What is a capacitor

A capacitor is an electrical element that is capable of storing a certain electrical charge. The main parameter of the element is the capacitance, which is calculated in farads. 1 farad is quite a large value. Modern capacitors have the following capacitance designations:

- picofarad is denoted pF or pF;

- nanofarad is denoted nF or nF;

- microfarad is denoted mF or mF.

The principle of operation of the device is quite simple. The operation and delivery of a pulse differs only from the current in the circuit to which it is connected.

AC circuit

In an AC circuit, a capacitor is a resistance. It quickly accumulates a certain charge and gradually releases it. Accumulation and full release occurs during a change in the electric wave.

DC circuit

In a DC circuit, charge accumulates on the plates, increasing the potential difference across the plates. The potential difference increases to the voltage value. As soon as it becomes equal to the voltage, the common circuit is broken.

Calculation using formulas

Calculation of the nominal capacity of an element is required in 2 cases:

- Electronic equipment designers calculate the parameter when creating circuits.

- In the absence of capacitors of suitable power and capacity, craftsmen use element calculations to select from available parts.

RC circuits are calculated using the value of impedance - complex resistance (Z). Ra - current losses due to heating of circuit participants. Ri and Re — take into account the influence of inductance and capacitance of the elements. At the resistor terminals in the RC circuit, the voltage Uр is inversely proportional to Z.

Thermal resistance increases the potential across the load, and reactive resistance decreases. Operating a capacitor at frequencies above resonant frequencies, when the reactive component of the complex resistance increases, leads to voltage losses.

The resonance frequency is inversely proportional to the ability to accumulate charge. From the formula for determining Fр, they calculate what values of C (capacitor capacitance) are required for the operation of the circuit.

To calculate pulse circuits, the circuit time constant is used, which determines the effect of RC on the pulse structure. If the circuit resistance and capacitor charging time are known, the capacitance is calculated using the time constant formula. The truth of the result is influenced by the human factor.

Craftsmen use parallel and series connections of capacitors. The calculation formulas are the reverse of the formulas for resistors.

A series connection makes the capacitance smaller in the connection of elements; a parallel circuit adds up the values.

Types of capacitors

There are several types and types of capacitors. They are divided among themselves according to the following principle:

- Changing capacity. This change classifies electronic elements into constant, variable and interlinear.

- The dielectric material can be air, mica, Teflon, polycarbonate, or electrolyte.

- Installation. Based on the installation method, these radio components are divided into mounted and printed.

There are several types of capacitive devices, divided according to the principle of construction and performance:

- Ceramic. These elements are made of a disk with a conductor on both sides. Such printed parts have low operating voltage but high capacity.

- Film. Such capacitors have a film rolled into a roll inside the housing. A large charge and high operating voltage can be placed across all layers. The layers are made of foil with a dielectric on one side.

- Electrolytic. These devices are similar in structure to film devices. The difference is the dielectric material. For these printed elements, the dielectric is paper impregnated with electrolyte.

- Variables. These are devices for precise adjustment of instruments. The capacitance is changed mechanically.

- Interlinear. These are elements of one-time setting of parameters in devices. Such settings are performed only at manufacturing plants.

- Launchers. These capacitors are used to start electric motors. They operate on an alternating current circuit of 220 volts.

Defining parameters

It’s very easy to check the element’s functionality yourself. Modern multimeters and testers have a corresponding function for this. The main parameter during testing will be the compliance of the declared and actual capacity, as well as the throughput of the radio component. The test can be carried out both on the board itself and by removing the part from the printed circuit board.

Capacity check

Often capacitors, especially old ones, have unclear capacitance markings on their housings. In order to find out the capacity of the working device, you need to use a multimeter that has a capacity measurement function. Modern multimeters have a measuring range from 20 nF to 200 mF. To determine the capacitance of an unmarked capacitor, you will have to test it in 5 modes: 20 nF, 200 nF, 2 mF, 20 mF, 200 mF. You will also have to take polarity into account if the element is polar. Before measurement, it is necessary to remove the capacitor from the circuit.

- The device switches to capacity test mode. Be sure to switch the probes to the cX socket.

- The element under test must be discharged before testing. This is done by shorting both ends.

- Both probes are connected to the terminals.

