For welding parts made of aluminum and alloys based on it, aluminum wire is used, which is also used to weld workpieces made of this metal. All work using such wire is carried out in a protective gas environment, which is most often used as argon. Aluminum welding wire, if selected correctly, can ensure high quality and reliability of the weld being formed and the stability of its mechanical characteristics.

Aluminum Welding Wire Spool

Aluminum is known to be one of the most difficult metals to weld. This fact, which any experienced welder can confirm, is explained by the properties of this metal: a refractory oxide film is always present on its surface. Aluminum itself, if you do not take into account the mentioned film, has a low melting point, which also introduces difficulties into the welding process.

The optimal way to obtain reliable connections of parts made of aluminum and its alloys is mechanized arc welding. For its implementation, aluminum wire is used.

Features of welding aluminum and alloys based on it

Structures are most often made from 99% aluminum, aluminum-magnesium alloys, where the amount of magnesium is in the range of 4.8 ÷ 6.0% (the rest is aluminum) and aluminum-silicon (5.0% silicon, the rest is aluminum). These materials are characterized by unique properties:

- light weight (up to 3 times lower than that of steel and up to 7 times lower than that of reinforced concrete);

- corrosion resistance;

- high strength characteristics;

- do not lose their qualities at temperatures from minus 80 to 300 0C;

- connected by all known methods (mechanical, soldering, welding);

- do not react to most acids, oils, gases, ultraviolet radiation;

- do not lose their qualities in explosive areas and aggressive environments;

- polished;

- painted (anodized);

- duration of operation (more than 80 years).

What does a welder need to know to weld aluminum semi-automatically? Firstly, he must know what factors complicate the process of joining parts, secondly, be able to choose a semi-automatic welding machine for aluminum and, thirdly, know the technology of welding work that ensures quality.

The complexity of welding aluminum-based alloys stems from the physicochemical properties inherent in this material. These include:

- melting point;

- thermal conductivity;

- electrical conductivity;

- fluidity;

- interaction with oxygen;

- tendency to shrink;

- it is not possible to determine the melting process by appearance (the color almost does not change);

- the amount of magnesium in the alloy (the more, the worse the parts are welded).

Due to the presence of an oxide film on the surface, the melting temperature of the material is different - for the metal itself it is 660 0C, and for the film it can reach up to 2200 0C. This happens as a result of the active interaction of aluminum with oxygen in the air. In the future, it serves as protection against further oxidative processes.

Before welding parts, it is necessary to remove this refractory film from the surface at the joint. You can get rid of it in the following ways:

- mechanical (cleaning with a metal brush, grinding machine, file);

- chemical (etching using special solutions, fluxes);

- punching with an electric pulse (the semi-automatic device must have a special mode).

A semi-automatic welding machine for aluminum should operate at currents in the range of 50 ÷ 450 A. The choice of current, as well as voltage, depends on the thickness of the workpieces and the grade of the alloy.

Due to the increased thermal conductivity of the material, it loses strength when heated, which can lead to a defect such as burn-through. And here it is important to choose the right welding temperature and arc length. This depends on the thickness of the parts being welded, their position in space, brand, Ø filler wire or electrode. During the welding process, it is necessary to use heat-dissipating pads (ceramic or metal), including water-cooled ones.

Note! Before welding, thick parts must be heated with a torch or in furnaces to the required temperature (depending on the brand of aluminum alloy, but usually does not exceed 110 0C).

Types of aluminum wire and rules for its use

Filler wire, which is used to join parts made from aluminum and its alloys, can fall into one of two categories:

- Aluminum wire used to perform the technological operation of cold heading (requirements for the quality characteristics of such filler wire are specified in GOST 14838-78).

- Wire for welding aluminum, as well as alloys based on this metal.

