Here is a very good option, “Moment Super Epoxy Metal” glue,

Glues any metals (steel, aluminum, alloys, copper, etc.) in any combinations (wood, plexiglass, fabric, stone, etc.).

The preparation is not difficult, it is best to use fine sandpaper on both wood and metal, the surface will become slightly rough, this will improve adhesion.

Of course, if there is rust on the metal (on steel, for example), then you also need a rust converter, or remove the corrosion mechanically.

Next, be sure to degrease (the wood should not release resin).

In any convenient place on a flat surface, add component “B” to component “A” in equal proportions.

Mix and apply a continuous layer to one of the surfaces (any).

They pressed it and fixed it in this state for about 15 minutes (you can press it down with a weight).

That’s it, in a day the glue will gain full strength and the parts can be processed, but in general the strength (initial) is achieved in a couple of hours, that is, the glue dries.

Use rubber-based adhesives, such as PATEX, 88N, ELASTOSIL-2, KR-1, Zh-3 and others.

The most important thing is the preparation and the gluing process itself. It is important to understand that the metal surface oxidizes under the influence of moisture and the oxidation film peels off from the material along with the glue, so the entire process must be carried out in a dry room.

First treat both surfaces:

- treat the wood with solvent and dry the surface.

- first treat the metal with sandpaper, removing oxides, then rinse with a solvent and dry, then thoroughly wipe with a solution of nitric or sulfuric acid and also dry.

Next, a layer of glue is applied to the surface of the metal and wood and, without pressing the materials against each other, they are kept for a specified period of time, depending on the instructions. Basically it's about 10 hours, but no more.

Now glue is applied to both surfaces again and connected to each other, placing the connected parts under a press or tightening them with a clamp - this is mandatory, otherwise the gluing will not be of high quality.

Also, in addition to rubber adhesive bases, they suggest gluing these two materials together with silicone rods, which belong to the group of hot-melt adhesives, but I personally am not familiar with the technological process, although I can assume that silicone is first applied to the metal, and then wood is pressed to the surface. But for hot-melt glue, small surfaces are good, where you can maintain the temperature of the glue in one mode until gluing.

Source: www.remotvet.ru

Gluing metal to metal

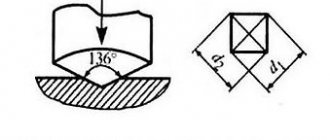

To glue two metal parts, it is optimal to use epoxy glue; it is a two-component composition, sold in two containers. Mix the resin and hardener in the proportions indicated on the package. Next, we clean the gluing areas and degrease them with acetone. Then we apply a thin layer of glue to both surfaces and connect the surfaces by placing them under a weight. You can also additionally reinforce the seam with fabric.

For example, we can use CB electrical tape, which we thoroughly soak with glue and apply to the seam. When the glue dries, you will get a very strong connection.

I liked Moment Super Epoxy Metal glue, but there are other brands.

Weatherproof steel

When galvanizing, steel acquires a protective layer of zinc. During hot-dip galvanizing, parts are immersed in a bath of zinc heated to +450°C. When galvanizing, zinc is applied to the part.

in an electrolyte bath. Fasteners treated in this way retain their anti-corrosion properties for up to 40 years. True, salty air reduces this period to 25 years.

made of stainless steel are not subject to corrosion at all. Even this type of high-alloy steel is susceptible to two types of corrosion: crevice and pitting. To maintain a decent appearance of stainless steel, regular washing of metal products with warm water and a surfactant is required.

Which is better: heated floors or radiators?

Warm floorBatteries

Before applying the powder-varnish coating, the products are galvanized. The powder, then applied to the product, is melted in an oven at temperatures above +200°C. After cooling, a durable anti-corrosion coating is formed on the product. In order for the metal to retain its anti-corrosion properties for a long time, the coating must not be damaged.

Link by topic: How to make a stool-bedside table with your own hands

Gluing metal to wood

Gluing metal to wood is a more complex process than metal to metal, but this task is quite doable.