Ballistic galvanometer method.

and then

Rice. 23. Circuit for measuring capacitance with an ammeter, voltmeter and wattmeter. Rice. 24. Circuit for measuring capacitance with a ballistic galvanometer. If the switch P\ and Yar (Fig. 24) is set to position I, then the model capacitor C0 will receive a charge Qv = UiC0, where Ui is the voltmeter reading. If you move the switch P-l to position 2, the capacitor Co will discharge and a charge Q0=U1C0=C0ai=C^uu will pass through the ballistic galvanometer where ai is the deflection angle of the moving part of the galvanometer. Ballistic constant of the galvanometer If, at position 1 of switch P2 and position 2 of switch P1, the voltage is raised to a value of Uz, then the capacitor under test will receive a charge. If you move the blade of switch P2 from position 1 to position 2, the capacitor will be discharged through the galvanometer, i.e. a charge will pass through it and its moving part will be thrown at an angle a- Fig. 25. Schemes for measuring the capacitance of three-phase capacitors. a - when connecting the phases with a triangle; b - when connecting the phases with a star (in both diagrams the arrows are directed towards the measuring instruments). The measured capacitance is found according to the formula When measuring by this method, significant errors are possible due to residual charge (incomplete charge of the capacitor). Capacitor capacitance measurement circuits. Measuring the capacitance of single-phase capacitors using any of the above methods gives a direct value of the capacitance of the capacitor without any recalculation. The resulting measurements of the capacitance of three-phase capacitors require appropriate recalculation to move to the phase capacitance. In Fig. Figure 25 shows diagrams for measuring the capacitance of three-phase capacitors. According to the diagram in Fig. 25, but the capacitance Ci-zs is measured (when the phases are connected by a triangle) between terminals I and terminals 2 and 3 connected together, and according to the diagram in Fig. 25.6 (when phases are connected by a star) - capacitance Ci_2 between terminals I and 2. For each three-phase capacitor, it is necessary to make three measurements between different combinations of terminals, after which the capacitance of each phase of the capacitor can be found using the formulas: b) for a three-phase capacitor connected by a star , a) for a three-phase capacitor connected by a triangle, In table. 3 shows the procedure for measuring the capacitance of three-phase capacitors connected in a triangle. Table 3 Procedure for measuring the capacitance of three-phase capacitors connected in a triangle

| Short-circuit the terminals | Measure the capacitance between the terminals | Designation of measured capacitance |

| 2 to 3 | 1 - (2 and 3) | |

| 1 and 3 | 2— (I and 3) | Cs_13 |

| 1 to 2 | 3 - U and 2) | From 3-12 |

It follows from the table that when measuring, you should alternately connect the leads in pairs and measure the capacitance between them and the third terminal. When the capacitor unit is automatically disconnected again due to the action of a relay or a blown fuse, turning on the capacitors is permitted only after identifying and eliminating the reasons that caused the repeated disconnection, with a mandatory check of the capacitance of each capacitor. When capacitors are connected directly to the terminals of asynchronous motors, the latter may self-excite when disconnected from the network and increase the voltage above normal. To avoid this, it is recommended to select a capacitor value such that the capacitive current is less than the magnetizing current of the motor. After the voltage test, it is recommended to measure the capacitance of capacitors having sections connected in series to check the absence of partial breakdown. Before installation in the frame, it is recommended to select single-phase capacitors so that the capacitance across the phases is uniform (with an accuracy of 5%). Capacitors in the frame should be positioned so that the markings are visible to maintenance personnel.

- Back

- Forward

Checking with a multimeter

To determine polarity using a multimeter, you must:

- Completely discharge the part by short-circuiting its leads.

- Connect the resistor to the “+” terminal of the multimeter.

- Connect the second end of the resistor to the terminal of the 12 volt power supply.

- Connect the resistor to the terminal of the capacitor.

- Connect the negative wire of the power supply to the 2nd terminal of the capacitor.

If the multimeter does not show the presence of current in the circuit, then the polarity of the element is correct. The “+” wire of the power supply was correctly connected to the “+” of the capacitor. If the multimeter shows the presence of current, then the polarity was not observed in the circuit.

Measuring circuit

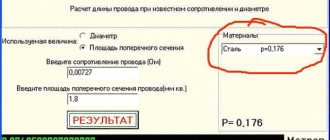

To determine the capacitance of an unknown capacitor, you should include it in a circuit consisting of a resistor and a power source. The input voltage is selected slightly lower than the rated voltage of the capacitor; if it is unknown, 10–12 volts will be sufficient. You also need a stopwatch. To eliminate the influence of the internal resistance of the power source on the circuit parameters, a switch must be installed at the input.

