To make housekeeping easier, mankind has come up with a huge variety of gardening tools. Not only hand tools simplify work on the ground, but also various types of transportation, with which you can easily transport bulk or piece goods. Choosing a garden cart is quite simple if you know its strengths and weaknesses.

Advantages and disadvantages

It is difficult to overestimate the importance of a four-wheeled garden cart. These are units that allow you to perform various jobs: remove household waste, dry leaves and herbs, transport firewood, coal and other light and heavy materials. In general, this is a technique that significantly speeds up any work process on the site.

Four-wheeled cars are the most reliable and easy to drive, although there are rare reviews that these devices are somewhat clumsy. Meanwhile, the multi-purpose carts on four wheels are stable and will not tip over during operation.

Body made of... barrels

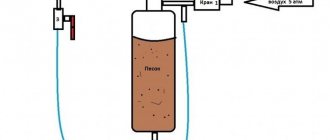

As an option, you can install a platform from a used 200-liter barrel on your wheelbarrow. But not from under bitumen, otherwise your cargo will turn into oil waste. Using a hand grinder, cut it lengthwise - according to height.

Strengthen the former barrel on the frame with the half-bottom closer to the “driver” of the car. Even damp bulk material can easily spill out of it, and the wheelbarrow does not need to be placed with the handles up; a slight tilt forward is sufficient.

General characteristics

Devices for transporting country goods can be made of different materials. The most common are metal and wood . The wheelbarrow can have different designs. folding model , which, if the owner wishes, can be assembled and stored in a small room, and there are devices that cannot be transformed .

The latter require large spaces for storage.

The area of economic work, as well as construction, is quite large. Therefore, depending on the purpose, a 4-wheeled garden cart can be manufactured with a minimum load capacity of 70 kg and a maximum load capacity of 250 kg. The size of the vehicle also depends on the maximum cargo weight parameter.

If the model will be used only for household needs, then a load capacity of up to 100 kg should be fully sufficient. Such wheelbarrows are small, maneuverable, simple and very easy to use. Options with a carrying capacity of more than 200 kilograms are used only for construction work: they are not so maneuverable, large and weighty. It is not recommended to purchase them for work in the garden.

Assembling a durable assistant

If you plan to use a wheelbarrow to transport various heavy loads, building materials, large items, it should be made with 4 wheels. This design is usually made of metal elements. To compile it, the contractor must have a welding machine and tools for a mechanic. The trolley frame is made up of pipes and pieces. They are welded together onto one platform.

The handle and wheels are welded to the frame. Experts recommend equipping it with tires, which increases the load capacity and simplifies the movement process. Each wheel is welded to the frame separately. The container is mounted on the platform. Various cargoes are loaded into it for transportation. For these purposes, use an old or new pallet. The device for loading and transporting materials is preferably fixed on the platform.

The operation is performed by welding or fastening. The first option is suitable for carts that are not planned to be disassembled soon. The bolted connection allows you to change the container if necessary for transportation.

Originally posted 2018-03-28 15:13:01.

How to choose?

Before you buy a wheelbarrow, you need to decide what work on the land will be performed most often with its help. If you have to transport large loads, then the best option would be a 4-wheel garden wheelbarrow with a reinforced body . Such a unit has frontal stiffening ribs over the entire area of the sides and bottom of the equipment. Thanks to this design characteristic, the cart will easily transport massive and voluminous loads, and no deformation of the body will occur .

If you will mainly transport bulk or liquid cargo , for example, sand, organic fertilizers, then it is better to buy a cart that does not have corners and additional stiffeners, since part of the transported goods will certainly get stuck in the cart, causing a lot of inconvenience to the person.

These carts will need to be cleaned and washed frequently. You also need to look at the width of the body, which should not be excessively large. The wheelbarrow should easily pass through the gate opening and not impede movement around the site.

Handle holders in garden wheelbarrows must be positioned correctly. Before purchasing, it is better to test the unit in use and understand for yourself how easy it is to use. The handles should be far from each other and moderately long. This arrangement allows you to minimize the load on the person’s back and arms. Moreover, ideal mobility of the four-wheeled vehicle during its movement is ensured.

There are two options for placing handles - two parallel or one continuous longitudinal . You can only understand which model is better through trial use. In any case, the handles should be long, with grooved nozzles for more comfortable work, so that the gardener’s hands do not slip.

Wheel diameter is also important . If the wheels are large, driving a two-axle wheelbarrow is much easier. Depreciation also depends on the diameter. A convenient wheel diameter for garden wheelbarrows is considered to be from 35 to 45 cm.

Regarding the production material, we can confidently say that metal wheelbarrows are more durable, reliable and have a long service life. And plastic models are much lighter, ideal for simple work on the ground, collecting garbage and transporting crops. They are easier to care for, they do not rust over time, they are durable and cheaper than the first option. Wooden wheelbarrows are often presented in the format of decorative elements. They decorate landscapes and do not use wheelbarrows for their intended purpose.

