 10704-91 |

| Pipe 89x4 | 89 | 4 | 8.3800 kg. | 119.3 m. | 7850 | GOST 10704-91 |

| Pipe 108x3.5 | 108 | 3.5 | 9.0200 kg. | 110.9 m. | 7850 | GOST 10704-91 |

| Pipe 108x4 | 108 | 4 | 10.2600 kg. | 97.5 m. | 7850 | GOST 10704-91 |

| Pipe 108x5 | 108 | 5 | 12.7000 kg. | 78.7 m. | 7850 | GOST 10704-91 |

| Pipe 133x4 | 133 | 4 | 12.7300 kg. | 78.6 m. | 7850 | GOST 10704-91 |

| Pipe 159x4 | 159 | 4 | 15.2900 kg. | 65.4 m. | 7850 | GOST 10704-91 |

| Pipe 159x4.5 | 159 | 4.5 | 17.1500 kg. | 58.3 m. | 7850 | GOST 10704-91 |

| Pipe 159x5 | 159 | 5 | 18.9900 kg. | 52.7 m. | 7850 | GOST 10704-91 |

| Pipe 159x6 | 159 | 6 | 22.6400 kg. | 44.2 m. | 7850 | GOST 10704-91 |

| Pipe 219x6 | 219 | 6 | 31.5200 kg. | 31.7 m. | 7850 | GOST 10704-91 |

| Pipe 219x8 | 219 | 8 | 41.6300 kg. | 24 m. | 7850 | GOST 10704-91 |

| Pipe 273x8 | 273 | 8 | 52.2800 kg. | 19.1 m. | 7850 | GOST 10704-91 |

| Pipe 325x6 | 325 | 6 | 47.2000 kg. | 21.2 m. | 7850 | GOST 10704-91 |

| Pipe 325x8 | 325 | 8 | 62.5400 kg. | 16 m. | 7850 | GOST 10704-91 |

| Pipe 426x8 | 426 | 8 | 82.4700 kg. | 12.1 m. | 7850 | GOST 10704-91 |

| Pipe 426x10 | 426 | 10 | 102.5900 kg. | 9.7 m. | 7850 | GOST 10704-91 |

| Pipe 530x8 | 530 | 8 | 102.9900 kg. | 9.7 m. | 7850 | GOST 10704-91 |

| Pipe 530x10 | 530 | 10 | 128.2400 kg. | 7.8 m. | 7850 | GOST 10704-91 |

| Pipe 630x8 | 630 | 8 | 122.7200 kg. | 8.1 m. | 7850 | GOST 10704-91 |

| Pipe 820x10 | 820 | 10 | 199.7600 kg. | 5 m. | 7850 | GOST 10704-91 |

Conclusion

Pipes with a diameter of 159 mm are often used for laying various communications. Moreover, this does not always require the use of new products. For laying sewers or creating cartridges for water supply networks, used goods are quite suitable. Their price is more affordable compared to factory originals.

They are usually purchased by weight, like regular scrap metal. State Standards No. 8732-78 and 10704-91, which, accordingly, regulate the parameters of all-metal and welded products, will help you approximately determine the weight of pipe 159. The video in this article will give you more information on this issue.

Did you like the article? Subscribe to our Yandex.Zen channel

GOST and TU standards available in calculator calculations and weight tables:

- GOST 494-2014 (x/d) - Brass pipes. Cold-worked

- GOST 9941-81 — Cold- and heat-deformed seamless pipes made of corrosion-resistant steel

- GOST 10707-80 — Cold-deformed electric-welded steel pipes

- GOST 494-2014 (p) - Brass pipes. Pressed

- GOST 617-2006 (p) - Copper and brass pipes of round section for general purpose. Pressed

- GOST 3262-75 — Steel water and gas pipes. Galvanized

- GOST R 52318-2005 — Round copper pipes for water and gas

- GOST 32598-2013 — Round copper pipes for water and gas

- GOST 617-2006 (x/d) - Copper and brass pipes of round section for general purpose. Cold-worked

- GOST 10704-91 — Longitudinal electric-welded steel pipes

- GOST 18482-2018 — Pressed pipes made of aluminum and aluminum alloys

Table of water weight in a pipe

To calculate the weight of water in a pipe, you need to know the internal diameter of the pipe and its filling with water. Below are the common diameters of water pipes and the weight of water in them.

