Cutting, cleaning and grinding are the three main functions of an angle grinder. The technology involves performing work while holding the tool in your hands. To reduce the load, stationary devices for various purposes are made on the basis of the grinder. They are obtained through design refinement and modernization, which significantly expands the functionality of the tool. Special devices for grinders and attachments are sold in retail chains, but most craftsmen perform them themselves. They allow the tool, which is in demand in production and at home, to be used to perform diverse operations on materials for various purposes during installation and construction work. The modified design can work as a cutting, trimming, milling, sharpening, grinding machine, wall chaser, pendulum saw, miter box, etc. To manufacture the device, you need to purchase the necessary attachments, components and fasteners from the retail chain. You can make a device with your own hands if you set such a goal and understand the intricacies of the design that you plan to create. This will expand the capabilities of the grinder, make it easier to work with the tool, reducing the load on your hands, and make the process of performing many operations more productive. On the Internet you can find a large number of drawings, photographs and videos that will help you realize your plans. It all depends on the capabilities that a person has, his thinking and flight of fancy. Let's consider the nuances of converting an angle grinder into the machines, devices and devices presented below.

Cutting machine

A cutting machine is used for cutting and cutting metal and profiles, obtaining blanks of the same size, cutting to a certain depth, cutting ceramic tiles, etc. You can purchase a ready-made design in a retail chain, which costs a lot of money. You can make a device that will perform the same functions at home and small workshops from an angle grinder with a power of 0.9 kW or more.

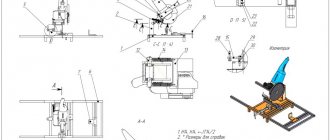

The figure shows that to manufacture such a device, you only need to think through the design and reliable fixation of the angle grinder. To do this, you must first determine the dimensions and secure them at 2-3 points so that the tool does not move during the cutting process. And this is very important.

The grinder can also be located at the bottom of the table top. In this case, it will not only cut different materials into pieces, but also work as a circular saw.

Types of devices, their advantages and disadvantages

There are two types of designs of cutting machines, differing in the location of the grinder, which can be made at home.

The first installation is a frame with an angle grinder rigidly fixed underneath it. Only the cutting disc is visible on the working surface, which fits freely into the table slot. Cutting a metal profile or sheet in this case is completely identical to cutting wooden blanks using a circular saw. Despite the very simple design, this scheme is not particularly popular. Those who have made such a device note that it is inconvenient to use due to the need to move the workpiece. This significantly reduces the accuracy of the work and makes the process unsafe. The only advantage of a machine with a bottom angle grinder is the ability to quickly cut thin metal sheets.

A cutting machine with a lower angle grinder can be used both for cutting metal and as a circular saw

The second scheme, in which the part remains stationary and the cutting wheel itself moves, is more convenient. The so-called pendulum saw, placed above the tabletop, allows you to cut the workpiece exactly at the required angle, and it becomes possible to make the required number of parts of the same type. Due to the location of the grinder on top, cutting workpieces does not require effort, and operation of the unit becomes simple and safe. The undoubted advantages of the design include the ability to quickly dismantle the grinder for traditional use. As for the disadvantages of this method, the weak link can be considered the hinge joint, which complicates the design of the machine.

A machine for cutting metal with an upper angle grinder has a more convenient design and makes it possible to cut workpieces at the desired angle

Pendulum saw

The accuracy of high-speed cutting of various materials and at the required angle is ensured by a special device called a pendulum saw. At home, it can be made from an angle grinder with a power of 0.9 to 2.5 kW, having thought through the design, which directly depends on the angle grinder model. All that needs to be done is to make a metal platform with a slot, an angle, a pendulum and securely attach the tool itself to it. To do this, you need to use the holes for installing the handle on the grinder itself. To suit their size, it is necessary to make a bracket, strips, pins and bearings, with the help of which to secure the angle grinder in the working position. The angle grinder device is ready.

Required tools and materials

When starting to manufacture a cutting machine, you should understand that the accuracy of its operation is directly related to the stability of the structure.

Therefore, the choice of a material of a certain thickness is dictated not so much by the requirements for the strength of the body, but by the need for its rigidity. Before you start working, you need to prepare:

- square profile pipe (25x25x2.5 mm);

- profile pipe “rectangle” (40x20x2.5 mm);

- metal sheet 4–5 mm thick;

- ball bearings No. 202, 203 or 204 – 2 pcs.;

- calibrated rod with a thickness equal to the diameter of the hole in the inner race of the bearing (up to 100 mm);

- rod with a diameter of 8–10 mm;

- metal tire (20x4 mm);

- bolts and nuts with M8 or M thread.

