The brass sheet is a solid yellow profile with a rectangular cross-section, for the manufacture of which simple and complex brass is used. Its properties may vary, as they depend on the production method, composition and condition of the material. The thickness of the brass sheet is from 0.4 to 25 millimeters. Moreover, the thickness of the hot-rolled assortment is greater.

Decoding the alloy grade and its characteristics

The interpretation of L63 is as follows: L indicates brass, and the numbers indicate the presence of 62-65% copper in the composition. Single-phase structure promotes ease of processing. The production of brass L63 is regulated by GOST 15527-2004; it is used not only for practical but also for decorative purposes.

Among the key characteristics of L63 brass alloys is increased corrosion resistance compared to copper. The material exhibits these qualities:

- in the marine environment;

- in alcohol solutions;

- in fresh water;

- among halogen gases.

The material has good casting characteristics. Suitable for gas and electric welding. Melts at a temperature of 906 °C. During the melting process, components harmful to the human body are formed, so the procedure is carried out in ventilated rooms. The zinc present in the composition is flammable. The wear resistance is increased by hot firing.

This is interesting: Brass

Brass rod. Weight of brass rod.

Brass rod can be made in various shapes: hexagonal, round, oval, square. When delivering it to warehouses, we need to know the quantity we need in kilograms. To calculate the theoretical weight of a brass bar, you can choose the easiest way by using the metal calculator on this site. In the first column at the top we select the type of metal - brass, and in the second - the alloy: double (LS59-1, L63) or multi-component (see above), then select the type of profile and indicate the length. As a result, you will get the theoretical weight of the brass rod.

If this method does not suit you, you can use the table of the theoretical weight of 1 linear meter of brass rod (see below). The table shows the theoretical weight only for two types of dual alloys: L63 AND LS59-1

Theoretical weight of 1 linear meter of brass rod L63, L59-1.

Source

Classification of brasses

Depending on the chemical composition there are:

- Simple (two-component) brass. They contain only copper and zinc. Simple brass is marked with the letter “L” and a number that indicates the percentage of copper. For example: L85 contains 85% copper and 15% zinc.

- Special (multi-component) brass. They contain copper, zinc, lead, aluminum, iron and other elements that improve the basic properties of the material. Such elements are called alloying elements. Special brass is marked with the letter “L”, as well as letters and numbers indicating additional alloying elements and their percentage. For example: LA77-2 contains 77% copper, 2% aluminum and 21% zinc.

Special brasses are divided into classes named after the main alloying element (manganese, aluminum, silicon, tin, nickel, lead).

According to the degree of processing of brass there are:

• deformable (brass tape, wire, pipe, brass sheet); • foundry (fittings, bearings, instrument parts).

Read more about brass alloys

Brass L63, Brass LS59-1

There is also a classification based on the amount of zinc in the alloy:

• 5-20% zinc – red brass (tompak); • 20-36% zinc – yellow brass.

Specific gravity of various metals

After defining the very concept of the specific gravity of a given material, you can move on to some indicators that can subsequently assist in working with metals.

Of course, it’s no secret that each metal, as well as each alloy, has its own indicators of this value, different from others. In order not to get confused in all the available data on various alloys and metals, metals and alloys will be considered separately below.

Specific gravity of metals

First, we should consider metals that do not contain impurities and have their own chemical designation in the periodic table.

Metals are divided into ferrous and non-ferrous. The most typical black “representative” is iron. Its specific gravity will be indicated in the table below. The table will also show the specific gravity of ferrous metals such as chromium, molybdenum, tungsten, manganese, nickel, and titanium.

The remaining materials that are present in the table, but were not named in the list of metals above, are non-ferrous. All non-ferrous metals that will be listed below can be divided into three groups:

- light: aluminum, magnesium;

- noble metals, also called precious: semi-precious copper, silver, gold, platinum;

- fusible metals: tin, zinc, lead.

| Name of metal | Specific gravity, kg/cub.m |

| Aluminum | 2698 |

| Zinc | 7130 |

| Tin | 7290 |

| Lead | 11337 |

| Tungsten | 19300 |

| Molybdenum | 10220 |

| Iron | 7850 |

| Platinum | 21450 |

| Gold | 19320 |

| Silver | 1050 |

| Tantalum | 16650 |

| Vanadium | 6110 |

| Nickel | 8910 |

| Magnesium | 1740 |

| Copper | 8960 |

| Titanium | 4505 |

| Chromium | 7190 |

Specific gravity of metal alloys

Of course, the specific gravity of metals is extremely useful information, and this would be quite enough for a purely introductory reading of this article. But it should be remembered that pure metals are rarely used in construction and other areas. Usually they are replaced by various alloys , which can be divided into two groups: light and heavy.