The weight is indicated for 1 linear meter, at 50% and 100% filling of the pipe with water. 1 liter = 1 kg.

| Inner diameter, mm | water in pipe, l | |

| 50% | 100% | |

| 16 | 0.1 | 0.2 |

| 20 | 0.16 | 0.32 |

| 25 | 0.24 | 0.49 |

| 32 | 0.4 | 0.8 |

| 40 | 0.63 | 1.26 |

| 50 | 0.98 | 1.96 |

| 65 | 1.66 | 3.32 |

| 80 | 2.5 | 5 |

| 90 | 3.18 | 6.36 |

| 100 | 3.92 | 7.85 |

| 110 | 4.75 | 9.5 |

| 125 | 6.13 | 12.27 |

| 150 | 8.83 | 17.67 |

| 200 | 15.71 | 31.42 |

| 250 | 24.5 | 49 |

| 300 | 35.3 | 70.7 |

| 400 | 62.8 | 125.6 |

| 500 | 98.15 | 196.3 |

Weight taking into account pipes is difficult, due to the wide variety of materials from which pipes are made. Therefore, we suggest going to special pages with scales of pipes of various diameters and materials.

Source

Casing.

Seamless hot-rolled steel pipes (drill and casing pipes).

Table 1. Theoretical weight 1 linear. m of pipe (kg), for a given wall thickness (drill and casing pipes).

| N p/p | Dн, mm | 2.5 | 2.8 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| 1 | 25 | 1,39 | 1,53 | 1,63 | 1,86 | 2,07 | 2,28 | 2,47 | 2,64 | 2,81 | 2,97 | 3,11 | 3,24 | 3,35 |

| 2 | 28 | 1,57 | 1,74 | 1,85 | 2,11 | 2,37 | 2,61 | 2,84 | 3,05 | 3,26 | 3,45 | 3,63 | 3,79 | 3,94 |

| 3 | 32 | 1,76 | 2,02 | 2,15 | 2,46 | 2,76 | 3,05 | 3,33 | 3,59 | 3,85 | 4,09 | 4,32 | 4,53 | 4,74 |

| 4 | 38 | 2,19 | 2,43 | 2,59 | 2,98 | 3,35 | 3,72 | 4,07 | 4,41 | 4,74 | 5,05 | 5,35 | 5,64 | 5,92 |

| 5 | 42 | 2,44 | 2,70 | 2,89 | 3,32 | 3,75 | 4,16 | 4,56 | 4,95 | 5,33 | 5,69 | 6,044 | 6,38 | 6,71 |

| 6 | 45 | 2,62 | 2,91 | 3,11 | 3,58 | 4,04 | 4,49 | 4,93 | 5,36 | 5,77 | 6,17 | 6,56 | 6,94 | 7,30 |

| 7 | 50 | 2,93 | 3,25 | 3,48 | 4,01 | 4,54 | 5,05 | 5,55 | 6,04 | 6,51 | 6,97 | 7,42 | 7,86 | 8,29 |

| 8 | 54 | 3,77 | 4,36 | 4,93 | 5,49 | 6,04 | 6,58 | 7,10 | 7,61 | 8,11 | 8,60 | 9,08 | ||

| 9 | 57 | 4,00 | 4,62 | 5,23 | 5,83 | 6,41 | 6,99 | 7,51 | 8,10 | 8,63 | 9,16 | 9,67 | ||

| 10 | 60 | 4,22 | 4,88 | 5,52 | 6,16 | 6,78 | 7,39 | 7,99 | 8,58 | 9,15 | 9,71 | 10,26 | ||

