TOP 6 drawings will help you make a cutting machine from an angle grinder with your own hands without errors and extra costs. Answers to frequently asked questions, recommendations.

TEST:

Is it possible to make a homemade cross-cutting machine from an angle grinder: a verification test with answers based on the materials presented

- What switches are installed for emergency stop of the machine?

a) manual;

b) hand and foot.

- Which angle grinders are suitable for creating a cutting machine?

a) pneumatic and electric;

b) battery-powered.

- Minimum power of the electric motor of an angle grinder for a cutting machine from an angle grinder:

a) 400 W;

b) 900 W.

- What machines can be made based on angle grinders?

a) trimming, cutting;

b) grinding, milling, sharpening.

- Where can you place the grinder in the cutting machine?

a) above the tabletop;

b) under the tabletop.

Answers:

- The correct option is b). Foot switches are more convenient because they operate quickly.

- Theoretically, there is enough power in all three options. In practice, a) - electric and pneumatic models are used. A battery is not needed for a stationary machine. For a pneumatic drive, you will have to purchase a compressor of appropriate capacity.

- 900 W or more. Correction is made if workpieces made of relatively soft materials are expected to be processed, or at high speed.

- Both options are correct. A powerful grinder is suitable for creating various machines at the household and semi-professional level.

- Two mounting options are allowed. Experts prefer the top one.

An electric grinder performs many different work operations. To reduce labor costs while increasing accuracy, it is used as the basis for the machine.

“Bulgarian” is a common name for an angle grinder (angle grinder). By changing the disk, this universal device can be converted for cutting and performing other work operations.

Bulgarian women

How to make a cutting machine step by step with drawings: 4 reasons in favor of implementing the project

In order not to doubt the correctness of the decision made, study the following facts:

- without reliable fastening, the workpieces vibrate, increasing the risk of damage to the disk;

- it is difficult to manipulate a heavy tool with high precision while maintaining the perpendicularity of the cut;

- difficulties increase when processing thick products, when creating a large batch of similar parts;

- Using both hands significantly increases the likelihood of injury.

A high-quality machine is necessary to solve the noted problems and improve productivity. It is created according to the following algorithm:

- clarify the purpose and scope of work;

- study drawings of factory analogues and homemade products, choose the appropriate option;

- compose a set of design documentation with a list of necessary purchases;

- carry out assembly according to the approved plan with performance testing.

Main advantages

Quite often, home craftsmen are faced with a situation where they need to cut workpieces evenly. Despite the fact that the grinder is an indispensable tool in the household, the principle of its operation is monotonous. It can be extremely difficult to hold the weight of this unit in one hand for a long time, trying to make cuts as evenly as possible. In this case, craftsmen often have the idea to make a durable and stable support for it.

In order for the result to exceed all expectations, you need to make high-quality fasteners, as well as prepare all the necessary materials at hand: small wooden blocks and plywood. It is these details that will help to install the stand permanently on a flat plane. Having made such a holder for an angle grinder with your own hands, a specialist will no longer need to hold the tool suspended, worrying about the abrasive wheel flying out. This situation is fraught with serious injury.

The main advantages of such a rack include the following:

- The master always has the opportunity to position the grinder at the desired angle.

- The workpiece can be fixed in the most suitable position. For these purposes, a vice is used, which helps to cut workpieces of the required size.

- By making a homemade angle grinder stand with your own hands, you can quickly and accurately cut light metals: ceramic tiles, aluminum profiles, metal corners.

- In a short period of time, the master will be able to produce the required number of blanks.

- If necessary, vertical movement of parts is implemented to perform certain tasks. The main tool in this case is an angle grinder (angle grinder).

- Labor productivity increases significantly.

- The operation of such racks is characterized by a high level of safety.

- Guaranteed high degree of stability for the rotating holder.

- There is no need to hold a heavy tool in your hands.

- The risks of the grinder possibly falling out or slipping out of your hands are completely minimized.

Despite all the advantages, novice craftsmen often wonder whether a homemade machine for attaching an angle grinder will allow them to cut metal smoothly. After all, the rotation speed and frequency of this tool are simply elusive to the human eye. Of course, it is much easier to purchase a ready-made machine from a specialized store, but factory-made devices (such as Metabo) also need to be improved. After all, they are all made of thin metal, which is why they are considered flimsy and short-lived.

TOP 6 drawings with explanations for making a homemade metal edger

It is not difficult to create a standard circular saw if you attach a grinder under a work table with a slot. It is necessary to consider a guide system for high precision movement of workpieces.

