Nitric acid

A weakly concentrated 58% solution can be purchased without any permitting documents in departments selling chemicals.

You can remove rust with nitric acid in a matter of minutes. For metal processing it is diluted to 10%. But acid can also poison the metal itself. Therefore, carrying out such experiments requires some experience.

The concentration of the solution intended to remove rust will need to be accurately calculated depending on the amount of metal. You will also need to monitor the process: as soon as the acid reacts with the oxide, the process of metal decomposition may begin. Plus, when working with such solutions, you need a high-quality exhaust hood and strict adherence to safety precautions.

Since acid can corrode not only rust, but also metal, this method is not suitable for processing metal-cutting tools (for example, dies, taps). The thread diameter can change significantly. Acids are especially dangerous for carbon steels. The more carbon they contain, the more damaged the metal will be.

Cleaning methods

There are several working methods for getting rid of metal corrosion. Experienced metalworkers successfully use them individually or in combination, depending on the complexity of the situation. These include the following methods:

- mechanical cleaning;

- chemistry;

- alternative (available means).

Which one to choose is up to the owner of the problem to decide, taking into account the available resources, including reagents, time, and the scale of the damage.

Mechanical

One of the most practiced ways to combat rust. It consists of slowly but surely removing corrosion products from the surface of steel or alloys. Hard brushes, special attachments for power tools, and abrasives are used. At the end of the procedure, dust and dirt are removed, the freed metal is cleaned and dried.

See also

Rules and methods for quickly removing dust after sanding walls

Chemical exposure

It consists of treating a rusty part or surface with concentrated acids. Alkalies are used less often.

An elementary chemical reaction occurs: under the influence of the reagent, iron oxides form a salt.

The process is not fast, and it is slowed down by the use of a weakly concentrated composition. But as a result of processing, loose, exfoliated fragments dissolve into pure metal. All that remains is to remove and wash off the remaining reaction with water.

The use of folk remedies

What to do, having experience, knowledge, and the ability to use industrial methods to solve the problem, is already clear. But what to do if all this is missing? You will have to use alternative, folk methods.

Hydrochloric acid

It acts as quickly as nitrogen. The metal begins to turn white literally before our eyes. Since the reaction process produces hazardous gases, you should not get too close to the container in which the treatment is being carried out.

A slower, but also safest method of cleaning is to mix the acid with flour. Its addition will significantly reduce the rate of metal etching. However, it will take more time to remove the rust. You can also try adding methenamine, which is a corrosion inhibitor (suppressant), to the hodgepodge.

When processing any of the acids to neutralize its residues, the product must be washed in ammonia or a weak alkaline solution of soda or soap. Please note that after removing the oily film, the metal product can literally turn red again within half an hour. Therefore, after cleaning with an anti-rust agent, it must be immediately wiped dry or thoroughly calcined so that the water completely evaporates.

The part is then lubricated, coated with a layer of zinc or painted. If it is not possible to treat the metal with an anti-corrosion compound in the near future, it is coated with a spray bottle with a mixture of lithol (solidol) and gasoline.

How does corrosion affect the performance of equipment and tools?

What is metal corrosion? As people of the older generation would say, this is such a hellish foreign group that destroys our brain with its music. But let’s not argue about tastes and leave the “Metal Corrosion” group alone, but the essence of the statement is true: this is a chemical process that destroys a metal surface.

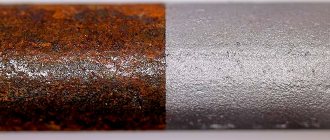

Equipment and tools made of metal and subjected to a corrosive process begin to change in appearance. At first it is almost invisible to the naked eye. Then rusty pitting and roughness appear on the surface

The process is started, and if it is not stopped, the damage penetrates deep into the material. All metal devices damaged by rust begin the countdown until they are written off. Therefore, to prevent this from happening, you need to remove corrosion in a timely manner.

Phosphoric acid

This method is perhaps the most common and safest. After all, phosphoric acid does not remove the oxide layer, but turns it into a film that can serve as an anti-corrosion coating. However, this method is only suitable for metal products that are only slightly affected by rust.