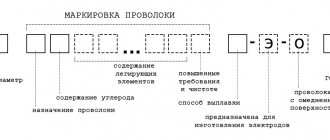

Recommended wire grades for welding aluminum alloys

When choosing a welding wire for welding aluminum alloys with different chemical compositions, it is better to opt for universal types of such consumables. In addition to the high reliability of the resulting connection, such wire allows you to provide:

- resistance of the weld to the formation of hot cracks;

- high strength of the formed seam;

- plasticity of the resulting connection;

- the ability of a weld to successfully resist corrosion processes.

Special flux-cored wire allows you to weld workpieces without gas. This video will help you understand the feasibility of using this technology.

Properly selected aluminum wire is not the only condition that allows you to obtain a high-quality and reliable welded joint. Proper preparation of the parts to be joined is also very important, which consists of thoroughly cleaning their surfaces and removing the refractory oxide film from them. It is important to perform this procedure immediately before starting welding, since the aluminum surface is quickly covered with an oxide film under the influence of the environment.

For the same reason, wire intended for welding aluminum, after opening the packaging in which it is supplied from the factory, must be used fairly quickly. Otherwise, its surface will be subject to active oxidation. In this case, the quality characteristics of the wire will be significantly deteriorated, which will also affect the characteristics of the welded joint formed with its help.

Temporary storage of an opened spool of aluminum wire

The wire that is used for semi-automatic welding of aluminum parts can have a different chemical composition. For such welding, wires made mainly of aluminum in combination with manganese, silicon and magnesium are used. The choice of a specific type depends on what elements are included in the chemical composition of the parts being welded.

The nuances of welding with semi-automatic machines

Welding is carried out in principle on any welding equipment. However, some requirements must be met. A semi-automatic welding machine for welding aluminum and its alloys must have:

- The feed mechanism is with U-shaped grooves and be with 4 rollers. This will allow the filler wire to be fed correctly without affecting its surface;

- the tip must be designed for feeding aluminum wire (it must be marked AL);

- the diameter of the hole in the tip feeding aluminum wire is 0.4 mm larger than the diameter of the wire (due to expansion that occurs due to heating during feeding);

- a hose feeding wire no longer than 3 m, in order to avoid deformation of the wire, and its channel must be Teflon or graphite to reduce friction (feeding is carried out at high speed).

Types of aluminum wire and rules for its use

Aluminum welding wire for semi-automatic machines consists of individual rods or coils of a certain diameter. In any case, they are hermetically sealed. The first feature of using this material is connected with this.

- Electrodes for working on aluminum are not recommended for use when carrying out important work that requires high quality. They are suitable not for industrial purposes, but for home and household purposes.

The fact is that aluminum under normal conditions is covered with a durable and elastic oxide film. Its melting point is about 2500º C. At the same time, the melting of pure aluminum is not higher than 600º C. For alloys the situation is not much different.

- To effectively clean and degrease aluminum and its alloys, it is recommended to supplement mechanical cleaning with the use of chemicals (for example, white spirit, acetone or a special hot alkaline bath)

A consequence of this feature of aluminum and its alloys is the need to first remove the oxide film from the surface of the parts being joined (for example, with a mechanical or hand tool). The electrode itself must be initially free of oxide.

- If the package of electrodes is not completely used up, it must be sealed again with silica gel added inside to absorb moisture.

Aluminum wire for semi-automatic machine

When choosing a wire for welding aluminum alloys, you need to consider what qualities are required from the future weld:

- Seam tensile strength.

- Plasticity of the connection.

- Corrosion resistance.

- Resistant to cracking from heat.

- The diameter of the aluminum wire for semi-automatic welding without gas should be 0.3-0.5 mm greater than the thickness of the parts it welds

It is most convenient to use the table below.

When using welding electrodes, you need to remember the need for their preliminary preparation. In a special purchased or home-made oven, preliminary uniform heating of the electrodes and their so-called roasting are carried out. This will allow you to form a very high-quality seam.

- Aluminum does not change its color when heated, unlike many other metals, so you need to be especially careful when working with it - it’s easy to burn through

In addition to preliminary preparation of the electrodes, you always need to prepare the parts to be connected. They need to be heated evenly in advance. And ensure that this uniform heating is maintained throughout the formation of the seam.

