09Mar

- By: Semantics

- Uncategorized

- Comments: 0

Let's find out how to prepare a part, body, structure for applying paint and varnish.

Let's consider how to degrease metal before painting at home, what products and methods can and should be used in various situations. And we’ll also suggest a few life hacks for household savings with excellent results. Let us immediately note that for some reason many people neglect this stage of pre-processing, and completely in vain. Simply cleaning the surface from rust or dirt is not enough, because oily stains impair the quality of adhesion to paintwork materials. It is necessary to provide all the conditions for the coating to lay down in an even layer - then it will look attractive and be able to fully provide its protective properties.

- What is defatting

- How to properly degrease metal before painting: basic methods

- Chemical methods

- Aqueous solutions

- Alkaline degreasers

- Emulsion compositions

- Ultrasonic and electrochemical methods

- How to degrease metal for painting, what products exist

- Popular solvents

- White Spirit

- Solvent 646

- Acetone: the classic solution

- Complex formulations

What is defatting

This is a procedure for removing all kinds of foreign substances from the substrate, the list of which includes:

- oils present in preservative lubricants, cooling emulsions, polishes and retained on the part;

- fingerprints, sweat marks;

- etching and rinsing residues.

In a word, everything that worsens the quality of surface wetting with a coating composition and harms film formation destabilizes the final properties of the coating.

Depending on the method, it is carried out in a certain sequence, within which emulsifying, dissolving, saponifying processes are implemented.

The degree of contamination (per 1 m2) can be different:

- weak – up to 1 g;

- average – 1-5 g;

- high – from 5 g or more.

Based on the difficulty of removal, these foreign substances are divided into those that cannot be destroyed (like emulsions) and those that can be pollinated (residues of lubricants and polishes).

Aqueous solutions

Water itself is not an ideal liquid for degreasing surfaces - just remember attempts to wash greasy dishes with cold water. This is due to its high surface tension and its inability to emulsify fats.

To make surface degreasing with aqueous solutions effective, the following methods are used:

- increase pH acidity level;

- heat the solution to 55-60 oC;

- add surfactants (surfactants).

Water based degreaser

Aqueous solutions are quite effective against light and medium levels of contamination. They are significantly less dangerous to use than organic solvents.

How to properly degrease metal before painting: basic methods

All methods existing today can be divided into 4 groups:

- Chemical – purification is carried out with special compounds (based on alkalis or other reagents); effective, modern and therefore the most popular.

- Ultrasonic – processing is carried out in a special container with an ultrasonic field; They are well suited for small and critical parts with complex surfaces, but are relatively expensive to implement.

- Electrochemical - require fewer reagents, but also involve the use of reservoirs (to which electrodes are connected).

- Mechanical - boil down to removing oily contaminants (along with the top layer of material) using a brush, sandpaper, or drill.

The latter methods, despite their apparent simplicity, are not very convenient in practice. They require significant physical effort and spend quite a lot of time. Moreover, it is not always possible to remove stains really carefully, without scratches. That is why they were used only until more advanced technologies appeared, and today they are considered obsolete. Therefore, we stop paying attention to them, but we will consider the remaining options in more detail.

Chemical methods

How can you degrease the surface before painting the metal? In everyday life, organic solvents, for example, chlorinated or aliphatic, are excellent for this. Among their advantages:

- speed of action - give results almost immediately;

- penetration depth – even high-level contaminants are suitable for cleaning;

- profitability - they are relatively cheap with moderate consumption.

But they also have disadvantages: they are flammable, fire and explosive, so they must be used with caution. Another serious disadvantage is that they do not remove abrasives and minerals. To remove any deposits, you will have to use additional means.

Although in general they are convenient for use in the garage, at the dacha, in your own workshop, and even in the conditions of individual production of non-critical parts.

Aqueous solutions

When deciding how best to degrease the metal surface before painting, remember that H2O has a high surface tension and is incompatible with fats. It will therefore be a poor cleaner, unable to form a stable emulsion unless strengthened. Therefore, manufacturers of household chemicals add all kinds of surfactants to products based on them, and also change the pH balance, increasing acidity, or temperature conditions, expanding the range of application to 65 0C.

