Advantages and disadvantages

Fechral is considered an ideal alloy that can withstand temperatures up to 1450 degrees and has a high ohmic resistance that remains unchanged when heated (the resistance of fechral wire is 5.47 Ohms). Such characteristics make it possible to manufacture heating elements from the alloy. Fechral wire also has other advantages:

- Light weight.

- Preservation of anti-corrosion properties in various environments.

- High yield strength.

- Affordable price.

- Resistance to mechanical loads.

Fechral wire has disadvantages, including fragility, which dictates certain features of the production of small-diameter wire and tape and complicates the manufacturing process. Nickel or similar additives help eliminate this deficiency. The use of special additives increases the cost of the alloy and products made from it.

Basic qualities

Melting point of silumin

This alloy combines a high melting temperature of 1500 °C and significant electrical resistance: up to 1.3 Ohmxmm2/m. The relatively low density (7.2 g/cm³) makes the alloy 17% lighter than nichrome. Thanks to the use of inexpensive aluminum instead of scarce nickel, production costs are reduced by 6 times compared to nichrome. Fechral is characterized by high corrosion resistance in vacuum, air, carbon-containing and oxidizing, sulfuric environments. The Achilles heel of fechral is its fragility, which makes it difficult to make thin ribbons and wires from it. This drawback is eliminated by adding nickel additives, but then the price of the product increases.

| Alloy | Si | C | Cr | Mn | Fe | Al | Ti | Ni |

| Х23У5Т | ≤0.50 | ≤0.05 | 22.0−24.0 | ≤0.30 | remainder | 5.00−5.80 | 0.2−0.5 | ≤0.60 |

| Х23У5 | ≤0.60 | ≤0.05 | 21.5−23.5 | ≤0.30 | remainder | 4.60−5.30 | 0.15−0.40 | ≤0.60 |

| Х13У4 | ≤0.70 | ≤0.08 | 13.5−15.5 | ≤0.70 | remainder | 4.00−5.50 | 0.2−0.6 | ≤0.60 |

| Х15У5 | ≤0.70 | ≤0.08 | 14.5−15.5 | ≤0.70 | remainder | 4.50−5.50 | 0.2−0.6 | ≤0.60 |

Production Features

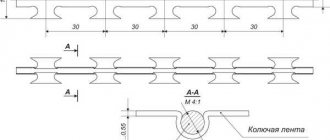

Cold working technology is not applicable to the alloy due to its fragility. The thread is drawn using energy-intensive technologies, which is reflected in the final cost of rolled metal. Most often, fechral wire is produced by pressing or drawing. The material is shipped in coils or coils.

Modern industry has a significant need for wire made from fechral. The products have an affordable price, good consumer properties and excellent technical characteristics. Fechral in wire is slowly but surely pushing nichrome out of the market. The alloys have almost identical properties, however, the cost of fechral is largely determined by the addition of aluminum to its composition, rather than expensive nickel, and the diameter of the rolled metal produced.

Production

Fechral wire is produced by cold drawing without preheating the workpieces. This method produces cold-drawn wire, which is then annealed, which increases its softness.

The following production stages:

- The surface is etched to remove dirt.

- The wire is wound onto coils or coils.

- Finished products are labeled and packaged.

- The products are shipped to the customer.

The thread is drawn using a special technology using energy-intensive and high-precision equipment, which increases the final cost of thin wire with a diameter of up to 0.1 mm.

Nichrome or fechral?

Compared to nichrome analogues, fechral has a number of advantages:

- The cost of fechral wire is several times lower.

- The characteristics of wire made from fechral X23Yu5T are better than those of nichrome alloys: higher electrical resistivity and low density. Such parameters make it possible to obtain high thermal power with a small volume, which allows you to reduce the price of products and save materials.

- Fechral wire is inert to sulfur and sulfur compounds, unlike nichrome and products made from it.

INTERNATIONAL BRANDS

Melting point of aluminum

Kh23Yu5T - 875 (W-KA1) contains 22% Cr, 72.2% Fe, 5.8% AL, melting temperature. 1500 °C. International name: eurofechral, Kanthal D, Alloy 815, Alchrome DK, Resistohm 135, megapir, Aluchrom 5, GS SY. Similar grades: OCr25Al5, 1Cr13AL4, OCr15Al5.

Kanthal D (Х21У) contains 22% Cr, 73.2% Fe, 4.8% Al, melting point 1500 °C. International name: eurofechral, Kanthal D, Alloy 815, Alchrome DK, Resistohm 135, megapir, Aluchrom 5, GS SY. Similar grades: OCr27Al7Mo2, OCr15Al5, OCr21Al6Nb, FeCrAl+Y.

Provider

The supplier "Auremo" offers to buy fechral in bulk or in installments. Large selection of semi-finished products in stock. Optimal price of fechral from the supplier. Buy fechral today. For wholesale customers, the price of fechral is preferential.

Properties of fechral

Compared to other metal alloys, fechral has a lower density - no more than 7210 kg/m3. The metal melts at a temperature of 1500 degrees and significantly increases in size when heated. Magnetic due to the large proportion of iron in the composition, it has a linear expansion coefficient equal to 0.000015 1/K.

The main property characterizing fechral alloys and wire is electrical resistance equal to 1.39 μOhm*m. Thanks to this parameter, the alloy is widely used to create various heating elements.

Fechral has certain anti-corrosion properties: it is resistant to oxidation even when exposed to sulfur compounds, which is important for the metallurgical industry.

In terms of hardness, the fechral alloy is comparable to low-carbon steel. The parameter ranges from 20 to 25 units on the Rockwell scale. Low tensile strength - about 735 MPa - leads to reduced ductility. For most grades of wire, tensile elongation does not exceed 16%. The fragility of the wire largely depends on these properties. For this reason, fechral spirals are wound after heating the metal to 300-400 degrees.