- An alkaline bath is the most effective way to comprehensively remove oxide films and degrease aluminum parts. To do this, you need to make a special solution of 2 liters of pure water, 100 g of trisodium phosphate, 100 g of soda and 50 g of liquid glass. The solution must be heated to a temperature of 60-70º C

It is also necessary to take into account that aluminum tends to cool unevenly and, as a result, crack. Of course, this is compensated by the plasticity of this metal. But if the welds are placed too close to each other (about 10-15 mm ), then cracks will certainly appear.

- Molten aluminum and its alloys are very fluid. That is why all seams are made in one layer in one pass. Where possible, it is recommended to use molten metal containment liners

Semi-automatic machines for welding aluminum-based alloys

Welding can be carried out semi-automatically without supplying shielding gas to the welding zone and with it. In the latter case, argon or a mixture of argon and helium is used. They prevent the formation of an oxide film. This especially applies to aluminum alloys, which contain more than 1% magnesium.

If welding is carried out without the use of shielding gas, then the wire for welding aluminum semi-automatically without gas should only be used as a powder wire or the welding process should be carried out under a layer of flux (evaporation forms protection for the molten pool from contact with air).

Semi-automatic welding of aluminum in a carbon dioxide environment is not carried out, because although it protects the molten metal from exposure to air, at the same time it reacts with aluminum. Because of this feature, it is impossible to obtain a high-quality and durable connection.

The advantages of semi-automatic welding include:

- high speed;

- the same penetration depth;

- the ability to weld seams without limiting their length;

- the ability to create products with complex configurations;

- reliable protection from harmful environmental influences;

- high quality welded joint.

Along with the advantages, it is necessary to note the disadvantages:

- the metal must be carefully prepared for joining;

- the semi-automatic machine must be adjusted depending on the brand of alloy;

- The welder must have the necessary qualifications and skills.

Note! Semi-automatic aluminum welding is not performed outdoors.

Advantages

- Gives high quality results when working with aluminum;

- There is a wide variety of choices, thanks to which you can choose the right option for almost any alloy;

- Has high corrosion resistance even when subjected to heat treatment;

- You can easily determine the thickness of the required wire, according to the thickness of the workpiece;

- Equally well suited for both manual and semi-automatic welding;

- Additional alloying elements help to better combat the negative aspects of aluminum welding.

Argon arc welding

There are 2 types of welding - TIG and MIG. In the first case, welding is carried out using a tungsten electrode in a shielding gas (argon). Semi-automatic welding of aluminum in argon, as well as alloys based on it, is performed using alternating current.

Such a device must be equipped with a special device. It facilitates the arc ignition process. The supply of inert gas and wire (solid or flux-cored) occurs through a specially designed welding torch. In this case, the welder has the opportunity to control the welding process.

MIG welding or it is also called semi-automatic pulse welding is carried out by an inverter. The device can change the voltage frequency, which affects the quality of the weld. A pulse semi-automatic machine for aluminum welding is the optimal solution, because... increases welder productivity and saves electrical energy consumption.

What to look for when choosing welding wire

When the desired type of welding wire has already been selected. It is necessary to pay attention to the high-quality preparation of the workplace and the conditions in which welding will be carried out.

First of all, you need to take care of the cleanliness of the metal with which you plan to perform welding work.

- It must be thoroughly cleaned of dust; sponges or brushes are used for this purpose.

- If there are burrs or chips on its surface, they must be carefully cleaned with sandpaper.

- After this, the material must be degreased so that the welding quality is higher.

- Degreasing is done using a solvent. At this stage, you should carefully choose a solvent, guided by the specific type of metal.

Only after preparatory procedures and checking the electrodes for integrity and quality can welding of parts begin.

Types of wire

Wire for semi-automatic welding of aluminum is a filler material. During the welding process, it melts and becomes part of the seam. Therefore, the main requirement for its selection is that the chemical composition must be close to the chemical composition of the material that will be welded. Also, its melting temperature should be either the same as the elements being welded or slightly lower.