The following video is about the Westman 250 4 wheel garden cart.

The garden wheelbarrow and cart are known to anyone who has a summer house or any plot of land, who wants to build a house or any other structure. Also, these tools are necessary if you are going to transfer a significant amount of soil, fertilizer, building materials or other cargo.

- Make it yourself or buy it

- Types of wheelbarrows

- How to approach the matter

- DIY options

- We also recommend reading

- Master class on making a wheelbarrow (video)

- Wheel options

- Fastening wheels (video)

- The simplest car

- conclusions

Show all content

If you have not yet bought a cart or wheelbarrow, but want to do so, then you need to understand everything in order to know the general concepts of what types of such tools there are. It is also important to know about all the advantages and disadvantages of them, and maybe consider the option of making a cart yourself. In this article we will try to give a detailed answer to the question - how to make a wheelbarrow with your own hands? Along the way, we will also try to give an answer to such a question as: what material should the wheelbarrow be made of and what kind of design could it be ?

Read also: Table of conductor resistivities

Homemade car

About the cost

What is the price of a snowmobile trailer? Obviously, the cost depends on the specific type of trailer, the manufacturer and the presence/absence of additional functions.

For example, to buy a trailer for transporting a snowmobile with a folding tailgate, an awning, treated with an anti-corrosion coating, will cost the buyer 45-50 thousand rubles (excluding the cost of the awning).

A trailer, covered with an awning, equipped with a spring-shock absorber suspension, with an extended drawbar (which has a positive effect on handling), the sides and bottom of which are made of special laminated plywood, resistant to moisture, will cost about 60-65 thousand.

Or you can buy a trailer for two snowmobiles for 80 thousand. It will be an open trailer with a low platform and small diameter wheels to ensure high stability.

Finally, the cost of a two-axle trailer with a plastic cover, the front and rear sides of which fold down, will be about 120-130 thousand.

Make it yourself or buy it

The very first question that should be asked in our situation is whether it is worth “reinventing the wheel”? Is it better to buy a ready-made tool?

First, go to the first online construction store that will give you a Google search and look at the prices. Of course, buying at retail is more expensive than making it yourself, but not so much as to completely discard this option.

After comparing prices and assessing your own efforts that will be spent on making your own cart, you can come to a certain conclusion - your own cart will come out inexpensively if you don’t need to buy material for manufacturing, and you have everything on your farm, and you are asking the only question how to assemble it from what is there. Otherwise, the work will be unprofitable.

In the same store, the price of wheels ranges from 400 to 5000 rubles.

However, if you are a crafter at heart and get satisfaction from this kind of manual activity, then why not give it a try.

Hygienic requirements

When moving the cart, you need to regularly change the position of your hands to avoid overstraining your muscles. Pneumatic wheeled carts are more convenient in this regard, since vibration from an uneven road is not transmitted to the hands through handles or handrails. On large carts, handrails are more often used, and handles are most often found on one- and two-wheeled carts - they are almost always equipped with removable covers, which are made of rubber or soft plastics. But the determining factor for ease of use is not so much the material as their size and adaptability to the shape of the palm.

Inconvenient covers quickly cause calluses on your hands, so they must be replaced. This is not always easy to do: commercially available covers for bicycle and motorcycle handlebars usually have a fitting diameter for the pipe of 22 or 24 mm, while trolleys have a larger frame thickness - 28 or 32 mm. If you can’t find anything suitable in the store, we can only advise you to look for handles from old Soviet motorcycles or put pieces of a suitable hose on the pipes. It is very desirable that there are safety brackets on the outside of the handles: they protect the hands from injury when hitting walls and in doorways.

With handrails the question is simpler: their length and thickness allow you to change the position of your hands as you wish, and good work gloves are quite enough for comfortable work.

The trolleys also have one more ergonomic feature. On a flat road, there is little resistance to movement, and the cart can be rolled literally with one finger. But given the inertia of the mass of the load, there is no point in sharply accelerating or braking the cart - this will only lead to premature fatigue; Smooth movements are not only more convenient, but also safer.

During long-term transportation, breaks should be taken every 15–20 minutes. During a stop, you can inspect the chassis and check the securing of the load.

Types of wheelbarrows

Wheelbarrows may differ in the number of wheels. The most common option is a two-wheeled cart or a cart with one wheel. You can also make a wheelbarrow on 4 wheels. Each of them has its own pros and cons. For example, a wheelbarrow with one wheel is very convenient to use as a garden wheelbarrow or in the vegetable garden, because it is agile and will travel along any, even the thinnest path, thereby not touching any plantings. A cart with two wheels is not suitable for this type of work. But, for example, for construction work or for transporting something heavy over long distances, this is an ideal option. In turn, a unit with one wheel is not suitable for this, because it is unstable and requires enough energy to carry it in your hands. Transporting soil in wheelbarrows with two or four wheels is much easier. It would be ideal if you have two options for such carts.