The resistance is selected experimentally, more for the convenience of timing, in most cases within five to ten kiloohms. The voltage across the capacitor is monitored with a voltmeter. Time is counted from the moment the power is turned on - when charging and turning off, if the discharge is controlled. Having known resistance and time values, the capacitance is calculated using the formula t = RC.

It is more convenient to count the discharge time of the capacitor and mark the values at 90% or 95% of the initial voltage; in this case, the calculation is carried out using the formulas 2.2t = 2.2RC and 3t = 3RC. In this way, you can find out the capacitance of electrolytic capacitors with an accuracy determined by the measurement errors of time, voltage and resistance. Using it for ceramic and other small capacitances, using a 50 Hz transformer and calculating capacitance, gives an unpredictable error.

Checking the health of capacitors

Modern multimeters are capable of measuring and checking the performance of any radio components. But this device is not always at hand. You can check the capacitor using a tester.

Multimeter

If the multimeter has a special function for measuring capacitance, then it can be used to test any type of device. Ceramic, electrolytic, and starting radio components have the same operating principle, which means that serviceability checks can be carried out in the same way.

- Unsolder the part under test from the board and discharge it by closing the contacts.

- Set the multimeter to the “cX” capacitance detection mode.

- Switch the device to determine the maximum capacity range.

- Connect the probes to the legs or terminals of the capacitor.

- The multimeter will show the capacitance value. If one or more “0”s are displayed before the value, the device switches to a lower parameter.

Polarized capacitors (if the polarity is correct) show gradually increasing values from “0” to “1”. If the display shows “1” without changes, then the capacitor is not working. If the readings are “0”, then the element is closed internally.

Non-polar capacitors are checked by setting the multimeter to 2 MΩ. If the readings are higher than this value, then the device is working properly. Values less than 2 MΩ indicate a malfunction.

Tester

You can check the capacitor using a tester only to determine its general serviceability. Capacitance loss or voltage variation cannot be determined.

- To check, you need to set the tester to resistance mode.

- Unsolder and discharge the element being tested.

- If the radio component is polar, you need to connect the tester terminals to the terminals according to the polarity.

- Polar capacitors (having a large capacity) will charge for a few seconds, non-polar ones will show their value immediately.

TECHNICAL SPECIFICATIONS Ftike A6243L

| Key Features of the ESR Meter | |

| Capacitance measurement range | 2 nF, 20 nF, 200 nF, 2 µF, 20 µF in 1 pF steps, accuracy ± (1.5% + 5d) 20 µF, accuracy ± (2.0% + 5d) |

| Inductance measurement range | 2 mH, 20 mH, 200 mH in 1 μH steps, accuracy ± (2.0% + 5d) 2 H, 20 H ± (5.0% + 5d) |

| Components tested | polar and non-polar capacitors; inductors; chokes; |

| Hold data function | There is |

| General characteristics | |

| Display | LCD 1999 digits, 44 mm x 28 mm |

| Nutrition | DC 9 V, battery 6F22 "Krona" |

| Dimensions | 140 mm x 70.6 mm x 31 mm |

| Device weight | 200 g |

| Equipment | capacitor esr meter Ftike A6243L – 1 pc 6F22 “Krona” battery – 2 pcs probes with alligator clips – 1 pc |

Testing without soldering

Testing the capacitor directly on the printed circuit board is very problematic. First, the faulty electrical appliance must be completely de-energized. It is also necessary to achieve the discharge of all capacitive elements in the circuit. Testing without soldering can show the resistance values of elements soldered nearby. But the check can still be carried out using a tweezer indicator.

First way

The first method is the simplest. The subject is checked by a tester and called with a multimeter. The device is put into resistance testing mode. It is also worth considering polarity. The multimeter probes are connected to the terminals of the capacitor and the resistance is measured. It is worth considering that the obtained value has no practical use, since it may be an indication of another element. In this way, you can check the capacitive part for a short circuit. If the values on the display begin to increase gradually, then the printed part is being charged by the tester and is in good condition.

Second way

The second method requires soldering a capacitor with the same values into the circuit next to the element under test. Soldering must be done in parallel. Both elements are measured on a de-energized board.

Important! Without soldering, you can only test parts that are part of low-voltage circuits. For high-voltage circuits, such testing is prohibited.

Third way

A situation often arises when there are several capacitors on the board, and it is very difficult to determine which one is faulty. Soldering each one is quite labor-intensive; they often fail when heated. In order to check without desoldering, it is necessary to measure the output voltage. It must be the same as indicated on the element body. If there is no voltage, then the part is broken or shorted. If the voltage is less than the optimal value, the element has lost part of its capacity.