Due to their outstanding high-temperature mechanical properties and serious strength indicators, alloys have long firmly taken their place in various industries and various industrial fields. The most common base materials for light alloys are titanium, beryllium, aluminum and magnesium. But it is worth mentioning the fact that alloys that were created on the basis of the last two metal elements cannot be used in working conditions where high temperatures are provided.

The basis for heavy alloys are the following elements: tin, lead, zinc, copper. Most often, heavy alloys such as brass and bronze . They are quite often used in various industries due to their excellent mechanical properties. These alloys are used to make sanitary fittings, as well as parts used in architecture.

Below is a table containing data on the specific gravity of some alloys:

| Metal alloys | Density of alloys, kg/cub.m |

| Aluminum bronze | 7700 — 8700 |

| Beryllium bronze | 8100 — 8250 |

| Brass | 8470 |

| Ordinary bronzes | 7400 — 8900 |

| Stainless steel | 7480 — 8000 |

| Carbon steel | 7850 |

| Cast iron | 6800 — 7800 |

| Cupronickel | 8940 |

| Nickel silver | 8400 — 8900 |

All the alloys presented in the table above are among the most popular in a wide variety of industrial fields and are used for the manufacture of a wide variety of items used by people in everyday life.

What negatively affects the anti-corrosion properties of L63

Sharp processing negatively affects the corrosion resistance of products made from L63 alloy. This happens due to the destruction of the crystalline structure of the material. Cutting also causes a lot of internal stress. Corrosion cracking is often observed on objects made of such material. The reasons for their appearance may be:

- high humidity;

- presence of ammonia in the operating environment;

- heat;

- wet vapors;

- high pressure

To protect against cracking, products are annealed at low temperatures. Corrosion resistance is also affected by contact with mineral acids, mine waters, chlorides, and hydrogen sulfide. Most often, cracking is observed on materials made of thin sheets. For example, on thin-walled pipes and containers. But under conditions of proper use, such products can last a good period.

Features of heat treatment and corrosion resistance

The product in question melts at a temperature of 906oC. In the range from 750oC to 880oC it still exhibits good ductility and can therefore be machined. An important stage in the production of alloy L63 is annealing, which is performed in the range of 550-650oC. As a result of this processing, two main processes occur:

- mechanical stress is relieved;

- metastable phases dissolve to form a single-phase structure.

The presence of mechanical stress is extremely undesirable for L63. It is known that the addition of zinc to copper leads to a significant improvement in its corrosion resistance, therefore all brasses are fairly chemically passive alloys. They are destroyed over time only in aggressive environments, for example in perchloric and nitric acids. However, the presence of stress in brass structures significantly reduces their corrosion resistance.

Due to the formation of the above-mentioned stresses, it is not recommended to subject L63 products to rapid cutting.

Main characteristics

Brass sheet can be produced by cold or hot forming. To obtain such rolled products, manufacturers can use two types of brass:

- multicomponent (its chemical composition, in addition to copper (about 40%) and zinc (1–2%), contains alloying additives such as aluminum, tin, nickel and lead);

- two-component (contains only copper (60–97%) and zinc).

The popularity enjoyed by brass sheets among modern manufacturers is explained by a number of advantages that distinguish such a product. Let's list them.

- The simplicity of processing allows you to create blanks and finished products of almost any configuration from this type of rolled metal without significant labor costs.

- The exceptional decorative characteristics of the brass sheet are not lost during the operation of the finished product.

- On the modern market, brass sheets are available in a wide range of thicknesses (0.5–25 mm), which allows consumers of such products to choose the material that best suits their requirements. All such products comply with the requirements of the regulatory document (GOST 2208-2007).

- Products made from sheet brass are highly corrosion resistant and can be successfully used in contact even with very aggressive environments.

Cold rolling brass strip

Additional advantages of using such a material include the fact that brass, sheets and other types of rolled products from which can be successfully operated in a fairly wide temperature range (from –80 to +120°

), easy to polish (this is especially important for decorative items). Even complexly deformed brass products retain the unique structure of the original material and, accordingly, all its original characteristics.

Brass sheet, the requirements for the parameters and characteristics of which are specified by the provisions of GOST 2208-2007, does not resist wear well enough, but this disadvantage of this product is compensated by a whole list of its advantages. In particular, this should include good machinability using plastic deformation methods at any temperature, as well as good weldability using argon arc welding.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

This is interesting: Characteristics and application of brass - an alloy of copper and zinc

Online metal calculator

When you need to buy rolled metal, you need to know which transport will be more convenient to transport it. The tonnage of cars or other vehicles for delivery depends on the total mass of metal products. Therefore, the question arises of how to calculate the mass of the required amount of rolled metal.