| 11 | 63.5 | 4,48 | 5,18 | 5,87 | 6,55 | 7,21 | 7,87 | 8,51 | 9,14 | 9,75 | 10,36 | 10,95 | ||

| 12 | 68 | 4,81 | 5,57 | 6,31 | 7,05 | 7,77 | 8,48 | 9,17 | 9,86 | 10,53 | 11,19 | 11,84 | ||

| 13 | 70 | 4,96 | 5,74 | 6,51 | 7,27 | 8,01 | 8,75 | 9,47 | 10,18 | 10,88 | 11,56 | 12,23 | ||

| 14 | 73 | 5,18 | 6,00 | 6,81 | 7,60 | 8,38 | 9,16 | 9,91 | 70,66 | 11,39 | 12,11 | 12,82 | ||

| 15 | 83 | 6,86 | 7,79 | 8,71 | 9,62 | 10,51 | 11,39 | 12,26 | 13,12 | 13,96 | 14,80 | |||

| 16 | 89 | 7,32 | 8,38 | 9,38 | 10,36 | 11,33 | 12,28 | 13,22 | 14,16 | 15,07 | 15,,98 | |||

| 17 | 95 | 7,90 | 8,98 | 10,04 | 11,10 | 12,14 | 13,17 | 14,19 | 15,19 | 16,18 | 17,16 | |||

| 18 | 102 | 8,50 | 9,67 | 10,82 | 11,96 | 13,09 | 14,21 | 15,31 | 16,40 | 17,48 | 18,55 | |||

| 19 | Dн, mm | 2.5 | 2.8 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

| 20 | 108 | 10,26 | 11,49 | 12,70 | 13,90 | 15,09 | 16,27 | 17,44 | 18,59 | 19,73 | ||||

| 21 | 114 | 10,85 | 12,15 | 13,44 | 14,72 | 15,98 | 17,23 | 18,47 | 19,70 | 20,91 | ||||

| 22 | 121 | 11,54 | 12,93 | 14,30 | 15,67 | 17,02 | 18,35 | 19,68 | 20,99 | 22,29 | ||||

| 23 | 127 | 12,13 | 13,59 | 15,04 | 16,48 | 17,90 | 19,32 | 20,72 | 22,10 | 23,48 | ||||

| 24 | 133 | 12,73 | 14,26 | 15,78 | 17,29 | 18,79 | 20,28 | 21,75 | 23,21 | 24,66 | ||||

| 25 | 140 | 15,04 | 16,65 | 18,24 | 19,83 | 21,40 | 22,96 | 24,51 | 26,04 | |||||

| 26 | 146 | 15,70 | 17,39 | 19,06 | 20,72 | 22,36 | 24,00 | 25,62 | 27,23 | |||||

| 27 | 152 | 16,37 | 18,13 | 19,87 | 21,60 | 23,32 | 25,03 | 26,73 | 28,41 | |||||

| 28 | 159 | 17,15 | 18,99 | 20,82 | 22,64 | 24,45 | 26,24 | 28,02 | 29,79 | |||||

| 29 | 168 | 20,10 | 22,04 | 23,97 | 25,89 | 27,79 | 29,69 | 31,57 | ||||||

| 30 | 180 | 21,59 | 23,70 | 25,75 | 27,70 | 29,87 | 31,91 | 33,93 | ||||||

| 31 | 194 | 23,31 | 25,60 | 27,82 | 30,00 | 32,28 | 34,50 | 36,70 | ||||||

| 32 | 203 | 29,14 | 31,50 | 33,83 | 36,16 | 38,47 | ||||||||

| 33 | 219 | 31,52 | 34,06 | 36,60 | 39,12 | 41,63 | ||||||||

| 34 | 245 | 38,23 | 41,09 | 43,85 | 46,76 | |||||||||

| 35 | 273 | 42,64 | 45,92 | 49,10 | 52,28 | |||||||||

| 36 | 299 | 53,91 | 57,41 | |||||||||||

| 37 | 325 | 58,74 | 62,54 | |||||||||||

| 38 | 351 | 67,67 |

Table 1. Theoretical weight 1 linear. m of pipe (kg), for a given wall thickness (drill and casing pipes, continued).