Without desoldering, you can determine the faulty element visually. The capacitor may simply burst, have damage on the housing, carbon deposits or swelling.

↑ Graduation of scales

As I already said, the appearance of scales and measuring ranges can vary widely.

Here the main determining elements are the sensitivity of the measuring head, the resistance of resistors R10, R12 and R11, R13. Even more combinations may appear if, in addition to this, you experiment with the resistances of the resistors of the measuring circuit (R5, R6) and the transformation ratio Tr1 (within reasonable limits, of course). Before calibration, instead of resistors R10, R12 (R11, R13), variable resistors with values close to the expected values are installed, and the resistor slider R14 is set to the middle position. Then a resistor with a resistance corresponding to the end of the measuring range is connected to the measuring probes, and resistor R10 (R11) sets the arrow closer to the left side of the scale, where the last point of the measuring range will be. For obvious reasons, it cannot be in place of the mechanical zero of the microammeter. Next, short-circuit the probes and use resistor R12 (R13) to set the arrow to the far right mark of the scale. These operations are repeated several times until the arrow accurately positions itself at the start and end points of the range without our help. Now that we have “found” the boundaries of the measuring range, we measure the resistance of the corresponding variable resistors and solder constant ones in their place.

We find the intermediate points of the scale by connecting resistors of the corresponding resistances to the probes. To simplify the process, it is permissible for these purposes to use a resistance store with bifilar winding of coils. Subsequently, I checked the assembled device with the P33 magazine - the deviations in the readings turned out to be insignificant. To remember the location of intermediate points, it is not necessary to mark the scale with a pencil; it is enough to write down the numerical values obtained according to the factory scale on a piece of paper, then put the marks on the corresponding place of the template in the program.

Attached are my scale options made in Sprint. The file already contains a factory scale template, which can be enabled by checking the “display” box. The scale obtained in this way is glued to the factory scale using an adhesive stationery pencil.

DIY device

To test capacitors, you can assemble your own device. It will determine the capacity no worse than professional equipment. Assembling such a device with your own hands is quite simple. Using this device you can check the performance of any capacitive elements and even SMD.

The device will require the following parts:

- A microcircuit from the 555 series, for example, NE555 or the domestic analogue KR1006VI1. This microcircuit is a time timer, but in the device it will play the role of a generator.

- Resistors: R1 and R5 for 6.8 K. R12 for 12 K. R10 for 100 K. R2 and R6 for 51 K. R13 and R11 for 100 K. R3 and R7 for 68 K. R14 for 120 K. R4 and R8 for 510 K. R15 at 13 K.

- Capacitors: C1 with a capacity of 47nf, C2 with a capacity of 470pf, C3 with a capacity of 0.47 mkF.

- VD1 is suitable for any low power diode, for example, SOD 232.

- SA1 is any 5 position switch.

- Multimeter X1.

- Battery or power supply up to 12 volts.

Basic capacitor malfunctions

Capacitive elements play a large role in the circuit diagram of any device. Their main function is to charge a certain amount of current and pulse discharge into the circuit. The main malfunctions of capacitors include:

- Normal breakdown. A breakdown can be caused by an increase in operating voltage. Repair requires not only replacing the element, but also determining the cause of the high voltage.

- Internal break. If a radio component breaks, it loses its capacity, since both of its outputs become isolated. A break can occur when the device is dropped or the element itself is poorly assembled.

- A leak. This problem is due to the loss of some capacity. The smaller the permissible and optimal capacity, the smaller the charge size.

Useful tips

Testing a capacitor, especially a high voltage capacitor and a starting capacitor, involves some risk.

Before checking you should consider:

- If the electrical device is energized or has been disconnected for a short time, do not touch the printed circuit board in the area of the capacitors. The device will discharge upon contact and result in an electric shock.

- High-voltage capacitors must not be discharged with metal tools. A spark may occur and the uninsulated part of the object may receive an electric shock.

- The maximum test value for modern multimeters is 200 µF. It will not be possible to check a larger value.

- Elements with a capacity of less than 0.25 µF can only be tested for short circuits.

- When testing polar devices, it is important to identify the poles of the element. Connecting a tester with a change in poles can lead to failure of the capacitor itself.

When repairing electrical appliances of any power, safety precautions should be strictly observed. Checking any radio components can only be done with the device de-energized.