Once upon a time, solving this issue took a lot of time even for highly qualified specialists. After all, to perform the necessary calculations, it was necessary to know the theoretical mass of the weight of various metals, formulas for calculating the volume of various rolling forms, etc. Such computational complexity required the search for new solutions. This solution was the online metal calculator.

Now, when drawing up any construction specifications, a rolled metal calculator is used instead of many tables, formulas and painstaking calculations. Using our online rolled metal calculator service, you can calculate the mass of the following metals: - steel; - cast iron; - aluminum; - bronze; - brass; - magnesium; - nickel; - copper; - tin; - lead; — titanium; - zinc.

In order to make the calculation, you need to select the type of metal and type of rental in the drop-down menu of the Free Online Metal Calculator program. The calculation is made for the following types of rental: - corner; - leaf; - pipe; — circle/wire/wire rod; - square pipe; - rental; — channel; — tape/strip; - beam; - hexagon.

Foil, tapes, sheets and brass plates. Specifications

| Designation: | GOST 2208-2007 |

| Status: | active |

| Type: | GOST |

| Russian name: | Foil, tapes, sheets and brass plates. Specifications |

| English name: | Brass foil, ribbons, sheets and plates. Specifications |

| Date of text update: | 06.04.2015 |

| Description update date: | 01.06.2019 |

| Publication date: | 01.06.2008 |

| Effective date: | 30.06.2008 |

| Last modified date: | 12.09.2018 |

| Reissue: | reissue |

| Area and conditions of application: | This standard applies to brass cold-rolled foil, strips, cold-rolled and hot-rolled sheets and hot-rolled plates for general purposes. The standard does not apply to brass bands intended for radiators |

| Instead: | GOST 2208-91 GOST 931-90 |

| List of changes: | No. 0 from (reg.) “Introduction date postponed” No. 1 from (reg.) “Amendment” No. 2 from (reg.) “Text change; Reference NDs have been changed" |

| Is located in: | All-Russian Classifier of Standards → Metallurgy → Non-ferrous metal products → Copper products Classifier of state standards → Metals and metal products → Non-ferrous metals and their alloys. Rolled products from non-ferrous metals → Tapes All-Russian Product Classifier → Rolled non-ferrous metals → Rolled heavy medium-melting metals → Rolled brass → Sheets, plates → Tapes → Foil |

| Application #0: | Change No. 1 to GOST 2208-2007 |

| Application #1: | Change No. 2 to GOST 2208-2007 |

| Appendix No. 2: | Amendment to GOST 2208-2007 |

Let's look at how alloying elements affect the properties of brass.

- Tin significantly increases the anti-corrosion properties in sea water and increases the strength of the alloy. Brass with tin is often called marine brass.

- Manganese increases strength and corrosion resistance. Manganese brasses are often combined with tin, iron and aluminum.

- Nickel improves corrosion properties and strength in various environments.

- Silicon reduces strength and hardness and also improves weldability. Brasses containing silicon and lead have good anti-friction properties. Such alloys can replace more expensive ones, such as tin bronze.

- Lead significantly improves machinability, but at the same time degrades mechanical properties. Lead brass is called automatic, since it is processed on automatic machines. This alloy is the most common.

- Aluminum reduces the volatility of zinc due to the formation of a protective film (aluminum oxide) on the surface of molten brass.

Rolled metal

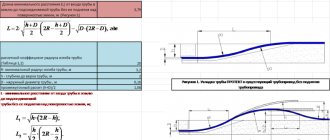

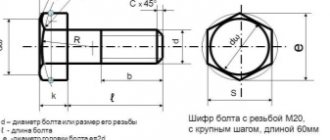

Pipes in accordance with GOST 494 from LS59-1 are produced by pressing. In addition, a wide range of products from this material are produced in accordance with GOST. Since the alloy has low mechanical properties for pressure processing, although it is generally considered pressure-processable, pipes are made from it using continuous casting methods. And their cost is much lower than pressed ones.

Cold-deformed general-purpose wire is produced in accordance with GOST 1066, and has a square, round or hexagonal cross-section.

Cold-worked sheets LS59-1 have high hardness and wear resistance, and, as mentioned above, are used in machine tool construction. This is one of the most popular types of rolled brass sheets. In addition, sheets are produced from LS59-1 in soft, semi-hard, and hard states.

LS59-1 bars of hexagonal and square shape have found the greatest use. This is a very inexpensive type of rolled product that is easy to cut, and in addition, it has strong ribs. Thanks to this, at minimal cost it is possible to produce all kinds of small and large parts with good anti-friction properties from rods. This alloy is used to produce drawn and pressed rods in hard, soft or semi-hard states.

