Why does rust appear?

Metals are subject to rust due to the fact that they are not mined and used pure, but in the form of chemical compounds with oxygen, carbon, water, sulfur and other elements. Corrosion is not a problem for pure metals, since they do not tend to form compounds with environmental substances. However, there are few such materials - silver, gold and platinum.

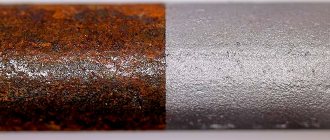

There are a huge number of different ways to remove rust from metal, but not all of them work as desired.

Most mined contaminated metals are smelted, purified, and reduced to make them pure. However, in this case they become unstable and tend to react with environmental elements. Thus, when a metal comes into contact with air, an oxide is formed, and with moisture, a hydroxide is formed. These processes are natural for iron and are called corrosion, and their result is rust.

Even if you can’t remove the rust the first time, with some effort you can always return the item to its original appearance.

Since metals are mainly used as durable materials, which are the basis for various structures, they are constantly in contact with the environment and the corrosion process is inevitable. If air oxygen and moisture are constantly present, then after some time the iron can be destroyed to the ground, completely converted into rust.

There are various ways to remove corrosive plaque if the process has not gone too far.

However, corrosion is not a very fast process, so iron products are destroyed over a fairly long period of time. In addition, new methods are being invented to delay the appearance of rust as much as possible.

Note! High-quality removal of rust from a metal surface is one of the most effective ways to preserve a product in proper condition.

However, rusty deposits can often be present on various non-metallic surfaces such as tiles or bathtubs. This occurs due to rusting plumbing fixtures and other equipment with metal elements that are exposed to the environment. Rust is then carried by water, contaminating surfaces in addition to limescale. However, all such coatings are quite easy to clean.

Household chemicals are the most effective means for removing rust.

It is worth removing rust in the following cases:

- Before gluing or painting metal products. Traces of corrosion will not allow glue or paint to firmly adhere to the metal surface, and therefore they must be removed.

- To protect against destruction. In order for a metal product to last a long time, it must be promptly cleaned of iron oxides and coated with anti-corrosion materials such as zinc oxide.

- For aesthetic reasons.

Rust on metal - causes of its occurrence

The first and very important question with which you need to start fighting corrosion involves finding out the cause of its occurrence. Having learned the reasons for the reaction, you can not only choose the optimal method for removing corrosion, but also prevent its reoccurrence.

Why does metal rust? The main reason for the reaction is the composition of the metal. It consists of various compounds such as oxygen, carbon, sulfur and others. It is these components that become the result of the appearance of rust stains on metal parts placed in water or a humid environment.

This is interesting! Pure metals do not rust, and these include gold, silver and platinum.

Metal in contact with air forms oxides, and with moisture - hydroxides. The effect of moisture and oxygen on metal contributes to its destruction, and the thinner the steel, the faster the process of its destruction occurs. This phenomenon is called corrosion, and the result of its occurrence is rust. It is almost impossible to avoid the occurrence of these processes, but various methods and techniques are used to reduce the rate of corrosion development.

Corrosion is a long-term process, so the destruction of metal products requires a long period of time, which directly depends on the thickness of the iron. It follows from this that the main reasons for the appearance of rust on metal are the following factors:

- Exposure of untreated metal to oxygen and moisture. In this case, the part does not necessarily have to be in a damp room. If you store a metal product in a dry and ventilated area, then signs of corrosion will also form after some time.

- Lack of special protective coatings - these include not only varnishes and paints, but also zinc coatings, which provide highly effective protection against the destructive effects of corrosion.

- Type of steel - high-alloy steels are susceptible to rusting with less intensity, which is due to the low percentage of carbon in the composition. However, such steels are quite expensive, so they are used for the manufacture of various high-precision parts or consumables for power tools.

Many people mistakenly believe that a type of steel such as stainless steel does not rust. We will not go into details of the composition of this material, but it is worth noting that even stainless steel is subject to the corrosion process. This is due, first of all, to the fact that the chrome film, which forms upon contact with oxygen, and thereby protects the metal from rust, is damaged, which ultimately leads to the appearance of rust.

To summarize, it should be noted that metal rusting is a normal natural phenomenon, which is a global problem for humans. And we are talking not only about problems with a rusting car body, but also about such global disasters as the sinking of ships, the destruction of bridges, etc., provoked by rusting metal.