| N p/p | Dн, mm | 8,5 | 9,0 | 9,5 | 10 | 11 | 11 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| 1 | 42 | 7,02 | 7,32 | 7,6 | 7,88 | |||||||||

| 2 | 45 | 7,65 | 7,99 | 8,32 | 8,63 | |||||||||

| 3 | 50 | 8,70 | 9,10 | 9,49 | 9,86 | |||||||||

| 4 | 54 | 9,54 | 9,99 | 10,43 | 10,85 | 11,67 | ||||||||

| 5 | 57 | 10,17 | 10,65 | 11,13 | 11,59 | 12,48 | 13,32 | 14,11 | ||||||

| 6 | 60 | 10,80 | 11,32 | 11,83 | 12,33 | 13,29 | 14,21 | 15,07 | 15,88 | |||||

| 7 | 63,5 | 11,53 | 12,10 | 12,65 | 13,19 | 14,24 | 15,24 | 16,19 | 17,09 | |||||

| 8 | 68 | 12,47 | 13,10 | 13,71 | 14,30 | 15,46 | 16,57 | 17,63 | 18,64 | 19,61 | 20,52 | |||

| 9 | 70 | 12,89 | 13,54 | 14,17 | 14,80 | 16,01 | 17,16 | 18,27 | 19,33 | 20,35 | 21,31 | |||

| 10 | 73 | 13,52 | 14,21 | 14,88 | 15,54 | 16,82 | 18,05 | 19,24 | 20,37 | 21,46 | 22,49 | 23,48 | 24,41 | 25,30 |

| 11 | 76 | 14,15 | 14,87 | 15,58 | 16,28 | 17,63 | 18,94 | 20,20 | 21,41 | 22,57 | 25,68 | 24,74 | 25,75 | 26,71 |

| 12 | 83 | 15,62 | 16,42 | 17,22 | 18,00 | 19,53 | 21,01 | 22,44 | 23,82 | 25,15 | 26,44 | 27,67 | 28,85 | 29,99 |

| 13 | 89 | 16,87 | 17,76 | 18,63 | 19,48 | 21,16 | 22,79 | 24,37 | 25,89 | 27,37 | 28,80 | 30,19 | 31,52 | 32,80 |

| 14 | 95 | 18,13 | 19,09 | 20,03 | 20,96 | 22,79 | 24,56 | 26,29 | 27,97 | 29,59 | 31,17 | 32,70 | 34,18 | 35,61 |

| 15 | 102 | 19,60 | 20,64 | 21,67 | 22,69 | 24,69 | 26,63 | 28,53 | 30,38 | 32,18 | 33,93 | 35,64 | 37,29 | 38,89 |

| 16 | 108 | 20,86 | 21,97 | 23,08 | 24,17 | 26,31 | 28,41 | 30,46 | 32,45 | 34,40 | 36,30 | 38,15 | 39,95 | 41,70 |

| 17 | Dн, mm | 8,5 | 9,0 | 9,5 | 10 | 11 | 11 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 18 | 114 | 22,12 | 23,31 | 24,48 | 25,65 | 27,94 | 30,19 | 32,38 | 34,53 | 36,62 | 38,67 | 40,67 | 42,62 | 44,51 |

| 19 | 121 | 23,58 | 24,86 | 26,12 | 27,37 | 29,84 | 32,26 | 34,62 | 36,94 | 39,21 | 41,43 | 43,60 | 45,72 | 47,79 |

| 20 | 127 | 24,84 | 26,19 | 27,53 | 28,85 | 31,47 | 34,03 | 36,55 | 39,01 | 41,43 | 43,80 | 46,12 | 48,39 | 50,61 |

| 21 | 133 | 26,10 | 27,52 | 28,93 | 30,33 | 33,10 | 35,81 | 38,41 | 41,00 | 43,65 | 46,17 | 48,63 | 51,65 | 53,42 |

