Principle of operation

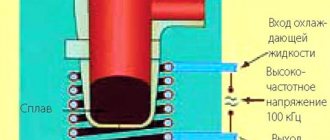

Such a furnace device is an electrical transformer with a secondary short-circuited winding. The operating principle of an induction furnace is as follows:

- using a generator, an alternating current is created in the inductor;

- an inductor with a capacitor creates an oscillatory circuit, it is tuned to the operating frequency;

- in the case of using a self-oscillating generator, the capacitor is excluded from the device circuit and in this case the inductor’s own reserve capacitance is used;

- the magnetic field created by the inductor can exist in free space or be closed using an individual ferromagnetic core;

- the magnetic field acts on the metal workpiece or charge located in the inductor and forms a magnetic flux;

- according to Maxwell's equations, it induces a secondary current in the workpiece;

- with a solid and massive magnetic flux, the created current is closed in the workpiece and a Foucault current or eddy current is created;

- after the formation of such a current, the Joule-Lenz law comes into effect, and the energy obtained using an inductor and a magnetic field heats the metal workpiece or charge.

Despite multi-stage operation, the induction furnace device can provide up to 100% efficiency in vacuum or air. If the medium has magnetic permeability, then this indicator will increase; in the case of a medium made of a non-ideal dielectric, it will fall.

What are the differences from other plates?

Induction cookers compare favorably with other types of stoves (gas and electric).

A number of points are worth highlighting:

The efficiency of induction furnaces reaches 90%. For comparison, in gas stoves this figure is only 30-60%, and in electric stoves - no more than 70%; High heating rate (devices with heating elements or gas burners cannot boast of this feature); Efficiency. After removing the dishes, you do not need to turn off the work area manually - this happens automatically. In electric or gas stoves, the burner continues to work, which leads to excessive consumption of gas and electricity

In the summer, this is especially important, because there is additional heating of the air, which complicates the process of air conditioning (cooling) the room; Precise temperature control. On stoves with heating elements or gas-fired, temperature control occurs “by eye”

In the case of induction cookers, you can maintain the same setting throughout the entire cooking time;

Safety. If a person accidentally mixes up the cookware and places a product with a non-magnetic bottom, the burner will not work. To activate the burner, the cookware must cover its area as much as possible, 50% or more; Many additional functions that classic gas or electric stoves cannot boast of.

Device

The furnace in question is a kind of transformer, but it does not have a secondary winding; it is replaced by a metal sample placed in the inductor. It will conduct current, but the dielectrics do not heat up in this process, they remain cold.

The design of induction crucible furnaces includes an inductor, which consists of several turns of a copper tube, coiled in the form of a coil, with coolant constantly moving inside it. The inductor also contains a crucible, which can be made of graphite, steel and other materials.

In addition to the inductor, the furnace has a magnetic core and a hearth stone, all of which are enclosed in the furnace body. It includes:

- induction unit casing;

- bathroom casing;

- frame.

In high-power furnace models, the bath casing is usually made quite rigid, so there is no frame in such a device. The housing fastening must withstand strong loads when the entire oven is tilted. The frame is most often made of shaped beams made of steel.

A crucible induction furnace for melting metal is installed on a foundation into which supports are mounted; the axles of the tilting mechanism of the device rest on their bearings.

The bath casing is made of metal sheets, onto which stiffeners are welded for strength.

The induction unit casing is used as a connecting link between the furnace transformer and the hearth stone. To reduce current losses, it is made of two halves, between which there is an insulating gasket.

The halves are connected using bolts, washers and bushings. Such a casing is made cast or welded; when choosing a material for it, preference is given to non-magnetic alloys. The two-chamber induction steelmaking furnace comes with a common casing for both the bath and the induction unit.

In small ovens that do not have water cooling, there is a ventilation unit that helps remove excess heat from the unit. Even if you install a water-cooled inductor, you need to ventilate the opening near the hearth stone so that it does not overheat.