Special removal products

Chemicals allow you to quickly and effectively remove contamination of almost any complexity and age. Such products can be produced in various forms - liquid, spray or gel. In this case, all the necessary components are already included in the composition.

You can buy rust remover liquid in specialized stores.

Important! When working with concentrate, the substance must be diluted with water in accordance with the instructions.

The cleaning products contain the following elements:

- Acids, for example, hydrochloric, sulfuric, phosphoric or silicon. The substances they contain can only be used to clean acid-resistant surfaces. The strongest acids are used in combination with inhibitors due to their high causticity.

- Inhibitors. These substances slow down the chemical reaction of the acid with the metal surface, which allows the solution to remove only the rust layer without destroying the structure of the product. In this case, a special protective layer is formed on the processed surface.

- Surfactants (surfactants). Nonionic substances are more common due to their high cleaning power and good compatibility with other components.

- Dyes, water and some other substances.

When starting to remove rust with your own hands, always wear plastic or rubber gloves.

Note! Special chemicals are highly caustic, so work with them should only be done using thick rubber gloves, respirators and safety glasses in a well-ventilated area with running water.

Rust converters are quite popular. These substances do not remove existing plaque, but block the development of corrosion. In this case, the rust turns into a new protective film, which leads to the formation of chemically pure iron. However, after treatment with such compounds, the surface of the metal changes its color, becoming blue-violet.

Rust converter is a chemical solution or primer that is applied to the surface of iron or iron alloy.

Chemical exposure

How can you remove rust from metal using chemical methods? The product is selected in accordance with the required degree of rust removal from the metal. The choice is up to the buyer. Sometimes cleaning is done using several means at the same time.

So what can you use:

- Acid for rust removal. The substance can be purchased at any hardware store. The method of use is usually indicated on the packaging. Anti-rust acid is an aggressive agent, so it can dissolve not only the oxidized environment, but also metal surfaces.

- Anti-rust product. By corroding the corrosive coating, it preserves the material itself on which the problem area was concentrated. This is the best rust remover that can be used at home.

- Rust converter. This is a currently relevant remedy that is actively used to remove damaging formations. The key to effectiveness lies in the correct use of the composition in relation to a particular surface and material.

There are actually a lot of drugs that cope remarkably well with corrosion and its derivatives. Each product has its own characteristics regarding use and principle of operation. The choice depends on how quickly the cleansing needs to be done and what level of damage will be treated.

Mechanical removal

Since corrosion products have low adhesion, they are easy to remove from the surface of the product by mechanical action. This method is convenient for removing rusty deposits from large, smooth metal surfaces. It is also advisable to use this method for cleaning heavily rusted products as the first stage of completely removing contamination.

The mechanical method includes removing rust using special brushes, grinding wheels, and sandpaper.

To clean large items, you can use a grinding machine, starting with the coarsest grains and finishing with the finest grains. Metal brushes and abrasive attachments for an angle grinder or drill are also suitable. It is more convenient to clean small parts with sandpaper.

Products with complex geometry are difficult to mechanically influence, so it is more effective to use other methods for them.

Note! The areas of metal treated in this way remain without protection from the environment, and therefore, without special treatment, they will become covered with rust even faster.

Where problems appear

Corrosion appears in places that are affected mechanically. The most common problems that arise are:

- First, rust appears on the surface of the thresholds;

- problems often arise with the hood due to small pebbles from the vehicle in front;

- the car underbody suffers from rust;

- Aggressive chemicals negatively affect the area where arched structures are located under the wheels of a vehicle.

Note! If rust appears in a timely manner and is eliminated, the car owner can prevent further problematic situations. After this, corrosion does not spread.

To cope with the problem, you need to decide how to paint over rust on a car with your own hands.

Traditional methods

The main rules when using any of these products are strict adherence to the exposure time to prevent damage to the product itself and thorough drying to delay re-corrosion.

Aluminium foil

In this case, the foil acts as an analogue of an abrasive brush, that is, it has an exclusively mechanical effect. A piece of foil must be crumpled into a tight ball that can be used to clean the surface. It is worth considering that this method is suitable for minor stains on household appliances. But to clean rusty pipes it is better to use chemicals.

You can remove rust from such areas and give them a smooth look using a crumpled up ball of aluminum foil.