Aluminum welding wire for semi-automatic machines is produced by Russian and foreign manufacturers Ø 0.8 ÷ 3.2 mm. Welding of aluminum with wire is carried out with the grades indicated in the table.

| Brand according to international classification | Domestic analogue |

| OK Autrod 1070 (18.01) | St. - A85, St. - A97, St. - Amts |

| OK Autrod 1450 (11/18) | St. - 1201 |

| OK Autrod 4043 (18.04) | St. – AK5, St. – AK6 |

| OK Autrod 5183 (18.16) | St. – AMg5 |

| OK Autrod 5356 (18.15) | St. – AMg3 |

Wire for semi-automatic welding of aluminum according to another common classification EN ISO 18273 can be marked ER 4043, ER 5356. These are the most commonly used filler materials for welding cast alloys such as AD31, AD33 and AD35, if they do not require an anodizing operation. Supplied in coils or on cassettes of different weights.

Semi-automatic welding of aluminum without gas is carried out using flux-cored wire; it is also called self-shielding. It has a tubular structure inside which there is a powdery filler. It simultaneously performs several functions - deoxidizes, alloys, protects from harmful effects of air, forms a seam, etc.

The choice of diameter and brand of self-shielding wire depends on the thickness of the products that will be welded and the composition of the aluminum alloy.

Types and varieties of welding wire

The first thing you should know is that different types of metals are used as the welding mixture. The most popular are steel, aluminum, brass, and stainless alloy. It is also worth noting that the wire may be coated with a small layer of copper.

All consumables are subject to mandatory certification; they must fully comply with GOST 2246. Let's consider several varieties:

Solid section

They are most popular due to the fact that they have the lowest cost on the market. They are a solid-state consumable that is quite convenient to work with.

The selection criteria depend on the type of metal and its thickness. It must be remembered that thin, thin steel with a low carbon content does not contain slag during operation, and the cord cools much faster.

Cored wire

According to the type of work, it is used in exactly the same way as conventional electrodes. This wire consists of a metal type sheath and has a hollow space inside, which is filled with flux for welding.

This type of wire is chosen if you have to work with thick materials. This is due to the fact that during operation such wire leaves slag, which contributes to slower cooling.

Activated model

In many ways it is similar to the previous version, but has several differences. The first is the lower flux content inside the wire.

The total amount of granular additives does not exceed 7%. Such wire, as a rule, can only be used when welding in CO2 and also when welding its mixtures.

On sale, all these varieties are presented in the form of drums of different diameters. There are 0.8, 1.0, 1.2, 1.6 mm.

Experienced welders recommend choosing copper-coated wire. This is explained by the fact that consumables with such a coating allow for better quality welding. In addition, they protect against oxidation and greatly facilitate electrical contact.

Semi-automatic aluminum welding technology

The quality of the resulting weld depends on many factors - the apparatus used, the filler material, the quality of the argon (for argon-arc welding), and the skills of the welder. How to weld aluminum semi-automatically? Depends on the model of the device, but no matter what it is, you must perform the following steps:

- preparation of workpiece surfaces . Remove various types of contaminants using rags. Next, you need to remove the oxides. They are removed using a metal brush, an angle grinder and etching with special solvents and reagents. At the same time, these rules are adhered to. The brush should not be pressed too hard on the product and cleaning should only be done in one direction. Residues of etching liquids must be removed using acetone solvents or by washing. For products with a thickness of more than 3 mm, the edges are cut. Cutting angle 60 0;

- heating . Carry out in ovens or using a burner. This is especially true for workpieces that have different thicknesses. The warm-up temperature should not exceed 110 0C;

- setting up the device . Regardless of the type of device used, the wire diameter, tip diameter, current strength and voltage are selected. Most often, special tables are used, which are included in the product instructions. The most profitable are pulse-type devices equipped with a special program. The welder only sets the current value, and the microcontroller selects the remaining parameters automatically;

- determine the position of the torch and the speed of the welding process . It should be located at an angle of no more than 20 0 to the vertical, welding is carried out at high speed only from right to left. Particular attention must be paid to the end of the seam. It is welded, returning back 20 mm, without turning off the welding arc.

