Not everything can be connected with nails and screws. The process of repair and finishing work includes many technological operations that require glue that sticks tightly. In most cases, different types of adhesive mixtures are used for materials such as plastic, iron or drywall. However, there is a glue that can join almost anything - from fabric to ferrous metals. And it is produced under the general name “BF”.

Compound

The chemical composition may vary depending on the type of glue. The permanent component is polyvinyl butyral. The number immediately after the abbreviation “BF” indicates the proportion of the main active ingredient in dry form.

The adhesive mixture may also include:

- ethanol;

- phenol-formaldehyde resin.

Ethyl alcohol is necessarily present in BF medical glue. In other types it can be replaced with acetone or chloroform.

Externally, BF glue looks like a thick translucent mass of a reddish, yellow, brown or brown hue.

Advantages and disadvantages

The main advantage of BF glue is its versatility. It is suitable for bonding non-metals to metals, repairing textiles, joining wound edges (in medicine). It is applicable to materials such as:

- ferrous and non-ferrous metals;

- stainless steel;

- plastic;

- tree;

- gypsum masses;

- textile;

- ceramics;

- glass.

BF glue is not subject to corrosion and rotting processes. It is waterproof, resistant to oil, gasoline and weather.

The main disadvantage of this product is that BF glue is flammable. In addition, if we compare it with specialized compounds, it loses to the Viam brand in terms of strength and to VS-10T glue in terms of heat resistance.

Types and applications

Each variety differs not only in composition, but also in its scope of application. Some types contain toxic components, so they cannot be used to repair products that come into contact with food and drinking water.

BF-2

This type of butyralphenol glue is used for gluing static surfaces of metal, ceramics, wood, glass and marble. It can also be used when repairing acoustic equipment or during restoration work (used for impregnation).

To polymerize the composition it must be exposed to high temperature. The glue itself is heat resistant. Its limit is +180°C.

The percentage of viscosity of the composition changes depending on the storage temperature (the lower it is, the thicker the solution), therefore, before use, BF-2 is kept at room temperature for at least 2-3 days. The adhesive demonstrates good resistance to oil products, water, mold and acidic environments. At the same time, it is less resistant to alkali, alcohol and acetone.

BF-4

Just like BF-2, this variety is intended for joining parts and surfaces made of plastic, metal, leather, wood, and glass. The main difference from the previous type is that the mixture “works” on parts subject to bending and vibration. It is BF-4 that is most often used for joining metals and non-metallic surfaces.

BF-4 has a slightly lower heat resistance temperature (+175°C). Active use accompanied by multiple impacts on parts or surfaces can also reduce the strength of the adhesive seam.

BF-88

BF-88 is a universal adhesive for everyday use. It is also often used for repairing wood, glass, leather and plastic parts. BF-88 can be used on textiles, both natural and synthetic fabrics.

In addition to polyvinyl butyral, the product contains petroleum solvent, rubber (chloroprene) and ethyl acetate. Externally, BF-88 looks like a thick beige or greenish-gray mass, with a small amount of sediment.

BF-19

This type can be used in both hot and cold gluing processes. The first method usually combines wood, metals, ceramics and glass. The second is textiles, cardboard and paper, plastic and rubber parts.

BF-19 glue is a toxic type and is therefore not suitable for fixing parts in contact with food and water. It also cannot be used for medical purposes.

BF-2N, BF-4-N

Separately, it is worth mentioning the subspecies BF-2N and BF-4-N. Their main purpose is to connect parts made of ferrous metals, for example, iron.

Before use, you must wait until the glue has completely dried. With temperature changes below -60°C and above +80°C, the adhesive composition loses its strength.

BF-6

Medical-grade glue is unlikely to be useful during repairs, but it will not hurt in a home first aid kit. After use, BF-6 forms a film on the skin that has protective and disinfecting properties.

This type of glue can be used in the treatment of deep scratches, for healing burns, when suturing shallow wounds, and in dentistry. BF-6 should be used with caution, as it can provoke an allergic reaction.

Useful tips

To work with glue for fabric or decoupage as productively as possible, to create high-quality, reliable and durable work, you can use the following tips from professional craftsmen:

- On the surfaces and materials to be glued, it is necessary to remove any foreign objects, including protruding threads, scraps, and remnants of old glue that will negatively affect the adhesion.