Vinegar

It is worth using white vinegar, since its flavored and colored analogues not only will not help remove dirt, but can also leave new stains. The operating procedure is as follows:

- pour vinegar into a spray bottle;

- apply the substance to the affected area;

- leave the treated surface for a couple of hours;

- remove plaque with a wire brush;

- wash off traces of vinegar with warm water;

- Dry the treated area in the sun or wipe thoroughly with a rag.

Vinegar is the most popular and affordable means for removing corrosive deposits from metal products and more.

Note! Small metal objects can be placed entirely in vinegar for up to a day.

Soda

Effective enough for small stains. Soda must be diluted with water to obtain a paste-like mass, which should be applied to the surface in a thick layer. After half an hour, the plaque can be easily removed with a metal sponge or brush.

If necessary, the procedure can be repeated.

Lemon acid

A fairly effective remedy with a number of advantages:

- availability;

- maintaining the appearance of paint covering a metal product;

- absence of aggressive chemicals;

- harmless to the skin of the hands (the use of gloves is still recommended).

This method removes corrosion in all hard-to-reach places.

Before starting work, the metal surface must be degreased, which can be done using dishwashing detergent. Next, the product is placed in a concentrated solution (80 g of citric acid per 100 ml of warm water) for several hours. In this case, the reaction begins within a few minutes, as indicated by the formation of bubbles. After the reaction is completed, the surface should be washed under running water, if necessary, removing remaining contamination with a wire brush.

Oxalic acid

The algorithm for working with this substance is as follows:

- wash the rusted product using any dishwashing detergent;

- dry thoroughly;

- mix six teaspoons of oxalic acid with 300 ml of water;

- immerse the object in the solution for half an hour;

- remove rust residues with a stiff brush;

- dry the product thoroughly.

When using it, you must adhere to safety precautions: wear safety glasses and rubber gloves.

Important! When working with oxalic acid and its solution, you must use rubber gloves, a respirator and safety glasses.

Hydrochloric acid

A 2% hydrochloric acid solution will effectively clean rust from a white item. In this case, it is enough to simply treat the item to be cleaned with acid until the contamination disappears. Afterwards, it must be rinsed in a solution of ammonia and water (a couple of tablespoons of ammonia per liter of water).

Using this product, you can effectively clean rust from white items.

Hydrogen peroxide

This substance has oxidizing and reducing properties, which allows it to effectively remove traces of rust from objects such as a bathtub, toilet bowl, knives or tools.

Note! To increase the effectiveness of the peroxide, it can be used in combination with trisodium phosphate.

Hydrogen peroxide is used according to the following scheme:

- dilute four tablespoons of trisodium phosphate powder in three liters of water;

- carefully pour 50 ml of peroxide into the solution, dividing into five portions;

- soak the product in the mixture for half an hour;

- thoroughly wipe the treated area with a regular sponge, then leave the product for another ten minutes;

- rinse the surface with clean water.

Coca-Cola

This drink contains phosphoric acid, and therefore can be used to remove rust. It is enough to place the damaged product in liquid for 25-30 hours, after which it should be rinsed with clean water and wiped dry.

Surely many housewives have heard that you can remove rust with cola.

How heat treatment helps against rust

You can simply burn off rust on metal with an acetylene torch and then paint it. This method has a drawback: the stains may appear again if such treatment is not carried out carefully enough, and it is quite difficult to notice the surviving source of metal corrosion through the flame. After the first flame treatment, carefully inspect everything and try again, or you can use some other method.

There are many other recipes for removing rust, such as a mixture of glycerin with tooth powder, salt with lime juice, vinegar with flour and salt, hydrogen peroxide and ammonia, kerosene, Coca-Cola and Fanta and others.

For especially valuable things (ancient coins, for example), craftsmen use electrolysis. It’s very effective, but not everyone can assemble the necessary installation for this, but if you succeed, you won’t regret it. The process is easy to control, and the result is simply excellent. Try, experiment, share your experience with others, because you are not the only one who has to fight this problem.

Do not forget to dry metal surfaces after any wet treatment by wiping them with a napkin or rag.

This is especially important if you are going to paint them!

How and with what to remove rust from metal

Removing traces of corrosion from various objects has its own specifics that must be taken into account.

