If you like to make something useful with your own hands (in a small workshop or garage), you have probably already thought about purchasing various auxiliary equipment for work.

But not everyone has the opportunity to buy branded tools and equipment for a home workshop - the prices are quite significant. And delivery in some cases is also expensive.

However, many home-made craftsmen, as you know, do not look for easy ways, and can always use an alternative option.

For example, you can bet on homemade machines for the garage and workshop, which will not be difficult to make yourself from inexpensive and accessible materials.

Even simple “handicraft” devices can greatly simplify and speed up the processing of metal and wood workpieces.

If you need to save money, homemade machines are perhaps the best option. All the necessary diagrams and drawings can be found on the Internet, including on our website.

Crafting table

Dimensions of the workbench

The height of the surface of the tabletop should be such that a worker can operate tools and equipment while standing. The workshop owner determines the height of the workbench himself - according to his height. The height of the desktop ranges from 75 cm to 80 cm.

The size of the countertop is determined by the area of the utility room. The table should not impede free passage around it.

Workbench material

- Tree. A wooden table is often used. The workbench is made of timber and boards. The legs of the table are secured with diagonal crossbars for reliability.

- Metal. The most reliable workbench design is a workbench welded from a metal profile. Manufacturing a welded product requires having a welding machine and experience working with it.

The table top is made in the form of a shield from knocked down boards using pieces of timber. The shield is rested on the legs of the table and fastened with nails or screws. The connection parts are made from angle steel.

The options for assembling a wooden workbench are different, but they have one thing in common - the table structure must be stable and withstand static and dynamic loads.

If the surface of the workbench will be subject to accidental impact from cutting and sharp tools, then the tabletop is covered with tin or a metal sheet is placed on top.

The supporting frame and table legs are welded from steel angle and strip. For auxiliary parts, pieces of reinforcement are used.

The table top is made of metal sheet, 8 - 12 mm thick. A thick sheet will significantly increase the weight of the workbench, which will make it difficult to move.

Bend

Probably almost all of you have seen such beautiful tables and chairs with bent legs. It looks very impressive. If such legs are cut and sawed out, they will turn out to be much less durable, because the longitudinal integrity of the fibers will be damaged. It is best to achieve this shape by bending the wood. To prevent workpieces from breaking, you must first increase their ductility. In production, chemical plasticization of wood is used, and amateurs usually have only one method available: first moisten the wood and then heat it, after which they can gradually bend the workpiece.

Stool

Making a stool with your own hands is quite simple:

- 4 supports, 50 cm long, are made from timber 40 x 40 mm.

- The legs in the middle of the length are fastened with crossbars.

- Grooves are made in the supports using a chisel.

- At the ends of the transverse planks, protrusions are cut out using a chisel to fit the grooves.

- The protrusions are lubricated with wood glue and inserted into the grooves.

- While the glue dries, the supports are tightened with a belt.

- The seat is cut out with a circular saw from a wide board 30 mm thick.

- A seat measuring 300 x 300 mm is nailed or screwed to the legs of the stool.

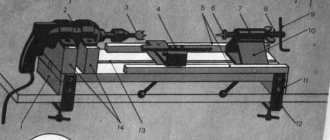

Features of wood lathes

In a number of cases, a hardworking owner has a desire to make furnishings and utensils that have a circular cross-section throughout their entire length.

Most often these things are:

- Holders for hammers and files;

- Stair posts, flowerpots, handles for railings;

- Rolling pins, potato presses, grape crushers;

- Vertical pencil cases;

- Cups, mugs, saucers, plates, trays, stoppers.

It will be impossible to cut such things with planes and saws. In this case, you will need at least the most primitive machine.

Mini vise made of metal loop

When performing small operations, small parts often need to be clamped. To do this, use a mini vice made from a one-piece door hinge.

Matching holes are drilled in both hinge flaps.

A bolt of suitable diameter is threaded through them. On the other side, a wing nut is screwed onto the bolt thread. The parts are inserted into the opening between the doors and clamped by tightening the nut. The device can be used as a clamp.

Veneering

Previously, this term was used to describe the procedure of gluing carpentry products with plywood - thin sheets of wood of other, more valuable varieties.