First of all, clean the surfaces to be glued with fine sandpaper and degrease with acetone. After this, rinse the metal with clean water and let the surfaces dry.

For gluing metal and wood, rubber adhesives such as “KR-1”, “Patex”, “Zh-3”, “88-NP” and others are best suited.

The first stage is to apply a thin layer of glue to both surfaces, wait 10 minutes for the glue to dry, again apply glue and connect the surfaces, placing them under a weight for a day.

Excess glue can then be easily cut off with a sharp knife.

Advantages and disadvantages of different types of wood adhesives

| Glue type | Advantages | Flaws |

| PVA | + affordable price + environmental friendliness + versatility + ease of use | - insufficient strength - afraid of moisture — destroyed at high temperatures (+60°C) |

| Polyurethane | + high strength to dynamic loads + inert attitude to temperature changes + resistance to moisture + UV resistant | - high price - Strong smell |

| Based on organic resins | + connection strength + versatility of use + resistance to water and aggressive compounds + reasonable price | - skin protection required — high consumption - requires precise mixing of components |

How to glue metal to wood using glue

During World War II, the first results in gluing metal to wood were obtained, and the British produced the first aircraft that used wooden structures bonded to metal using rubber glue.

You can also glue wood and metal with a silicone rod, which is sold at any hardware store. You should buy a rod, heat it with a lighter, lubricate the surface of the metal and glue it to the wood.

Another popular method is gluing wood and metal using epoxy resin. For example, two-component epoxy resin Permabond ET515 or POXIPOL, more popularly known as “cold welding,” is suitable. Another option is the two-component Supergrip adhesive. Any large hardware store has a wide range of adhesives that will help solve the problem of gluing metal and wood.

Briefly about the main thing

It may be necessary to combine metal and wood in different situations: when building a cabinet or staircase, when repairing furniture, or restoring an object.

The main difficulty lies in the difference in material characteristics. When choosing an adhesive composition, you should pay attention to the areas of application: the adhesive should be suitable for both wooden and metal parts.

When working, it is important to follow the instructions, especially when using two-component compounds. If mixed in the wrong proportions, the glue will not have all the necessary properties, and the product may fall apart.

Do not forget about the simplest option: connection using self-tapping screws and metal corners. This option is usually used in construction, renovation work or furniture creation.

What is the best way to glue wood to wood?

For carpentry needs, a fairly wide range of adhesive materials is used: various types of PVA adhesives, polyurethane compounds, epoxy resin, contact adhesive, etc. The choice of the most suitable adhesive option is made with a focus on the following features of the project:

- characteristics of the tree itself (oily content, level of adhesion, etc.);

- characteristics of the loads that will fall on the seam (including shocks and vibrations);

- conditions in which the product will be used (humidity, temperature changes, exposure to moisture).

You can read about the working properties and areas of application of the main types of wood glues here.

The influence of plywood grade on the choice of adhesive composition

The brand of suitable plywood adhesive directly depends on the level of strength required and on how high the humidity is in the room in which the structure is planned to be used.

What glue should I use to glue plywood to plywood if the finished product will be located in a well-ventilated room? PVA, protein or synthetic, works well.

If you plan to make country furniture that will be located both indoors and outdoors, then it is better to use one of the synthetic compounds.

Once the choice has been made in favor of a moisture-resistant material for the interior, you need to determine how to glue the plywood to the plywood. Reviews indicate that the connection is best done with compounds based on urea resin. The use of uncoated sheets makes it possible to glue plywood with any type of glue.

How to glue wood correctly?

Carpentry adhesives are applied in a thin, even layer to both surfaces to be joined. The only exception is the technology of gluing wood with polyurethane glue: in this case, the material is applied to one of the surfaces, and the second is moistened (slightly moistened with water). Applying the compound in excess does not improve the quality of gluing in any way, but only leads to wasted material consumption and smearing of surfaces with squeezed out excess (by the way, this adds headaches at the finishing stage).

