The grade book of steels and alloys contains information on the classification, application, chemical composition, physical and mechanical properties, weldability, technological parameters and information on the corrosion resistance of steels and alloys.

The stamp was created by specialists from Lasmet LLC. Our organization has the ability to manufacture most of the steels and alloys described in the brand book. You can place an order for the products you are interested in.

In the steel and alloys brand directory you can also find information about GOST standards for steel and download them. Also, when you hover over the symbols of physical quantities, you will receive a brief information about them.

If you did not find the answer to your question in the brand book, you can ask it here to the specialists of Lasmet LLC.

Use in its pure form

Nickel is a silver-colored metal. It has high strength and ductility. It has ferromagnetic properties, is well welded, forged and stamped. Resistant to acids and alkalis. Will not oxidize in open air due to the oxide film.

Areas of application of the material in its pure form:

- Used as a protective coating for other metal surfaces. In this case, the protective layer is applied using cladding or galvanoplasty methods. Protects other metals from corrosive processes.

- Containers for storing and transporting chemicals, acids, and alkalis are made of metal.

- It is often used as a catalyst. This is due to the catalytic properties of the material, which are similar to palladium. However, this metal is much cheaper.

- Manufacturing of neutron beam choppers. Thanks to this, the metal became widespread in nuclear physics.

In addition to its use in the food and chemical industries, the pure material is used in the manufacture of alkaline batteries.

Hardening of austenitic chromium-nickel steels.

Carbon in the composition of austenitic chromium-nickel stainless steels without titanium and niobium additives affects the hardening temperature of the steel. When hardening, it is necessary to heat the steel above the dissolution temperature of chromium carbides; subsequent rapid cooling is intended to fix the homogeneity of the solid solution. Thus, with an increase in carbon content, a higher heating temperature for quenching is required. In general, the heating temperature range during hardening of austenitic chromium-nickel stainless steels ranges from 900 to 1100 ºС.

Long-term holding of austenitic chromium-nickel stainless steels upon reaching the hardening temperature is not required. For sheet stainless steel, the total heating time to 1000-1050 ºС and holding time is 1-3 minutes per 1 mm of sheet thickness.

But cooling should be fast. For austenitic chromium-nickel stainless steels with a carbon content of more than 0.03%, which are classified as “unstabilized,” cooling in water is used. Stainless steels with lower carbon content and small cross-sections can be cooled in air.

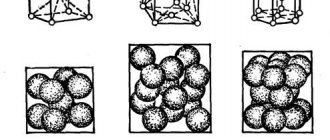

Magnetic properties of materials

All materials according to their magnetic properties are divided into:

- Paramagnets - tin, platinum, aluminum - increase the external magnetic field due to the coincidence of molecular currents with it.

- Diamagnets - copper, silver, zinc, their internal field weakens the external one.

- Ferromagnets - iron, cobalt, nickel, in which magnetization is greatly enhanced even under weak influence of an external field.

Why is stainless steel magnetic? This happens when the external magnetic field is strengthened by the internal one. Moreover, the more intensely they increase each other, the magnetization will be stronger. In addition, the magnetic properties of stainless steel depend both on the ratio of alloy additives that make up its composition, and on the phase state of the steel.

Provider

Are you interested in austenitic chromium-nickel steels? Austenitic-grade chrome-nickel steels from the supplier Auremo comply with GOST and international quality standards. We offer to buy stainless steel from specialized warehouses of the supplier “Auremo” with delivery to any city. For wholesale customers the price is preferential. Buy today.

Buy, favorable price

The warehouse of the supplier "Auremo" offers the widest selection of stainless steel. Rolled steel is always available, the price is determined by the technological features of production without including additional costs. Buy stainless steel today, the best price from the supplier. We are waiting for your orders. We have the best price-quality ratio for the entire range of products. Experienced managers are in touch and will quickly help you buy stainless steel in bulk or in installments. Regular customers can buy stainless steel products at a discount; the price is the best in this rental segment. The supplier "Auremo" is a recognized expert in the rolled metal market. Thanks to representative offices in Eastern Europe, we have the opportunity to quickly interact with trading partners.

Peculiarities

Nickel and alloys based on it have certain features and characteristics. It is important to consider them before using them in industry.