Modern furnace installations not only have a water-cooled inductor, but also provide water cooling of the casings. Fans powered by a drive motor can be installed on the furnace frame. If such a device has a significant mass, the ventilation device is installed near the stove. If an induction furnace for steel production comes with a removable version of induction units, then each of them is provided with its own fan.

Separately, it is worth noting the tilt mechanism, which for small ovens comes with a manual drive, and for large ones it is equipped with a hydraulic drive located at the drain spout. Whatever the tilt mechanism is installed, it must ensure that the entire contents of the bathroom are completely drained.

Frame

The frame is the basis for fastening all the elements of the stove. On large-capacity stoves, the frame is replaced with a solid casing.

The frame elements must have great strength and withstand significant loads. Since the frame is located in the zone of the strong electromagnetic field of the inductor, it can, under certain conditions, heat up almost in the same way as the metal in the crucible.

To reduce heating losses of the frame, it is necessary to weaken the currents induced in it. This is most simply achieved by dividing the frame into separate elements electrically insulated from each other, and then it is better to make it from non-magnetic, or even better, from non-electrically conductive materials. However, since the most accessible structural material is steel, the frame is most often made of steel parts isolated from each other.

Sometimes it is advisable to reduce the magnetic field strength near the frame. This can be achieved by installing magnetic cores or magnetic screens between the inductor and the frame.

The magnetic core is made in the form of packages made from sheets of electrical steel 0.2-0.5 mm thick and installed around the circumference between the inductor and the frame. Due to the higher magnetic permeability of electrical steel compared to air, the magnetic field lines are closed along the magnetic circuit and do not reach the frame. The total cross-section of the magnetic circuit is chosen such that the concentration of heat generated in it is small and it does not heat up. This condition is met when the magnetic circuit is made sufficiently massive. Often the mass of the magnetic core significantly exceeds the mass of the charge.

Installation of magnetic cores, in addition, complicates the design of the furnace and maintenance of the inductor. For these reasons they are of limited use.

Simpler and more compact are furnaces with electromagnetic screens, made in the form of a cylinder from copper or aluminum sheet and installed between the inductor and the frame.

The essence of frame shielding is that electromagnetic waves emanating from the inductor induce currents in the screen that are opposite in direction to the inductor current. These currents create a field opposite to that of the inductor, and it reaches the frame significantly weakened.

To ensure small losses in the screen, it is necessary that its thickness is at least 1.3 times the current penetration depth. Therefore, it is most advisable to use electromagnetic screens in high-frequency installations. For industrial frequency furnaces, the thickness of the copper screen must be at least 1.3 cm.

Power calculation

Since the induction method of steel melting is less expensive than similar methods based on the use of fuel oil, coal and other energy sources, the calculation of an induction furnace begins with calculating the power of the unit.

The power of an induction furnace is divided into active and useful, each of them has its own formula.

As initial data you need to know:

- the capacity of the furnace, in the case considered for example, it is 8 tons;

- unit power (its maximum value is taken) – 1300 kW;

- current frequency – 50 Hz;

- The productivity of the furnace plant is 6 tons per hour.

It is also necessary to take into account the metal or alloy being melted: according to the condition, it is zinc. This is an important point, the heat balance of cast iron melting in an induction furnace, as well as other alloys, is different.

Useful power transferred to liquid metal:

- Рpol = Wtheor×t×P,

- Wtheor – specific energy consumption, it is theoretical, and shows the overheating of the metal by 10C;

- P – productivity of the furnace installation, t/h;

- t – overheating temperature of the alloy or metal billet in the bath furnace, 0C

- Rpol = 0.298×800×5.5 = 1430.4 kW.

Active power:

- P = Ppol/Yuterm,

- Rpol – taken from the previous formula, kW;

- Yuterm is the efficiency of a foundry furnace, its limits are from 0.7 to 0.85, with an average of 0.76.

- P = 1311.2/0.76 = 1892.1 kW, the value is rounded to 1900 kW.

At the final stage, the inductor power is calculated:

- Rind = P/N,

- P – active power of the furnace installation, kW;

- N is the number of inductors provided on the furnace.

