The grinder is a simple but extremely popular hand-held power tool that has managed to gain noticeable popularity in most types of technical and repair work. Its capabilities cannot be called too broad, as is the range of functional abilities, but the tasks themselves that the grinder solves are inaccessible to other tools.

Users appreciate angle grinders and are constantly trying to refine and improve the set of functions and capabilities. Let's consider one of these options that can make using the tool clean and comfortable.

Purpose of the dust collector for angle grinders

Homemade vacuum cleaner: example

Using an angle grinder (grinder) to carry out repair work on concrete at home creates a large amount of dust.

If you need to level a wall, sand it for painting or applying other types of finishing coating, all irregularities or bumps become tiny particles of concrete suspended in the air.

Despite the personal protection used, they penetrate the mouth, eyes, and respiratory organs.

In addition, dust settles on all pieces of furniture, walls, ceilings and other surfaces, requiring labor-intensive and time-consuming cleaning. Dust from brick walls eats into surfaces and irreversibly spoils their appearance.

There are several designs of casings with a pipe for connecting a vacuum cleaner, which significantly improve the process. They are purchased in a store and installed on an angle grinder, connected to a vacuum cleaner. Working with such devices almost completely eliminates the spread of dust and can significantly reduce the pollution of the room and indoor air. Outwardly, they resemble conventional protection, but with a closed housing and an outlet for connecting a vacuum cleaner hose.

Causes of dust formation

The grinder is a universal tool. With its help, using various attachments, you can cut metal, stone, porcelain stoneware and tiles, process wood and other materials. But one of the disadvantages is the formation of a huge amount of dust. Work that causes the formation of large amounts of small debris:

- Grooving grooves on walls. The work is carried out using plaster, and cement and sand have a fine fraction. The height of the passage of the channels is at the level of one and a half or two meters. From such a height, dust settles evenly over the entire area of the room.

- Sanding of wooden structures. Before painting or varnishing, wooden products must be removed from the cellulose fibers that form during the sawing process. Cellulose is thin, light and hangs in the air for a long time.

- Removing old paintwork. Before applying fresh paint, the old paint must be removed. A flap sanding wheel is used. The paint it removes is fine.

- Cutting floor and decorative ceramic tiles. Sintered ceramic has a fine grain structure and it penetrates everywhere.

- Sanding parquet or wooden floors. Floor leveling occurs by removing the top layer. The irregularities have different heights and therefore, in addition to shavings, a lot of wood dust is formed.

Upon completion of the repair, dust must be removed from all possible cracks and cavities. To protect adjacent rooms from construction dust, protective screens made of polyethylene film or light fabric are installed in doorways. Special devices are also used that you can make yourself.

Types of casings

Housing for a grinding attachment

There are quite a few types of accessories for an angle grinder that perform dust collection and removal tasks.

Manufacturers are aware of the problem and solve it by producing special devices for their equipment.

Based on the type of functionality, two options are available:

- for cutting discs;

- for grinding discs.

The first ones outwardly resemble conventional protection with a closed housing and a pipe for a vacuum cleaner. The second option is a closed lid with an outlet for connecting a vacuum cleaner hose. Both types are installed in the usual way on an angle grinder and do not require special tools for installation. Most users are familiar with the common models:

- Stomper SG-230;

- Stomper SG-230 R;

- BOSCH 1605510180;

- BOSCH 2605510107;

- BOSCH 2605510224;

- BOSCH 2602025285;

- Metabo GED125;

- Metabo GED125 Plus.

Important! It is impossible to provide an exhaustive list of protective covers for angle grinders, since the model range is constantly being supplemented, new developments are appearing, and the most promising models are being improved.

Features of cutting with a grinder

After choosing the equipment and the circle for it, before cutting concrete with a grinder, you need to familiarize yourself with the recommendations for carrying out the work:

The tool must be held with both hands

In this case, if a reverse strike occurs, it can be held, which will minimize the displacement of the cutting line; Work should be carried out only on a flat surface so that the person’s balance is maintained; The power cord should be located on the opposite side of the drive to prevent accidental damage to it. A cut cord can cause a shock wave from the unit and a short circuit in the electrical network; The tool must be held firmly in your hands until it stops completely; When changing the place of sawing, the grinder must be turned off so as not to accidentally touch surrounding objects; In the event of a power outage, be sure to disconnect the equipment from the network

This will prevent it from turning on when electricity is supplied without operator control.