When gluing a tenon-groove joint, only the cheeks of the tenon and the walls of the groove are lubricated with glue. This gluing method provides the most reliable connection: the joint is glued “tightly”, not inferior in strength to the surrounding wood. Applying the compound to hangers does not improve the quality of gluing; all you get in this case is just excess bleed through and a waste of time, which is especially valuable in complex multi-component assembly.

Methods for laying plywood

How to glue plywood to plywood? The most environmentally friendly is water-based glue. It is completely odorless and can be diluted with water and used instead of a primer. This installation requires additional fastening, and the main disadvantage is long-term drying.

Solvent-based glue dries a little less quickly – 3-5 days. In this case, you must first impregnate the concrete screed with a special primer. The disadvantage is the strong smell.

How to glue plywood to plywood and save time? This desire can be maximally satisfied by using two-component glue. It dries in about 24 hours and does not require dowels or nails.

What is the most effective way to apply glue?

It is important to distribute the glue over the surface of the wood in an even layer, so you should not limit yourself to simply squeezing strips out of a bottle or tube. For smearing, a small brush with stiff bristles is usually used. But the simplest toothbrush will be a more effective assistant: bristles of optimal stiffness will carefully and evenly distribute the composition over the surface, providing an optimal adhesive layer.

Glue selection

The peculiarities of choosing adhesive for different surface hardnesses are determined as follows:

- Optimal geometric dimensions.

- Corresponding physical and mechanical properties.

- The composition of the connecting base should reduce the difference between the principle of elasticity and the thermal coefficient of expansion.

If the principle of distinguishing between different materials is not respected, then you need to choose only the glue that can smooth out such differences. If you are connecting hard and elastic materials, then choose hard glue for the hard version, and soft glue for the elastic one.

The most important part of using adhesives is gluing steel and non-metallic surfaces, so let’s look at how you can glue wood, stone, plastic, and rubber with the same product.

Requirements for adhesive joints with metal:

- High strength.

- Ability to resist corrosion and rot.

- Durability.

- Heat resistance.

Is it necessary to degrease surfaces and what is the best way to do this?

When gluing wood to wood, there is no need to degrease the surfaces. Although in some cases, for example, when working with oily rocks, this will not be superfluous. In this case, it is advisable to degrease the wood before gluing with white spirit.

When gluing dissimilar elements: wood with plastic, glass and other materials with low adhesive properties, the degreasing process is more important. Degrease only one of the surfaces, wiping it with white spirit.

Gluing aluminum to wood

Wood expands and contracts much more compared to aluminum. We cannot somehow influence the coefficient of elasticity and thermal expansion of the wood, so we must compensate for the deformation at the gluing line. This means that it is necessary to apply the glue in a thicker layer. Bonding wood to aluminum is itself a challenge due to the porosity of wood and aluminum oxides.

PURACOLL 8110 Aluminum Construction Adhesive creates a stunning bond between aluminum and wood thanks to its unique formulation. It is necessary to use a hybrid polymer that is 100% Eco-Compliant and will not shrink but will elongate. This characteristic is of paramount importance for gluing wood to aluminum, even in outdoor applications. External use of adhesives for aluminum and wood is very demanding on the characteristics of the adhesive due to weather conditions. Weatherproof aluminum adhesive can be applied to wet surfaces even under water.

The glue can be painted with any type of paint. When using some types of glue to bond wood to aluminum there is absolutely no need for any additional fasteners, since the cured bond will be 277N/CM², you can say that the wood and aluminum are welded "tight" It is very important to clean the aluminum before sticking, even if aluminum is new because of the oxides.

For high initial adhesion, it is necessary to use PURAFLEX 9155 adhesive, which has this characteristic. For extremely high loads when gluing aluminum and wood, MS-polymer adhesives should be used. With its help, heavy aluminum sheets can be immediately glued to a wooden frame without slipping.