Table of theoretical mass of round brass pipes according to GOST and TU

| Pipe name and dimensions | Diameter, mm | Wall thickness, mm | Pipe meter weight | Meters per ton | Density, kg/m³ | Standard |

| Pipe 3x0.5 | 3 | 0.5 | 0.0334 kg. | 29940.1 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 4x0.5 | 4 | 0.5 | 0.0467 kg. | 21413.3 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 4x0.8 | 4 | 0.8 | 0.0720 kg. | 13888.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 4x1 | 4 | 1 | 0.0840 kg. | 11904.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 5x0.8 | 5 | 0.8 | 0.0940 kg. | 10638.3 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 6x0.5 | 6 | 0.5 | 0.0734 kg. | 13624 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 8x2 | 8 | 2 | 0.3350 kg. | 2985.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 15x3.5 | 15 | 3.5 | 1.1250 kg. | 888.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 16x1 | 16 | 1 | 0.4000 kg. | 2500 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 16x4 | 16 | 4 | 1.3410 kg. | 745.7 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 19x1 | 19 | 1 | 0.4800 kg. | 2083.3 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 20x1 | 20 | 1 | 0.5310 kg. | 1883.2 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 20x5 | 20 | 5 | 2.0960 kg. | 477.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 22x5 | 22 | 5 | 2.3750 kg. | 421.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 25x2 | 25 | 2 | 1.2860 kg. | 777.6 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 25x6 | 25 | 6 | 3.1870 kg. | 313.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 37x2.5 | 37 | 2.5 | 2.3020 kg. | 434.4 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 47x3.5 | 47 | 3.5 | 4.0630 kg. | 246.1 m. | 8500 | GOST 494-2014 (p) |

| Pipe 72x3.5 | 72 | 3.5 | 6.3980 kg. | 156.3 m. | 8500 | GOST 494-2014 (p) |

| Pipe 104x2 | 104 | 2 | 5.7010 kg. | 175.4 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 108x4 | 108 | 4 | 11.6300 kg. | 86 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 114x7 | 114 | 7 | 20.9300 kg. | 47.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 125x4 | 125 | 4 | 13.5300 kg. | 73.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 129x2 | 129 | 2 | 7.0900 kg. | 141 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 300x8 | 300 | 8 | 65.2800 kg. | 15.3 m. | 8900 | GOST 617-2006 (x/d) |

Methods of obtaining

The technology for producing brass involves the processes of the copper and zinc industries, as well as the processing of recyclable materials. The raw materials for the production of alloys are blanks of copper, zinc and other metals for the production of multicomponent alloys. We also use our own production waste and secondary raw materials. All blanks are manufactured in accordance with GOST.

For smelting brass, various types of smelting furnaces are used, which are used for smelting copper alloys. The most effective are electric induction low-frequency furnaces with a magnetic core. Melting is carried out under exhaust ventilation, since some elements of the alloy evaporate intensely and can harm human health. It is undesirable to overheat the alloy, due to the likelihood of some components igniting in air. Pure and recycled metals are used as charges for smelting brass.

The raw materials are first prepared and the ovens are cleaned. Copper heated to red heat is placed in a furnace, and then lumps of zinc are added. When melting copper-zinc alloys, the significant oxidation of zinc is taken into account. To reduce oxidation, a number of measures are carried out. To make multi-component alloys, copper is added first, followed by the remaining components carefully.

The homogeneous mass is poured into molds to produce foundry brass. The result is flat and round ingots. After casting, wrought alloys undergo a deformation procedure. The resulting products differ in the degree of hardening and aging, as well as the hardness of the material. Preliminary heat treatment of workpieces significantly increases the strength and corrosion resistance of brass.

Corrosion resistance of material LS59-1

After processing brass blanks LS59-1

, the material does not experience strong stress, lead forms a separate phase, for this reason, it is more resistant to seasonal cracking, which manifests itself with increasing humidity and ambient temperature, in which it is superior to L68 and L63.

In general, our multi-component alloy is resistant to corrosion, under the same conditions as most brasses. It should not be used in contact with Fe, Al, Zn. He also shows himself poorly:

- in air saturated with moist vapors, at high pressure,

- in contact with fatty acids,

- in hydrogen sulfide,

- mine waters,

- mineral acids,

- as well as in oxidized solutions,

- and with chlorides.

Resistance to corrosion is manifested by:

- in air and maritime climates,

- in dry vapors,

- fresh waters,

- freons, alcohols, antifreezes,

- salty sea water in a sedentary state.

And the presence of excess oxygen, ammonia or carbon dioxide in vapor or water negatively affects the corrosion resistance of this material.