The undoubted advantage of such funds is their low cost and availability. They are presented in entire series and are always widely available. But it should be borne in mind that they are unlikely to cope with persistent stains - for complex cases something more serious is required.

Alkaline degreasers

Their most popular representatives have a number of practical advantages:

- a combination of fire safety and environmental friendliness, which is not as common as we would like;

- high cleaning ability - penetrate as deeply as possible;

- Several application options at once - brush, spray, just pour, depending on the case.

Separately, it is necessary to say about the mechanism of their action. They destroy those oils that lend themselves to this and emulsify unsaponifiable contaminants, causing them to peel off from the substrate and turn into a liquid that can be easily washed off with a stream of aqueous solution.

It would seem that this is it - something that can be used to degrease metal before painting, an ideal option - but alkaline products also have one serious drawback: after their application, you also have to carry out anti-corrosion treatment.

The main active components (which provide the double effect) of such compositions are surfactants - once on the substrate, they:

- form stable foam;

- reduce the force of surface and interfacial tension;

- destroy contaminants, both viscous and hard, and/or change their shape, making them more convenient for physical removal;

- increase wettability.

The concentration of surfactants in such products is usually at the level of 9-10%. If you also need to remove a thin hydroxide film, you need products containing 1-3% phosphoric acid.

It is mandatory to wash the part after the alkali: there should be no salt residue, because it will increase the moisture permeability of the paintwork material, contribute to the appearance of under-film corrosion and generally worsen the performance characteristics of the coating.

Emulsion compositions

They become the answer to the question of how to degrease the metal surface in cases where it is necessary to remove:

- grease;

- oil soot;

- old pollution.

Their effectiveness is explained by a combined composition containing both solvents (aliphatic and chlorinated hydrocarbons) and diluted surfactants. They do not interact with each other, but where some pass, others come into action.

The only disadvantage is that in order to process the workpiece evenly, it should be placed in a tank with such a two-component liquid, and this is not always convenient and available at home, and it is not entirely rational in terms of cost if it concerns one or two parts, and not a large their quantities.

Ultrasonic and electrochemical methods

Above, we looked at whether it is possible to degrease metal with a solvent, and found out that yes, but in the case where they have to cover a relatively simple surface. But what to do when the workpiece has a complex topography and/or is small and you need to get a perfectly smooth paint coating? In such situations, it is advisable to place the part in a special container with a detergent composition and expose it to an ultrasonic field: it will help the particles of contamination to separate and will enhance the washing properties of the liquid.

True, the larger the object, the stronger the power of the radiation-producing device should be. Therefore, the method is well suited for isolated cases - experimental or especially critical samples purified in laboratory conditions - and has very limited use in industry.

The electrochemical method provides very high-quality cleaning, but is relatively difficult to implement, since it requires the installation and use of an entire unit consisting of the following functional units:

- racks and guides - for fastening other elements;

- bath with a workpiece and a “plus” clamp;

- a cathode needle, an electromagnet that fixes it and a 3D manipulator for its movement;

- power supply that supplies direct current.

When turned on, a gas is produced, which removes oily contaminants from the substrate. The consumption of reagents is reduced (compared to the chemical method), the degree of purification is high, but organizing the processing of large parts is problematic, so this option has found application not in industry with its productivity, but in science, when creating one-piece specimens, and in medicine.

Multi-step cleaning

The first step is to treat the body with white spirit. What to do if there are traces of corrosion on the surface? In this case, it is necessary to treat the surface using phosphoric acid with alcohols. This composition is a mixture of ethyl alcohol in a ratio of 15%. Part of the water and phosphoric acid is also mixed in a ratio of 1 to 5. Additionally, an emulsifier is used - wetting agent OP-7 in an amount of 0.5%. 0.1% nitrobenzene is also required. It is quite difficult to obtain this mixture at home - some substances are not commercially available. It is also worth remembering that the composition is hazardous to health.

How to degrease metal for painting, what products exist

Their entirety can be divided into the following groups:

- Organic solvents - their most famous representatives are gasoline and kerosene, but this category also includes substances containing chlorine. They are produced in large volumes and therefore are inexpensive, but they are flammable, explosive, and toxic. In addition, their effectiveness is seriously reduced if they themselves are contaminated.