Structure and composition

The structure of nickel-based alloys varies depending on what components are included in their composition. The characteristics of the finished material also depend on this. This material is a silver-colored metal found in the earth's crust, water and air. In nature you can find not only a homogeneous metal, but also mixtures based on it. This is due to the fact that it combines well with other materials. Common components in mixtures are iron, molybdenum, copper, chromium.

Properties and characteristics

The physical and chemical properties of a material help determine where it can be used and how it will change during certain processing steps. Characteristics:

- Density - 8800 kg/m3.

- Melting point - 1455 degrees Celsius.

- Boiling point is about 2900 degrees.

- Maximum tensile strength - 9000 MPa.

- Thermal conductivity - 90.9 W/(m*K).

- Electrical resistance - 0.0684 μOhm*m.

Due to their characteristics, nickel and mixtures based on it are used in various areas of industry. They lend themselves well to processing on industrial equipment, which expands their scope of application.

Stamps

According to the state document GOST 849-2008, 7 grades of nickel are designated. These include H0, H1,2,3,4, H1Ay and H1y. The composition of the brands is the content of the main substance up to 99.9%, a small amount of cobalt and third-party impurities.

Stainless steel 12Х18Н10Т application, properties.

Steel 12Х18Н10Т is an excellent example of chromium-nickel austenitic stainless steel, widely used in the production of welded structures. It can work in contact with nitric acid and other strong oxidizing agents; in some organic acids of medium concentration, organic solvents, atmospheric conditions, etc. These are containers, heat exchangers, as well as welded structures using cryogenic technology (up to -269 °C).

Examples of using stainless steel 12Х18Н10Т:

- rolled forged round, square, hexagonal

- the leaf is thick;

- thin sheet;

- cold rolled strip;

- seamless hot-deformed pipes;

- cold- and heat-deformed seamless pipes;

- wire;

- shaped steel profiles.

The corrosion resistance of stainless steel 12Х18Н10Т against intergranular corrosion is determined by testing according to the AM and AMU methods of GOST 6032-89 with a duration of exposure in the control solution of 24 and 8 hours, respectively. Tests are carried out after provoking heating at 650 °C for 1 hour.

During continuous operation, stainless steel 12Х18Н10Т is resistant to oxidation in air and in the atmosphere of fuel combustion products at temperatures up to 900 °C. Stainless steel 12Х18Н10Т has fairly high heat resistance at temperatures of 600-800 °C.

Stainless steel 12Х18Н10Т, having good manufacturability, can be subject to significant plastic deformation. The temperature range for pressure treatment of stainless steel 12Х18Н10Т is 1180-850 °C, the heating and cooling rates are not limited. When cold, they allow high degrees of plastic deformation.

How to Determine Whether Magnetic or Non-Magnetic Steel is Stainless

Considering all of the above, we can draw the following conclusion: even if steel has magnetic properties, this does not mean at all that it cannot be classified as a stainless-type alloy. There is a fairly simple way to check whether magnetic steel is stainless steel. In order to determine this, it is necessary to clean the surface area of the product being tested to a metallic shine, and then apply a few drops of concentrated copper sulfate to this area.

The fact that this is stainless steel is indicated by a coating of red copper that covers the cleaned area. This simple method allows you to very accurately determine whether magnetic steel is stainless. But it is almost impossible to check (and especially determine at home) whether stainless steel belongs to the food category.

If you decide to check whether magnetic steel is stainless or not, keep in mind that its properties, such as the ability to magnetize, do not in any way impair its corrosion resistance.

Source

Corrosion-resistant alloys based on iron-nickel and nickel

They are used to provide higher corrosion resistance in environments such as sulfuric and hydrochloric acids. In these cases, alloys based on iron-nickel are used, for example, alloy 04ХН40МДУ, which, after quenching and tempering at 650...700 0C, has an austenite structure and an intermetallic g-phase of the Ni3 (Ti, Al) type. The alloy is designed to work under heavy loads in sulfuric acid solutions.

For work in salt environments, solutions of sulfuric, nitric, and phosphoric acids, the N70MF nickel alloy is used. Alloy KhN65MV is used for work at elevated temperatures in wet chlorine, hydrochloric acid and sulfuric acid environments, chlorides, mixtures of acids and other aggressive environments.

Heat-resistant steels > Continue >

What is anti-corrosion steel?