As you probably noticed, a wheelbarrow is made for specific purposes and to work in specific conditions.

And one more argument in favor of having two options for wheelbarrows - for example, if you have a wheelbarrow for manure in the spring, then in the fall it is no longer suitable for harvesting.

It’s good to have more than one car at your dacha

Trolley parameters

Before purchasing a cart, it is worth considering its purpose and taking into account the main parameters. If you need a simple model for small construction or gardening work, the way you attach the wheel to the wheelbarrow is very important. The wheel mounting bolts must turn easily, which ensures uninterrupted transportation of goods.

You should also select the housing material. Plastic models are suitable for carrying light loads (such as leaves or garden waste). The disadvantage of such wheelbarrows is the fragility of the plastic, especially when exposed to low temperatures.

Metal options are much more durable. Before creating a cart, it is worth checking the thickness of the walls. When transporting heavy materials, the housing may become bent or damaged, making it more susceptible to corrosion.

It is also worth considering the capacity and depth of the wheelbarrow. It must meet existing needs.

DIY options

If at this stage you have not yet changed your mind about making a wheelbarrow yourself, then let's start studying this topic.

First, let's look at what frame and body designs can be.

Wheelbarrow made of profile pipe and galvanization

One of the options for the frame is to weld it from a square rod with a cross section of 25 mm. You need to put two wheels on the axle. In turn, the axle is a pin mounted on nuts.

We also recommend reading

The body itself will consist of galvanized sheets. They need to be cut to the required sizes and screwed to the frame. As a result, we get a household item.

Wheelbarrow from scrap materials

In this picture, we see that the master did not try too hard to make the wheelbarrow aesthetically beautiful. He needed to make a tool for transporting earth, so that it would take a minimum of time and money.

In the picture we see the fruit of the craftsman’s labor

- An unnecessary container was taken for mixing the solution, which later became the body

- A frame was made from metal plumbing pipes. They were bent into an arc and welded together.

- The axle for the wheel was also attached by welding. And the body was tightened with wire so that it would not fall out when turned over.

This is not the most ideal car option, but it will cope with its functions.

Metal wheelbarrow

In this picture we most likely see the result of the work of a perfectionist. Since the creator of this cart did not have a tool for bending pipes, a combination grinder was used to score the cart handles. The support legs were installed ready-made. The body is completely welded from scratch from a 3 mm thick sheet of iron.

If you look closely, you can notice something:

- The edges on the body are cut very evenly, it feels like it’s not even an angle grinder.

- Along the entire length of the body we see very high-quality welds.

- Pay attention to what color paint was chosen. This is an indication that the wheelbarrow was not made to carry earth or bricks in it, but for very clean work.

Here the owner did not try to make a car like at the factory: the bends are not as high quality, the quality of the seams is also not very neat. Although all this will not affect the performance of its functions.

Master class on making a wheelbarrow (video)

But what if you don’t have a welding machine at hand, or have never used one? In this case, there is a lot of information on the Internet on how to make a garden wheelbarrow with your own hands, with only boards, screws, an axle and devices to attach it to the cart itself.

Read also: 09G2s hardness in delivery condition

During assembly, it is preferable to use self-tapping screws made of galvanized material. Before you start tightening the screws, make holes in the boards, but make them smaller than the screws. This is done so that the board does not split when assembled with self-tapping screws.

Drawing of a wooden wheelbarrow

In this picture, we see another version of the car. A board bottom is not as practical as a galvanized sheet bottom. In this option, all that remains is to make the sides and put two wheels on the axle.

Another option for a garden wheelbarrow is to make it from a barrel. Moreover, the material of the barrel is unimportant. It can be plastic, metal, or even wood, although you will probably have to struggle with it. The barrel is cut into two parts vertically, which means that two wheelbarrows can be made from it. The procedure for performing a “barrel” cart:

- Mode purchased barrel into two parts.

- We assemble the frame, the options for which you read above.

- We make the sides or ribs on which the barrel will rest.

- We install the wheels.

Wheelbarrow from an old barrel

As you can see, old things can sometimes come in handy, so think twice when you want to clean up your garage. Then you can wrap the holders with electrical tape to make it more comfortable for your hands. We can say that the car is ready. You can start making the “sister car”.

If you have an old bed, then we have another option for you. For this you will need: the bed itself and wheels. The wheels must be powerful. Wheels from an ancient Cossack are one of the options. The design of the trolley can be either on two wheels or on four. Assembly order:

- Removing the bed net

- We attach the wheels using welding or fasteners.

- We fasten the bottom and sides from a thick steel layer.

- We mount the handle - to your taste, but it is better to make it with the letter “p”, because it will be more ergonomic.

That's it, the creation is ready. It turns out to be a good homemade garden wheelbarrow for transporting goods. This is an indispensable tool for transporting hay, building materials, firewood and so on.