Cutting concrete along a line

After the grinder for concrete has been prepared, work can begin.

- The cutting line is outlined. At the same time, it is advisable to fasten wooden blocks along the line, which will make the cut line more even;

- The grinder is turned on and a cut is made with a depth of approximately 5 - 10 mm;

- The bars are removed;

- A cut is made to the required depth. If the cut is made dry, the procedure should be stopped periodically to allow the instrument to cool.

The video shows in detail how to cut concrete with a grinder correctly. The process is best performed with the tool cooled.

- An ordinary spray bottle sprays water directly onto the furrow to reduce the amount of dust;

- Water is sprayed directly onto the disk, in the absence of a nearby power source. This will reduce the heating of diamond blades and extend their service life;

- If it is not possible to spray liquid onto the disc, cooling can be done with air. Periodically, the circle should be removed from the cut and given the opportunity to work in the air.

If you have questions about cutting concrete, or if you want to know how to polish concrete with a grinder and other details on using similar equipment, check out the video in this article.

Self-production

It is not always possible to select a ready-made protective casing for an angle grinder with a dust extraction, since not all products have the same connection dimensions. In addition, they are not always available. The third limiting factor is the price - the Metabo GED125 model will cost 3,800 rubles, and the Bosch GWS 22-230 costs 13,800 rubles, which is 2 times more expensive than the grinder itself. Such prices force angle grinder owners to think about making dust protection themselves, especially since this undertaking is not particularly difficult.

Important! Homemade protection is used only for small angle grinders with discs with a diameter of 115, 125 and 150 mm.

People with a technical mind invent similar devices and remake containers that happen to be at hand for this purpose. As a result, fully functional, albeit unsightly-looking devices appear. They perform their tasks no worse than industrial designs, and cost practically nothing. Let's look at some options:

Homemade casing from a saucepan

From an old pan, you can make a casing with your own hands, both for concrete grinding and for a cutting wheel or groove.

Canister

If you don’t have welding skills or your wife flatly refuses to give permission to damage the pan, then there is a third option, how to make a protective casing with a dust extractor, which also miraculously connects to the vacuum cleaner tube. What will you need for this?

Find a canister in your garage, closet, or at your neighbor's. Using a construction knife or an ordinary knife, you will need to cut out constructive holes from it, in accordance with the shaft of the grinder and the location of the disk on it. It would be good to remember about safety precautions. Why? Trivial - to preserve the integrity of the hands

Moreover, it is important to choose the right knife. It should have a high-quality handle and fit well in your hand without slipping out

Afterwards, you need to attach the vacuum cleaner tube to the neck of the canister so that it becomes like a nozzle. How? Cut the neck lengthwise and put on a clamp so that you can then tighten the vacuum cleaner tube with it.

It is important to remember that in order to achieve good suction of the vacuum cleaner, it is necessary to ensure that all parts of the casing fit snugly against each other

Detailed instructions on how to make an attachment for an angle grinder with your own hands

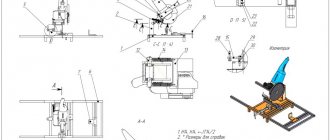

Manufacturing algorithm:

- Mark the contours of the internal partition of the nozzle on a sheet of metal, using the standard casing from the machine as a template.

- Make blanks for the mounting clamp. Some craftsmen retain the factory screen with standard fasteners, to which they weld a plate to reduce the overhang of the cutting tool.

- Cut the workpiece and cut windows for installation on the tool body.

- By analogy, prepare the blank outer wall of the nozzle.

- Cut a rectangular plate of the outer part of the protective screen, which has an increased length. The excess is needed to form the abutment surface.

- Connect the parts at points using resistance welding, and then completely weld the seams. It is permissible to install a stud on the outer part of the cover used for mounting the auxiliary handle.

- Bend the protruding corners of the outer part of the nozzle at a right angle.

- Clean the joints with an abrasive tool.

- Cut a hole on the outer part of the nozzle into which to install a dust removal tube for welding.

- Degrease the surfaces and coat with impact-resistant paint.

- Mount the attachment on a grinding machine with installed diamond discs, using the standard mount on the internal partition for fixation.

- Connect the vacuum cleaner hose to the tube (for example, through a layer of masking tape to seal the joint), and then make a test cut.