There is a special product on sale called “Anti-rust”. It is made precisely on the basis of orthophosphoric acid. True, such a solution acts a little slower.

If the plaque is large enough, it is better to use a combination of the first and second methods. First, treat the part with hydrochloric acid, and use phosphoric acid to only record the result.

Harm to health

The product is potentially dangerous and toxic to the body if used incorrectly. If it comes into contact with the skin, it causes burns, burning, and irritation. Even low concentrated acid causes irritation upon prolonged contact.

If the substance is accidentally ingested, the following symptoms may occur:

- difficulty breathing;

- convulsions;

- vomit;

- kidney damage;

- hypocalcemia;

- stomach ache.

Prolonged contact with the skin causes cyanosis and gangrenous changes.

Vinegar or lemon

You can even remove rust from metal using these acids. The cleaning method is simple and safe. The metal product is placed in a solution of citric acid (a couple of 20-gram bags will be enough for 2.5 liters of water). Large surfaces are sprayed with a spray bottle.

The exposure time depends on the degree of damage to the metal. As a rule, it is no more than a day. You can do it differently. Soak the part in the solution for a couple of hours, and then rub the softened layer with a metal brush or foil. It will come off easily. To speed up the process, the citric acid solution can be pre-boiled.

Another advantage of citric acid treatment is the possibility of further galvanizing without pre-cleaning. Zinc will not adhere to the phosphate film formed as a result of the interaction of “rye” with orthophosphate acid. Another advantage is that lemongrass does not affect varnished or painted surfaces.

Processing with vinegar is carried out in the same way. The greater its concentration, the better. You can even use a 70% solution. When you add regular salt to the vinegar (pour enough of it until it stops dissolving), the effect will increase. If the layer of plaque is large, before cleaning the rust with acid, the surface can be treated with an iron brush or sandpaper.

Industrial methods of prevention

In addition to forced rust removal, there are methods to prevent metal oxidation. These include:

- galvanic treatment;

- cathodic protection;

- application of inert coatings.

See also

How to clean your computer from dust at home, step-by-step guide

It is problematic to apply these methods in everyday conditions due to the lack of appropriate equipment and the complexity of technological processes.

Galvanization

The method involves depositing a thin layer of a substance that is slightly susceptible to oxidation onto ferrous metal using electrolysis. The nuance of the situation is that as soon as the protection is broken, corrosion immediately begins.

Cathodic protection

A method that involves the use of a direct current source that creates a zone of negative electrical potential on the protected surface. Successfully used on large objects (ships).

The weak point is the need for a continuously operating battery to power the device.

Special coatings

Protection methods using specially applied metal coatings may be no less effective than others. Typically, they are made using substances that do not react with condensation or moisture.

Galvanization

Coating with a layer of zinc perfectly protects the base metal from oxidation and makes it inert towards slightly aggressive environments. Widely used to protect body parts, in the manufacture of hardware and fasteners.

Tinning

The basis of the method is coating the metal with molten tin solder. The resulting layer resists oxidation well and prevents the spread of corrosion.

Using electrolysis in soda ash

This treatment allows you to keep even chrome surfaces intact. Using soda ash we will obtain carbonic acid, which will clean the metal.

We'll tell you how to clean rust from metal in a similar way:

- When making a small amount of solution, even an old phone charger can serve as a power supply. To process a significant volume of parts, you can take, for example, an old computer power supply.

- It is necessary to connect a minus to the workpiece, and a plus to the electrode.

- For better conductivity, the area to which the wire will be connected must be cleaned with sandpaper.

- A suitable sized piece of tin is used as a positive electrode.

- In 3-4 hours of such treatment, even significant layers of iron oxide can be removed. If necessary, electrolysis is repeated.

- Remaining rust can be etched in a vinegar solution.

You can get rid of rust at home using any of the methods described above. For processing large parts, the use of acids is acceptable. Cleaning metal-cutting tools and machine parts in this way to avoid etching of the metal is unacceptable. It is better to subject them to electrolysis or place them in a solution with kerosene or diesel fuel.