- Water-alkaline and acid mixtures are saturated surfactants, due to which they give results. They peel off oily deposits, but increase the tendency of the substrate to oxidize. After applying and washing them off, there is also a need to use anti-corrosion agents.

- Professional compositions with a neutral pH balance - due to the phosphating effect, they also give the coating protective properties. Relevant for the most difficult cases, including on an industrial scale.

Of course, among them there are specific products that have earned greater or lesser recognition among consumers. Let's look at them.

Ultrasonic and electrochemical methods

In addition to chemical exposure, ultrasonic cleaning is also used in industrial settings. Small-sized parts of complex configuration, with intricate relief and internal cavities, are immersed in a bath filled with a cleaning agent. Vibrations at an ultrasonic frequency (20-150 kHz) are excited in the bath. These vibrations not only destroy the fat layer, but also enhance the effect of the active components of the cleansing solution. For large-sized products, this method is rarely used, since they require very high power of the oscillator and the operation becomes ineffective from an economic point of view.

Another method of enhancing the impact of cleaning compounds is electrochemical. It also uses baths of dielectric material filled with solution. The part to be cleaned and another metal electrode are lowered into the bath and an electric current is passed through them. Due to the electrochemical reaction, gas bubbles are abundantly formed on the parts - the electrode; their collapse reduces the density of contaminants and enhances the chemical activity of the components of the composition. By using this method, it is possible to increase processing efficiency and reduce solution consumption.

Popular solvents

So, what comes to mind first when we decide how to degrease metal before gluing, priming, or painting at home, that is, in the garage, at the dacha, or even at home? Let's highlight 4 products that everyone has heard of.

White Spirit

A colorless liquid, completely transparent, with a pungent aroma characteristic of fuels and lubricants - it is difficult to confuse it with anything else. The name under which it can also be found in stores is Nefras-S4, although modifications are possible.

It is distinguished by its versatility - using it, you can:

- remove fats, oils, organic matter;

- dilute enamels, varnishes, paints.

The good thing is that it evaporates quickly. It is also used so often because you don’t have to wait for the substrate to dry - after treating it with white-spirit, you can almost immediately apply paintwork to the part. This is convenient in urgent cases when time is pressing.

Solvent 646

In everyday life they use not only gasoline: you can degrease metal using this composition. This is a yellowish liquid with a powerful and persistent odor, the range of applications of which is quite wide. So, it is intended not only for cleaning, but also for thinning paintwork materials, and for removing their old layers, and even for washing painting tools. It also effectively dilutes melaninoamide (MP), nitrocellulose (NC), acrylic, glyphthalic (GF), and epoxy enamels.

The main thing is to use the product correctly, that is, apply it at the appropriate temperature (+5... +30 0C) and humidity level (up to 85%). If these conditions are met, there is every chance of getting an even paint coating of the same shade, shiny and with high anti-corrosion properties.

But you should work with this composition with extreme caution, because it is explosive and fire hazardous, so you must first put on special clothing, goggles/mask and gloves to protect your skin, eyes, and respiratory organs. If the procedure is carried out indoors, you need to take care of ventilation so that fresh air enters the room through a hood, windows or door and there is no risk of poisoning from fumes.

Acetone: the classic solution

People ask about it as often as they ask whether metal can be degreased with kerosene. And yes, this is quite possible: this liquid - colorless and transparent, with a characteristic pungent aroma - will cope with the removal of not only oil stains, but also resins.

It is also used to dilute various enamels, varnishes, primers, and is added as the main active ingredient to solvents. It is effective and convenient due to the fact that it is made on the basis of alcohol, which quickly evaporates from the substrate.