From the body of a car

Rust often forms on the car body. The following products are best suited to remove it:

- Orthophosphoric acid. Its solution is applied to a sponge, which is used to wipe the car body.

- Zinc. Mixtures are made from it that allow you to get rid of contamination after the first treatment.

From a water tap

The optimal remedy for rust on metal, especially for cleaning enameled metal surfaces, is Adrilan, produced for washing household appliances. Since it is very concentrated, it is diluted in warm water before use.

An effective cleaning agent, and not only against rust, but also against any contaminants.

Note! The faucet in the bathroom or kitchen must be cleaned very carefully to avoid damaging the coating.

From a bicycle

You can easily get rid of rust stains that appear on a bicycle frame over time using citric acid. Moreover, before removing rust from metal, the surface must be degreased, and then rinsed and dried thoroughly.

From skates

If skates are stored for a long time in conditions of high humidity, a rusty coating begins to form on them. You can remove it using a mixture of baking soda and lemon juice. To do this, the components are mixed until a mushy substance is obtained, which must be applied to the contaminated surface for an hour and a half. After this, the skates need to be washed and dried.

Effective folk remedies will help eliminate rust stains from skates.

From a horseshoe

An old rusty horseshoe can be cleaned with oxalic acid. To create a solution, you need to mix acid and boiled water in a ratio of 1 to 12. A horseshoe is placed in the resulting liquid for forty minutes, after which it is washed with running water.

From the tools

Metal tools that are rarely used will corrode over time. You can clean them from rusty deposits using a vinegar solution. To prepare it, you need to mix white vinegar with warm water in equal proportions. The resulting liquid is applied to contaminated instruments, after which they can be easily cleaned with a wire brush or sponge.

Pour vinegar into a container large enough to fit the spoiled item. Immerse the product in a container with product.

Once cleaned, polished metal instruments can be treated with a solution of gasoline and wax or paraffin to protect them from further corrosion. To obtain it, you need to add paraffin or wax to gasoline heated in a water bath.

From the nut

You can clean the nuts from corrosive deposits using a vinegar solution. To do this, dilute 100 ml of white vinegar in a bucket of water, after which all rusted nuts are placed in a container for three to four hours. After this time, the nuts are washed with clean water and wiped off any remaining rust.

Cleaning small household items

All of the above methods can be used to clean small metal objects. The only difference is the ability to place the rusty product entirely into the product being used.

Follow all the above rules and you will notice that rust can be removed quickly and without much effort.

Natural rust removers

If the rusty spots are still small, then you just need to clean them with sandpaper or a stiff brush, and then the product is covered with paint, which will protect it from corrosion in the future.

And if this method is not suitable, then you can get rid of minor red spots using natural remedies that do not contain chemicals. https://youtube.com/watch?v=6m7ca6oHoy4

Lemon with potatoes

If there is a thin red film on metal utensils or small items, they should be wiped with potatoes cut in half. It contains an acid that helps dissolve rust, which in small quantities will not be harmful to the metal. Leave the area treated in this way for about 5 minutes, then wipe with a soft, lint-free cloth, which can be used to remove any remaining plaque and juice.

You can also clean rusty areas using potato gruel with the addition of crushed lemon and 2 tablespoons of coarse salt. Apply this mixture to the rust, leave for 15 minutes, then rub in with a toothbrush and wash off with a damp cloth.

Dry lemon zest can serve as sandpaper. It is suitable for cleaning fragile metal items or jewelry and, unlike sandpaper, will not leave scratches on the surface.

If the rust has already set in, you can get rid of it using a mixture of lemon juice and table vinegar. They need to be mixed in equal quantities and applied to the surface using a rag or sponge. It is better to work with rubber gloves. Leave the item for several hours, then rinse with warm water and treat the item with a hard metal sponge.

Flour and soda

If you need to clean old rusted items without damaging them, we recommend using baking soda. This is done like this:

- Dilute 2-3 tablespoons of soda in warm water to a homogeneous thick consistency;

- place coins or objects into the resulting mass;

- take it out after 20 minutes;

- Scrape off the plaque with a washcloth or wire brush;

- If one procedure is not enough, the procedure must be repeated.

To clean brass products, it is recommended to use table vinegar with salt at the rate of 120 ml of vinegar per 10 g of salt. Then add corn or wheat flour or oatmeal powder. Knead a thick dough and apply it to the affected areas of the metal. Wipe off the paste after half an hour with a soft cloth, then rinse the product in warm water and dry with a towel.