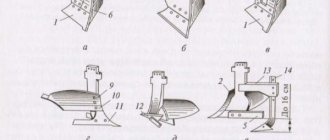

Picture No. 1. Schematic diagram

Look at picture No. 1 to see what a typical edger looks like. Here the angle grinder is mounted on a movable hinge, which somewhat complicates the design. This scheme has several advantages:

- simple and reliable fastening of the workpiece;

- the significant weight of the upper part will help to use less effort when cutting workpieces;

- if necessary, hand-held electric tools are dismantled to perform work operations as usual.

Picture No. 2. Stand for an angle grinder

This power frame is assembled from standard steel angles and pipes with a square cross-section. Welded joints are more durable. But it is also possible to create a prefabricated structure using screws and nuts.

Picture No. 3. Assembly drawing of a pendulum saw

This project can be used as an example for making a high-quality metal edger. Equipping with wheels makes it easier to move a heavy product.

For your information! In other racks it is necessary to install screw supports. With their help, unevenness in the floor covering is compensated.

Picture No. 4. Pendulum circular saw

Look at the picture for an example of a machine for processing wood. This technique is suitable for cutting large workpieces. It is necessary to choose a grinder with sufficient power so that it is enough to work with large-diameter discs. A load is secured on the reverse arm of the lever (instead of an electric motor, as in the drawing). The weight and mounting location are selected in accordance with personal requirements and the characteristics of a particular design.

Picture No. 5. Drawing of a circular saw

This machine can be converted to be mounted at the bottom of an angle grinder. If longitudinal sawing of wood is planned, such an engineering solution will be optimal.

Picture No. 6. Design of a factory miter saw for wood

Look at Picture No. 6. You can use it to make a set of drawings with your own hands. It is recommended to pay attention to the spring, which lifts the working unit to its original state. A rotary table with measuring devices will help create a machine with increased tolerance requirements.

Picture No. 7. Drawing of the frame

In the manufacture of this part of the machine, thick metal is used. This solution increases cost and weight, but extends service life, increases reliability, improves fastening of hinged elements and processing accuracy.

The simplest device for an angle grinder stand

Actually, this device cannot be called a stand, but the work with it can be done almost the same as that provided by the most technologically advanced stand. The principle of its operation is clear from the short video:

But if instead of a strip you use a corresponding corner with a sawn-off part of one of the shelves, as one of the authors of a similar design did, then there will be no need to drill a blind hole in the head of the angle grinder.

In this case, the tool will be fastened with two screws into the threaded holes for the handle existing on the head of the angle grinder. But the principle of operation of the sole will not change - only its rigidity will increase.

The method of using an angle grinder as a kind of circular saw using the same sole, shown in another video by the same author, will also not change:

We recommend other articles on the topic

Hydraulic jack - its design and principle of operation

Electric impact wrench - what are the advantages of the tool?

Malka - a tool for moving corners and arranging door slopes

Chainsaw Partner 350 S - characteristics, troubleshooting, operating instructions...

Converting an angle grinder into a machine step by step: 10 assembly stages, electrical diagram for drawings

To create a machine yourself, you need to choose a design that matches your existing skills and capabilities. The easiest way is to assemble a machine from blanks created according to drawings in a specialized metalworking workshop. Otherwise, you will have to master welding technologies and purchase the necessary equipment.

Below is a step-by-step self-assembly algorithm with useful comments:

- After approval of the project parameters, the necessary materials, workpieces, tools and replacement attachments are purchased. The shopping list is determined based on the prepared set of design documentation. Compliance with current standards is not required in this case. However, all important details must be included, as in the examples above.

- Blanks for the power frame are cut. The table is made from sheet steel with a thickness of at least 5 mm.

- A transverse shaft is welded to the pendulum arm. When creating this unit, the perpendicularity of the parts is carefully controlled.

- A grip in the shape of the letter “P” is suitable for attaching an angle grinder. A hole for bolts is made in its side parts. With these fasteners, the hand tool is rigidly attached to the machine bed. Choose a fairly strong part of the grinder body.

- Additional fixation is provided using a metal clamp. All of the above mounts are made rigid to improve accuracy.

- The swivel bearings are pressed in. Instead of standard factory-made units, steel pipes with thick walls of suitable internal diameter are used.

- The assembled units are fixed on the axis of two sides.

- The pendulum is attached to the platform by welding. To avoid damaging the bearings, it is recommended to limit the temperature rise. To cool, use a cloth soaked in water.

- Weld a block with a mount for an angle grinder. Reinstall the angle grinder, protective devices, and return spring.

- They check the quality of the assembly, the reliability of the fastenings, and the functionality of the pendulum. Connect the machine, check the functionality first at idle and then in operating mode. The groove in the table is cut with a disk of appropriate width.

Picture No. 8. Connecting a magnetic starter with shutdown buttons and a protective thermal relay.

Look at Picture No. 8. Here is an electrical diagram for the drawings that improves the protection of equipment from overheating. It is also useful for quick emergency shutdown. One or more buttons for breaking the corresponding circuit are installed in a convenient place in the machine body. Foot operated switches are also used.