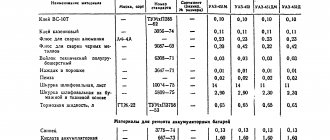

We offer a visual comparison of the most popular means - they are summarized in the following table:

| Product | Rating (1 to 5) | Peculiarities |

| White Spirit | 5 | 80+% of motorists buy it; rich in liquid hydrocarbons, fumes are toxic. |

| Kerosene | 4 | For small substrates; It is important to be clean - only then will it give results. |

| High octane gasoline | 3 | The simplest option, but it also removes up to 95% of oil stains, which is enough to ensure an even paint coating. |

| Acetone | 3 | Also suitable for plastic and rubber, but not for automotive parts, as it may react with some materials and destroy their integrity. |

| Soap solutions | 3 | They wash away particles of contaminants, but for maximum effectiveness they require the application of physical force. |

We hope you now understand whether it is possible to degrease metal with gasoline (before painting). Yes, but doing this is not always rational - in some cases it is more reasonable to use other means. However, we have not considered all of them yet.

Working with degreasers

To degrease the part, special solvents are used. Most of them are fire hazards and have high chemical activity and, if handled incorrectly, can cause serious harm to health or damage material assets. To prevent this from happening, you must follow the following safety rules:

- Work in a room equipped with exhaust ventilation.

- Provide good lighting to the work area.

- It is strictly forbidden to use open fire within 5 meters of the work site. Of course, this also applies to smoking.

- Be sure to use personal protective equipment: rubber gloves, safety glasses or a transparent protective shield, a respirator, thick clothing, a hat and shoes that do not leave exposed skin.

- It is also recommended to use an apron made of thick canvas.

- Particular care must be taken when working with aluminum surfaces - in combination with some degreasers, fire and even explosion are possible.

The surface should be treated as follows:

- Apply the degreasing solution with a lint-free cloth.

- A second napkin of the same type is used to wipe and dry the surface.

- The procedure is carried out immediately after mechanical treatment of the surface, immediately before painting or gluing, so that it does not have time to become contaminated again.

- After the operation is completed, do not touch the degreased surface with your hands or other objects.

To check the quality of the operation performed, attach a piece of white paper to the surface. If dirt remains, it will be visible on the paper.

Another way to check is to drop water on the surface. On a well-treated surface, the water will spread out like a film; on a dirty surface, it will form a ball.

Complex formulations

The top solutions for removing oils from substrates include:

- Trichlorethylene - suitable only for ferrous metal, removes film as quickly as possible, but does not help well against organic matter; cannot be mixed with water.

- Tetrachlorethylene – broad-spectrum, also effective in cases with non-ferrous metal; often used for workpieces made of aluminum and magnesium alloys.

- W900 - made on the basis of volatile compounds, which is why it is so convenient to cover smooth and textured, simple and complex parts; good for processing auto elements.

- Nefras BR-2 - with it you don’t have to ask whether it is possible to degrease the metal with gasoline before painting, because it costs less and does an excellent job; a Russian-made product actively sold on the domestic market.

- Body 770 – has a wide range of applications; removes organic matter as well; presented in liquid or spray form, produced in Greece.

- Antisilicone – cleans non-ferrous metals, rubber, paintwork, plastics; Packaged in spray bottles, bottles, jars, also suitable for glass.

- REOFLEX – fast solvent with reduced evaporation characteristics; You can apply it already at + 18 0C, but be careful, because it is very flammable.

- CarFit is a German product for removing oil stains from the body and other parts of the car.

We have looked in detail at what and how to degrease the surface before painting the metal: choose your method, and we will provide you with the composition for the treatment - contact us for a profitable order of quality products. The Rokta company also sells band saw machines, call us at the contact numbers. Our managers will advise you. At the end of the topic, we suggest watching the video:

Why do you need to degrease?

The dust layer and dirty fatty films on the surface of the material prevent molecules of adhesive or paint from penetrating into the pores of the material. Paint or glue, instead of the surface of the material, connects with the molecules of the fatty layer. This significantly reduces the strength of the joint or the quality of the paintwork.

During welding, fat molecules turn into slag and reduce the quality of the weld until defects form in the welding joint.

To prevent this from happening, it is necessary to degrease the surface before starting the next operation. Degreasing is a mandatory requirement of any technology associated with gluing, painting or cooking surfaces.

Degreasing metal before painting a car

This is necessary for any materials:

- metal;

- glass;

- plastic;

- wood;

- leather;

- ceramics.