Steel that does not become rusty during use is popularly called stainless steel. It is obtained from an alloy of iron with carbon and various alloying additives: nickel, chromium, niobium, titanium. Each of these components enhances or reduces certain properties of the alloy - magnetism, strength, hardness, ductility, corrosion. The main quality of stainless steel is corrosion resistance. It just depends on the chromium content in it.

The more of this metal in the alloy, the less susceptible it is to corrosion. Therefore, all steels that are resistant to rust contain at least 10.5% chromium. The uniqueness of this metal is that when it reacts with oxygen, it creates an oxide film on the surface of the product, which prevents the alloy from reacting with aggressive environments. Moreover, if the surface is damaged, the film forms again after the oxidation of chromium with oxygen.

Stainless steel that is not magnetic

Very often, alloys with a high content of chromium, nickel and manganese are used to produce anti-corrosion steel. They are used to produce a large number of different equipment and products for use in various fields. Non-magnetic steels include:

- Austenitic. They are used to make equipment for ships, refrigerators, the food industry, kitchen utensils and plumbing equipment.

- Austenitic-ferritic. The main advantages of such alloys are strength and increased resistance to cracking.

People most often in everyday life come across equipment and products made from these steels, so to the question “Is stainless steel magnetic or not?” and answer in the negative, although this is incorrect.

How to identify a stainless steel product?

Many consumers often try to determine on their own what metal a particular household item is made of. Visually, ordinary steel cannot be distinguished from stainless steel, so it is customary to use a magnet to check. There is an opinion that real anti-corrosion steel is not magnetic. Can stainless steel be magnetic or not? Anything can happen. Therefore, this method of verification does not give a reliable result. Sometimes it happens that a product is attracted to a magnet, but serves for a long time without changing its qualities.

Application area

Pure metal is not used as often as nickel alloys. Application areas of alloys:

- They are used in mechanical engineering, construction, and pipeline manufacturing. Massive structures are made from this metal and are protected from rust.

- Parts for equipment that operates in aggressive environments. The alloys are resistant to acids, corrosive processes, and alkalis.

- Alloys are used to make gas turbines.

- In everyday life, products made from nickel alloys can be found in the form of furniture fittings, taps and mixers.

- Nickel is part of the alloys that are used to make white gold.

Nickel-cadmium batteries are made from this material. Metal compounds are diverse and due to this they are used in various areas of industry.

Alloys

Nickel is the basis of many alloys. It is worth taking a closer look at the most popular compounds based on this metal.

Nickel based alloy

With copper

The most popular compounds are nickel and copper. The result is a material that is not similar in its characteristics to the original metal. In the manufacture of metal mixtures, 3 popular compounds can be distinguished:

- Monel is a material that contains approximately 67% nickel. Has a high strength index. It can be compared with different types of steels. Used in aircraft manufacturing, shipbuilding, and in the manufacture of power tools. You can find monel parts in musical instruments.

- Cupronickel is a well-known alloy whose main component is copper. Nickel in the composition can contain up to 30%. Used in the manufacture of jewelry, figurines, cutlery.

- Copel is a mixture of 44% nickel. The wire from which compensation wires are made is made from it.

There are other mixtures with the addition of zinc, which have their own characteristics and characteristics.

With chrome

Compounds of chromium and nickel are known to many as nichrome. The peculiarity of this alloy is its high electrical resistance and high melting point. Nichrome also has good strength and heat capacity. Applications:

- Manufacturing of parts for devices operating in aggressive environmental conditions.

- Production of heating elements and equipment for heat treatment.

- Nichrome wire is used in the manufacture of electric furnaces.

- This alloy is used to make evaporation filaments used in electronic cigarettes.

If nichrome is coated with a silicon-based alloying layer, it can be used in the chemical industry. The additional coating makes the material resistant to acids.

With molybdenum and other metals

When combining nickel with molybdenum, chromium is added to the composition. The percentage of base metal reaches 77%. In this case, molybdenum in the composition can contain up to 9%. The rest is occupied by chromium. The peculiarity of the connection is its high strength and rigidity.

An alloy with molybdenum is used in medicine. Bridges are made from it. Difficult to process. It is almost impossible to make castings from such material. However, due to their characteristics and low cost, alloys with molybdenum are highly popular.

With iron

This mixture is called invar. It is a compound of iron and nickel. They use ready-made material in the manufacture of parts for mechanical watches.

Compound of iron and nickel