Preparing to make a wheelbarrow

Before starting to manufacture a garden cart, they create drawings with their own hands based on a well-thought-out model. The main purpose of the device is first determined, what exactly is planned to be transported and over what distances. Depending on the purpose, the optimal dimensions of the body and wheels, as well as materials, are chosen.

DIY garden wheelbarrow

Having drawn an exact diagram of the planned structure, you need to determine how much materials will be needed. After conducting an inspection in your household, you can say with confidence which components are available and what needs to be purchased. In this case, you can immediately calculate financial costs, determining the profitability of your actions.

Which wheels to choose

If you have unnecessary children's bicycles, scooters, or strollers, the issue of finding wheels can be resolved very easily and quickly. Without any monetary costs, a homemade wheelbarrow for a summer residence will be provided with wheels. Depending on the design design, you can use a different number of wheels - from one to four.

If there is nothing suitable on the farm, then there is a need to purchase new wheels. They can be of different prices, but you don’t need to save too much on them by buying the cheapest ones. It should be taken into account that the wheels will bear quite a large load, so it is worth taking care of high-quality and durable parts.

Important! When buying new wheels for a cart, you should pay special attention to their size. Small wheels can significantly complicate the movement of the structure on uneven ground; considerable physical effort will be required to move the wheelbarrow. Therefore, it is worth giving preference to medium-sized inflatable wheels with a metal rim, which will make it possible to move heavy loads in the cart even on loose and uneven soil

Therefore, it is worth giving preference to medium-sized inflatable wheels with a metal rim, which will make it possible to move heavy loads in the cart even on loose and uneven soil.

Optimal body material

Depending on the purpose of a homemade garden wheelbarrow, the size of the body, shape and material for its manufacture are determined. Most often, metals are used for these purposes: aluminum or steel.

Aluminum is a more expensive material, but it has a number of advantages:

- significantly reduces the weight of the finished structure, which facilitates its operation;

- The body is absolutely not subject to corrosion and does not require constant painting.

Steel is stronger than aluminum. If you have a welding unit, you can perform any operations with it, giving it the desired shape. A trolley with a steel body is heavy, which may require additional effort from the worker. At the same time, the increased strength of the body allows you to move even very heavy loads without fear of damage.

Durable body

If you have wood on your farm, you can make a cart body from wood. Old baby bathtubs or troughs can easily work. Even from unnecessary metal or plastic barrels, craftsmen make a body for a wheelbarrow. To do this, the container is cut in half vertically, and the cargo bowl is ready for mounting on the frame.

Note! The body made of a plastic barrel makes the structure quite light and mobile, however, moving very heavy bulky cargo can lead to its breakage and cracks.

What and how to make handles from

A DIY garden cart is usually made with one transverse or two longitudinal handles. The advantage of making household appliances yourself is that you can design the structure, taking into account individual characteristics of use and body type (height). Some gardeners note the particular convenience of a cart with one transverse handle, because it is comfortable to carry both in front of you and behind your back. You can move such a structure behind you, holding it with one hand, while walking along an uneven road, while it would be extremely inconvenient to carry a wheelbarrow with two handles in this way.

Handles are attached to the frame with the body, for the manufacture of which different materials can be used:

- metal,

- tree.

Most often, preference is given to metal because of its greater strength. If there are metal pipes of small diameter in the household, they can be used in the construction of both frames and handles.

Additional Information! Metal parts are best joined together by welding rather than mechanical fastening. For convenience, the part of the metal handles that you hold with your hands can be wrapped in rubberized film.

Wheel options

If you are thinking about not buying wheels for your homemade car, then we have several options for you.

- You can use a baby stroller that is no longer useful anywhere. It would be better if it was a Soviet stroller, where the wheels are made of steel spokes. The result is a self-propelled car. One may get the impression that what was made in the USSR was designed for the purpose of being used after the child grows up. And the durability seems to border on that of a truck.

- Bicycle wheels, no matter small or large. Of course, if the wheel is from a large bicycle, then you cannot install them one by one.

Fastening wheels (video)

Let's move on to consider the question of how to attach wheels if you do not have a welding machine.

A pin with a diameter of 16 to 20 mm can be used as an axle. It depends on which wheel. To secure the stud, you can also use nuts and clamp it on the sides.

If you use a wooden frame, some problems may arise. If the wheelbarrow is heavily loaded, the frame in the area where the axle is installed may break or crack. This problem can be solved by tightening the cut timber with iron plates.

Please note that the plates are not screwed down with screws, but are tightened with bolts, having first drilled a hole through. This design will not allow the beams to crack, provided, of course, that a reasonable load is applied to the axle.

Assembling a metal cart

A metal product has two main advantages - endurance and durability. It’s difficult to make, but quite possible. Prepare:

- steel sheet thickness 1 – 2 mm;

- corner 25*25;

- wheels;

- steel pipe of the appropriate diameter.