Chemical composition of L63 alloy used for the production of brass pipes

A popular material for brass pipes is L63 alloy, which in its chemical composition must meet the requirements of GOST 15527-2004. L63 brass is a two-component alloy containing from 62 to 65 percent copper and 43.22 to 37.5 percent zinc. A feature of the copper-zinc alloy of this category is that a significant part of the copper is replaced by zinc, which helps reduce the cost of products with high performance characteristics. Many consumers of brass alloy L63 also highlight the quality of its aesthetic appearance, which allows it to be used not only for the manufacture of products used in industry (brass pipes, wire, rods, etc.), but also for decorative products.

| Fe | P | Cu | Pb | Zn | Sb | Bi | Impurities |

| up to 0.2 | up to 0.01 | 62 — 65 | up to 0.07 | 34.22 — 37.5 | up to 0.005 | up to 0.002 | up to 0.5 |

Density of non-ferrous metals

Table of density ρ of materials g/cm3 (kg/dm3)

* According to the reference book P.M. Polivanov, E.P. Polivanova. Tables for calculating the mass of parts and materials: Handbook. 13th edition, 2006 (revised in accordance with GOST standards).

| Group name | Name of material, brand | ρ |

| PURE METALS | ||

| Pure metals | Aluminum | 2,7 |

| Beryllium | 1,84 | |

| Cadmium | 8,64 | |

| Silicon | 2,55 | |

| Magnesium | 1,74 | |

| Copper | 8,94 | |

| Molybdenum | 10,3 | |

| Manganese | 7,2-7,4 | |

| Nickel | 8,9 | |

| Tin | 7,3 | |

| Lead | 11,37 | |

| Titanium | 4,5 | |

| Chromium | 7,14 | |

| Zinc | 7,13 | |

| Zirconium | 6,53 | |

| ALLOYS FROM NON-FERROUS METALS | ||

| Aluminum casting alloys | AL1 | 2,75 |

| AL2 | 2,65 | |

| AL3 | 2,70 | |

| AL4 | 2,65 | |

| AL5 | 2,68 | |

| AL7 | 2,80 | |

| AL8 | 2,55 | |

| AL9 (AK7ch) | 2,66 | |

| AL11 (AK7TS9) | 2,94 | |

| AL13 (AMg5K) | 2,60 | |

| AL19 (AM5) | 2,78 | |

| AL21 | 2,83 | |

| AL22 (AMg11) | 2,50 | |

| AL24 (AC4Mg) | 2,74 | |

| AL25 | 2,72 | |

| Tin and lead babbits | B88 | 7,35 |

| B83 | 7,38 | |

| B83S | 7,40 | |

| BN | 9,50 | |

| B16 | 9,29 | |

| BS6 | 10,05 | |

| Tin-free bronzes, foundry | BrAmts9-2L | 7,6 |

| BrAZH9-4L | 7,6 | |

| BrAMZH10-4-4L | 7,6 | |

| BrS30 | 9,4 | |

| Tin-free bronzes, pressure-processed | BrA5 | 8,2 |

| BrA7 | 7,8 | |

| BrAmts9-2 | 7,6 | |

| BrAZH9-4 | 7,6 | |

| BrAZhMts10-3-1.5 | 7,5 | |

| BrAZHN10-4-4 | 7,5 | |

| BrB2 | 8,2 | |

| BrBNT1.7 | 8,2 | |

| BrBNT1.9 | 8,2 | |

| BrKMts3-1 | 8,4 | |

| BrKN1-3 | 8,6 | |

| BrMts5 | 8,6 | |

| Bronze tin deformable | BrOF8-0.3 | 8,6 |

| BrOF7-0.2 | 8,6 | |

| BrOF6.5-0.4 | 8,7 | |

| BrOF6.5-0.15 | 8,8 | |

| BrOF4-0.25 | 8,9 | |

| BrOTs4-3 | 8,8 | |

| BrOTsS4-4-2.5 | 8,9 | |

| BrOTsS4-4-4 | 9,1 | |

| Bronze tin castings | BrO3TS7S5N1 | 8,84 |

| BrO3Ts12S5 | 8,69 | |

| BrO5TS5S5 | 8,84 | |

| BrO4Ts4S17 | 9,0 | |

| BrO4TS7S5 | 8,70 | |

| Beryllium bronzes | BrB2 | 8,2 |

| BrBNT1.9 | 8,2 | |

| BrBNT1.7 | 8,2 | |

| Copper-zinc alloys (brass) foundry | LTs16K4 | 8,3 |

| LTs14K3S3 | 8,6 | |

| LTs23A6Zh3Mts2 | 8,5 | |

| LC30A3 | 8,5 | |

| LTs38Mts2S2 | 8,5 | |

| LTs40S | 8,5 | |

| LS40d | 8,5 | |

| LTs37Mts2S2K | 8,5 | |

| LTs40Mts3ZH | 8,5 | |

| Copper-zinc alloys (brass), pressure-processed | L96 | 8,85 |

| L90 | 8,78 | |

| L85 | 8,75 | |

| L80 | 8,66 | |

| L70 | 8,61 | |

| L68 | 8,60 | |

| L63 | 8,44 | |

| L60 | 8,40 | |

| LA77-2 | 8,60 | |

| LAZ60-1-1 | 8,20 | |

| LAN59-3-2 | 8,40 | |

| LZhMts59-1-1 | 8,50 | |

| LN65-5 | 8,60 | |

| LMts58-2 | 8,40 | |

| LMtsA57-3-1 | 8,10 | |

| Pressed and drawn brass rods | L60, L63 | 8,40 |

| LS59-1 | 8,45 | |

| LZhS58-1-1 | 8,45 | |

| LS63-3, LMts58-2 | 8,50 | |

| LZhMts59-1-1 | 8,50 | |

| LAZ60-1-1 | 8,20 | |

| Magnesium alloys foundry | Ml3 | 1,78 |