Nowadays we understand “plywood” as multi-layer laminated boards, and we call thin wood sheets “veneer”. Accordingly, instead of “veneering” today many people say “veneering”. Using veneer, you can give a beautiful, even sophisticated look to products made from “simple” types of wood that grow in our latitudes. For example, oak veneer can be used to cover birch furniture. By the way, today many examples of furniture, including “elite” foreign ones, are actually covered with veneer of more valuable species and are sold as made from solid wood, at much higher prices. I don’t recommend that beginners start gluing veneer right away, since this is a non-trivial task that requires skill, patience, and in the case of large parts, also serious equipment in the form of powerful presses or vacuum bags for uniform gluing of veneer.

Hammer upgrade

A common occurrence is a wooden handle falling out of the hammer socket. One of the ways to create a reliable handle fastening is to make a cut in the upper end of the handle. The holder is inserted into the hammer socket. The cut is filled with Moment glue. A wooden wedge is driven into the groove.

In order not to look for nails while working, and especially not to hold them with your teeth, a round magnet is glued into the bottom of the hammer handle. Magnetic nails will always be at hand for the worker. It is dangerous for the hammer to accidentally fall out of your hand at height. To prevent this from happening, a hole is drilled in the handle through which the cord is threaded. The worker's belt is threaded through the loop.

Pipe bender

A device for bending metal pipes is a metal rod welded to the frame. I make the rod from a piece of reinforcement. The pipe is placed on a pin, and on the other side a long piece of reinforcement is inserted into the pipe. By pressing the lever, the pipe is bent at the desired angle. The device is suitable for small sections of round pipes.

Making a pipe bender with your own hands

- Two axles are welded to a metal frame from pieces of smooth reinforcement, onto which old car hubs are placed.

- Protruding chamfers are removed from the hubs so that the side surfaces of the rollers are smooth.

- The channel is placed in the opening between the hubs with the shelves facing up.

- The same profile, smaller in width, with the flanges down, is placed into the channel.

- An axle is welded to the top of the inner profile, onto which the third hub is placed.

- A vertical shelf made of steel sheet is welded to the frame.

- A hole is cut in the vertical bar and the bearing is pressed into it.

- A nut is secured to the middle channel by welding.

- One end of the screw rod is screwed into the nut.

- The screw shank is threaded through a bearing in a vertical bar.

- A rotary handle is welded to the shank on the back side of the bar.

- A swing arm is welded to the axis of the drive hub.

The machine is ready for use. A profile pipe is inserted between the rollers and clamped with a screw. The rotary lever drives the rollers, which pull the pipe, bending it. The bending radius is set using the rotary handle of the screw.

A pipe bender made from car hubs is one of the device options. There are many designs of bending devices. In some models, the drive roller is coaxially connected to the motor shaft.

Impact screwdriver from starter

There are situations when it is impossible to unscrew a rusted bolt or screw with a conventional tool. An impact screwdriver does this job perfectly. The tool is made by hand from parts of a car starter:

- The shaft and bushing are removed from the starter housing.

- Part of the shaft is cut off, leaving a splined rod.

- A piece of pipe of suitable size is placed on the sleeve.

- A piece of bolt of equal diameter is welded to the end of the pipe.

- The end of the shaft is ground into a tetrahedron shape, onto which heads of the required size are placed. For screws, a bit is inserted into the head.

When you hit the head of the bolt with a hammer, the shaft slides with beveled splines inside the sleeve, performing a rotational movement. The stronger the blow, the more force the shaft rotates.

Homemade bow saw

A bow saw is a convenient tool for cutting tree trunks and lumber. The design of the saw is simple; making a hand tool with your own hands is not difficult. To do this you need to prepare tools and materials:

Tools

- drill;

- hacksaw;

- chisel;

- hammer;

- knife.

Materials

- cord;

- wooden slats 20 x 40 mm;

- cotter pins – 2 pcs.;

- stalk ø 10 mm;

- saw blade;

- stain;

- wood varnish.

Step-by-step instructions for making a bow saw

- The lath is cut into three parts (two vertical side strips and a middle horizontal strip).

- Grooves are made in the side handles using a chisel.

- At the ends of the centerpiece, protrusions for grooves are cut out with a chisel.

- The centerpiece is connected to the side handles.

- Through holes are drilled at the joints. Wooden cotter pins are driven into them.