To prepare such a solution, you cannot use apple or wine vinegar, only clear table vinegar. Other types leave streaks on the metal surface and are very difficult to erase.

And there is also a very old method that was known a hundred years ago. You need to take a couple of grams of camphor and 100 grams of melted pork fat. A metal object is treated with this mixture and left for a day. Then it is rubbed with a woolen rag.

Preventing rust

To protect metals from rust, various alloys are created. Thus, chromium, molybdenum, nickel, sulfur, titanium and other elements are often added to the composition, which are responsible for certain properties of the resulting alloys. However, this method is not always acceptable and is also quite expensive.

A stainless alloy is formed if the chemical composition contains more than 13% chromium.

A more convenient option is to apply coatings to existing metal, forming a barrier between the surface of the product and the environment, which helps slow down the corrosion process. Paints or primers are often used as a coating, but the most effective option is to apply a thin layer of another metal that rusts very slowly. For example, iron can be coated with chromium, tin, copper or nickel. At the moment, zinc is considered the most optimal option, combining ease of application, low cost and high efficiency. It corrodes three times slower than the vast majority of metals and, when applied correctly, can completely stop corrosion for 25-30 years.

Galvanizing is a coating of metal with a layer of zinc to protect it from corrosion.

A rusty coating eventually affects almost any metal. However, with timely cleaning and treatment, the service life of the product can be significantly extended.

You can remove rust stains from any metal surfaces.

How to remove plaque using folk remedies?

The effectiveness of the exposure method is increased by a combination of chemical treatment and mechanical action. Homemade recipes are based on the use of easily available products that may already be in the household. Their main advantage is low cost and availability.

As a rule, the choice in favor of folk recipes is made with minor corrosion. Most often it is not difficult to deal with it.

Coca-Cola

Using Coca-Cola in the household allows you to clean various surfaces. One popular recipe is to use the drink to remove rust.

In order for the orthophosphoric acid in the drink to take effect, you can use a rag soaked in Cola. A rag is soaked generously in the drink and applied to the surface that needs to be cleaned from corrosion.

This recipe is suitable when the rust has not penetrated deep into the metal, since the concentration of phosphoric acid in Coca-Cola is low. The exposure time should be at least several hours, preferably a day.

But if the metal is seriously damaged, this method is ineffective. At the end of exposure, the cola is washed off with water and the surface is wiped dry. When using Cola, it is enough to use only rubber gloves as a means of protection. Read more about using Coca-Cola against rust here.

Lemon

One of the easiest recipes to deal with rust is to use citric acid.

To do this, the acid powder is diluted so that a very concentrated solution is obtained, with all grains completely dissolved.

The product can be used in two ways:

- apply generously with a sponge to the affected areas of the metal;

- soak a rag in the solution and apply to the rusted areas.

The last of the presented options is more effective, but even this method will not eliminate serious corrosion.

The duration of action of the composition is at least an hour. After this, the metal should be cleaned with a stiff brush, and the residue should be washed off. Read more about the use of citric acid in the fight against rust here.

Vinegar

Vinegar also allows you to remove rust during mild corrosion processes.

For exposure, undiluted vinegar is used. If the rusted items are small in size, they can be placed in a container and simply poured. For large metal objects, ensure that the cleaned surface comes into contact with vinegar.

After exposure to acetic acid, the surface is refined by mechanical rubbing and washing off the remaining vinegar.

Before painting directly, the metal must be primed. You can learn more about using vinegar to combat metal corrosion in this article.

Sorrel

Oxalic acid is a drug that comes in powder form. This remedy gives good results, but requires very careful use, as it is poisonous. Use may only be carried out in compliance with all necessary protective measures.

Before using acid, the metal surface should be prepared - washed with soap and dried. The treatment solution is prepared by diluting 6 tsp. acid in 300 ml. water.

How to use:

- Apply the solution generously with a brush.

- Leave for 30-40 minutes.

- Remove loose rust.

- Rinse off any remaining product with water.

Oxalic acid is suitable for advanced cases and large area surface treatment.

Orthophosphoric

Phosphoric acid is a commonly used component of ready-made rust converters.

This substance is highly effective and can be used even in advanced cases.