Tools you will need:

- Angle Grinder;

- drill or drilling machine, set of drills;

- a set of dies for cutting metric threads;

- open-end wrenches;

- welding machine.

To make a machine, it is better to choose an angle grinder from a well-known manufacturer.

The main component of the cutting machine is the angle grinder. It is not recommended to use a “small” grinder designed for cutting discs with a diameter of up to 125 mm and a power of up to 500–600 W. Remember that the larger the diameter of the cutting wheel, the more versatile and reliable the machine will be.

The careful selection of power tools is also due to the wide variety of angle grinder designs available on the market. Since such equipment is not unified, the cutting machine is built for a specific model and size of angle grinder. If the equipment is unreliable, then if it fails, it will be difficult to install another angle grinder in its place without the need to rework the mounts and pendulum. That is why it is better to choose products from trusted manufacturers - Makita, Bosch and so on.

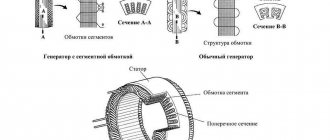

Milling machine

In a milling machine, the main movement is made by the cutter, which is used to process shaped and flat surfaces on workpieces made of different materials. A machine using a grinder can be made in the following options:

- with a movable angle grinder. In this case, the tool is securely attached in a vertical plane to a special frame, which allows you to move the grinder relative to the milled workpiece, which is fixed motionless;

- with a rigidly fixed angle grinder. With this design, the workpiece moves in the desired direction, and the grinder is motionless.

In both cases, you need to think through the design, purchase everything necessary for its assembly, and also buy a collet-type cutter holder or make it yourself from a hexagon. The picture shows a simple, quickly manufactured design of a milling cutter made from an angle grinder.

Machine for porcelain tiles

Cutting porcelain tiles with a grinder requires skills and knowledge of the structural features of the material, since it is difficult to draw an even line while holding the tool in your hands. The work requires a special approach: it is necessary to ensure movement without deviations and control the depth of the cut during the operation. Any violation leads to damage to the material, the appearance of chips and unevenness. This leads to additional costs, and porcelain tiles are not cheap. In order for the grinder to move without deviations, you can make a special device with guides. The figure shows a manufacturing option for such a device, where the main material is plywood and fasteners.

Bench Grinder

The stationary grinding machine can be made from an angle grinder in two versions.

In the first case, the grinder is fixed motionless on a special device. And another manufacturing option is shown in the figure. In the second case, it is a belt-type grinding machine. It is shown in the picture. Here it is necessary to consider the tensioning mechanisms (on 2 or 3 rollers) and fastening to the tabletop.

Miter box from a grinder

A miter box is a device used to cut tiles, metal blanks, baguettes, plinths and other linear materials at a given angle. If you install a disk with holes in a rotatable design with locks under the grinder in the workbench or table top on a metal axis, you will get a device for high-quality cutting of workpieces at the desired angle. The rotating part is a guide for the grinder's cutting disc. The material is clamped motionlessly, and the angle at which cutting must be performed is recorded using marks.

Work technology

triangle shaped cutout

Next, six holes should be drilled in the plate structure. The diameter of each of them should be 4 mm. Subsequently, it is in these holes that the self-tapping screws will be installed. With their help it will be possible to fix the handle, corners and timber. All holes must have special recesses for screw heads.

To securely fasten the beam handle, a few self-tapping screws are enough. The fasteners used during this work must have dimensions of 3x35 mm. This will result in an L-shaped part.

After this, all the elements together with the plate are assembled into a single structure. The created tool fixture must be secured using 3x20 mm self-tapping screws.

So, the basis of the future structure has been made. Next, you will need to install metal corners. You should have several of these items available. They must have the following dimensions:

- 75x30x55 mm;

- 45x60x60 mm.

Please note that the first corner must be bent to 60 degrees. If you don’t do this, then you won’t be able to achieve your main goal - to attach the manufactured structure to the angle grinder.

When the installation of the metal corners is completed, the tool itself is attached directly to them.

To connect the tool and structural elements, use a separate handle on one side, and bolts with nuts on the other side. The latter are necessary so that during work the screw of the structure does not unscrew.

If desired, you can refuse to install the nut on the handle, since it will be held by the hand of the master during work. At this point, the work on creating a cutting structure can be considered complete.