- Cotter pins form hinge joints. This is necessary for the mobility of the lower ends of the side slats when the canvas is tensioned.

- Cuts are made at the lower ends of the sidewalls - parallel to the middle.

- Short bolts are inserted into the holes of the saw blade and tightened with nuts.

- The blade is inserted into the cuts so that the bolts are on the outside of the structure.

- Circular grooves are cut out at the upper ends of the handles.

- Loops are made at the ends of the double cord, which are placed on the grooves.

- A handle is inserted between the strings of the cord, the long end of which rests on the mullion.

- The saw string is twisted using a handle, achieving the desired degree of tension on the saw blade.

- The wood is covered with stain and two layers of varnish.

- After the varnish has dried, the saw is ready for use.

Homemade folding stand

A very original idea for a folding stand for hand tools. Everyone is in their place. It doesn't take up much space. The design is based on furniture guides. The clamp holds the stand in the upper position. Neodymium magnets prevent instruments from falling out of their stocks. A great idea for DIYers who love to do everything with their own hands.

Advantages and disadvantages

Homemade furniture machines, like any other tools, have advantages and disadvantages. The benefits include:

- ease of use;

- simple design does not require special skills when working;

- obtaining holes without defects;

- increase in productivity;

- relatively low cost of production;

- The equipment does not require much space to operate; a small area of the desktop is sufficient.

Drilling on a machine

Despite its positive aspects, homemade equipment has disadvantages:

- the ability to use only one type of drill;

- low speed during tool operation;

- there is no possibility of multifunctionality; processing requires the use of additional equipment;

- insufficiently automated device;

- You cannot switch modes.

The disadvantages of drilling devices are not noticeable when making furniture at home, since in this case it is not necessary to produce large volumes. The equipment ensures smooth holes, resulting in high-quality and durable furniture.

Making a furniture unit with your own hands is not difficult; you do not need to have special knowledge and skills. Everything is done from improvised means. The result is drilling equipment, which is indispensable when creating structures for your home yourself.

Cheap homemade grinder

The most budget version of the grinder, created by the Samodelkins. Plastic bottles are used as rollers. They are mounted on bearings. The belt on the rollers is adjusted using thumbwheels. The tension is adjusted with a bolt. The structure is driven by a drill. You can slightly improve Samodelkin’s design by replacing plastic bottles with polypropylene tubes.

Useful hammer upgrade

When working with a hammer in an inconvenient place, you often have to take nails with you in your pocket or even in your teeth. Agree, this is not very pleasant.

By installing a small but powerful magnet on the hammer handle, you can at least partially solve this problem. The upgraded hammer will carry the nails itself and you can safely work without holding the next nail in your teeth. It's convenient, and your teeth don't get damaged.

Buying a lathe

Today you can purchase such a device with a click of the mouse by going to a specialized online store. True, such a purchase will hurt your pocket, especially if you choose a high-quality model and not a cheap Chinese craft.

However, this does not mean that the idea of founding a miniature workshop will have to be given up. The problem of high cost can be solved by taking a different route. A simple and durable electrical unit must be made by hand.

Turning round architectural decorations

Such a mechanism will be an excellent help if you need to make inexpensive repairs to a cottage equipped with

- Flights of stairs with wooden balustrades;

- Decorative trims;

- Carved shutters;

- Window earrings.

Homemade soldering iron stand with your own hands

Many offline and online stores sell good and quite convenient stands for soldering irons, and inexpensively. But if you wish, you can make them yourself. It will be cheaper, plus you can adapt the stand to your own needs.

There are a lot of ideas for making them, so we decided not to limit ourselves to just one, but to make a selection of the most interesting, in our opinion, homemade soldering iron stands, made with our own hands.

We make a carpentry workbench with our own hands according to the drawings: video instructions and photo examples

Among the common tools for a do-it-yourself carpentry workshop is a workbench. A durable and dimensional table that allows you to securely fasten the workpiece is useful for high-quality cutting of wood and creating various elements from it.

Example of a carpentry workbench

The device package includes:

- Working surface. Hard wood is used for it to increase the life of the device. The thickness must be at least 6 cm.

- Supports. Assembled from wooden beams or metal plates. The main task is to ensure the stability of the entire mechanism.

- Vise for securing the product. If the table is long, you can install two vices at once.