This material is intellectual property. Any use of the Materials is permitted only with indication of the source of information

Author: Yukhov Maxim Petrovich

Source

How tight should I tighten the clamps?

It is important to understand that the strength of the gluing does not depend on the amount of pressing force, but on the quality of surface treatment and their accuracy of fit. There is no need to tighten the clamps too much. A small amount of glue showing through is a sure sign that sufficient clamping pressure has been created.

The use of clamps is not always advisable. If we are talking about gluing small crafts, for example, wooden boxes and boxes for tightening, you can use adhesive tape or masking tape, but, again, provided that the joints are well fitted.

General rules for working with adhesive composition

In order to carry out gluing reliably, and at the same time not harm yourself during work, you need to follow a number of general rules. They are as follows:

- Good ventilation must be provided in the room where gluing will take place, due to the presence of toxic substances in the compositions;

- The master must protect himself by wearing a respirator, protective clothing and goggles;

- Prepare the necessary tools and materials.

Surface preparation

Before gluing duralumin, you need to prepare it for this process. To clean the material:

- Areas with rust are eliminated; fine-grained sandpaper is used for this purpose.

- The surface is degreased; acetone is suitable for this purpose.

- Sanding is carried out for better adhesion.

- The surface must be completely dry before applying glue.

Gluing

The gluing process is simple, you can do it yourself, you should follow the steps below:

- In a separate container, the adhesive solution is combined with the hardener.

- Mix the components thoroughly until a homogeneous mass is obtained; you need to use the substance in 10-60 minutes; the exact data can be found by studying the instructions from the manufacturer.

- Glue is applied to both parts. You can make stripes, or apply it pointwise in places where there will be joints. The parts are pressed together without force so that the glue does not go beyond the boundaries.

- The excess is wiped off. You can do this with a damp rag or soaked in solvents.

- Having fixed the parts, they are left in this position until the curing process is completed.

The hardening time varies, check it on the packaging, usually the process does not take more than an hour.

How to clean a surface from dried glue?

It makes sense to remove excess glue from the surface of the wood either while it is completely fresh or when it has completely hardened. If you rush to sand a damp area of wood, you will most likely end up with an even greater aesthetic defect when the fibers deformed by sanding dry. The hardened glue is cleaned by hand sanding (along the fibers) or cut with a chisel.

Before applying decorative finishing, check to see if there are any stained areas on the product. Otherwise, traces of dried glue will appear under the finishing compound. To more effectively detect defects, wipe the surface of the wood with a cloth soaked in white spirit.

Source: woodschool.ru

Characteristics of popular brands

To glue aluminum to various types of materials, many compounds are produced. Before choosing glue for silumin or simple aluminum, you need to consider the most popular brands. These include:

- Mastic is a cold welding that can be used at temperatures from -50 to +145 degrees. Can be used as a sealant for aluminum, creates reliable fixation of parts;

DIY laminated wood

Before gluing, the parts are processed; this is done not only to clean the surface, but also to open the wood pores. When applied, the adhesive composition penetrates through the pores into the wood structure, into the intercellular space, and when hardened, it forms many thin threads (webs) that reliably “stitch” the workpieces together. The strength of a correctly executed seam exceeds the strength of the wood itself; when testing for fracture, the part breaks not at the gluing site, but along the whole wood.

Gluing wood allows you to obtain products with better parameters than solid ones. During the gluing process, elements that are suitable in texture and shade are selected, damaged, cracked and knotty areas are rejected. As a result, the glued parts have greater strength than ordinary wood, and by gluing the finest veneer onto the front surfaces, the products are given the appearance of the most valuable species. Wood glued according to all the rules is much less likely to warp, crack and dry out than solid wood.

How to choose and use aluminum adhesive correctly

Aluminum is widely used due to its strength and resistance to environmental factors. But at the same time, the metal does not have adhesive properties (adhesion) due to the formation of a film of oxides on the bonded surface.

To ensure a high-quality connection, it is necessary to select an adhesive for aluminum that contains special additives that prevent the formation of oxides.