| 22 | 140 | 27,57 | 29,08 | 30,57 | 32,06 | 34,99 | 37,88 | 40,72 | 43,50 | 46,24 | 48,93 | 51,57 | 54,16 | 56,70 |

| 23 | 146 | 28,82 | 30,41 | 31,98 | 33,54 | 36,62 | 39,66 | 42,64 | 45,57 | 48,46 | 51,30 | 54,08 | 56,82 | 59,51 |

| 24 | 152 | 30,08 | 31,74 | 33,39 | 35,02 | 38,25 | 41,43 | 44,56 | 47,65 | 50,68 | 53,66 | 56,60 | 59,48 | 62,32 |

| 25 | 159 | 31,55 | 33,29 | 35,03 | 36,75 | 40,15 | 43,50 | 46,81 | 50,06 | 53,27 | 56,43 | 59,53 | 62,59 | 65,60 |

| 26 | 168 | 33,43 | 35,29 | 37,13 | 38,97 | 42,59 | 46,17 | 49,69 | 53,17 | 56,60 | 59,98 | 63,31 | 66,59 | 69,82 |

| 27 | 180 | 35,95 | 37,95 | 39,95 | 41,92 | 45,85 | 49,72 | 53,54 | 57,31 | 61,04 | 64,71 | 68,34 | 71,91 | 75,44 |

| 28 | 194 | 38,89 | 41,06 | 43,23 | 45,38 | 49,64 | 53,86 | 58,03 | 62,15 | 66,22 | 70,24 | 74,21 | 78,13 | 82,00 |

| 29 | 203 | 40,77 | 43,05 | 45,33 | 47,59 | 52,08 | 56,52 | 60,91 | 65,94 | 69,54 | 73,78 | 77,97 | 82,12 | 86,21 |

| 30 | 219 | 44,12 | 46,61 | 49,08 | 51,54 | 56,43 | 61,26 | 66,04 | 70,78 | 75,46 | 80,10 | 84,69 | 89,23 | 93,71 |

| 31 | 245 | 49,56 | 52,38 | 55,17 | 57,95 | 63,48 | 68,95 | 74,38 | 79,76 | 85,08 | 90,36 | 95,59 | 100,77 | 105,90 |

| 32 | 273 | 55,45 | 58,60 | 61,73 | 64,86 | 71,07 | 77,24 | 83,36 | 89,42 | 95,44 | 101,41 | 107,33 | 113,20 | 119,02 |

| 33 | 299 | 60,89 | 64,37 | 67,83 | 71,27 | 78,13 | 84,93 | 91,69 | 98,40 | 105,06 | 111,67 | 118,23 | 124,74 | 131,20 |

| 34 | 325 | 66,35 | 70,14 | 73,92 | 77,68 | 85,18 | 92,63 | 100,03 | 107,38 | 114,68 | 121,93 | 129,13 | 136,28 | 143,38 |

| 35 | 351 | 71,80 | 75,91 | 80,01 | 84,10 | 92,23 | 100,32 | 108,36 | 116,35 | 124,29 | 132,19 | 140,03 | 147,82 | 155,56 |

Computer program GEOFPRO Fluid

Calculation of well hydraulics

The computer program will calculate the pressure loss due to friction in the drilling fluid over the well intervals, calculate the EDS, and the wellbore cleaning index:

— inside sections of drill pipes and BHAs,

— between the walls of the well and the drilling tool,

— between the string of casing and drill pipes.

The hydraulic calculation of the well is presented in the form of a graphic report, with clear and simple diagrams and graphs.

On our website you can download a FREE computer program - a calculator for calculating the mass and weight of casing and drill pipes, tubing tubing.

Geofpro Calculator (link to site section)

Weight table for steel water and gas pipes.