To prepare metal for painting, an acid concentration of 15-20% is required. Exposure to orthophosphoric acid should not be long - just 5 minutes is enough. After this, you can walk over the surface with a brush.

All work must be carried out in conditions of sufficient ventilation and using protective equipment. Read more about the use of phosphoric acid here.

Materials

Before removing rust from a tool with your own hands, you should prepare:

- the instrument to be restored;

- screwdriver;

- sandpaper of different grain sizes;

- drill;

- wire brush;

- polish;

- polishing attachment.

Step 1

. The most difficult stage in this work of restoring an instrument is disassembling it. Due to rust, the threads and screws are thoroughly stuck, and it is not easy to unscrew them. It is not possible to do this manually, using just a screwdriver and pliers.

To disassemble the tool into its component parts, you need to place it in a vice. If in your case it’s still not possible to disassemble the instrument, you will have to resort to chemicals that corrode the rust. Be careful with any method of work; you may no longer find similar bolts and screws for old tools. Be careful not to break them, and don't throw away any of the parts.

Step 2

. You will first need to remove dirt, paint and old rust from all elements of the key with a wire brush. During this work, the main contaminants will disappear, and you will already see shiny steel. Don't touch the thread yet.

Step 3

. Continue to remove dirt from previously cleaned elements, trying to clean hard-to-reach places as well. Use 200-gauge sandpaper for this job.

Step 4

. Continue to work, but using paper of a different caliber each time: from 400 to 2000. When stripping, choose one direction of movement and move strictly along the given lines. During the work, some of the metal will also be removed along with dirt and rust. It is important that the material is also washed evenly, and you can clearly see the areas that have already been treated.

Step 5

. Clean the screw and thread using fine-grained sandpaper.

Step 6

. Take the materials prepared for polishing and the drill attachment. Proceed to finishing the metal.

Ready! Ideally, the surface of your old tool should look like new.

Homemade products from a washing machine engine:

1. How to connect a motor from an old washing machine through a capacitor or without it 2. Homemade emery from a washing machine engine 3. Homemade generator from a washing machine engine 4. Connecting and adjusting the speed of a commutator motor from an automatic washing machine 5. Potter's wheel from a washing machine machines 6. Lathe from an automatic washing machine 7. Wood splitter with an engine from a washing machine 8. Homemade concrete mixer

How to remove rust from tools, bolts and nuts with your own hands

- how to remove rust from a tool?

- how to clean rust from a coin?

- how to remove rust from a knife?

There's an answer!

Have you ever been cleaning out your garage and found a bucket of tools that might be wet and rusty?

DO NOT THROW THEM OUT!

There is a simple solution to restore their appearance for very little money, because buying new tools will cost you a decent amount.

So, have you found bags of nuts, bolts and tools corroded? If you do not know about the properties of vinegar, you will think that they are useless, nothing more. Wear gloves to avoid getting rust on your hands, because rust is very difficult to wash off. Gather all your corroded tools, nuts and bolts together. Depending on how many rusty things you find, select a container so that everything will fit. You can use a large basin.

Read also: Slavyanka engine winding diagram

Place your tools in a bucket and fill the bucket with vinegar until the vinegar covers the contents of the bucket. You won't believe the properties of the almighty vinegar. It will eat up the rust on tools, bolts and nuts!! This will all bubble up and you will watch as the rust starts to rise to the top.

If your tools are very corroded, you will need to leave them for several days, maybe even up to a week. Check them and when you see clean metal then it's time to take them out. Be sure to wear gloves when checking your tools! After taking them out, rinse them under running water and let them dry on a rag, or wipe them dry using the same rag. The vinegar cost practically pennies compared to what new tools would have cost!

- Potatoes remove rust

Fresh potatoes contain oxalic acid, which will help us in this matter. If the rusty spot is small, for example on a knife blade, then sprinkle salt on the cut potato and clean the knife with it. You can simply hold the potato with salt on the rusty spot for about 15 minutes, then rinse and dry.

- Vinegar and lemon juice

We mix these two components, which can be found in any kitchen in equal parts, and apply the mixture to the rust stain on metal, clothing or tiles. For metal, the mixture should be kept for two hours, for other materials, 15-20 minutes. After finishing the treatment, we also wash and dry the surface.