What it is?

In the course of carrying out construction or repair tasks, there is a need to carry out the most even cutting of the raw materials used. A tool such as a grinder can cope with the task, but its implementation is complicated by the peculiarity of the tool’s operation, which stands out for its monotony - as a result, the operator’s hand may not be able to cope with holding a rather heavy device in the required position for a long time. In this case, the way out of this situation would be to install a special stationary support for the tool, which is a stand for an angle grinder.

Such a holder allows a craftsman, at home or in a production workshop, to quickly and without extra costs turn an angle grinder into a multifunctional cutting saw, and then use all the ensuing advantages in his work. In this case, the main positive feature is the high accuracy of the cut; in addition, it greatly facilitates the operation of the grinder and the overall safety of operations performed with metal, polymer, wood or other raw materials.

In terms of its design properties, a tool fastening machine is a very simple device, consisting of a base made of a durable metal alloy with a pendulum-type mechanism installed on it, on which there are special areas for reliable fixation of the device, handle and protective casing. As well as a rotary system for the correct positioning of the working material in relation to the grinder at a given angle.

Typically, the production and sale of stands for grinders are carried out by the same companies that offer angle grinders on the market. Some products are additionally equipped with some useful tools, for example, a set of stands or a bench vice. As a useful functionality in the frame for grinders, it is worth highlighting the presence of an angular or standard ruler; in addition, manufacturers of modern tool supports equip their models with a return spring mechanism.

In order to have the most complete understanding of the functionality of the angle grinder stands, you should consider situations where the installation of this auxiliary device is rational.

- The bed is necessary for cutting or grinding structural parts or assembled structures, the raw materials for the manufacture of which are difficult-to-cut materials. Also, the advisability of purchasing or making equipment yourself is determined by the need to work with large-area materials.

- If necessary, the stand will need to be used to make precise cuts down to a millimeter on the material using a grinder when using small-diameter discs.

- The frame will help the master at home or in the professional field when performing work related to the processing of several elements with the same parameters.

When selecting a particular tripod model for an angle grinder, the diameter of the working disk with which the machine can perform its tasks is first taken into account. The need to select a support model based on this parameter is due to the fact that the device can only function with a stand whose diameter will correspond to the same size of the cutting disc in the tool

Machine reinforcement and other operator protection

A reliable power frame is the basis of safety. Additionally, they cover moving parts and prevent unauthorized persons from accessing the work area. When processing parts, goggles, masks, mittens, and other personal protective equipment are used.

In addition to the reliable strengthening of the machine, a certain location of the grinder serves to protect the operator. For safety and to prevent damage to clothing, it is installed so that the sheaf of sparks during operation is directed in the opposite direction from the person.

All 5 options for homemade grinder machines for various purposes

The drive of tools in this category is highly powerful. A high-quality grinder is small in size, durable, and resistant to high workloads. Some models provide speed control. Modern angle grinders are equipped with overheating protection as standard. Such products are a good basis for the manufacture of homemade machines for various functional purposes.

Picture No. 9. This homemade cross-cutting machine is suitable for processing granite and marble slabs

Grinder lathe

Picture No. 10. Diagram of a wood lathe made from a grinder.

The standard design is used here. The only excellent component is the device for transmitting force to the spindle. A gearbox is needed to regulate the speed and torque within the appropriate range.

Homemade wood milling machine with your own hands, other types of equipment

Picture No. 11. To secure different tools, a do-it-yourself wood milling machine must be equipped with a universal head

For your information! This device can be attached to the electric motor shaft after dismantling the standard gearbox.

Picture No. 12. Quick solution to problems

Look at Picture No. 12 shows how you can assemble a full-fledged sawing/circular machine from available materials in 15-20 minutes. With its help, it is easier to ensure precise processing of wooden workpieces compared to using hand-held power tools.

Picture No. 13. From the picture it is not difficult to understand the principle of operation and design of the grinding/surface grinding machine

3 other machines: sharpening machine, for sharpening chains and cutting bricks

Picture No. 14. Sharpening machine

Here, potentially dangerous places are protected from damage by sparks using strips of foil. A temporary, but inexpensive and quick solution to a practical problem.

Picture No. 15. When equipped with a suitable disk, such equipment is used for cutting brick, ceramic tiles, natural/artificial stone Picture No. 16. Rigid attachment to a durable table top turns an ordinary grinder into a convenient machine for sharpening chains

VERY DANGEROUS! In any case, we must not forget about the intended purpose of the equipment. If you are making a homemade metal cutting machine, you should consider strengthening the structure. Processing of plastic and wooden workpieces is carried out with less stress.

The simplest stand with a stationary table

If the machine does not allow for complex cuts, the stand for the grinder can be made using a simplified version without a rotary table. That is, the tabletop is tightly welded to the frame.