A casing for an angle grinder for a vacuum cleaner is a necessary device when renovating an apartment

In addition to a lot of advantages, the grinder has one significant drawback. When working with stone or wood, it produces a huge amount of fine dust, which then has to be removed from all the cracks in the house. Cutting metal, even in an apartment, is not particularly difficult. Factory protective dust cover for an angle grinder. The dustiest types of work performed indoors are:

- Wall chipping;

Regardless of the material, fine dust is produced in huge quantities. The process is complicated by the fact that work is often carried out at a height of 1.5-2 meters. At the same time, dust flying from above settles evenly throughout the room.

Ceramic tile cutting;

The most common dusty job. Moreover, the ceramic dust turns out to be especially fine and penetrating everywhere.

Sanding wooden floors.

The procedure is voluminous and is carried out over a large area. Therefore, there is a lot of dust and sawdust at the exit.

To combat dust formation, manufacturers offer ready-made solutions to the problem. For example, they equip the appropriate equipment with a dust collector.

But this option is more suitable for construction crews. What should a home craftsman do, who performs most of his work with one tool, for example, an angle grinder (angle grinder)? You can purchase a casing with a dust extractor at the store, or immediately buy an angle grinder equipped with such a device. But the high cost of such devices makes the purchase impractical for one-time use; it is cheaper to hire a team of specialized workers. However, there is a way out.

There are plenty of creative options. There are even specimens made of durable steel using a welding machine.

In fact, making an attachment for an angle grinder for a vacuum cleaner is not that difficult. Let's consider two typical options, so to speak, from scrap materials:

casing for a vacuum cleaner from an existing angle grinder casing or pan

How to choose?

Protective attachments play a huge role when working with angle grinders, and special attention should be paid to choosing a casing for the vacuum cleaner.

Since not every device can be suitable for an angle grinder and protect the room well from dust, it is important to consider some basic points before purchasing

- To work with concrete surfaces, stone and brick, you need to choose casings with increased protection. Their body must be made of durable material. If desired, protective equipment can be made and connected to the vacuum cleaner yourself, but this will require additional time and experience.

- The nozzle must correspond to the dimensions of the nozzle and the modification of the angle grinder. This way the tool can process the material without creating dust.

- The choice of casing manufacturer is also important. Today, the market is represented by products of domestic and foreign brands, but not all of them have positive reviews.

Preparation for repairs and necessary tools

To rewind the stator you will need special tools:

- hammers: wooden, metal;

- round nose pliers and pliers;

- steel brush;

- calipers;

- megohmmeter;

- electric drill;

- ruler;

- varnish

http:

The first and most important stage is cleaning the stator from contamination. The old winding is removed from the slots. All this can be done with a steel brush. Cleaning is carried out manually using steel brushes and electric drills. It is also necessary to remove the old insulation. To make the task easier, you can use transformer oil. You need to warm it up a little and lower the launcher into it. This measure will soften the damaged insulation and make it easier to remove. A weak caustic solution (temperature – 80ºС) mixed with compressed air is also used for cleaning.

After treatment, the stator must be rinsed well with water and dried. The condition of the stator and steel packages must be thoroughly checked. Then the pins tightening the core are tightened, and the grooves are cleaned of burrs. Insulation resistance is measured using a megger. Parts of the core, pressure washers and grooves are varnished. Washers and grooves must be insulated.

An accompanying note that displays basic data can make further work easier:

- phase connection diagram and their number;

- coil and phase resistance;

- number of grooves and their sizes;

- winding cross-section, coil pitch along the slots;

- method of insulating the groove, the number of interlayer spacers and their sizes.

Next, the remaining winding is removed and a new one is wound. There is a special template for making the winding. It is mounted on an axis holding 2 large metal plates.

http:

The simplest method

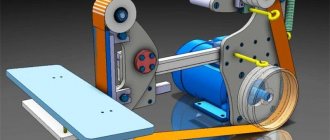

The first version of a homemade casing does not require large investments, since it uses the one that is already included in the kit. To turn it into a nozzle with a dust extraction you will need:

- Cut an exact copy of the factory casing from a metal plate. You can easily find his image on the Internet by entering the marking of your ear.

- The next step is to select a pipe that will act as a dust drain. It is worth noting that the size of the pipe must be selected so that the pipe fits tightly into the vacuum cleaner tube, or, conversely, fits tightly onto it.