For example, a two-component liquid material or mastic based on epoxy resin with steel powder should be used.

Types of glue

The most suitable glue for working with aluminum surfaces is polyurethane glue or one made on the basis of epoxy resin.

Polyurethane-based adhesives are:

- one-component;

- two-component.

One-component formulations contain polyurethane polymer and no solvent. Similar products are used on open parts of products. Before bonding, the surface must be moistened with water. This allows the one-component adhesive to react with the aluminum, thereby forming a very strong bond.

PERMATEX Cold Weld

Due to the hardener contained in two-component compositions, wetting the surface with water is not required. Such products are resistant to oils, fungi, mold, and are characterized by increased plasticity and heat resistance.

Two-component epoxy resin-based compounds are characterized by improved adhesive properties and are resistant to high temperatures.

They are often used when installing aluminum structures, as well as for joining materials with different thermal expansion rates (wood, porcelain, stone).

It is difficult to achieve high-quality gluing of surfaces made of different materials, therefore mechanical devices, for example, elastic tape, are additionally used.

Abro Steel

Resin-based compositions are:

- hot hardening - used, for the most part, in industrial enterprises and hardens at a temperature of +1000 ° C;

- cold - harden at temperatures from +15 to +350° C.

Any two-component adhesive is mixed with a hardener before application; the proportions may vary; the relevant information is on the packaging.

Cosmopur 819

Characteristics of popular brands

There are several adhesive compositions that allow you to qualitatively, firmly and reliably connect aluminum with aluminum or other materials:

- Mastix . The mixture is suitable not only for gluing aluminum surfaces, but also for sealing joints. And also for repairing products made of ferrous and non-ferrous metals. The composition allows high-quality gluing of parts at low ambient temperatures; its working range is from –50 to +145° C. In addition, Mastix reliably and quickly bonds wet surfaces. The average cost of a 50 g bottle is 30 rubles.

- Cosmopur 819 is a polyurethane material that allows for strong and reliable bonding of aluminum to aluminum by creating a ductile seam between the surfaces. Ideal for bridging gaps and gluing corners. Cosmopur 819 is most often used for joining structural parts. Price for 300 ml is approximately 500 rubles.

- ASTROhim ACE-9305 is a cold welding that allows you to instantly eliminate various breakdowns. The glue qualitatively connects surfaces made of aluminum and its alloys at temperatures from –50 to +145° C. The composition is most often used to restore broken fragments of parts, for example, threads. One package costs on average 80 rubles.

- “Epoxy Metal Moment” is a two-component adhesive that reliably holds together not only aluminum surfaces, but also combinations of other metals with wood, marble, and glass. The composition effectively eliminates gaps and cracks. The price for a 50 ml package is approximately 350 rubles.

- Abro Steel is a universal cold welding product from the American manufacturer of the same name. It serves as the best option for repairing sanitary and household equipment and tanks for storing liquids, as it ensures perfect tightness. The composition is used to connect metal, wood, ceramics, as well as materials of different types to each other. The adhesive is highly sensitive to the cleanliness of the areas being bonded. If storage was incorrect, the composition will not be able to be used for its intended purpose. Price - approximately 150 rubles for 57 grams.

- PERMATEX Cold Weld is a two-component heat-resistant adhesive based on epoxy resin, hardens very quickly, is fireproof, and perfectly bonds various materials, including aluminum. Polymerization of the composition occurs within 15 minutes, the material can withstand prolonged heating up to +149° C, short-term heating up to +177°. The formed seam is very resistant to shear and tear loads. The cost of a 56 g package is about 300 rubles.

- “Titanium” is characterized by its low cost and resistance to any mechanical loads. A 310 ml bottle costs about 250 rubles.

- WURTH Liquid Metal is a cyanoacrylate composition from a German manufacturer. It is the best option for connecting metal surfaces of various parts. It hardens very quickly, making it ideal for quick repairs. It forms an invisible seam, which makes it possible to glue not only metal products, but also transparent materials. The price of a 20 g bottle is approximately 100 rubles.