Recommendations for surface treatment

To ensure that rust removal has maximum effect and does not cause harm, it is recommended to use the following expert advice:

When using caustic acids and their solutions, it is necessary to use personal protective equipment, including a respirator.- It is advisable to carry out work outdoors. Or in a room with very good ventilation.

- If there is significant corrosion, it is recommended to clean the metal with a stiff brush before treating with acid.

- After washing off the acid, the metal surface must be dried.

- Several acids should not be mixed together unless specified in the recipe.

Using purchased products to remove rust is more convenient than making your own solutions.

You will find a lot of useful information about rust removal in this section of the site.

Mechanical rust removal

The problem of rust is constantly encountered in metal structures factories.

Storage of rolled metal at bases takes place in the open air. The raw materials are exposed to moisture and air, and a rusty mark forms quite quickly.

Hand Brushes for Rust Removal

For small production volumes, the simplest brushes with metal bristles are used. They differ in the stiffness of the bristles (wire), as well as in the method of attachment to the handle.

Some wire brushes have a brass coating on the surface of the bristles. During processing, the effect of transfer of the copper-zinc alloy to the workpiece occurs. The forming film further protects the part from oxidation.

To perform the work safely, parts are fixed on workbenches in special devices or in a vice. Be sure to wear safety glasses or masks. Gloves are put on your hands.

Mechanical brushes for processing steel products

If you have power tools or pneumatically driven devices, use mechanical brushes. They are manufactured in radial and end versions.

For installation in the chuck of an electric drill or screwdriver, the brushes are equipped with a cylindrical shank. When using an angle grinder (angle grinder), an M14 thread is created on the tool. It is screwed onto the drive shaft.

Despite their apparent simplicity, working with mechanical brushes is quite difficult. The instrument tries to escape from your hands. Therefore, special mandrels and guides are used; they help the worker hold a complex technical device in his hands.

If it is necessary to process a workpiece from all sides, it must be positioned in different positions. Special clamps allow you to firmly secure the part to the workbench. The tool is brought to the surface of the part in different ways, which helps to remove fragments of the rusty film outside the processing area. The impact speed can reach several meters per second.

Attention! Mechanical rust removal produces a large amount of metal dust. Therefore, it is necessary to protect the respiratory system from its entry. It is assumed that the worker's face and hands are protected.

Sandblasting units for removing dirt and rust

In large-scale and mass production, sandblasting machines are used to process a large number of products and semi-finished products. Sand is used as the working fluid. It is directed to the surface of the parts at high speed by a powerful air flow.

Sand grains hit the surface. Any rust that is present flies off in small fragments. Since the impact speed is quite high, the process occurs quite quickly. Large areas are cleaned within a few seconds. After such processing, the part acquires a metallic shine.

Waste sand is collected in a container. It contains knocked down rust particles; they are also used in subsequent processes for cleaning steel parts.

Processing in screens for cleaning workpieces from rust

At many enterprises, products and workpieces are cleaned of rust using screens. These are special machines (most often of the rotary type), in which parts come into contact with abrasive (sand). As a result, rust is scrubbed off the surface.

The workpieces are located inside mesh rotating cylinders. When rotating, the parts roll along the surface. The height of the fall depends on the diameter and angular speed of rotation.

The productivity of screens is measured in tens of tons of workpieces per hour. Vibrating tables are made at home. On them, parts and abrasive interact with each other. Productivity is lower, but sufficient for home production conditions.

Why even a little rust can become a big problem

As soon as man learned to mine and use iron ore, he began to look for ways to preserve the metal from corrosion. Herodotus, in his works, described in detail the technique of coating iron with a layer of protective tin, and archaeological excavations of more ancient cultural layers indicate the practice of protecting metal products using lubricant.

Only high-quality lubricant can prevent corrosion.

So what happens to such a hard and durable metal, why does it become loose and brittle over time? It's all about oxygen. It is he who causes a chemical oxidation reaction, gradually capturing deeper and deeper layers. There is only one way to stop this reaction: to cover the object with a protective layer that will prevent direct contact of the metal with air. If this is not done, the rust will grow from a small speck into a huge ulcer, and then completely turn into a hole. Objects made of thin sheet metal especially suffer from this process: plumbing fixtures, dishes, various household containers.