- Tool box. A useful recess or pull-out design that provides quick access to needed small parts.

Purchased folding workbench for work

To assemble a carpentry workbench for your workshop yourself, you should choose a drawing and purchase materials for the work.

Instructions for assembling a wooden workbench with your own hands

You can buy a wooden workbench in a store or through online catalogs, but it’s cheaper to make it yourself. Let's take as a basis a simple option with typical tabletop dimensions: length - 150-200 cm, width 70-120 cm.

The manufacturing work will include several stages:

| Image | What need to do |

| Make the top cover from thick boards to create a shield with a width of 70 to 200 cm. You fasten the elements with long nails, and you need to drive them in from the outside and carefully bend them from the inside. The working surface of the workbench is made only of wood or chipboard. | |

| Make the top cover from thick boards to create a shield with a width of 70 to 200 cm. You fasten the elements with long nails, and you need to drive them in from the outside and carefully bend them from the inside. The working surface of the workbench is made only of wood or chipboard. | |

| Sheathe the lid along the lower perimeter with a 5 by 5 cm beam. This will make it more convenient to attach the vertical supports. The location of the supports depends on the size of the tabletop. It is better to make them from thick rectangular timber at least 120 by 120 mm. | |

| The carpentry workbench must be installed correctly. Be sure to secure it firmly. If it will be mounted outdoors under a canopy, dig holes for supports. Indoors, use other fastening methods. |

Gluing and protective and decorative coating

These are the main operations after the manufacture and assembly of the parts themselves.

And for their implementation certain conditions are required. A barn is not a house; it is not heated. When I started carpentry, I realized that I couldn’t glue or paint it, because it was already winter outside and the workshop was too cold; I couldn’t even store materials at that temperature. At the same time, it is uncomfortable to work in a cold workshop. This, of course, upset me very much, because insulating the barn would have been quite expensive. I recommend that you either immediately take care of insulation, or during the cold season, do gluing and painting in other warm rooms.

Making a carpenter's vice for a workbench with your own hands

Professional “homemade workers” assemble not only tables for work, but also vices with their own hands according to drawings. Any design of such a clamp will include several elements:

- Supports, where each one has a sponge for clamping.

- Moving jaw.

- Metal guides. The sponge moves over them.

- Lead screw for moving elements.

- Collar. Necessary for rotating the screw.

When making a homemade vice with your own hands, you can use various available materials. For example, there is a design option made from a profile pipe. To do this, prepare several pieces of pipe of different sizes, a steel stud with large threads and double nuts.

Instructions for creating a bench vise from a profile pipe:

| Image | What need to do |

| The largest pipe acts as a body. Supports are soldered to it from below. A 3-4 mm steel flange is put on the back side. A hole for the running nut is drilled in the center, and a rear jaw is welded opposite the front support. | |

| The largest pipe acts as a body. Supports are soldered to it from below. A 3-4 mm steel flange is put on the back side. A hole for the running nut is drilled in the center, and a rear jaw is welded opposite the front support. | |

| A front steel flange is welded onto the internal moving part. A stud is mounted in it, with lock nuts attached to it. Thrust washers are placed on both sides of the flange. The last element is a movable tube attached to the front jaw. |

DIY metal workbench drawings

A metal workbench does not differ much from a carpenter's workbench. It is based on a rigid metal rather than wooden frame. A vice is attached to it, and the entire workbench is designed to withstand the force of a sledgehammer.

Option for a home metal workbench

Do-it-yourself metal workbenches can have one, two or three cabinets, and also not have shelves or drawers for small parts. In terms of strength for working in a garage, you can make a regular table made of metal up to 5 mm thick and a reinforced structure where sheets from 10 to 30 mm are applicable.

Here are some useful plans for making a metal workbench for your workshop:

A simple version of a mechanic's workbench

Dimensions of a homemade tool

Combining a workbench and a work table

Fixed vice

Drilling machine for home workshop

You can make a drilling machine attachment from a drill with your own hands. The drawings will help you understand the design. For such a design you will need the following elements:

- base or frame;

- rotation device;

- mechanism for ensuring supply;

- stand for fastening the door.

Installing the machine in the workshop

Here are the main steps in making a homemade drilling machine with your own hands:

- Chipboard is used for racks. In this case, you need to choose a thickness of at least 20 mm;

- To maintain the accuracy of the drill machine, it is necessary to use guides. In this case, you can use steel strips;

- For the pads, steel clamps are used.