You will also need a grinder and welding.

First of all, sketch out a drawing of the future device. All parts must be drawn on it and dimensions indicated. It is advisable to make the volume of the body 100 liters. Wheels can be taken from a bike, stroller or motorcycle.

Brief instructions:

- Cut the sheet, focusing on the prepared sketch.

- Weld the body.

- Make support posts from the corner.

- Make a handle from a pipe.

- Attach the wheelbase.

The metal cart is ready!

conclusions

We believe that you found this article useful, and now you at least have a general idea of what homemade cars can be, and perhaps you have your own ideas. If you have not found a car that suits your needs, you have the option of buying a ready-made car.

Anyone who has dealt with work on a personal plot knows that you can’t do without a trolley when doing any work. Working in garden plots requires constant movement, moving some kind of load (it doesn’t matter whether it’s large loads or a simple bucket of fertilizers).

A garden cart can make your work easier. It can be purchased ready-made at a hardware store or constructed at home from scraps at hand.

The need for a cart for a garden

If you have a cottage, garden, workshop or even your own business on a farm, the need for a cart increases.

In fact, such a thing is very necessary in the household, as it greatly facilitates work and saves time. Much less physical effort is required if you transport all heavy tools in a basket on wheels. In addition, there is no need to waste your free time. Just imagine that a small construction project is being built. You need to go to the shed and get a shovel, a hammer, a hand axe, bring some power tools, paints and decor brushes, and everything else. How many times will you have to walk from the barn or garage to the construction site? How much time can you gain if you transport everything? After all, you can simply load the cart with everything you need and at the same time move everything to the place of work.

Homemade carts and their versatility

A structure that will help gardeners move any type of cargo is called a trolley. Using a cart or wheelbarrow, you will spend less time and effort moving goods from point A to point B. Using a cart will allow you to spend less time and effort on transporting heavy loads.

Homemade carts are also considered universal - if the structure is equipped with additional removable holders and drawers, it can be used to move not only liquid cargo, but a variety of small items and other accessories, in addition to the usual large cargo.

Homemade models are intended for moving not only gardening or gardening tools; there are also boat carts that you can also build with your own hands.

Load securing and operating features

Work with trolleys in the industrial, transport and trade sectors is additionally regulated by the Intersectoral rules for labor protection during the operation of industrial transport (floor-mounted trackless wheeled vehicles) POT RM-008-99 (entered into force on February 1, 2000) and the Intersectoral rules for labor protection during loading and unloading operations and cargo placement POT RM-007-98 (date of introduction 06/1/1998). These documents are well researched and compiled in sufficient detail, so it will be useful to study them for general educational purposes.

Quite valuable goods are transported by hand trucks, often on bad roads; these can also be dangerous goods, therefore, during transportation, special attention should be paid to the quality of their stowage and fastening. In the field of transportation, this subject is considered by cargo science - it is studied in educational institutions of the transport profile. Since the properties of cargo do not depend on the type of transport, it is very advisable to familiarize yourself with the basic principles of this science in publicly available textbooks.

There are no particular difficulties when transporting on hand trucks, you just need to follow a few basic rules.

On almost all trolley designs, the load is secured to the elements of the supporting frame as far as possible from moving parts; no special fastening is required in the body. If your cart has a smooth solid platform or a body with solid sides, then for ease of securing cargo it is necessary to equip it with standard fastening loops for cargo compartments of cars.

When packing, the heaviest loads are placed at the bottom of the bag, then the rest is packed. Fragile cargo must be wrapped in soft material or cardboard is used. It is better to attach the bag to the cart using handles or buckles. For fastening with a clamp, rubber luggage cords with hooks are usually used - fastening with a rope is weakened by vibration. For heavy and bulky cargo, the best option would be a luggage strap with a ratchet, which is considered a car accessory and is needed for tying cargo to the roof rack. If you need to weigh any cargo, take an ordinary floor scale for this.

In most cases, the mass of the load is several times greater than the mass of the trolley, so the main rule here is proper alignment. The center of gravity should be as low as possible and placed along the length so that minimal load is placed on the hands. Incorrect alignment will quickly cause the load to shift and tip over, which can cause serious injury to a person. The likelihood of such an incident occurring when transporting water is very high, especially on uneven roads, so water containers must be completely filled and securely fastened.

In rainy weather, waterproof bags and bags, as well as awnings, which can be made from oilcloth or awning fabric, can be used to protect the cargo. The low speed of the trolley does not cause much splash from the wheels, but it will be useful to equip them with guards or mudguards.

All areas of application of hand trucks, as well as driven transport, are quite clearly divided into two groups: loading and unloading operations on a short haul and long-distance flights. If you use a cart in a warehouse, construction site, summer cottage, or industrial building, do not save time on preparing passages. Widen passages that are too narrow, level the surface for traffic if possible, equip thresholds and other elevation differences with temporary or permanent entrances. Many types of carts can be used on stairs, but you need to move slowly and firmly hold the handles: remember that it is very easy to tip over here.