Read also: The grinder burned out, how to repair it

Is it possible to prevent this process? Careful care, protective coating and timely lubrication are all simple preventative measures. What to do if corrosion does appear?

Removing rust from bathtubs and other enameled objects

- In a clean, dry half-liter glass jar, mix 100 ml of ammonia and 50 ml of hydrogen peroxide. Using a dry sponge or rag, apply the mixture to the rust and wait 10-15 minutes. Then simply rinse the solution with water and clean the surface with any household cleaning powder.

- Prepare the mixture in a glass jar: add 2 tablespoons of salt to 100 ml of wine vinegar, mix and heat the solution in the microwave to a temperature of 60-65 degrees. Use the resulting mixture to wipe off the dirt and then rinse everything off with cold water.

- Hydrochloric acid is a solution that perfectly removes rust marks from enameled metal products. Don't forget about precautions! Apply the mixture to a dry cloth and apply to the problem area for 10-15 minutes. After the cleaning procedure, thoroughly rinse the treated surface with plenty of water, then, if the method was used in the bathroom, wash with detergent and rinse again.

Video

We invite you to watch videos on the topic of cleaning metal objects from rust:

Graduated from the economics department of the Aviation University. Married, has a daughter. Loves to play musical instruments and spend time in pleasant communication. She always strives to learn something interesting and master a new craft. Loves to cook for the whole family. Life motto: “Never give up!”

Found a mistake? Select the text with the mouse and click:

There are special traps to combat moths. The sticky layer with which they are covered contains female pheromones that attract males. By sticking to the trap, they are eliminated from the reproduction process, which leads to a decrease in the moth population.

Fresh lemon is not only suitable for tea: clean dirt from the surface of an acrylic bath by rubbing with half a cut citrus, or quickly wash the microwave by placing a container of water and lemon slices in it for 8-10 minutes at maximum power. The softened dirt can simply be wiped off with a sponge.

The habit of using an automatic washing machine “sparingly” can lead to the appearance of an unpleasant odor in it. Washing at temperatures below 60℃ and short rinses allow fungi and bacteria from dirty clothes to remain on internal surfaces and actively multiply.

The easiest way to remove scale and carbon deposits from the soleplate of the iron is with table salt. Pour a thick layer of salt onto the paper, heat the iron to maximum and run the iron over the salt bed several times, applying light pressure.

Before removing various stains from clothing, you need to find out how safe the selected solvent is for the fabric itself. It is applied in a small amount to an inconspicuous area of the item from the inside out for 5-10 minutes. If the material retains its structure and color, you can move on to stains.

Stretch ceilings made of PVC film can withstand from 70 to 120 liters of water per 1 m2 of their area (depending on the size of the ceiling, the degree of its tension and the quality of the film). So you don’t have to worry about leaks from neighbors above.

If your favorite things show the first signs of gestation in the form of untidy pellets, you can get rid of them using a special machine - a shaver. It quickly and effectively shaves off clumps of fabric fibers and returns things to their proper appearance.

Threads made of gold and silver, which were used to embroider clothes in the old days, are called gimp. To obtain them, the metal wire was pulled for a long time with pliers to the required fineness. This is where the expression “to drag out the rigmarole” came from - “to do long, monotonous work” or “to delay the completion of a task.”

The dishwasher cleans more than just plates and cups. You can load it with plastic toys, glass lamp shades and even dirty vegetables, such as potatoes, but only without using detergents.

Reading time: 5 minutes No time?

Any unprotected metal will become rusty over time. The more severe the operating conditions, the faster this happens. Home plumbing, car body parts, tools, dishes - all of this is subject to corrosion. If you notice red spots in time, you can quite easily deal with them with home remedies, without resorting to serious chemicals. This material from Housechief.ru will tell you how to remove rust from a metal surface.

Read in the article

What is the best way to remove rust stains from plastic and acrylic?

- A method that will help you deal with stubborn stains on any plastic or acrylic surface. Take a lemon and make a fresh cut. Sprinkle the cut with salt and wipe away any rust marks. There is no need to wait: wash off the treatment composition immediately. Repeat the procedure if necessary.