DU diameter, mm (inch)

Outer diameter dn , mm

Lungs

Regular

Reinforced

Wall thickness s , mm

Weight 1m, kg

Meters per ton

Wall thickness s , mm

Weight 1m, kg

Meters per ton

Wall thickness s , mm

Weight 1m, kg

Meters per ton

The weight of a linear meter of steel pipe in the table is theoretical. Actual value may vary by 4-8%. To convert meters to kg. pipes, you need to multiply the weight value per linear meter in the table by the total length of the rolled pipe.

Standard designation of pipe diameter in the range (see table):

- Internal diameter is the main dimensional characteristic of pipes and connecting parts (fittings) to them.

- Outer diameter of pipes (in the table - dn).

- The nominal pipe diameter (in the table - Dy, Du) is the nominal size of the internal diameter in mm. or its rounded value in inches.

- Wall thickness, mm. (in Table S).

Source

Advantages of metal pipes

This product has a number of important advantages.

These include:

- wide range of applications;

- maintaining good performance properties throughout the entire service life;

- availability of products due to their availability from a large number of suppliers;

- the possibility of purchasing and using used goods that have a lower price compared to new ones.

Special attention should be paid to the last point. Let's look at it in more detail.

Pipe calculator

| Cost per ton with price per meter of pipe, ₽: | But |

| The price of a meter of pipe at the cost of a ton, ₽: | But |

| Total weight of 6 m of pipe, kg: | But |

| Total length 1000 kg. pipes, m.: | But |

| Name | Pipe Calculator (Round) |

| Requirements | Javascript |

| OS | Windows, Android, OSX, Linux |

| Category | Business, Education |

| Price |

Install the widget on the site

Formula and calculation methods

The weight of pipes made of various metals (steel pipes, stainless steel, copper, etc.) is calculated based on the data available in the GOST and TU reference books. The weight of a meter of pipe, the range of which is not included in the directories available on the website, is calculated online using the formula m = Pi * ro * S * (D - S) * L; Pi is a mathematical constant that expresses the ratio of the circumference of a circle to its diameter, equal to

3.14; ro is the density of the metal from which the round pipe is made in kg/m³; To calculate the specific gravity of 1 linear meter of pipe (m), it is necessary to indicate the dimensions of the pipe profile: diameter D in mm, as well as the thickness of the metal from which the pipe is made (wall thickness S) and length L (default 1 m). The calculation of the theoretical weight of a rectangular profile pipe is carried out similarly to a round one, with the exception of the part of the formula for determining the cross-sectional area.

Areas of application for pipes

Currently, these products are often used in the following cases:

- carrying out construction work;

- laying communications;

- construction of air pressure lines;

- pipeline protection.

As part of the last point, this steel blank is used as a protective frame. Essentially, it plays the role of a cartridge in which another object is located. This is most often the water line.

Weight tables for 1 meter of round pipes of various metals and alloys according to all available GOSTs and TUs

| Pipe name and dimensions | Diameter, mm | Wall thickness, mm | Pipe meter weight | Meters per ton | Density, kg/m³ | Standard |