- Rind =1900/2= 950 kW.

The power consumption of an induction furnace when melting steel depends on its performance and the type of inductor.

Tilt mechanism

The tilting mechanism must ensure that the furnace is tilted to completely drain the metal.

Currently, a wide variety of mechanisms are used. For small-capacity furnaces, mechanisms are used consisting of a winch with a manual or electromechanical drive and a cable thrown over a block.

Larger stoves are tilted using a hoist, engaging its hook with an earring mounted on the frame. Large furnaces are equipped with a hydraulic tilt drive, which is in principle similar to the hydraulic tilt drive of arc furnaces.

The rotation of the furnace is carried out, as a rule, around axles, the axis of which passes under the toe of the furnace. In some cases, rotation begins around the lower trunnions and is carried out at high speed until the upper trunnions fit into the socket. After this, the furnace rotates around the upper pair of axles, but at a lower speed (the radius of the point of application of forces increases).

Species and subspecies

Induction furnaces are divided into two main types:

- Duct. In it, the secondary turn is a circular short-circuited channel into which the metal is placed. A generator or alternating current of industrial frequency is used as an energy source for the smelting process. The high efficiency of such furnaces is due to the transmission of a high-frequency field through a ferrite or steel core. Steel melting in induction furnaces of this type is characterized by the continuous supply of metal blanks and the production of molten metal. The only drawback of the channel unit is the difficulty of starting its operation, since it is first necessary to fill the channel with the melt.

- Crucible. In such furnaces, the energy source is a generator that can operate in the range from several tens to hundreds of kHz. Metal blanks in this type of furnace are placed in its heat-resistant crucible, which is located in the inductor winding. As soon as the melt reaches the desired temperature, the crucible is emptied and filled with the next batch of raw materials. Such a furnace device is characterized by a high rate of heating of the metal, since heat loss in the crucible is very small.

In addition to this division, induction furnaces are compressor, vacuum, open and gas-filled.

Features of melting some metals

In order to melt metal at home, this element must be placed in a small cup or crucible. The cup with the material is inserted into the oven. Then its melting begins. To melt the precious elements, they are placed in a glass ampoule. In order to make an alloy from several components, follow these instructions:

- First, a refractory element - copper or iron - is placed in the melting cup.

- Then a more fusible component is placed - tin, aluminum.

Melting aluminum in a homemade furnace

Steel is a refractory material. Its melting point is one thousand four hundred degrees Celsius. Therefore, to melt steel at home, you must follow the following instructions:

- To melt steel at home, introduce additional regenerators. If the furnace runs on electricity, then electricity is used.

- During induction heating, slags are added. They increase the speed of melting.

- Constantly monitor instrument readings. If necessary, lower the melting temperature by switching to a more moderate mode.

- It is always correct to determine whether the steel is ready for work or melting. Follow all the above steps. Only then will the resulting metal be of high quality.

Metal smelting

To melt iron at home, the furnace must be preheated. First, a large piece is placed, and then small ones. Iron must be turned over in time. A properly molten metal will have a spherical shape.

If you are going to make bronze, you must first place copper in the melting hole. Since this component is more refractory. When the copper is melted, tin is added.

And when melting aluminum, tin or iron, you must be careful. Rivet slowly and should be done with a small hammer. Heat the material frequently until reddened and cool in cold water. Only then will you get the perfect alloy at the end.

DIY induction furnaces

Among the available common methods for creating such units, you can find a step-by-step guide on how to make an induction furnace from a welding inverter, with a nichrome spiral or graphite brushes; we will give their features.

High frequency generator unit

It is performed taking into account the design power of the unit, eddy losses and hysteresis leaks. The structure will be powered from a regular 220 V network, but using a rectifier. This type of furnace can be equipped with graphite brushes or a nichrome spiral.

To create a furnace you will need:

- two UF4007 diodes;

- film capacitors;

- field-effect transistors, two pieces;

- 470 Ohm resistor;

- two throttle rings, they can be removed from an old computer system technician;

- copper wire Ø section 2 mm.