Let's look at a step-by-step photo describing the manufacture of the stand:

The pivot assembly will require two bearings, a threaded shaft at both ends, and a flange that can be removed from a passenger car pump. All parts mounted on the shaft are clamped with nuts. To prevent the bearings from moving, bushings are installed between them.

The hub is made from a piece of pipe with a larger diameter than the bearing race. First, the workpiece is cut off, and then this sleeve is sawed lengthwise.

Plates are welded on both sides of the cut. Holes are drilled into them so that the inserted bearings with the shaft can be firmly secured with bolts. I cut a corner to fit the plate, and drill holes in both shelves. The part is needed to mount the hinge on the bed frame.

A U-shaped bracket for fixing a power tool is bent from a steel plate 5 mm thick. Holes are drilled on the side shelves. They must coincide with the holes on the gearbox housing of the angle grinder.

A lever is welded from a profile pipe with a cross-section of 20x20 mm. It consists of a main jumper to which two elements are welded at an angle, forming the lever rods. The second end of the rods will be fixed to the hinge. I weld a U-shaped bracket onto the edge of the lintel to fix the grinder.

The frame of the bed is welded from a corner with a cross section of 32 mm. Guides from a profile with a cross-section of 20x20 mm are welded along the length of the frame. They are needed to install an adjustable stop with which the workpiece to be cut will be fixed.

The tabletop is cut out of a steel plate 3 mm thick. You should end up with two fragments. The plates can be welded or bolted to the frame.

A hinge mechanism is attached to the frame of the finished bed. The lever rods are secured to the flange using bolts. A return spring is installed between the frame and one of the lever elements. Now all that remains is to clamp the grinder in the bracket and try to make a cut, but first you need to secure the adjustable stop between the guides on the frame.

The size of any of the presented stands depends on the dimensions of the angle grinder. Here you will have to do your own calculations. It will take a couple of days to make the structure, but the homemade stand will be ideally tailored to your own requirements.

We make a machine for cutting metal using high-quality equipment: TOP 3 manufacturers of angle grinders

This list contains brands whose equipment has received high ratings from ordinary users and professionals:

- Bosch. It is famous for its reliability and well-thought-out small design elements. A significant limitation is the high cost even in the basic configuration.

- Hitachi were initially expensive. But these days, part of the production has been moved to China, which has reduced costs. Some models do not have automatic speed stabilization under load.

- Makita - Reasonable combination of price and quality. All new high power models are equipped with effective overload protection, which extends the actual service life.

How to avoid 4 mistakes during operation of grinding/surface grinding and other machines

In order for the machine to perform its functions for a long time, the following simple rules must be followed:

- Do not increase the load more than planned.

- Use suitable replacement tips as specified in the manufacturers' official instructions.

- Remove dirt promptly to avoid deteriorating the air cooling mechanism.

- Maintain the ideal state of electrical insulation and the functionality of protective devices.

Industrial bed designs

A stand for an angle grinder will be required in the following cases:

- A structure made of difficult-to-cut material or with a large surface area is being cut/grinded.

- Increased cutting accuracy is required.

- It is necessary to process several products with the same parameters.

- The workpiece material is not continuous in cross-section, and the presence of voids and cavities can provoke vibration, shock and, consequently, sudden movement of the machine body.

The frame for the grinder is produced by almost the same companies that produce the tool itself. The price for the simplest design, depending on its manufacturer, does not exceed 2500...3000 rubles, but with increasing functionality, the price of the frame increases to 20,000...25,000 rubles, and not every home craftsman can afford such costs. In addition, such racks are not particularly versatile, and, of course, do not take into account the individual needs of the user.

Such beds consist of the following elements:

- A base plate, which is made of thick sheet steel and is equipped with T-shaped slots for fastening the workpiece. It may also be a cast iron stove;

- The actual rack, on which a mounting device is provided for an angle grinder of a specific model;

- Adjustment devices that allow you to rotate the stand itself, as well as change the vertical position of the angle grinder;

- Optional: clamps or clamps for workpieces, the dimensions of which are unified with T-slots. Sometimes the kit also includes a bench vice with a set of profiled stands;

- A rotary handle, with the help of which the working movement of the grinder itself is performed;

- Measuring devices, usually an angular or regular ruler;

- Particularly advanced models also have a return mechanism with a spring.

Positive features include the ability to cleanly cut pipes from round profiles, which is problematic and even dangerous without stable clamping of the workpiece. The grinder bed is also necessary for corner cuts of any profile.

The technical capabilities of these devices depend on the area of the supporting surface of the plate and the lifting height of the angle grinder in the frame. Typically, the parameters are calculated for a grinder disc with a diameter of up to 250 mm, and for the size of the fixed part of the workpiece no more than 100...150 mm.