| Pipe 57x3 | 57 | 3 | 4.0000 kg. | 250 m. | 7850 | GOST 10704-91 |

| Pipe 57x3.5 | 57 | 3.5 | 4.6200 kg. | 216.5 m. | 7850 | GOST 10704-91 |

| Pipe 57x4 | 57 | 4 | 5.2300 kg. | 191.2 m. | 7850 | GOST 10707-80 |

| Pipe 76x3.5 | 76 | 3.5 | 6.2600 kg. | 159.7 m. | 7850 | GOST 10704-91 |

| Pipe 89x3.5 | 89 | 3.5 | 7.3800 kg. | 135.5 m. | 7850 | GOST 10704-91 |

| Pipe 89x4 | 89 | 4 | 8.3800 kg. | 119.3 m. | 7850 | GOST 10704-91 |

| Pipe 108x3.5 | 108 | 3.5 | 9.0200 kg. | 110.9 m. | 7850 | GOST 10704-91 |

| Pipe 108x4 | 108 | 4 | 10.2600 kg. | 97.5 m. | 7850 | GOST 10704-91 |

| Pipe 108x5 | 108 | 5 | 12.7000 kg. | 78.7 m. | 7850 | GOST 10704-91 |

| Pipe 133x4 | 133 | 4 | 12.7300 kg. | 78.6 m. | 7850 | GOST 10704-91 |

| Pipe 159x4 | 159 | 4 | 15.2900 kg. | 65.4 m. | 7850 | GOST 10704-91 |

| Pipe 159x4.5 | 159 | 4.5 | 17.1500 kg. | 58.3 m. | 7850 | GOST 10704-91 |

| Pipe 159x5 | 159 | 5 | 18.9900 kg. | 52.7 m. | 7850 | GOST 10704-91 |

| Pipe 159x6 | 159 | 6 | 22.6400 kg. | 44.2 m. | 7850 | GOST 10704-91 |

| Pipe 219x6 | 219 | 6 | 31.5200 kg. | 31.7 m. | 7850 | GOST 10704-91 |

| Pipe 219x8 | 219 | 8 | 41.6300 kg. | 24 m. | 7850 | GOST 10704-91 |

| Pipe 273x8 | 273 | 8 | 52.2800 kg. | 19.1 m. | 7850 | GOST 10704-91 |

| Pipe 325x6 | 325 | 6 | 47.2000 kg. | 21.2 m. | 7850 | GOST 10704-91 |

| Pipe 325x8 | 325 | 8 | 62.5400 kg. | 16 m. | 7850 | GOST 10704-91 |

| Pipe 426x8 | 426 | 8 | 82.4700 kg. | 12.1 m. | 7850 | GOST 10704-91 |

| Pipe 426x10 | 426 | 10 | 102.5900 kg. | 9.7 m. | 7850 | GOST 10704-91 |

| Pipe 530x8 | 530 | 8 | 102.9900 kg. | 9.7 m. | 7850 | GOST 10704-91 |

| Pipe 530x10 | 530 | 10 | 128.2400 kg. | 7.8 m. | 7850 | GOST 10704-91 |

| Pipe 630x8 | 630 | 8 | 122.7200 kg. | 8.1 m. | 7850 | GOST 10704-91 |

| Pipe 820x10 | 820 | 10 | 199.7600 kg. | 5 m. | 7850 | GOST 10704-91 |

Application in petroleum products transportation systems

Seamless pipes with a thickness of 3 mm or more are used for transporting petroleum products (gasoline, diesel, aviation fuel) in class II petroleum product pipelines located in cities and towns.

For gas pipelines of gas distribution systems intended for the transportation of natural gas and LPG (liquefied hydrocarbons), it is recommended to use 159 pipes of the following types:

- electric welded straight-seam pipes 159x4, 159x5, 159x6 mm, meeting the requirements of GOST 10705, GOST 10704

- main pipes GOST 20295 type 1 - straight-seam, and type 2 - spiral-seam, with a wall thickness of 4.5 mm

- seamless hot-deformed pipes with a thickness of 4.5 mm in accordance with GOST 8731, GOST 8732

GOST and TU standards available in calculator calculations and weight tables:

- GOST 494-2014 (x/d) - Brass pipes. Cold-worked

- GOST 9941-81 — Cold- and heat-deformed seamless pipes made of corrosion-resistant steel

- GOST 10707-80 — Cold-deformed electric-welded steel pipes

- GOST 494-2014 (p) - Brass pipes. Pressed

- GOST 617-2006 (p) - Copper and brass pipes of round section for general purpose. Pressed

- GOST 3262-75 — Steel water and gas pipes. Galvanized

- GOST R 52318-2005 — Round copper pipes for water and gas

- GOST 32598-2013 — Round copper pipes for water and gas

- GOST 617-2006 (x/d) - Copper and brass pipes of round section for general purpose. Cold-worked

- GOST 10704-91 — Longitudinal electric-welded steel pipes

- GOST 18482-2018 — Pressed pipes made of aluminum and aluminum alloys