- At the end, you will need to weld the prepared parts, clean them and paint them. That's it, your nozzle is ready.

The advantage of this option is a neat and reliable casing that will look like a factory one, but at the same time your wallet will be satisfied with the cost of such an attachment. The disadvantages include the fact that the depth of the cutter cannot be adjusted with such a dust extractor. Also, due to the fairly large distance from the casing to the outer cutting edge of the disk, construction dust and small particles may not be immediately sucked up by the vacuum cleaner through the dust extractor.

The second way to connect the vacuum cleaner

This method involves connecting a construction vacuum cleaner to an angle grinder using improvised means.

For this you will need:

• polypropylene sewer outlet with a diameter of 50 mm, at 45 degrees;

• reinforced tape (for greater reliability);

• good quality masking tape.

The described components for this method can be replaced by any suitable analogues.

Step-by-step instruction

Just five simple steps:

1) Place the grinder on the floor, table, etc. so that it lies with the disc facing up parallel to the plane of the base.

The angle grinder should be positioned quite stable.

2) Take the outlet with pliers or some kind of clamp.

3) Turn on the angle grinder and literally cut the pipe along the body, under the casing of the angle grinder, about 3 cm.

4) We take reinforced tape, and tightly, tightly, wrap the bend to the body of the angle grinder, with a slight insertion (a couple of centimeters) into the saw blade.

The pipe must be firmly fixed so that it remains absolutely motionless.

5) Take masking tape and cover the open side of the casing with it, connecting it to the outlet.

This design makes it easy to connect a construction vacuum cleaner and cut with a grinder without dust.

For such work, you can only use a construction vacuum cleaner.

When sawing, the disc should be inserted into the material being processed from the engine side, closer to the nozzle.

This way all the dust will go through the outlet into the vacuum cleaner.

Sawing of objects is carried out with the engine forward.

Safety precautions

Such a dust removal system does not involve any serious structural changes in the structure of the angle grinder.

We just attached the pipe to the body of the tool.

And they covered the second part of the casing with masking tape; this element can create a false impression of security.

Masking tape is designed to protect against dust only.

Therefore, it is necessary to observe all safety precautions when working with angle grinders.

An angle grinder is considered a multi-functional tool. In addition to many advantages, it has one significant drawback - during cutting and grinding of material, it produces a large amount of dust. To free themselves from lengthy cleaning of the room after working with an angle grinder, craftsmen use devices equipped with a vacuum cleaner. The main element of any such device is the protective casing. It can be easily selected for any angle grinder model. The main thing is to be able to correctly attach the part to the exhaust system.

How to choose?

Before purchasing a protective mask, you should pay attention to some features. So, it is necessary to pay attention to the degree and possibility of injury while working with an angle grinder

If you plan to use the tool in more hazardous areas where chemicals are present, in this case it is best to buy more reliable and durable masks made of polycarbonate or polystyrene.

Consumers often buy protective transparent masks of standard size 125 mm in stores.

Before purchasing such a model, make sure that it has a special steam outlet. It will allow you to work with the tool for a long time, and the glass will not fog up.

And also don't forget to check the dimming system. Remember that the automatic filter must operate within a split second during sudden electrical flashes.

Dust extraction from an old saucepan

If sheet steel is available, then it can be used as a basis in the manufacture of a dust extractor for an angle grinder. When carrying out such work, you will need a welding machine. If you don’t have a machine, you can make a nozzle from an old aluminum pan. The principle of making a device from an aluminum pan is as follows:

- The basis is taken from a part of the pan with the bottom. The bottom acts as one side of the nozzle, and the other side is made by bending the sides of the pan

- It is recommended to use rivets to connect sheet aluminum

- A hole of the appropriate diameter is drilled in the wall of the dust collector for fastening to the shaft of the power tool

- To secure the hose from an industrial vacuum cleaner, you will need to make a hole on the outside of the side wall to which to attach the neck of a plastic canister, bottle or plastic tube. It can be secured to the aluminum base using threaded connectors with washers

- The reliability of the connection between the hose and the nozzle is ensured by a metal clamp

The principle of making a homemade nozzle is simple, so you can practice making casings from different materials. If you make a nozzle of two parts - movable and stationary, you will end up with a wall chaser for making grooves in concrete.