The tools used are a soldering iron and pliers.

Here is a diagram for an induction furnace:

Induction portable melting furnaces of this type are created in the following sequence:

- Transistors are located on radiators. Due to the fact that during the process of metal melting the device circuit heats up quickly, the radiator for it must be selected with large parameters. It is permissible to install several transistors on one generator, but in this case they need to be isolated from the metal using gaskets made of plastic and rubber.

- Two chokes are manufactured. For them, two rings previously removed from the computer are taken, copper wire is wound around them, the number of turns is limited from 7 to 15.

- The capacitors are combined into a battery to produce a capacitance of 4.7 μF at the output; they are connected in parallel.

- A copper wire is wrapped around the inductor; its diameter should be 2 mm. The inner diameter of the winding must match the size of the crucible used for the furnace. A total of 7-8 turns are made and long ends are left so that they can be connected to the circuit.

- A 12 V battery is connected to the assembled circuit as a source; it lasts for about 40 minutes of oven operation.

If necessary, the housing is made from a material with high heat resistance. If an induction melting furnace is made from a welding inverter, then a protective housing must be present, but it must be grounded.

Graphite brush design

Such a furnace is used for smelting any metal and alloys.

To create a device you need to prepare:

- graphite brushes;

- powdered granite;

- transformer;

- fireclay brick;

- steel wire;

- thin aluminum.

The technology for assembling the structure is as follows:

- The base is made in the form of a box, which is made of fireclay bricks, it is placed on a fire-resistant tile.

- A sheet of asbestos cardboard is placed on top of the box; if it needs to be given a certain shape, its surface must be moistened with water. To make the structure rigid, you need to wrap it with wire. The dimensions of the box depend on the power of the transformer. It is best to use it from a welding machine. If it is of high power, then it should be rewound.

- To prevent the transformer from overheating, it is wrapped in thin aluminum.

- There is a clay substrate at the bottom of the brick box to prevent the molten metal from spreading.

- Graphite brushes are installed.

Device with nichrome spiral

Such a device is used for smelting large volumes of metal.

The following materials are used as consumables for setting up a homemade stove:

- nichrome;

- asbestos thread;

- piece of ceramic pipe.

After connecting all the components of the furnace according to the diagram, its operation is as follows: after applying electric current to the nichrome spiral, it transfers heat to the metal and melts it.

The creation of such a furnace is carried out in the following sequence:

- Winding a spiral, a wire with a diameter of 0.3 mm is used for it, the length of the workpiece should be about 11 meters.

- The wire is wound around a long tube, its diameter is 5 mm.

- A piece of ceramic pipe acts as a crucible; it is cut to the required size, about 15 cm. An asbestos thread is inserted into one end so that the molten metal does not spread.

- Laying a spiral around a pipe. An asbestos thread is placed between its turns; it will limit the access of oxygen and thereby prevent a short circuit in the furnace.

- In this form, the coil is placed in a high-power lamp, it contains a cartridge of the required diameter, which is most often made of ceramics.

This design is characterized by high performance; it cools down for a long time and heats up quickly. But it is necessary to take into account that if the spiral is poorly insulated, it will quickly burn out.

Harm to health

Today there is a lot of discussion regarding the harm of induction cookers, because the principle of their operation is based on electromagnetic fields, the negative effects of which are well known. Many experiments have been carried out on this matter.

Scientists have proven that at a distance of one centimeter from the source, electromagnetic radiation is always higher than the permissible ICNIRP standard.

If the pan is displaced relative to the center of the working surface or in a situation where its diameter is smaller than the diameter of the burner, the indicated indicator will be greater than the norm at a distance of up to 12 cm.

This parameter is typical for cases when special utensils are used for cooking. If there is an enameled object on the work surface, the danger zone is larger - up to 20 cm.

Why is this dangerous for health?

