Pitting (pitting) corrosion is a type of corrosion destruction that exclusively affects passive metals and alloys. Pitting corrosion is observed in nickel, zirconium, chromium-nickel, chromium, aluminum alloys, etc.

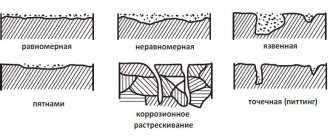

With pitting (spot) corrosion, only certain areas of the surface are destroyed, on which deep lesions are formed - pitting (spot ulcers).

Pitting corrosion is observed when a metal or alloy is exposed not only to passivators (the surface is brought into a passive state, for example, an oxidizer), but also to activator ions (Cl-, Br-, J-). Pitting (pitting) corrosion occurs actively in sea water, a mixture of nitric and hydrochloric acids, ferric chloride solutions, and other aggressive environments.

The pittings are classified according to their sizes:

— micropittings (up to 0.1 mm);

— pittings (0.1 – 1mm);

- spot, ulcer (more than 1 mm).

Pitting can be closed, open or superficial.

Open pitting is clearly visible on the surface with the naked eye or under slight magnification. If there are a lot of open pittings, corrosion becomes continuous. In open pitting, the bottom of the pore acts as an anode, and the passive film acts as a cathode.

Closed pitting is a very dangerous type of corrosion destruction, because such damage cannot be seen with your own eyes; their presence can only be determined using special instruments. Closed pitting develops deep into the metal or alloy. Closed pitting can cause breakdown even in stainless steels.

Superficial pitting is a type of pitting that develops more in width than in depth, forming potholes on the surface of the metal or alloy.

External manifestation of pitting corrosion

There are various forms of destruction of metals. Pitting or pitting is one of these forms, which is localized defects on the surface of a metal. Most often, pitting corrosion occurs on stainless steel, aluminum and its alloys, titanium, nickel and occurs when the passive state of the material is partially disrupted.

Pitting is quite dangerous for metal, despite the small size of its manifestations. The rest of the surface continues to remain in normal external condition, and only in some places white or reddish small dots, ulcers, and small stripes appear. Their appearance is deceptive and their depth is usually considerable, yet the user rarely notices them at an early stage of development.

Reasons that initiate pitting

Often the prerequisite for the appearance of pitting corrosion is a violation of metal production technology. For example, if casting rules are not followed, microimpurities and inclusions appear in steel that change the normal structure. Low-quality metal may be too porous or residual scale may appear in it - this also contributes to the occurrence of pitting.

Pitting also occurs when steel and other metals are used in an aggressive environment: solutions containing oxidizing agents and activating anions (hydrochloric, nitric acids, sea water, chloride compounds).

Other causes of pitting corrosion are:

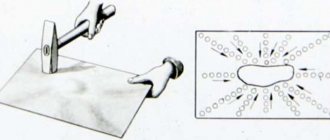

- mechanical impact leading to chips, scratches and causing damage to the outer protective film;

- excessive internal stress of the metal;

- operation of the product at high temperatures.

Pitting corrosion is more likely to appear on rough stainless steel than on smooth, polished steel, so uneven surface texture is also considered a risk factor.

Selection of contacting metals

Between two different contacting metals (metal coatings), in the presence of moisture and air pollution, a galvanic couple arises, electrolysis begins, as a result of which the more negative metal (anode) is rapidly destroyed. Therefore, the choice of metal surfaces to be contacted is of great importance. When determining the possibility of using a current or another pair of contacting metals, the series of normal potentials of the metals are used. In this case, a normal potential difference of less than 0.5 V between two metals is often accepted as acceptable. This approach is fundamentally wrong for the following reasons. a) Normal potentials are determined by measuring the potential of metals at 25°C with respect to the standard hydrogen electrode they have when their ionic activity is in equilibrium with a solution of their own ions. Corroding electrodes, which are ultimately discussed when considering combinations of metals in relation to electrolytes, are naturally not in a state of equilibrium. b) Potential differences do not contribute to the complete identification of the corrosion behavior pattern, since kinetic inhibition has a decisive influence. Elze and Oelsner offer some practical series of stresses in condensate (water) and sea water. An air-saturated phthalate buffer solution with a pH value of 6 at 25°C and atmospheric pressure is used as condensate, and artificial seawater with a pH value of 7.5 at 25°C and atmospheric pressure is used as seawater. The values of electrode potentials in the indicated electrolytes are given in table. 12-7. According to the table. 12-7 in the normal series of stresses cadmium is more noble than iron, while steel in the practical series of stresses of metals in condensate and sea water is nobler than cadmium. Aluminum in the three voltage series indicated has very different potential values.