- COSMO PU-200.280 COSMOFEN DUO is a two-component high-strength polyurethane-based adhesive that does not contain solvents. It has excellent heat resistance and can withstand environmental factors. After complete curing, the seam can be painted. Used for gluing gypsum fiber boards, wood, sanded fiberglass plastic, aluminum, laminate, as well as for restoring and filling construction joints no more than 0.8 cm wide. A 900 g bottle costs approximately 800 rubles.

COSMO PU-200.280

Advice! When using Abro Steel, strictly follow the manufacturer's instructions on the packaging, since violation of the rules of use leads to a sharp deterioration in the technical characteristics of the glue.

How to work with adhesive correctly

Connecting aluminum parts using an adhesive composition at home is much simpler and therefore more often used compared to welding. In order to properly glue metal surfaces, you will need sandpaper, a special compound and a degreaser (usually acetone is used for these purposes).

Epoxy metal Moment

Advice! Carry out all work in a well-ventilated room, wearing gloves and a respirator. Adhesives often contain components that can cause serious irritation of the mucous membranes of the respiratory system and eyes.

Before sanding surfaces with sandpaper, remove dirt, dust and grease stains using a brush or stiff-bristled brush.

Instructions for gluing surfaces:

- Free the joined areas from rust and dirt using sandpaper (preferably a fine-grained version).

- Remove grease by wiping the surface with acetone: oiling under the adhesive layer reduces adhesion by approximately 20%.

- Wait for the area to dry.

- Combine the adhesive with the hardener in a container specially designed for this purpose.

- Stir the resulting mass until it becomes absolutely uniform in color and viscosity. The finished mixture must be used within 10-60 minutes. The specific time is indicated by the manufacturer on the packaging.

- Apply glue to both surfaces in dots or in a thin strip and connect them, pressing them tightly against each other. You should not press the surfaces too hard, as this will lead to squeezing out the adhesive mass.

- Remove excess mixture with a dry rag. It is allowed to moisten it in water or solvent.

- Fix the position until the composition has completely hardened (about 15 minutes).

- Depending on the brand of glue and the ambient temperature, final hardening occurs after 2-24 hours.

Advice! Different brands take different times to set, ranging from five minutes to one hour. It is for this period of time that the product must be left alone and not touched.

When choosing an adhesive, you should pay attention to the following characteristics indicated on the packaging:

- heat resistance;

- resistance to moisture;

- curing time.

WURTH Liquid Metal

Useful tips

Recommendations from experts will help you choose the most suitable composition for gluing aluminum, as well as make the connection of surfaces as high-quality and reliable as possible:

- Aluminum structures can be completely glued together with a two-component composition based on epoxy resin. But if you need to join the surfaces of an alloy that contains aluminum, then it is better to prefer a product containing methyl acrylate.

- For aluminum, only a special composition containing acids and alkalis is suitable. These components ensure the splitting of the oxide film, which significantly improves the adhesion of the adhesive.

- The use of epoxy resin-based adhesives is strictly prohibited if the product will in the future be used to store drinking water or food or come into contact with them.

The means used for gluing aluminum do not provoke oxidation of the metal, unlike gas welding. As a result, the repaired product will last much longer. Another positive point is the low cost of cold welding.

How to glue wood. Technology

There are several ways to connect parts when gluing.

- Gluing wood into a smooth fugue - joining smooth parts without increasing the penetration area.

- Microthorn gluing – increasing the penetration area by 2.5 – 5 mm by creating a toothed relief on the part (using a milling cutter).

- Gluing onto a serrated tenon – increasing the penetration area by 10 mm by creating a serrated tenon.

- Tongue and tongue gluing (tongue and groove, dovetail, oblique tenon) - additional adhesion due to the groove connection.

Although in certain situations where special conditions of use are expected, groove and tenon joints are relevant, in most cases the parts are glued together using a smooth fugue. Modern adhesives penetrate deep into the structure and create a strong joint without additional wood removal.