To prepare the composition, mix regular baking soda with water so that you get a not very thick paste. Apply this mixture to the rusty area of the metal surface for 15-20 minutes, then remove it with a steel wool. You may have to repeat this procedure a couple of times.

- Coca-Cola or other soda

Quite a modern rust remover. American housewives first started using Coca-Cola, who noticed that it copes well with rust stains. It's all about phosphoric acid, which dissolves rust. So think again about whether you should drink water that dissolves iron oxide.

Alka-Seltzer

Another miracle of modern chemistry that helps those suffering. It will help us remove rust stains from aluminum cookware. Place the dishes in a container, fill with water and add 4-6 Alka-Seltzer tablets. After 5-10 minutes, rinse with clean water and dry.

Yes, and it will come in handy in this matter. Place ketchup or tomato sauce on the rust stain, wait 5-10 minutes, then wipe dry

- Toilet bowl cleaner CILIT

Take an old rusty scraper:

And immerse it in CILIT toilet bowl cleaner for several hours. Is there a difference before and after?

- As for professional methods,

then there are a large number of rust converters or removers on sale that operate on the same principle - the composition enters into a chemical reaction with rust, transforming it into a dense black or dark blue coating, which can then be painted. As they say, fast and reliable. I recommend using these products to remove rust on water pipes, metal rods of buildings and other solid metal objects. It makes no sense to cite specific means, since it is not worth advertising for any brand, since its products may not suit everyone. Converters and rust removers are sold in auto stores and auto departments of construction supermarkets. So that you do not have to use all these means to remove rust, first of all take care of its prevention - regularly paint metal surfaces, treat them with anti-corrosion impregnation and protect them from moisture.

- Testing the B-52 rust destroyer

The work with Audi has been sooo long... I've been fighting rust for days now. I fight using metal brushes on a drill and flap wheels on a grinder. Flap wheels and steel brushes remove rust well, but are very rough on living metal. Brass brushes are more kind to metal, but they are also less effective at removing rust.

There is, of course, also sandblasting - it removes rust with a bang (it does a good job of cleaning rust from sinks), and it is quite gentle on metal (more precisely, steel). But I don’t use it openly in the garage (maximum in a sandblasting chamber), and the weather doesn’t allow it outside.

In my search for a way to carefully and efficiently remove rust, I came across the B-52 Rust Destroyer.

There are tons of descriptions of his theoretical work on the Internet, but I almost never came across any practical tests. So I decided to test it on a rusty piece of metal from my car.

According to the instructions, the product must be applied to the surface with a layer of 1-2 mm, left for 15 minutes, then rinsed with water, wiped the surface with a dry cloth, and then wiped with solvent 646; if necessary, the procedure can be repeated. Here is my “lab mouse” - a cutout from the rear left fender (above the canopy).

Immediately applied the exterminator locally. The circumstances were such that I lasted not 15 minutes, but 30.

Wipe it off with a wet rag.

The result may not be phenomenal, but it is there! Apply remover to the entire surface.

Periodically rubbed it with a toothbrush.

About 30 minutes after application, I wiped the “mouse” with a wet and then a dry cloth.

Now, it's more fun!

Then I applied the remover again to the entire surface and replaced the toothbrush with a more “fierce” one.

After another half an hour I got this result.

The experiment could have been continued, but I decided that it was enough to transfer the product, because... its effectiveness is now known.

As for the 646th solvent, I will say that it is necessary in the work. They definitely need to wipe the surface at the end of each cycle (after wiping it dry), otherwise the steel begins to turn red right before your eyes!

Finally, a video of the process of destroying rust using Pepsi-Cola, which acts the same as Coca-Cola. Actually, any soda containing phosphoric acid will do.

How does corrosion affect the performance of equipment and tools?

What is metal corrosion? As people of the older generation would say, this is such a hellish foreign group that destroys our brain with its music. But let’s not argue about tastes and leave the “Metal Corrosion” group alone, but the essence of the statement is true: this is a chemical process that destroys a metal surface.

Equipment and tools made of metal and subjected to a corrosive process begin to change in appearance. At first it is almost invisible to the naked eye. Then rusty pitting and roughness appear on the surface

The process is started, and if it is not stopped, the damage penetrates deep into the material. All metal devices damaged by rust begin the countdown until they are written off. Therefore, to prevent this from happening, you need to remove corrosion in a timely manner.