- Pure rubbing alcohol can easily remove minor rust marks. Apply the liquid to a cotton pad and wipe away any dirt.

- Undiluted white will help remove red marks from plastic window sills. Simply apply bleach to the stain and rinse off after 1 minute.

Use white only on thick and dense plastic! It is not recommended to use it for cleaning plastic panels!

Safety precautions when working with acid

Phosphoric acid is classified as a hazardous chemical. Contact of this substance with skin may result in painful burns. The substance also releases harmful vapors that are dangerous to the respiratory tract.

Based on the above, transportation, storage and work with this material requires compliance with certain safety standards. You can work with phosphoric acid only in protective clothing, gloves and a respirator.

In case of unwanted contact of the substance with the skin, the following actions must be taken:

- First of all, you need to remove clothing that has been exposed to harmful liquid.

- Next, rinse the affected area of skin with a significant amount of water. It is best if it is running water. The approximate duration of washing is 15-20 minutes.

- Under no circumstances should you rub the liquid over your skin. The substance should not be wiped off with napkins or a towel, but rather washed off.

- Sometimes a one-time rinse does not help. In this case, you need to extend the procedure for another 15-20 minutes. It is recommended to do the same if the burning sensation recurs after some time.

- Before the doctor arrives, it is recommended to apply a loose (non-constricting) gauze bandage to the affected area.

- If the pain syndrome is too bothersome, you can take a painkiller (for example, analgin).

So, all work with orthophosphoric acid must be carried out with extreme care and attention. If the incident does occur, then after providing primary assistance to the victim, you should immediately consult a doctor.

A little chemistry to understand the process of rust formation on metal

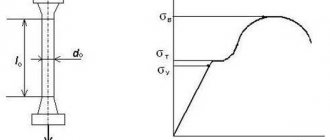

Rust is a product of iron oxidation. Most often it is a chemical compound Fe₂O₃. This oxide gives a reddish tint. However, dark inclusions can often be observed.

They indicate that the metal has not only trivalent properties, but also divalent properties. Therefore, the oxide will be written with the chemical formula FeO.

Based on numerous studies, it has been established that Fe₂O₃ predominates. It occurs in 85...88% of cases.

Information for the curious. Iron is smelted from ore. It is usually denoted as a Fe₃O₄ compound, but this formula does not give the real picture. In nature, the compound occurs in blast furnaces at temperatures above 850 ⁰C.

In the open air, iron actively interacts with oxygen in the air. Therefore, an oxide film forms quite quickly. In practice, to prevent oxidative processes, the metal surface is protected.

The density of the oxide film can be different. If a steel object has been exposed to the open air for a long time, the metal may be riddled with holes consisting of oxide (rust). In fact, it completely loses its properties.

Items that have recently been left without additional protection are covered with only a thin coating. The thickness of the oxide film is measured in microns. In such a case, the strength of its adhesion is insignificant. It can be easily removed from the surface.

When smelting iron from ore under the influence of high temperature, processes of metal reduction with carbon and hydrogen occur:

- 3Fe₂O₃ + CO = 2Fe₃O₄ + CO₂;

- Fe₃O₄ + CO = 3FeO + CO₂;

- FeO + CO = Fe + CO₂;

- 3Fe₂O₃+ H₂ = 2Fe₃O₄ + H₂O;

- Fe₃O₄ + H₂ = 3FeO + H₂O;

- FeO + H₂ = FeO + H₂O

In addition to the formation of pure iron Fe, iron carbide Fe₃C is formed in the blast furnace process. The reaction of its formation occurs at a temperature of 950...1000 ⁰С.

3Fe + 2СО = Fe₃C + CO₂.

The flue gas contains carbon monoxide CO₂ and water vapor H₂O. At a temperature of 1536 ⁰C, iron Fe melts.

In nature, the opposite process occurs. At the same time, cast iron, due to its high iron carbide content, oxidizes several times slower than steel.

Important! Steel is considered a mechanical combination of iron and carbon, provided the content does not exceed 2.14%. As the carbon content increases, the alloy becomes cast iron.