| ML4 | 1,83 | |

| Ml5 | 1,81 | |

| Ml6 | 1,76 | |

| Ml10 | 1,78 | |

| Ml11 | 1,80 | |

| Ml12 | 1,81 | |

| Magnesium alloys wrought | MA1 | 1,76 |

| MA2 | 1,78 | |

| MA2-1 | 1,79 | |

| MA5 | 1,82 | |

| MA8 | 1,78 | |

| MA14 | 1,80 | |

| Pressure-processed copper-nickel alloys | Kopel MNMts43-0.5 | 8,9 |

| Constantan MNMts40-1.5 | 8,9 | |

| Cupronickel MnZhMts30-1-1 | 8,9 | |

| Alloy MNZh5-1 | 8,7 | |

| Cupronickel MH19 | 8,9 | |

| Alloy TB MN16 | 9,02 | |

| Nickel silver MNTs15-20 | 8,7 | |

| Kunial A MNA13-3 | 8,5 | |

| Kunial B MNA6-1.5 | 8,7 | |

| Manganin MNMts3-12 | 8,4 | |

| Nickel alloys | NK 0.2 | 8,9 |

| NMTs2.5 | 8,9 | |

| NMTs5 | 8,8 | |

| Alumel NMtsAK2-2-1 | 8,5 | |

| Chromel T HX9.5 | 8,7 | |

| Monel NMZHMts28-2.5-1.5 | 8,8 | |

| Anti-friction zinc alloys | TsAM 9-1.5L | 6,2 |

| TsAM 9-1.5 | 6,2 | |

| TsAM 10-5L | 6,3 | |

| TsAM 10-5 | 6,3 | |

Corrosion resistance

Due to the presence of lead in the chemical composition of brass of the brand in question, a separate phase is formed in its internal structure, which has a positive effect not only on its workability, but also on its resistance to corrosion. Compared to other brass alloys, LS59-1 is more resistant to corrosion. are not subject to cracking and oxidation when used in conditions of high humidity and temperature changes.

However, there is no need to talk about the exceptionally high corrosion resistance of LS59-1: in this parameter, this alloy is similar to brasses of other brands. In particular, it is not recommended to use it in cases where it will come into contact with products made of iron, aluminum and zinc. In addition, the corrosion resistance of LS59-1 will be poor when:

- simultaneous exposure to high humidity and high pressure;

- contact with fatty acids;

- operation in hydrogen sulfide environment;

- contact with ore waters and mineral acids;

- constant interaction with oxidized solutions and chlorides.

LS59-1 demonstrates its corrosion resistance well under the following operating conditions:

- atmospheric air, including that saturated with sea salt vapor;

- dry steam;

- liquid medium characterized by a very low content of salts and acids;

- freon, alcohol solutions and antifreeze;

- salty sea water in a sedentary state.

It should be borne in mind that the interaction of LS59-1 brass with a gaseous or liquid medium characterized by a high content of ammonia, oxygen and carbon dioxide has a very negative effect on the corrosion resistance of the alloy.

Regulations

You can familiarize yourself with the GOST requirements for rolled brass sheets by downloading the document in pdf format from the link below.

GOST 2208-2007 Brass foil, tapes, strips, sheets and plates. Specifications Download

The current regulatory document, the provisions of which stipulate the requirements for rolled brass sheets, is GOST 2208-2007. GOST 2208-2007 also describes the range of such products. According to the requirements of this regulatory document, rolled brass sheets can be:

- by degree of accuracy - normal, high and increased accuracy;

- by product sizes - measured, unmeasured and multiple measured lengths;

- according to the degree of hardness - soft, semi-hard, hard and especially hard.

Types of rolled brass

Depending on the brand of brass, sheets can be produced using cold- or hot-rolled technology. For the production of sheet metal using hot-rolled technology in accordance with the provisions of GOST 2208-2007, brass grades such as L63, LMts58-2, LS59-1 and LO62-1 are used. To implement cold-rolled technology, brass alloys L68, L85 and L90 are used. At the same time, the regulatory document (2208-2007) allows that L63 brass can also be processed by the cold-rolled method.