When traveling long distances with a trolley on roads and sidewalks, you should strictly follow the Road Traffic Regulations, taking into account the absence of wheel brakes. They are not installed due to the low speed of movement, although a cart with a heavy load accelerated to only 10 km/h poses a great danger, especially when descending a hill. It can crush a car, damage a baby stroller, injure a pedestrian, or even roll out onto the roadway.

List of theoretical knowledge that may be needed when operating a hand truck

Rolling bearings: symbols, installation rules, causes of damage.

Pneumatic tires: symbols, installation and operation rules.

Cargo science: basic concepts, methods of securing cargo, properties of cargo.

Welding: technologies used, types and identification of defects.

Rules for the carriage of baggage in various modes of transport.

Properties and selection of lubricants.

Traffic Laws.

One-wheeled cars are much more convenient on narrow paths; you can turn on them by slightly tilting in the right direction, like on a bicycle. And with such easy turns you can balance a heavy load and even push a wheelbarrow with one hand.

Many cases of transporting goods on a trolley can be safely attributed to the so-called intermodal transportation, when one vehicle along with the cargo is completely placed in another vehicle and transported further in this form. Our carts are most often carried on public transport. In ground transport you can carry trolleys no larger than a baby stroller; payment is made as for luggage. Entry into the metro with large trolleys is restricted, as they are dangerous for other passengers, especially on escalators. Rail and air transport have their own transportation procedures, which can be found in the rules for passengers.

Carts can be stored both indoors and outdoors; no special conservation measures are required, you just need to protect the vehicle from precipitation and periodically inflate the tires if any. To save storage space, many types of carts can be installed vertically.

Manufacturing methods and materials

The wooden two-wheeled model is the easiest to implement. To produce it you will need a standard set of tools.

Small instructions for work:

- You will need a board 7x7 centimeters. It will serve as a frame. All parts of the frame must be connected to the board using screws. Additional parts are used for strengthening.

- Several slats need to be attached to the bottom of the structure.

- The handle will be made of metal. It will make the structure more resistant to loads. A handlebar from an old bicycle or an ordinary thick steel rod are perfect as a handle.

- The sides will be made of boards. Be sure to consider what kind of loads you plan to move - the more loads, the larger the boards needed for high sides. The frame and well-fixed wheels can give reliability to the product.

Read also: What is made of aluminum

Application and process description

Four-wheeled carts for moving large loads are always made of metal. Thanks to the presence of four wheels, such models are more spacious, durable and have a longer service life. Able to withstand weight up to one hundred kilograms. In order to make a similar design option with your own hands, stock up on a plumbing tool kit.

To make a cart with four wheels, you will need:

- Preliminary calculations for the platform on which the goods will be moved.

- Make a container where materials will be moved in the future. Depending on the container parameters, the frame size will be calculated.

- Using welding, it is necessary to install the structure with the frame. In order to secure the frame, you can take the remains of the pipes. Weld the handle to the frame.

- The wheels are welded almost last.

- It is best to use pneumatic tires as “shoes” for wheels. Thanks to them, you can increase the weight of transported cargo to eighty kilograms.

Material selection

When making it yourself, available materials are often used, and there is no question of choice. However, in case of purchasing the necessary components, the following options are available:

- Wood - allows you to get by with a minimum number of tools. The cutting is done with a hacksaw, the fastening is done with bolts and angles. However, the tree is not resistant to adverse weather conditions, and after a few seasons the joints will become loose, begin to rot and break.

Ferrous metal - a garden cart made with your own hands from this material will be durable and inexpensive. Although the work will require more tools, in particular, a welding machine and an angle grinder.

Stainless steel or galvanized steel is the most durable material that is not exposed to moisture. Such a cart will cost more than others and will require tools similar to the previous version, but it will last for many years and may even be inherited by children or grandchildren.

The choice of manufacturing material depends on financial capabilities, but it is highly not recommended to give preference to wood, due to its fragility.

Types of carts that you can make with your own hands

Designs for moving goods can have several varieties. The main difference is the number of wheels on it. Carts and wheelbarrows are made from different materials.

In order to transport oversized and not very heavy loads, you can use wooden wheelbarrows. To transport heavier materials, it is better to use carts made of metal structures.

It may contain removable holders, fasteners, drawers. The presence of these structures on the trolley will allow you to transport small items, as well as bulky cargo.

Ideas and sketches

A homemade transportation cart will be made based on the needs of the master. Therefore, it will be ideal for all work performed on a personal plot.

You can easily and without problems make the following trolley options yourself:

- With one wheel.

- Option with two wheels.

- The design is similar to a platform and has four wheels.

- Folding model.

Before you make a cart for moving goods with your own hands, you need to determine what goods will be transported, as well as how often you will use it.