A wide range of substances and methods are used to remove grease stains.

Types of automotive primers

When purchasing material, you need to navigate the types of primers, since each type of material is responsible for its own stage of work.

There are three main types:

- Acrylic. This type of material is used as a bonding layer between the metal surface and the base paint coating. It perfectly fills micro unevenness and levels the surface. But there is also a minus - it is hygroscopic. It absorbs moisture, and if water gets in, it can reach the metal and provoke pockets of corrosion.

- Epoxy. Such soil forms a sealed layer of film, which provides waterproofing of the surface. In addition to steel parts, it is also used to cover surfaces made of non-ferrous metals and galvanic coatings. Also provides a good level of adhesion.

- Acidic (phosphate). This type of material interacts with the metal, forming a film of oxides, and penetrates into the structure. Phosphate primers are rust converters, and they are used to more reliably protect the body from corrosive processes.

All these types of primers are often used, but combining them together is not always desirable, but it is possible if you follow the technology. For example, if you apply an acidic primer to metal and then apply an epoxy primer without waiting for it to dry completely, it will neutralize the effect of the acidic primer. If you wait the period correctly, then everything will be fine. There are no such problems with acrylic primer.

Answers

Himonas 7 (36803) 5 11 36 6 years

I have never encountered such a problem.

dika_klasnaya7 6 years

here’s a topic for you, everything is written there: https://forum.sibcolor.ru/index.php?topic=64.0

blblblbl 8 (115652) 8 15 115 6 years

Wrong soil. In principle, the soil is not degreased. Its functions are improved adhesion to paint and to the base. If it washes off with paint, look for a different primer. Or another paint. There won't be any sense

iljaajli 4 (1775) 3 11 6 years

a degreaser where they sell paint, so to speak. It smells like kerosene.

cnapmak (29) 4 (1608) 6 18 6 years

timurcik9 6 (12345) 2 6 14 6 years

The soil cannot be treated with anything! This is a special coating to bind the surface itself to the paint. After priming, you don’t need to touch it with your hands; apply paint right away. In extreme cases, you can wipe with neutral solvents, but you need to know the base of the soil, it can be pure alcohol or pure gasoline. It all depends on what the base of the soil is.

blush 2 (435) 1 2 6 6 years

anti-silicone and other degreasers

Is it necessary to degrease the primer before painting in order to end up with a perfect, even layer of enamel with high protective characteristics? Is it worth saving at this stage, risking further loss of the attractive appearance of the surface and reducing the effectiveness of its protection from adverse external conditions? What benefits does this operation provide if you do not ignore it?

Any product coming out of the production walls, as a rule, has a high-quality paint and varnish coating. It’s nice to look, for example, at a shiny new car or a snow-white refrigerator in your kitchen. But how is such perfection achieved?

Modern painting technologies include many seemingly insignificant, but very important operations. The main ones are preparation of the part, priming and final painting. But still, a real masterpiece can only be obtained by using certain subtleties in this difficult matter.

For example, the question: is it necessary to degrease the primer before painting in modern production is not even raised. This is a completely standard operation. The effect of its use cannot be overestimated - increased durability, durability of the coating, absence of defects. After all, it is precisely these parameters that technologists around the world strive for.

While developing new ways of applying paint and varnish, they do not forget to pay close attention to materials for those very, relatively speaking, minor operations.

Thus, a whole range of new special products for degreasing surfaces before painting has appeared. The newest chemicals have replaced controversial, outdated solvents and acetones.

What is a primer used for?

Before painting a body or a separate part, the primer performs a number of useful functions that provide a high-quality finish.

First, phosphate primer serves to prevent and remove rust from the metal surface.

Secondly, the main layer of primer levels the plane, filling small irregularities, and provides good protection of the surface from the effects of water and mechanical factors.

Thirdly, it increases the adhesion of paint to metal as an intermediate layer.

In addition, there are special primers for wheel arches that can withstand quite severe mechanical stress and prevent damage to the paint layer and subsequent corrosion of the metal.

Preparatory work

Before applying a primer to a car, the preparation steps preceding it are also important.