Depending on the production technology, the sizes of rolled sheets differ, which is also stipulated in GOST 2208-2007. Thus, GOST specifies the following values of the geometric parameters of a brass sheet:

- thickness: hot rolled – 5–25 mm; cold rolled – 0.4–12 mm;

- width: hot rolled – 500–2500 mm (deviation no more than 20 mm); cold rolled – 300–1000 mm;

- length: hot rolled – 1000–4000 mm (deviation no more than 30 mm); cold rolled – 1410–2000 mm.

The standard of 2007 also stipulates the theoretical weight of one square meter of rolled brass sheets, which, depending on the grade of the alloy, can be in the range of 3.4–217.5 kg. This weight is calculated based on the density of the brass from which the sheet is made.

Theoretical mass per square meter of brass strips, strips, sheets and foil used

The provisions of the regulatory document stipulate not only the geometric parameters of brass sheets and their theoretical weight, but also the hardness of the product, which can vary depending on the version in which it is presented (soft, semi-hard, hard and especially hard).

Brinell hardness of brass alloys

Properties

Copper is a non-ferrous metal of a reddish color with a pink tint , endowed with high density. There are more than 170 types of minerals in nature that contain Cuprum. Only 17 of them undergo industrial mining of this element. The bulk of this chemical element is contained in ore metals:

- chalcocine - up to 80%;

- bronitite - up to 65%;

- Kovelin - up to 64%.

From these minerals copper is enriched and smelted. High thermal conductivity and electrical conductivity are the distinctive properties of non-ferrous metal. It begins to melt at a temperature of 1063°C and boils at 2600°C. The brand of Cuprum will depend on the method of production. Metal happens:

- cold drawn;

- rental;

- cast.

Each type has its own special parametric calculations that characterize the degree of shear resistance, deformation under the influence of loads and compression, as well as the tensile elasticity of the material.

Non-ferrous metal actively oxidizes during heating. At a temperature of 385°C, copper oxide is formed. Its content reduces the thermal conductivity and electrical conductivity of other metals. When interacting with moisture, the metal forms cuprite, and with an acidic environment - vitriol.

Copper Specific Gravity

Due to its properties, this chemical element is actively used in the production of electrical and electronic systems and many other products for other purposes. The most important property is its density of 1 kg per m3 , since this indicator is used to determine the weight of the product being manufactured. Density shows the ratio of mass to total volume.

The most common system for measuring density units is 1 kilogram per m3. This figure for copper is 8.93 kg/m3. In liquid form, the density will be 8.0 g/cm3. The overall density may vary depending on the type of metal that has various impurities. For this purpose, the specific gravity of the substance is used. It is a very important characteristic when it comes to the production of materials that contain copper. Specific gravity characterizes the ratio of the mass of copper in the total volume of the alloy.

The specific gravity of copper will be 8.94 g/cm3 . The specific density and weight parameters of copper are the same, but such a coincidence is not typical for other metals. Specific gravity is very important not only in the production of products containing it, but also in the processing of scrap. There are many techniques that can be used to rationally select materials for forming products. In international SI systems, the specific gravity parameter is expressed in newtons per 1 unit of volume.

It is very important to carry out all calculations at the design stage of devices and mechanisms. Specific gravity and weight are different values, but they are necessarily used to determine the mass of blanks for various parts that contain Cuprum.

If we compare the density of copper and aluminum , we see a big difference. For aluminum, this figure is 2698.72 kg/m3 at room temperature. However, as the temperature increases, the parameters become different. When aluminum transforms into a liquid state when heated, its density will be in the range of 2.55−2.34 g/cm3. The indicator always depends on the content of alloying elements in aluminum alloys.

GOST for brass sheet metal

meet many requirements set out in GOST 931–90. Brass products are distinguished according to a number of indicators. They can be of high, increased and normal production accuracy, in length – measured, unmeasured and multiples of measured ones, as well as soft, hard, extra-hard and semi-hard in their condition.

Brass sheet L63 (LMts58-2, LS59-1 and LO62-1) is most often hot-rolled. Cold rolled products are made from alloys L85, L90, L68. At the same time, GOST allows the production of pre-furnace brass sheet L63 using “cold” technology. Note! Particularly hard products may be produced exclusively from L68 and L63 alloys.

Hot-rolled sheet products in accordance with GOST 931 can have a thickness from 5 to 25 mm, width - from 500 to 2500 mm (possible deviation in width - no more than -20 mm), length - from 1000 to 4000 mm (deviation - up to -30 mm) . Cold rolled sheet is characterized by a thickness of 0.4–12 mm, width – 300–1000 mm, length – 1410–2000 mm.