Trolley with one wheel

A structure that has one wheel and is intended for transporting any cargo is called a wheelbarrow. To use it, you need a narrow path. It is particularly maneuverable and reliable. In order to free the structure from the transported cargo, press the longitudinal handles and slightly tilt the wheelbarrow to the side.

The disadvantages of this model include the application of great force to maintain balance. The wheelbarrow is not intended to be moved on soft ground (sand or earth).

DIY two-wheeled cart

The two-wheeled cart can be made from wooden materials. To do this, take a standard set of tools. Do not forget that wooden structures have worse performance characteristics and capacity and strength than their metal counterparts, which may have more wheels.

All the steps for producing a two-wheeled structure are quite simple - you need to attach the frame to the frame, screw on the handle and do not forget about installing the sides. The final touch is installing the wheels.

Four wheel trolley

Four wheels are always better than two. Unfortunately, these carts will require wider tracks, but they are more spacious and durable than their two-wheeled counterparts. The service life of this model will be increased. To make a structure with four wheels, you need to make all the necessary calculations in advance regarding the dimensions of the loading platform.

Folding trolley

This design option can easily move loads weighing more than fifty kilograms from place to place. The main advantages of this type include its compactness.

In order to make such a design yourself, you will need to follow the instructions:

- Take the remaining pipes. Their thickness should be at least two millimeters.

- Be sure to draw a preliminary template. The scale should be 1:1.

- Next, proceed to welding the bushings to the platform frame. Then start working on the main structure.

- At the end of the work, be sure to polish and clean all seams.

Making your own cart for your work is not difficult. You just need to determine in advance what the structure will be needed for in the future, purchase the necessary material (or find leftovers that are probably lying around somewhere in the garage or barn), read the clear instructions for creating carts and do not forget about safety precautions. All drawings and sketches for carts and wheelbarrows can be found on the Internet. Good luck!

Creating a transport cart

The pipes must be cut into suitable pieces. It is worth remembering the crossbars of the reinforcement in order to naturally cut a square out of them. All these elements must be welded together.

After the frame, you should try to shape the strips themselves. Wheels must have threads on the ends to prevent them from falling off the axle. You can buy wheels in almost every specialized store.

All materials will be much cheaper than buying a ready-made transport cart. However, the quality will be worse. Making a self-propelled cart with your own hands will be more difficult, but still possible.

Question answer

The most durable is the welded base, which will be made from a profile. It’s quite simple to do – cut two pieces of pipe. They should be slightly longer than the width of the base. Don't forget about the clearance between the structure and the wheel. To prevent dirt from sticking and interfering with movement, make a gap of three centimeters.

Yes, sure. To do this, it is necessary to critically examine the condition of the cart itself. The interior may remain unchanged. You can place a variety of garden tools or boxes with cargo here. You can change the frame - make it more durable, install high sides. A couple of profile pipes can be welded along the frame. Install limiters at the top, L-shaped clamps along the bottom. As a result, we will get an improved cart for moving a variety of equipment.

Regular trailer vs snowmobile

Many people think of using a standard trailer to haul literally everything, including a snowmobile. But in reality, you will not be able to properly transport such equipment on a short flatbed trailer.

This is due to several factors:

- Remember that regular trailers are absolutely not suitable for transporting snowmobiles. Attempts to remake them or adapt them for such tasks will end in failure and the need to buy not 1, but 2 new vehicles at once.

- There are certain transport regulations that impose requirements on caravans. If you are going to transport snowmobiles on them, then the vehicles must:

- Some people also buy special sleds for snowmobiles to transport people. An interesting and fascinating thing, I tell you. Unforgettable feelings. But here it is important to follow the transportation rules so that during the next maneuver the sled does not skid and turn over. Safety comes first.

Homemade wheelbarrows: we mechanize manual labor. Part two

How to make a construction wheelbarrow with your own hands, a collection of ideas: complicated designs

In the first part of the article we looked at the following structures:

- a homemade garden wheelbarrow with a helicopter wheel;

- construction wheelbarrow from scrap metal;

- drawings of a homemade construction wheelbarrow.

In this sequel, the wheelbarrows evolve into construction carts and trailers, with the ability to not only turn, but also tilt the body. And also, we learn about the car, the existence of which the hero of the famous joke did not believe —

with a motor.

Construction wheelbarrow made of wood, like a bicycle trailer

Wheelbarrows for construction are made of metal. When making them, you cannot do without a welding inverter, an angle grinder and a drill. What to do if you don’t have a welder? Make a cart for transporting goods from wood.

I made a cart out of wood. I put it on two bicycle wheels. This is the second car. The first design was not very successful, as the wheels were too close to each other.

The evolution of the wooden cart. The user attached a long handle to the wheelbarrow. The wheels were set wider.

And this is the third option AndrejOrdynec

- bicycle cart.