The fechral alloy can withstand high temperatures, which allows it to maintain its properties when operating at temperatures up to 1400 degrees. The situation changes somewhat with temperature load, that is, turning the heater on and off. Such stresses, superimposed on the increase in metal volume and brittleness, lead to the appearance of cracks.

This reduces the service life of fechral several times under conditions of cyclical temperature changes.

Types of fechrals

| Alloy grade | Compound | Melting temperature | Other names |

| Х27У5Т | 26-28% Chromium, ~65-68% Iron, 5-5.8% Aluminum, 0.15-0.4% Titanium | 1450 °C | |

| Х23У5Т – alloy 875 (W-KA1) | 22-24% Chrome, 69-72% Iron, 5-5.8% Aluminum, 0.15-0.4% Titanium | 1500 °C | Kanthal A1, Alloy 875, Resistohm 145, Aluchrom 0, Alchrome 875, megapir GS SY, eurofechral |

| X23Yu5 - alloy 837 (W-KAF) | 23% Chrome, 71.7% Iron, 5.3% Aluminum | 1500 °C | Kanthal AF, Resistohm Y, Aluchrom Y, Alloy 837, megapir, GS SY, eurofechral |

| Х15У5 | 15% Chrome, 79.7% Iron, 5.3% Aluminum | 1500 °C | Kanthal AF, Resistohm Y, Aluchrom Y, Alloy 837, megapir, GS SY, eurofechral |

Application

Х27У5Т

— for heating elements with a maximum operating temperature of 1350 °C in industrial and laboratory furnaces.

Х23У5Т

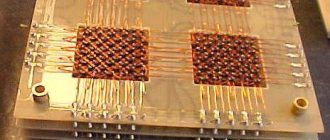

- a hard, brittle alloy, difficult to process, has a high electrical resistivity (1.2-1.3 μOhm m). Density 7100–7300 kg/m³, melting point about 1450 °C. The highest operating temperature is 1350–1400 °C. It is used for powerful electric heating devices, laboratory and industrial furnaces. The disadvantages include the general property of fechrals - a recrystallization threshold in the temperature range of 600-650 °C, which makes it difficult to use this alloy in thermal cycling mode, as well as low ductility. Also, this alloy is used as one of the most popular materials for the manufacture of heating coils in electronic cigarettes.

Х15У5

— has a density of 7.1 g/cm³, melting point about 1450 °C. The highest operating temperature is 750–950 °C. It is used for powerful electric heating devices, production of resistor blocks and resistance elements.

GS23-5 (Х23У5Т-Н-Ви)

is an improved version of the X23Yu5T alloy. Thanks to the introduction of a special alloy, it was possible to significantly improve its physical properties, which greatly facilitates the winding of spirals. Withstands operating temperatures up to 1350 °C. The disadvantages include the general property of fechrals - a recrystallization threshold in the temperature range of 600-650 °C, which makes it difficult to use this alloy in a thermocyclic mode.

GS T (Х23У5-Н-Ви)

— widely used in high-temperature electric furnaces, roasting and drying furnaces, various electrical thermal apparatus. Optimal for use in the production of tubular electric heaters (TEH) and household appliances.

Megapir-150

- widely used for the production of resistive elements, in electric furnaces and various electrical thermal devices.

Megapir-200

- used in high-temperature electric furnaces, roasting and drying furnaces, various electrical thermal devices, as well as for the production of resistive elements.

Application area

Wire made from fechral is used in the production of heating elements, resistance parts and tubular heaters. The main direction is the production of heating electric furnaces of various capacities. The grade of fechral alloy used and the diameter of the wire affect the operating temperature of the furnace.

Fechral alloy X23Yu5T is considered the most heat-resistant. The maximum temperature to which a wire with a diameter of 6 mm is heated is 1400 degrees.

Fechral wire is used for the production of resistive elements for electrical equipment.

Due to their properties and technological characteristics, fechral thread and wire are used in various fields of industry, gradually replacing the expensive and inferior nichrome.

General information

Fechral is an alloy whose main components are iron, chromium and aluminum. Actually, the name “fechral” comes from the first letters of these metals (iron in Latin sounds like ferrum). It belongs to the group of high-precision alloys with increased resistance. The type of chemical composition, physical properties and form of delivery are controlled by GOST 10994-94.

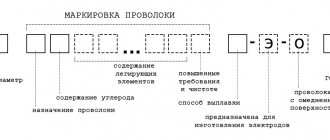

Fechral stamps

There are several types of fechrals. The most common brands are Kh23Yu5T, Kh27YuT5 and Kh15Yu. These abbreviations are deciphered as follows:

- "X" stands for chrome.

- "U" - aluminum.

- "T" is for titanium.

- The number after the letter shows the percentage content of this element. Its absence indicates that the volume fraction of the component is 1%.

It is not reflected in the name, but fechral, in addition to the named elements, contains small amounts of manganese (up to 0.3%) and silicon (up to 0.5%). They are necessary for the alloy to remove dissolved atmospheric gases from it: nitrogen, oxygen and hydrogen. Without them, the risk of zonal segregation - heterogeneity of the alloy in its properties - is significantly reduced.

The remainder of the chemical composition is iron. On average it is 77-78%. We should also not forget about the inevitable impurities: phosphorus and sulfur, the total content of which should not exceed 0.05%.

This is how fechral alloy is labeled in Russia. But the alloy is actively used abroad. They just designate it differently there. For example, fechral Х23У5Т in European countries is designated as:

- W-KA1.

- Alloy 875.

- Resistohm 145.

What special characteristics are hidden by all these abbreviations?