What is better Confirmat or self-tapping screw?

Self-tapping screws have different types. Confirmat is used for a more reliable screed. At the same time, a cap is often placed on the cap to make the fastener look more aesthetically pleasing. To make a table or cabinet, you may need different screws.

Interesting materials:

Is it possible to renew a medical policy in another city? Is it possible to transfer from one university to another in another city? Is it possible to undergo a medical examination for a license in another city? Is it possible to terminate a Rostelecom contract in another city? Is it possible to tilt a city? Is it possible to withdraw money from a deposit in another city of Rosselkhozbank? Is it possible to return a book to the Read the City store? What is the city of Venice based on? Do you need a permit to plant trees in the city? Do you need to turn on your headlights during the day in the city?

Advantages and disadvantages

One of the main advantages of using a special fastener is the eccentric tie, which provides, on the one hand, reliable fastening, and on the other hand, can be easily hidden from view.

They are especially often used for assembling cabinet furniture, ensuring a sound and durable connection of structural parts.

The most common disadvantage is the hex head, for which it is necessary to purchase the appropriate tool. And this is almost the only negative that can be found.

The selection of self-tapping screws is influenced by the type of construction and the desired appearance of the product.

How to choose the right self-tapping screw

First of all, in this matter we start from the material that needs to be fastened. For a thin sheet of solid wood plywood, the use of confirmations is impossible. The main criterion for choosing self-tapping screws is their availability.

The length of the screws can reach up to 50 mm and above. These fasteners are designed for thick solid wood panels.

For the lion's share of furniture assembly work, especially when working on a large project, confirmat is the best hidden fastener for chipboard furniture.

Furniture confirmations have a large rod and threaded surface, due to which the load on the material being fastened is small.

With our help, choose the most suitable fasteners for your furniture. You can be completely confident in the quality and durability of such fastening.

The use of confirmations will allow the structure to withstand significant loads for a long time.

Drill bit for furniture euroscrew

This fastener has a unique design, so for comfortable work with it, use a drill for a furniture euroscrew. As for the dimensions of such a tool, they are standardized. The products of different companies differ only in brand (quality), and the diameter of the drill for Euro furniture screws is determined by the size of the most popular confirmations.

It got its name from the Confirmat trademark, under which the German company produced fasteners.

To work with screws, different heads are used (phillips or hexagonal). Small screws (five millimeters) are tightened with a three millimeter key. Accordingly, for large sizes (seven mm), a four mm tool is suitable.

The main area of use of Euroscrews is the assembly of furniture structures.

The most popular euroscrew is 6.4 mm. A drill suitable for it is 4.5 (5) millimeters. Also in demand are tools with a diameter of 7 (or 4.5) millimeters - a confirmatory drill.

Does not destroy mounting holes, thus interior items can be assembled and disassembled.

The drill design consists of the following elements:

- the part directed under the screw thread;

- element for the smooth segment of the described screw;

- area intended for processing holes.

The disadvantages of Euroscrews include the fact that they are not hidden fasteners.

Important. The most popular European classification is: HSS 7×70 and further - ...7×50, 6.3×50, 5×50 (parts made of tool steel).

Types of furniture joints

To assemble furniture, two types of fastening can be used:

- furniture screws;

- confirmations.

Confirmat is one of the varieties of furniture screws; it is also called a screw tie, euroscrew and euroscrew.

The self-tapping screw has a sharp end and a small thread pitch, while the confirmat has a wider pitch and a larger rod diameter. The first type is most often used when assembling interior items made of solid wood, plain and laminated chipboard, and MDF.

This type of fastener, known as a self-tapping screw, is a type of metal screw with a screw thread and a pointed or flat end.

Confirmat has recently become more widely used; it differs from a self-tapping screw primarily by its expansion after the end of the thread when moving to the part with the fastening head. In this simple way, a higher quality screed is achieved.

Elements such as furniture confirmations are in considerable demand due to the incredible precision of their fit and ease of use.

While a self-tapping screw can be screwed into a panel with a regular screwdriver without pre-prepared holes, this cannot be done with a confirmat.

To install it, you will need a hex wrench or a drill with a special attachment.

Universal screws

Furniture screws allow you to obtain an acceptable quality of screed and an accurate connection, but when working with this type you should not make mistakes. A slight misalignment when fixing such fasteners - and both fastened elements can be damaged.

Self-tapping screws do not withstand repeated unscrewing from the same hole, so if you make a mistake at the preparation stage, you will have to drill out the space for the fastening element again.

The head of the element has a notch (straight, cross or polygonal) for twisting it into the fabric.

Also, most often the diameter of the self-tapping screw is inferior to the confirmat, so an equally reliable and durable tightening of the parts together is not achieved.

To quickly connect parts of a cabinet or other item, use a screwdriver for elements with a sharp end.

Depending on the material, the screw can be metallic, black or golden. Thanks to this, such fasteners can be easily masked without additional elements, only due to their own color.

Self-tapping screws are used to fasten parts without prepared holes or with them. Due to the thread, the screw is easily screwed into a wooden panel or chipboard.

Confirmations

As already mentioned, confirmats are able to provide higher quality screeds. A rather significant disadvantage of this type of fastener is that it cannot be used with material of shallow depth. It is this factor that limits the use of confirmat, but in most cases they are used for cabinets, tables, sets and countless other types of interior items.

Confirmats allow you to fasten together several parts made of natural wood.

Note! If you plan to use fasteners in aggressive conditions, especially high humidity, the confirmat must have anti-corrosion protection.