The welding result is influenced by the qualifications of the welder and his skills. He must use protective equipment - a mask, respirator, overalls, shoes and gloves. The welder should not have exposed areas of the body, as it is possible to get a burn from ultraviolet radiation.

A few words about the reasons for marriage. Most often, after welding, burns, cracks, and an incorrectly welded crater are found. Cracks occur due to a violation of the technological process.

When the heating temperature is exceeded, the alloy expands, and if slow cooling is not ensured, then rapid compression occurs, which leads to the occurrence of cracks and ruptures. The use of heat-dissipating pads will ensure the quality of welding. Unscrupulous preparation of the product for the welding process also negatively affects the quality.

A semi-automatic welding machine for aluminum welding is a device that allows you to increase labor productivity. Its use will be effective if all the requirements of the device manufacturer, which are specified in the passport, are taken into account. Therefore, it is necessary to carefully study the instructions and follow their instructions.

Features of feeding mechanisms for aluminum welding wire

The standard semi-automatic feed mechanism is not very suitable for working with aluminum wire. This is explained by such characteristics of this metal as high ductility and thermal conductivity.

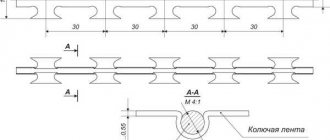

The feed mechanism of a standard semi-automatic welder, which uses two rollers, can crush the soft aluminum wire, which will lead to it getting stuck in the mechanism. That is why, when using aluminum wire in a semi-automatic machine, it is necessary to equip it with a feed mechanism consisting of 4 rollers, each of which has a U-shaped working groove profile.

Read also: How to take Mercury 234 electricity meter readings

Four roller wire feeder

To work with a semi-automatic machine that will use aluminum wire, it is necessary to equip it with a supply hose of minimum length (up to 3 meters). Otherwise, the soft wire will simply get stuck in the long feed hose. This problem can be solved by using a Teflon feed channel, which will make it possible to significantly reduce the friction of the wire against the walls of such a channel.

To avoid aluminum wire, which has a high coefficient of thermal expansion, getting stuck in the tip of the semi-automatic welding machine, you should select the tip so that the hole in it is slightly larger (1–2 mm) than the diameter of the wire itself.

A set of different tips makes it easy to select the desired hole for the wire

The feeding mechanism of the semi-automatic machine, on which it is planned to use aluminum wire, must operate without interruptions, which are a common cause of wire getting stuck in the feed channel. Interruptions in the operation of such a mechanism most often occur due to unstable operation of the reel braking device. To prevent such problems from arising during welding, it is necessary to adjust the force created by the coil: it should be able to be reduced to a minimum. At the same time, such force should be sufficient to prevent the coil from rotating.

The correct choice of wire for semi-automatic welding of aluminum parts in an argon environment, as well as the parameters for performing such a technological process, allows not only to obtain high-quality, reliable and beautiful welds, but also to minimize the risk of defects during their execution. Such parameters include not only the diameter of the wire used and its chemical composition, but also its feed speed, as well as the values of the welding current and the polarity of its connection.

The amount of welding work in a home workshop usually does not require a large consumption of aluminum wire, but small spools are not suitable for all devices. Ingenuity will help you install a small bobbin, as shown in the video.

Aluminum, without exaggeration, is one of the metals most commonly used by humans. But, due to its special chemical properties, welding work on it is much more difficult than with ordinary steel, especially if you are not a welding specialist. And yet, for this there is a very convenient way that requires less skills - semi-automatic aluminum welding (MIG/MAG), which makes it possible to easily overcome the resistance of the thinnest oxide film of the metal and, as a result, obtain an excellent connection. You will learn more about this method in our article.