The electromagnetic field that occurs near the human body can lead to the appearance of induced currents in the body and a negative effect on the central nervous system. To protect health, ICNIRP has established requirements for upper current limits.

To verify whether induction cookers meet these standards, a study was conducted with a group of volunteers of different ages and genders.

People were located in close proximity to the hob (at a distance of five centimeters). Scientists at this moment studied the currents that flowed in the body and the central nervous system of the body.

It has been proven that the current indicators in the case of using built-in models are minimal.

As for portable models, their current indicators are higher, but they also did not exceed the established norm.

It is worth noting that the limit established by ICNIRP is 50 times less than the minimum threshold at which stimulation of the human central nervous system occurs.

What is the outcome of the study?

Experts published the results of the experiments, but admitted that there is not yet enough information about the dangers of electromagnetic fields. It is important to understand that the nature of such radiation may vary depending on the nature of its occurrence.

There is another study, the results of which can be found on the WHO website.

People and animals took part in the experiment, but it was not possible to prove the negative effect of electromagnetic radiation on the central nervous system or the cardiovascular system.

Prices for ready-made induction furnaces

Homemade furnace designs will cost much less than purchased ones, but they cannot be created in large volumes, so you cannot do without ready-made options for mass production of the melt.

Prices for induction furnaces for metal melting depend on their capacity and configuration.

| Model | Characteristics and Features | Price, rubles |

| INDUTHERM MU-200 | The furnace supports 16 temperature programs, the maximum heating temperature is 1400 0C, the mode is controlled with an S-type thermocouple. The unit produces a power of 3.5 kW. | 820 thousand |

| INDUTHERM MU-900 | The furnace operates from a power supply of 380 V, temperature control occurs using an S-type thermocouple and can reach up to 1500 0C. Power – 15 kW. | 1.7 million |

| UPI-60-2 | This mini induction melting furnace can be used for melting non-ferrous and precious metals. The workpieces are loaded into a graphite crucible, and they are heated according to the transformer principle. | 125 thousand |

| IST-1/0.8 M5 | The furnace inductor is a basket in which a magnetic circuit is built together with a coil. Unit 1 ton. | 1.7 million |

| UI-25P | The furnace device is designed for a load of 20 kg, it is equipped with a geared inclination of the melting unit. The stove comes with a block of capacitor batteries. Installation power – 25 kW. Maximum heating t is 1600 0C. | 470 thousand |

| UI-0.50T-400 | The unit is designed for a load of 500 kg, the highest power of the installation is 525 kW, the voltage for it must be at least 380V, the maximum operating temperature is 1850 0C. | 900 thousand |

| ST 10 | The oven of the Italian company is equipped with a digital thermostat; SMD technology is built into the control panel, which is fast. The universal unit can work with different capacities from 1 to 3 kg, for this it does not need to be readjusted. It is intended for precious metals, its maximum temperature is 1250 0C. | 1 million |

| ST 12 | Static induction oven with digital thermostat. It can be supplemented with a vacuum casting chamber, which makes it possible to carry out casting right next to the installation. Control occurs using the touch panel. Maximum temperature – 1250 0С. | 1050 thousand |

| IChT-10TN | The furnace is designed for a load of 10 tons, it is a rather voluminous unit, for its installation you need to allocate a closed workshop room. | 8.9 million |

Vacuum melting plant

An induction-type vacuum device consisting of a chamber, an induction furnace and a casting mold is suitable for melting and casting. The positive qualities of the device include the ability to obtain high-quality products at minimal production costs. The principle of operation of a vacuum furnace is based on an improved technology for melting metals with increased degassing, the possibility of recharging the installation, adjusting the temperature regime, changing the chemical composition and deoxidation of the material in the working process.

The technological process makes it possible to obtain high-purity alloys, reduce heating and melting times, and use any form of raw materials. Vacuum-type devices can operate from an alternating network ; the final product is an alloy with a reduced percentage of hydrogen and nitrogen; the purity of the material is obtained by pumping air from the melting chamber and cleaning the metal from volatile components present in the charge.