The theoretical weight per square meter of rolled products made from alloys of the L80, L85 and L90 grades varies between 3.48–217.5 kg. Brass sheet L63, L062-1, LMts58-2, L68, LS59-1 has a weight from 3.4 to 212.5 kg. The theoretical weight is calculated taking into account that the density of brass is 8.7 (L80, L85, L90) and 8.5 (other brands) grams/cubic centimeter.

The Brinell hardness index for sheet products manufactured using the cold-rolled method should be according to GOST 931 as follows:

- LO62-1 – 145 units;

- LS59-1 – 200 (hard material), 100 (soft);

- L68 – from 70 to 155 depending on the specific condition;

- L85 – from 65 to 110;

- LMts58-2 – from 85 to 120;

- L80 – from 65 to 120;

- L90 – from 60 to 110.

Brass sheet L63 (remember that it is the one most often used in modern industry) has a hardness of 70 (soft), 135 (hard), 105 (semi-hard) and 160 (extremely hard). Also, products made from L63 alloy can be for special purposes (no more than two millimeters thick). They are called spring-hard. Their hardness is as much as 180 units.

But you can find out the exact weight of such products much easier on our website.

We bring to your attention a universal interactive mass calculator for independently calculating the mass of products of various shapes from cylindrical or sheet materials. Its peculiarity is that it allows you to find out the weight of a part or product not only made of rolled metal and alloys, but also any other materials: wood and MDF, plastics and polymers, paper, cardboard, rubber, concrete, brick. This can be done simply by entering the overall dimensions of the part, minus the sizes of holes and slots, as well as the density coefficient of the material from which the part is made. The exact data can be found in the adjacent table.

The mass of a cylindrical part is calculated as follows:

• In the appropriate fields of the mass calculator, enter the dimensional indicators: diameter, length and reference density of the material - the calculator will calculate the total mass of the product. • The second step - if the product has protrusions or steps - you need to add their dimensions. • And the third step is to subtract the dimensions of the holes, recesses, slits. • The result is the exact calculated mass of the cylindrical part.

The mass of a sheet part is calculated as follows:

• In the appropriate fields of the mass calculator, enter the dimensional indicators: width, length, thickness and reference density of the material - the calculator will calculate the total mass of the product. • The second step - if the product has protrusions - you need to add their dimensions. • And the third step is to subtract the dimensions of the rectangular or round holes. • The result is the exact calculated mass of the sheet metal part.

Our product weight calculator will be useful both for the designer and for customers, because it allows you to very quickly and with almost 100% accuracy obtain the necessary data regarding the weight of the product without complex mathematical calculations and weighing procedures.

Please note that the default weight in the calculator is steel grade 40 GOST 1050-88.

Source

Quality requirements

The above GOST also lists the requirements for the quality characteristics of rolled brass sheets. This should include:

- the presence of tarnish, darkening, defects of various types, serious contamination and other defects on the surface of the sheet;

- the amount of permissible deflection of sheets;

- quality of cutting edges of sheets;

- the value of the relative elongation of the product;

- the value of temporary tensile strength.

Checking the quality of cutting wide brass blades into strips

The regulatory document stipulates that rolled brass sheets, the thickness of which does not exceed one centimeter, must be subjected to bending tests, which are carried out along the rolling line. In this case, products that have been subjected to such a test are not subsequently tested for tensile strength.

Rules for labeling, packaging and transportation

Each batch of rolled brass sheets, regardless of its total weight and the number of products in it, must be delivered to the warehouse or consumer with a special label indicating the following information:

- batch number, number of products in it and their total weight;

- trademark and name of the manufacturer;

- mark on product inspection by the quality department:

- brand of brass from which the rolled product is made.

Marking scheme for brass sheets, strips, foil and tapes

Before they are released to the warehouse or to the consumer, brass sheets are placed in bundles of a certain weight. In this case, rolled products with a thickness of up to 1.5 mm are placed in special boxes, which should ensure their protection from mechanical damage. Packs of brass sheets with a thickness of more than 1.5 mm can be stored and transported without additional protective packaging. GOST stipulates both the dimensions of bundles formed from rolled brass and their weight, which cannot exceed 1250 kg.

Weight of round brass pipe

| Cost per ton with price per meter of pipe, ₽: | But |

| The price of a meter of pipe at the cost of a ton, ₽: | But |

| Total weight of 6 m of pipe, kg: | But |

| Total length 1000 kg. pipes, m.: | But |

| Name | Pipe Calculator (Round, Brass) |

| Requirements | Javascript |

| OS | Windows, Android, OSX, Linux |

| Category | Business, Education |

| Price |

Install the widget on the site