I made the cart from an old bicycle. The idea completely justified itself. On this cart I brought the brick 1.5 km from the site. A wheelbarrow fits 24 bricks. I also carried cement - 2 bags of 50 kg each and cobblestones from a quarry, weighing more than 100 kg.

The wooden cart came in handy for transporting building materials left over after demolishing the garage.

And this is a new version of the wooden cart, after taking into account the shortcomings of previous models. Load capacity up to 200 kg.

DIY four-wheel dump truck

Four-wheel dump trucks are available for sale. Such devices have undeniable advantages. Large load capacity. Mobility. Ease of use of a dump body. It is not surprising that many would like to purchase such a cart. It's just that the price on them bites. The solution is to make an analogue yourself.

The area of my plot is 30 acres. I carried a lot of things on a one-wheel cart. Sand. Crushed stone. Priming. Inconvenient and difficult. The cart balances on one fulcrum. I thought about buying a two-wheeler, but two wheels don’t save me from the stress on my arms and back. A four-wheeled cart with a dump body made of plastic caught my eye. The price for it starts from 6,000 rubles. I thought. I have welding. Cooking table and free time too. I decided to make an analogue with my own hands. Everything worked out.

Compare the IgorVVO

with the factory model.

Features of a homemade four-wheeled cart:

- Body volume – 180 liters.

- Maximum load capacity – more than 500 kg.

- The frame is welded from a profile pipe.

- Body – galvanized steel 1 mm thick.

- Wheel width – 70 cm.

- The length of the body at the top is 110 cm.

- Body width – 65 cm.

- The front wheels rotate 90 degrees.

The main feature of the trolley is its tilting body.

For tipping, I made a handle the size of two hands. When tipping over, the rear wheels roll toward the front wheels. This makes the process much easier. In fact, the load can be tipped with one hand. There is also a special latch, look at the photo, to prevent the body from spontaneously tipping over when transporting cargo. Particularly loaded trolley components are reinforced with metal corners. I made the “nickels” of the rotation axis from large washers, there are three of them, and everything is thickly lubricated with grease. The cart turns around in one place.

Close-up of the components of a homemade trolley.

Preparing for assembly.

Testing a four-wheeled construction trolley.

Construction wheelbarrow with electric motor

Many people dream of owning a self-propelled electric cart. But as soon as you look at the price tag, all desire to buy a “self-propelled gun” disappears. What should I do? Making a homemade cart based on units from electric scooters and electric bicycles? Also not a budget option. The solution is offered by PwrWW.

FORUMHOUSE user made a mechanized wheelbarrow with an electric motor, practically for free.

I have been using an electric wheelbarrow for two years now. I use it to transport small loads around the yard and garden. The power of the electric motor is enough to confidently pull a loaded wheelbarrow on a flat surface and, with a little help from me, uphill. The car has a 7 volt battery. The cart moves at a leisurely pace. The drive is an electric power steering from the car. 50 amp switching relay. I turn on the engine with a clock button attached to the handle of the wheelbarrow. One of the expenses is buying a battery. The motor was available. I assembled the car in half a day.

- Small wheel diameter.

- A tubeless wheel spins on the rim under load. I had to come up with a seal.

- The wheel broke under heavy load. I had to weld it and strengthen it.

- Due to the characteristics of the electric booster gearbox, there is no axial balance of the structure. Requires skill when working.

Electric wheel motor close-up.

Peculiarities

To make a tool cart, you will have to correctly estimate the dimensions of the future structure and draw up its drawings. Without drawing up drawings there is almost no point in getting to work. The fact is that the slightest mistake can result in serious consequences. It is also necessary to take into account that such a mobile vehicle with a tool can only be manufactured by a person who has welding skills . For installation, metal sheets with a thickness of 1 or 2 mm are mainly used - this depends on the size of the product and the number of tools required by the master for his work profile.

The cart is a metal cabinet with several drawers and a work table, which also serves as the top lid of the cabinet. Tool boxes are cut from sheet metal of the same (or different) sizes.

When marking, it is necessary to take into account the sides (side walls of future boxes), which are obtained by bending the edges of metal sheets cut to make boxes. The height of the sides is determined in advance - before marking the parts.

Usually two to four boxes are prepared. More of them are unlikely to be needed.

"Is the game worth the candle"

Indeed, is it worth making a wheelbarrow with your own hands, in principle? In most cases, the answer is no, and we see them being purchased at the store. Of course, it doesn’t make sense to purchase everything you need and spend a lot of time repeating the factory version, since the factory product will be cheaper. However, there are a number of circumstances under which people take up work:

- a non-standard design is required for special cargo or delivery conditions;

- Suitable parts and materials are available;

- I have the desire and time to build a cart myself.

Maybe it will be more convenient for you to purchase a ready-made car and modify it at your discretion. In any case, I wish you good luck in fulfilling your plans. When the homemade product has served its purpose, it can be painted again, filled with flowers and placed in an “eternal parking lot.”