The main steps include grinding and cleaning the surface. This includes not only cleaning up rust and chips with scratches, but also removing swollen and chipped layers of old paintwork.

Next, the surface is degreased and putty is applied in places where it is required. Usually these are scratches, chips, dents that were previously straightened, but there are minor irregularities. Be sure to wait for the putty to dry completely, since some types of putty absorb moisture well and are able to retain it inside, forming pockets of corrosion. The dried putty is sanded and degreased with white spirit, and then wiped with a dry lint-free cloth.

Primer technology

Now let's take a closer look at this stage of work. First of all, you need to prepare the work area. If this is a garage, then it is desirable that it be clean, well lit, warm and have ventilation. This way, you can avoid installing additional heating sources in the form of IR heaters or the appearance of dust accumulations on the body.

The next step is to cover all untreated areas of the body where the material may get when applied with a spray gun, and also remove all plastic covers on the parts that will be repainted. Usually they cover everything with a film using masking tape, leaving only those areas of the metal surface to which the primer will be applied.

From materials and tools you will need:

- grinding machine with various replaceable abrasives.

- sandpaper.

- primer, solvent and hardener.

- spray gun and air compressor.

This is a basic set of equipment and consumables.

The next step is preparing the finished primer composition before painting the car. It is important to strictly follow the proportions indicated by the manufacturer of the material on the packaging. It is advisable to use the hardener and solvent of the same brand so that there are no problems with differences in composition. You can also use 646 as a solvent. To maintain proportions, you can use measuring containers; do not do everything by eye, especially if you are not an experienced painter. Next, the composition is filtered with special filters offered by manufacturers, otherwise you take gauze, fold it into 3 - 4 layers and run the finished primer composition through it. This is done to filter out various lumps and debris, which may subsequently clog the spray gun.

In most cases, 2 - 3 layers of primer are applied to the surface of the car body, this is enough to ensure good conditions before applying the main paint.

Many people are interested in the question: “How long does the primer dry before painting?” The answer depends on the type of material used. So, say, if a hardener is used, then a drying period of 10 - 15 minutes is allowed between layers, and the finishing layer is dried for about 18 - 20 hours. Without using a hardener, one layer of material will dry in 24 hours, but this approach is very rarely used, due to a large loss of time for work.

When choosing a primer color, people often look at the shade of the finishing paint. So, if these are light colors, then take white or combine white and the desired tone of paint. If the surface is black, then take a black tint accordingly. But there is also a universal color - this is a gray primer, it is used for surfaces of both light and dark tones.

Layering process

The first layer of primer is usually applied in a thick enough layer to evenly cover the surface, and the material itself will fill all micro-irregularities and chips. Next, let it dry for about 10 – 15 minutes. If necessary, rub problem areas and apply a second layer. They wait for it to dry a little, if all is well, then leave it for about a day and move on to the final painting.

After drying, you need to clean the surface. It is not advisable to "wet sand" as some primers absorb moisture and this process can cause rust and blistering of the paint in the future. They are usually sanded with a machine. Preparation for acrylic is done using abrasives of grades R-400 and R-500, and for metallic grades R-600 and R-800.

If you decide to paint a new part that came from the factory, then you must remove the shipping black primer using a P-240 abrasive down to the metal. Subsequently, 2–3 layers of primer are applied. After a period of 15 - 20 minutes, a developer in the form of a contrast paint is applied to the part. The next day, while sanding, you can use the developer to see minor imperfections and eliminate them by applying an additional layer of material.

It is advisable to carry out all work in protective clothing and glasses, gloves, and a respirator. To avoid paint getting into your eyes or dust into your respiratory system.

Why is the primer additionally sanded? Since this is a binding layer, it has some roughness and bumpiness, and if applied unevenly, such places can form defects in the form of sagging or smudges. You need to work very carefully with a machine or manually using sandpaper, because you will be sanding a thin layer of primer paint; if gaps appear somewhere, they can be eliminated using primer in an aerosol can and spot painting. Sand with fine-grained abrasive P800 - P1000. If there are strong flaws indicated by the developer, then they are eliminated using locally applied finishing putty and primed again, achieving an ideal surface.

Here is a video with tips on applying primer before painting a car.