Wall chaser from an angle grinder

Using an angle grinder with a power of 1.2 kW or more, it is not difficult to make a device for making grooves (grooves) in the surfaces of walls, floors and ceilings. The main task is to install two disks on the shaft. After all, they are the ones who cut a groove of the same width and depth for laying cables, wires, and pipes of small diameter. The size of the original angle grinder shaft does not always allow them to be installed there, and even at a certain distance. In this case, you have to make bushings in order to secure the discs to them to the required size using spacers of different widths. Since the protective casing of the angle grinder is designed for one disc, there is a need to manufacture a new protective casing that would protect the worker during the operation. It often becomes necessary to equip such a protective casing with a pipe for removing dust and small waste to the vacuum cleaner. More advanced craftsmen install angle grinders on special rollers (from 2 to 4) in order to reduce the load on their hands while moving and move it effortlessly across the surface. It would not be superfluous to have a unit for adjusting the immersion of disks into the surface, the design of which also needs to be thought through.

When working with tools based on an angle grinder, it is necessary to observe safety precautions. Under certain circumstances, they can harm human health, cause injury and even death. Before starting work you must:

- wear protective clothing and personal protective equipment (mittens, safety glasses, dust mask, earplugs);

- check the reliability of fastening of all components of the device;

- check the integrity of the electrical cord and plug;

- make sure that the disk of the required diameter is installed, without flaws and suitable for the work being performed;

- Check the operation of the device at idle speed.

During the operation, you must adhere to the following rules:

- make sure that the electrical cord is not twisted or pulled;

- do not remove waste while the grinder is working with your hands;

- the material to be processed must be securely fixed if this is provided for by the technology for performing the work;

- do not work with the device if there are signs of its malfunction;

- Replace the disk with a new one or a failed one only after its rotation has stopped.

Upon completion of work, the device must be disconnected from the electrical network.

In the video you can clearly see devices where the angle grinder is a mandatory element of the design. They will help home craftsmen facilitate the performance of many operations, increase the quality and productivity of labor, and expand the capabilities of the grinder.

Anyone who has changed the functionality of an angle grinder or made accessories for it, please share your experience in the comments to the text.

Features of using an angle grinder

When performing construction and installation work, a large number of different tools are used. The most commonly used grinder is the grinder. The main task for which it is used: metal cutting ;

processing of building materials. If you also use attachments with this tool, you can expand the number of options for its use. In particular, using this tool with attachments, you can perform high-quality grinding of the base of workpieces. They will be cleared of foreign inclusions. Attachments for grinders can be purchased at the store. But if you do not want to pay money, then you can make them yourself.

In some cases, this tool is used as a wall chaser. With its help, grooves are created for laying pipes and electrical wires. To use an angle grinder in this capacity, you will have to perform some manipulations and increase the standard width of the protective casing. In addition, you will need to make a support plate.

This tool can be used with one disk or several at once. If the grinder is used with two disks, then it is necessary to make some changes to the attachment point of this tool. After this, the grinder can be used in standard mode.

It often happens that during repair work there is a need to clean the base of parts that are difficult to access. In such cases, craftsmen most often resort to using a homemade device for an angle grinder in the form of a special attachment, thanks to which a small disk can be carried beyond the dimensions of the angle grinder.

In this case, the rotation will be transmitted using a special belt drive from the main drive. Using this design, materials cannot be cut. However, scale can be removed from the surface of materials without any problems. It often occurs on the surface of welds.

Currently, the market offers a large number of attachments for tools such as an angle grinder. Their use allows you to significantly expand the options for using this tool. If we talk about the most commonly used attachments for grinders, we can highlight the following:

- a device for sanding the base and removing the paint layer from the surfaces of materials;

- beds;

- protractors.

Materials and tools to make attachments for an angle grinder

When the need arises to use an angle grinder for specific tasks, then in this case many craftsmen opt for ready-made attachments.

They can be purchased without any problems at a hardware store. The cost of the devices is not very high, so everyone can afford them. There are also no difficulties in finding these attachments. However, despite all this, many people still decide to make attachments for an angle grinder with their own hands.

If you decide to make attachments for this tool yourself, then before you begin, you need to prepare the following tools:

- An electric drill, it is advisable to purchase a set of drills in addition to it;

- It is advisable to choose discs with a diameter of 125 mm.

- Wooden bars.

- Metal corner.

- Duralumin steel plate.

- Self-tapping screws.