How to glue boards together. Options

The wood to be glued must have a moisture content in the range of 8–12%, maximum 18%. If there is a need to glue wet parts, a special compound is used; during the hardening process, it draws moisture from the wood. When gluing blanks with different humidity levels, a difference of more than 2% is not allowed in order to avoid internal stress in the adhesive seam due to deformation of the wetter part. The temperature of the workpieces being glued varies between 15 - 20⁰С, so work is carried out in warm rooms (18 - 22⁰С). In the cold, most compounds crystallize, which leads to deterioration in the quality of gluing and complicates the process.

Final preparation of wood (planing, jointing, sanding) is carried out immediately before gluing in order to increase the permeability of the glue and avoid warping. It is important not only to select parts according to dimensions, structure and external data, but also to arrange them correctly.

- When gluing along the length, planks of only one type of sawing are used - tangential or radial;

- When gluing both along the length and width, alternating different parts of the wood is not allowed - the core is laid with the core, the sapwood (the young, outer part) with the sapwood;

- The annual rings of adjacent blanks made of boards or bars should be directed in different directions or at an angle to each other of 15⁰.

Rating of the best wood adhesives

| Nomination | place | Name of product | price |

| The best PVA wood glue | 1 | Kleiberit 303.0 | 291 ₽ |

| 2 | ULTIMA JOINER PVA | 129 ₽ | |

| 3 | Moment Super PVA D3 moisture resistant | 490 ₽ | |

| 4 | TEX PVA Carpentry Professional | 149 ₽ | |

| 5 | Krass PVA PVA D3 | 205 ₽ | |

| The best polyurethane adhesives for wood | 1 | Titebond Polyurethane Wood Glue 2300 | 385 ₽ |

| 2 | Kleiberit 501.0 | 477 ₽ | |

| 3 | SOUDAL 66A | 450 ₽ | |

| The best resin wood glues | 1 | UHU PLUS ENDFEST 300 | 503 ₽ |

| 2 | TITEBOND ORIGINAL WOOD GLUE | 480 ₽ | |

| 3 | EDP EPOXY GLUE | 250 ₽ | |

| 4 | Titebond III Ulimate 1416 | 590 ₽ |

Wood gluing tool

To obtain the most durable connection, when gluing, the wood is pressed - subjected to compression using special presses. At home, improvised tools and means are used for these purposes - vices, clamps, cam devices, frames made of metal corners with clamping mechanisms. The pressure when pressing wood is maintained in the range from 0.2 to 1.2 MPa. In production, large values are possible; at home, such indicators are enough for the structural parts to stick together.

If the gluing technology is followed, the adhesive seam is strong and reliable, and, unlike the method of joining parts with metal fasteners, it does not spoil the appearance.

For those who like to create household items on their own, FORUMHOUSE has opened a topic about furniture for home and garden. You can find out how to organize a convenient corner for working with wood in the article about arranging a carpentry workshop. The video about wooden elements in a country house shows interesting products made by users of the portal.

Source: www.forumhouse.ru

The appearance of an adhesive connection instead of the classic version

The first use of adhesive occurred during World War II. The airline of England was the first to produce aircraft with laminated wood structures with reinforcement, where the glue was replaced by a composition based on phenol-formaldehyde resin. But even after the war, no one had any certainty about how best to join the metal: gluing, riveting, or welding. But nowadays it is impossible to create rockets, lunar rovers, and satellites without gluing a steel surface.

Often in everyday life we have to face the need to glue a steel surface with various materials.

Connecting steel surfaces using an adhesive has the following advantages:

- Smoothing vibration in the structure.

- High pressure sealing.

- Absence of temperature loads, for example, as during welding.

- Excellent smooth appearance, monolithic surface.

- Possibility of joining different steel materials, which is impossible, for example, when welding.

But the most important thing is the ability to connect a metal surface with non-metallic materials.