Table 12-7 Electrode potentials of some metals in various voltage series

Between copper and nickel, the difference in normal potentials is almost 600 mV, while in practical series their electrode potentials are close. In table 12-8 shows data on permissible metal vapors for tropical and tropical marine conditions, adopted for domestic electrical equipment. If it is necessary to bring pairs that are not allowed in the table into contact, you should either use intermediate coatings for contact, or separate the contacting surfaces with a layer of varnish, gaskets made of plastic or other electrical insulating materials (films made of fluoroplastic, lavsan, polyethylene, etc.). Polyvinyl chloride films should not be used, as when aging they release hydrochloric acid, which increases corrosion. Significantly slows down contact corrosion by tightly compressing the parts, which prevents moisture from penetrating between them. Contact corrosion was not observed, for example, in a humid environment with tight bolted connections of small parts, even if these parts were made of materials not recommended in Table. 12-8 for contact, since moist air did not pass between such parts. The corrosion process can be slowed down by painting the contacting surfaces with reliable paint coatings or lubricating the contacting metal surfaces. When using electrochemical series, the dimensions of the parts should be taken into account when assessing the danger of contact corrosion. If a small and large part are in contact, then the small one can be severely destroyed if its potential in the expected corrosive environment is more negative than the potential of the large one (i.e., if it is an anode). On the contrary, if a small part is the cathode and a large part is the anode, then significant destruction of neither of these parts may occur.

Features and development pattern of pitting corrosion

Pitting has a high flow rate. If you do not get rid of minor defects in time, the product may rust through. The higher the temperature at the location of the metal, the faster it will rust.

Pitting corrosion develops in three stages:

- The first stage is emergence. Typically occurs in areas where protection has been compromised, where the passive film on the metal surface has been torn, or where there is material heterogeneity. After oxygen is displaced by activator ions, the oxide layer is destroyed.

- The second is the growth of pitting. It obeys the laws of electrochemical reactions. Due to the dissolution of the oxide film, the anodic process intensifies at the site of pitting corrosion, while the normal surface becomes a cathode.

- The third is diffuse expansion. At this stage, the corrosion element moves deeper, and new rust spots may form nearby.

In some cases, pitting stops developing at the second stage and moves to the repassivation stage. This happens when the reaction shifts towards passivation, for example, when the acidity of the medium changes. If pitting corrosion has progressed to the stage of diffuse growth, it can no longer enter repassivation.

What factors determine the high resistance of stainless steel to corrosion?

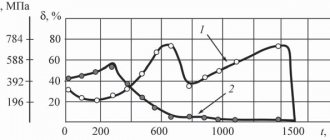

Stainless steels show significant anti-corrosion resistance due to their passivation properties.

The property of the metal becomes passive depends on the chromium content in the alloy. The higher the chromium content in the alloy, the higher its anti-corrosion resistance.

Another important element that affects resistance to corrosion processes is carbon. Here the situation is inversely proportional - the more carbon, the less anti-corrosion properties.

At the moment, it has been proven that stainless steels are resistant to rust formation in oxidizing environments. In non-oxidizing aqueous environments, chromium is unstable and this leads to its destruction and, therefore, to the destruction of the entire material under the influence of intercrystalline corrosion of the metal.

Pitting shape

From the photo you can see that some elements have the correct shape, others are incorrect in appearance. The exact shape depends on the voids in the crystal lattice that formed during pitting initiation. Typically, irregular pitting corrosion occurs on plain (carbon), low-alloy steel and stainless steel, while correct pitting occurs on aluminum and various alloys. In addition, the classification of pittings by shape looks like this:

- hemispherical, with a shiny, polished bottom;

- polyhedral;

- faceted, including those interconnected;

- in the form of complex polyhedra;

- pyramidal;

- prismatic.

Polished (hemispherical) elements are often found on aluminum, tantalum and titanium, as well as on cobalt and nickel alloys.