For its production, exclusively high-quality carbon steel is used.

Has an anti-corrosion coating based on zinc, nickel or brass. The shape of the confirmatory head is selected according to individual preferences. The only caveat is that if you plan to cover the surface of the cap, you should select elements that match its shape.

Scope of application

Carpentry, and more specifically working with furniture, is the main area of use of products. But in woodworking there are also several vectors where it is possible to use products:

- furniture industry (both in large production volumes and small workshop assemblies);

- production of various items by folk craftsmen;

- repair of various items;

- installation of wood products (and other materials), etc.

Fasteners are made from high quality materials, often carbon steel.

Note. The products have been in use for more than twenty years, and remain at the early stages of popularity in the market. This indicates the success of this project.

Drilling holes for confirmations

Such connecting elements are used in various fields of activity, as they are compatible with many working materials. But before screwing them in, it is necessary to drill holes of a certain diameter.

They are coated to prevent corrosion.

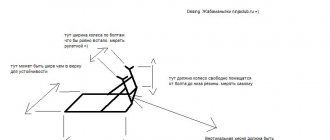

In practice, the drilling itself occurs as follows: an opening is made in the thickness of one product, in the end of another workpiece, and subsequently they are fastened together. The diameter of the holes has stepped transitions - this is due to the design of the fasteners. Since there is a thickened cone under the hat, the size of the hole should increase there and decrease along the thread itself.

For each of them, drills of different diameters are selected.

The work process can be divided into several ways:

- Three stages. An opening is made in two objects for a certain length of a European screw. (when drilling, the threaded diameter is not taken into account, only hollow elements and curls make their way into the product themselves). The second drilling is to fit the size of the cone under the cap. Working with a countersink to deepen the head.

- Working with a cutter (confirm drill). With this method, there is no need to work in several stages; the design of the equipment itself is of a stepped type. Going through the drill once is enough. This type of work is precise; there will be no deviations to the side. This is one of the common methods for installing screws.

A special drill designed specifically for the Euroscrew comes to the rescue.

Additional Information. Any displacement during work carries a risk to your safety and destroys the sample. It is necessary to use clamps when drilling. A well-known clamping equipment is the angle clamp.

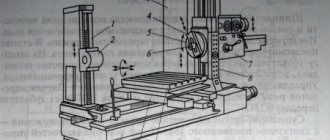

Necessary tool

If a person plans to start working with these clamps, you need to stock up on the following tools:

- roulette;

- pencil;

- awl;

- bat;

- screwdriver, various drills;

- and of course, Euroscrews.

Hole depth and width

The most popular product is size 6.4 (diameter with thread, and without it - 4.4 mm) by fifty. Conclusion: the normal depth with such a screw is fifty millimeters, and the width is four and a half or five.

It is screwed in with pre-drilled holes.

If you make it a little larger in size, the fastener will not cope well with fixation; if the hole is narrowed, the part may split the sample.

Important. It is best to use a confirmed drill - 4.5 mm. (universal products).

Marking drilling locations

The preparatory stage is no less important than the work itself. First you need to correctly mark the surface where the drilling will be done. Two measurements are taken on the end piece: height (varies from five to ten centimeters), and measurement from the edge of the workpiece (about eight mm).

Before installing the fastener, you must make the appropriate markings.

On another object on the facade, a point of contact is drawn. The measurements are virtually identical to the first option.

Any craftsman must clearly mark the surface of products - this will make it possible to avoid mismatch of parts during assembly.

If all stages of the work are done correctly, connecting parts in this way will be the most reliable, durable and at the same time convenient.

Note. In practice, craftsmen recommend making a through opening in the first object, and using the drill itself to mark a point in the second (attaching two parts).

Drilling into the layer of a part

The first thing you need to do is make a hole eight millimeters (from the edge). Place a piece of old board under the sample. Then, using a drill, holding the drill perpendicular to the ground, we make a through opening.

Before making a through hole, place a piece of unnecessary chipboard under the part, this will prevent chips from appearing on the back side.

Drilling at the end of a part

Face drilling means that the drill must be placed in a perpendicular position to the end of the object. This way the equipment is properly fixed and the sample will not be damaged. Try working in several passes, while knocking out the chips.

The main rule is that when drilling at the end, the drill must be strictly perpendicular to the end of the part.

Drilling in two parts at the same time

We fix the product tightly (in a vice) and drill. This is the most accurate method, and a noticeable saving of time when working.

This option is considered the most accurate and, moreover, the fastest.

Choosing the right drill

How to choose the perfect drill for the job?

- Always select the exact dimensions of the part.

- When purchasing, you need to pay attention to the material (what kind of steel).

- Take the time to read reviews about the manufacturer. The quality of work depends on this.

- Particular attention must be paid to price. A quality product cannot cost a penny.

If the master has been working in the field of furniture production for a long time, practical experience will tell you which product to purchase.

For drilling, use a confirmat drill with a diameter of 4.5 mm, which is equipped with an additional head for drilling an enlarged hole for the neck of the confirmat, which also makes a countersink for its head.

Additional Information. There are several secrets when choosing: the lower the roughness, the better (feather), the dimensions of the cone (the part under the cap) should be identical to the landing segment, the supporting part for the countersink is forty-five degrees and a measured transition, etc.

Confirmat is a popular product today, especially for working with furniture samples. When assembling various items, it is recommended to use high-quality equipment. With a little patience, any item will come together pretty quickly after a few practice sessions.

Using this fastening method, you can assemble and install furniture yourself.