To make a drilling machine you will need a rotary tool feed mechanism. The design uses springs and a lever. There are various tools for sharpening drills.

Assembling a drilling machine with your own hands: drawings with dimensions

The design will also require the manufacture of a homemade vice for a drilling machine. The simplest device can be assembled from a drill, without a steering rack. To minimize vibration processes, it is necessary to build a more massive table. The stand and table are connected at right angles. In this case, the drill can be attached using clamps. A vice is mounted on the table surface.

Complex drawing of a drilling machine

Knife sharpening device

No home is complete without a knife in the kitchen. It is quite difficult to sharpen correctly without special tools: it is necessary to maintain the desired angle and achieve the ideal sharpness of the blade.

Option for a home device for sharpening blades

For each knife, a certain sharpening angle must be observed:

- A razor and scalpel require an angle of 10-15⁰.

- Knife for cutting bakery products – 15-20⁰.

- Classic multifunctional knives – 25-30⁰.

- For hunting and hiking, take a device with a blade angle from 25 to 30⁰.

- If you want to cut hard materials, then sharpen at an angle of 30-40⁰.

In this way you can adjust the sharpening angle

To ensure the desired angle, it is worth buying or making a sharpening device. For example, you can assemble a sharpener from washing machine motors with your own hands.

If you do not use sharpening every day, then 1000 rpm is enough for high-quality results and a long service life of the device.

To assemble such a machine, you will need a motor from a washing machine with a power of 200 W. To create a sharpener from a washing machine engine, prepare:

- the motor itself;

- metal for the casing with a thickness of 2 to 2.5 mm;

- flange tube;

- sharpening stone;

- nuts;

- trigger mechanism;

- cable for connecting to the electrical network;

- a metal corner or a wooden beam for the frame.

There are simple do-it-yourself sharpening machines without motors. For example, you can make a device from bars. To do this, prepare two abrasive stones of the same size and a sharpening stone.

An easy version of the “homemade” sharpener

The progress of work on creating such a simple device will be as follows:

- Sand the wood blocks with sandpaper, removing any burrs. Make markings depending on the desired angle.

Materials for work

- Attach a stone to the drawn line to give the blade a sharp edge. To do this, attach it to the block and mark its width. Then, make cuts on the markings, up to 1.5 cm deep.

- Attach abrasive stones to the resulting recesses so that the grooves coincide. Then, install the sharpening stone by screwing it onto the bolts.

Ready-made sharpener option

There are many ways to make a homemade knife sharpener. Choose the one that suits you and try to create a convenient and useful tool for your home.

Device for sharpening drills for metal

They make their own not only a sharpener for blades, but also a machine for sharpening drills for metal. Here are a few drawings useful for work:

Convenient option for everyday use

Expanded drawing

Ready home machine

Another convenient option

DIY garage press options

Homemade garage presses allow you to process various products and materials under pressure. Structurally, the equipment consists of cylinders. In the garage, such a machine is useful for straightening or fastening various elements, as well as for bending sheets of metal or pressing cardboard.

An example of a homemade press

For private use, a capacity of 10-15 tons is sufficient. Most often, a bottle jack is used with a provided hand pump, which acts as the main structural element.

Here are some interesting options for homemade garage presses:

Option from scrap materials

Rails will also come in handy

Ready purchase model

Convenient homemade press

Turning

The three operations described - trimming, jointing and thicknessing - will allow you to make only some very simple products.

In a good way, you still need to master turning, that is, turning workpieces that are figures of rotation. For example, round legs for a stool or table, vases, bowls, or some other products. And in this case, you can’t do without a lathe. Of course, you can turn to the experience of generations and make an adapter from shit and sticks, with the help of which you can turn cylindrical blanks on a circular saw, but this is a dead-end path. If you want to make something more complex than a cylinder, you will have to buy a lathe. Fortunately, this is one of the simplest machines; it consists of a cast iron frame, a motor, a collet and a stop for a chisel (rest). You can find many interesting models on the secondary market, and there are also quite a few new modern models.

In order for you to get high-quality furniture, if you want to make it for yourself or sell it, you will have to equip the workshop with many other equipment.