Stainless steel care

It would be naive to assume that products made from stainless alloys themselves will retain their elegant and elegant appearance during long-term use. To maintain the performance and appearance of stainless steel, it will require appropriate periodic maintenance. Under normal conditions, when a chemically neutral, non-aggressive environment is used at normal temperatures, regular washing of the products with warm water and soapy water may be sufficient. It is not recommended to use detergents and cleaners based on ammonia or abrasive powders. When the first signs of pitting corrosion, such as spots and spots, appear, they should be removed with a stiff brush or thick sponge. If the process continues to develop, the use of more serious restorative agents will be required. Compositions such as Cilit or Tsinkar cope well in the initial stages. An 8% citric acid solution is also suitable. After using restorative agents, the treated areas should be rinsed with plenty of water.

Pitting classification

Pitting corrosion is classified not only by shape, but also by other characteristics: size, specifics of its development.

By size

Depending on the exact composition of the metal, environmental conditions (temperature, acidity), the size of pitting corrosion can be different:

- microscopic (micropitting) – less than 0.1 mm;

- conventional (pitting) – 0.1-1 mm;

- significant (ulcer) – more than 1 mm.

According to the specifics of development

Pitting can be superficial, open or closed. Surface corrosion elements develop intensively horizontally, without affecting the deeper structures of the metal. They cause the appearance of clearly visible shallow potholes. Open pitting is visible to the naked eye or at a small size when magnified with standard optical equipment. This type of rusting often turns into complete rusting if a lot of pitting begins to appear on the surface.

Closed corrosion is considered the most dangerous in terms of the further safety of metal products. It is impossible to examine it without instruments, so the elements grow deeper into the metal, remaining unnoticed for a long time. It is the closed pittings that cause the formation of holes. If the initial signs of corrosion are not removed in time, the product will become unusable.

Methods of protection against pitting

There are a number of modern methods for preventing corrosion, and many of them are already used at the production stage of the car. However, due to long use and constant contact with aggressive reagents, old machines are susceptible to rust. Pitting often occurs on various car parts: bearings, gear teeth, and rust spots on the body are considered a common occurrence.

Pitting corrosion is often found on household items, including stainless steel. To protect metal, you can use mechanical and chemical methods, some of which are suitable for independent use.

Mechanical method

This method includes tips for removing existing rust using grinding, laser processing, as well as mechanical application of barrier coatings (including paints). The choice of coating type depends on the type of metal and its operating conditions. The technique of galvanizing or nickel plating is usually used, but in industrial settings chrome plating, plating with copper, silver, aluminum, tin, and cadmium is also practiced. The created film isolates the metal from the environment and prevents it from coming into contact with acids, oxygen, and chlorine, thereby extending its service life.

There are kits on sale for do-it-yourself galvanizing of metal. First, the part is cleaned of existing rust by processing it with converters. After half an hour, the products are washed off, the product is cleaned, polished, a layer of a special solution is applied and an electrode with a zinc tip is connected. After a certain time, a thin zinc film will be created on the metal surface, which will prevent rust from further destroying the material.

Chemical method

The main chemical method of getting rid of corrosion is the elimination of a closed system with solutions of alkalis, sulfates, and chromates. The principle of operation is to reduce acidity and shift the reaction towards alkaline, in which corrosion processes stop. It is only important to control the release of hydrogen, since this element itself increases the risk of pitting.

Unfortunately, it is impossible to completely eliminate the risk of pitting corrosion in everyday life. There is only a chance to weaken the influence of risk factors. It is better to use the product correctly right away and prevent the acidity of the environment from increasing, rather than extending its service life by several years.

History of the creation of Teflon

Teflon was first created, like many miracle chemicals, as a result of a laboratory accident. In 1938, Roy J. Plunkett, a DuPont chemist, was experimenting with refrigerants when he discovered a white, waxy material that was very slippery.

It was an inert fluorocarbon, polytetrafluoroethylene (PTFE), which had excellent non-stick and water-repellent properties. In 1945, DuPont patented the chemical under the trademark "Teflon." The company advertised it as "the slipperiest material available."

By 1948, DuPont was producing about 1,000 tons of Teflon annually at its Washington plant.

For DuPont, Teflon, which was used to coat pots and pans, turned out to be a goldmine. Sales of Teflon cookware peaked at $1,000,000,000 in 2004.