- When using glue, you need to be extremely careful, especially when using quick-drying compounds; it will not always be possible to correct flaws. To protect the material from possible errors, you need to protect nearby areas from accidental contact with glue.

- It is necessary to take into account the peculiarities of using glued products, clothing or fabrics. For example, if this is a robe, then you need to choose the most strong and durable glue. Glue with a light and delicate texture should be used for weightless materials and summer items. In the case of light and white clothes, you need to choose transparent compounds that do not change color after drying.

- If the glue will come into contact with the skin, then you need to choose environmentally friendly compounds without foreign additives and impurities, so as not to provoke skin allergies.

Note! To remove glue residue from fabric, you need to take into account the type of adhesive solution, and also use alcohol, acetone, soapy water, vinegar, solvents, salt, gasoline or talc, as well as specialized products as a cleaner.

Which fabric glue to choose (2 videos)

Types of fabric glue (15 photos)

Bonding method

The choice of gluing method depends on the type of glue and materials used. Before use, the surface is cleaned of dust and dirt, sanded and degreased.

Hot way

With the hot method, an even layer of glue is applied to the prepared surfaces, after which they dry for an hour (for BF-2, 10 minutes is enough). Then a second layer of adhesive is applied and the parts are connected.

After this, the compound must be placed in an oven at + 150-170°C for 40 minutes (for BF-4) or for 1 hour at +130-140°C (for BF-2). The last stage is natural cooling to room temperature.

You can use the connected parts no earlier than 5 hours after the operation.

Cold way

Everything is much simpler here. The adhesive composition is applied to the surface of one part. After 3-5 minutes of drying, apply a second layer of glue and connect the parts, pressing them together as tightly as possible. You can use the result of your work no earlier than in a day.

Determining the type of plastic

To firmly glue plastic, you need to know its type, type, name. With the general division of plastics into thermoplastics and thermosets, the industry produces hundreds of types of plastic, among which the most commonly used in everyday life are:

- vinyl, polyvinyl chloride;

- polycarbonate;

- polyethylene;

- polyamides (nylon, nylon);

- plexiglass (polyacrylate);

- polyurethane.

Most of these plastics belong to the group of thermoplastics. For gluing thermoplastic plastic, it is better to use multi-component adhesives with catalysts. Epoxy adhesive is better suited for gluing thermoset plastics (thermosets).

Plastic markings for choosing adhesive

Manufacturers of adhesives, in order to increase sales and make it easier to choose an adhesive, do not use the chemical names of plastics on their labels. Most often, on the inside of the plastic part, in the instructions for the glue, you can find such plastic markings in Latin letters.

| Type of plastic | Marking |

| Polypropylene | PP |

| Polycarbonate | PC |

| Polyethylene | P.E. |

| Polyvinyl chloride | PVC |

| Polyurethane | PUR |

| Acrylonitrile (automotive) | ABS |

| Polyamides | PA 66 |

| Polyacrylate | PMMA |

Labeling plastic is not very important for household work. Symbols acquire decisive importance in automobile repairs. The markings on the inside of the plastic bumper determine the auto repair technology - sticking patches or welding with plastic electrodes.

Other types of glue

All adhesive mixtures can be divided into organic and inorganic. The BF series belongs to the latter. Organic glue is made from components of plant and animal origin: starch, resin, wax. Inorganic mixtures contain chemical elements and compounds: silicon, magnesium, formaldehyde, ethylene.

Adhesive is most actively used in the field of construction and repair work. It is used for fixing floor coverings, fastening drywall, heating and waterproofing equipment.

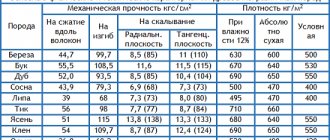

Tree

To fix parquet, as well as other woodworking derivatives, use:

- PVA glue;

- polyurethane glue;

- resin based product.

PVA glue is considered environmentally friendly and can be used even in rooms without exhaust ventilation. It is distinguished by:

- fast setting;

- high strength (able to withstand high static loads);

- long service life;

- versatility.

This type is often used for minor household repairs. You can increase the strength of the composition by adding wood dust to the mixture.

Polyurethane glue is a little more expensive, but it can withstand not only statistical, but also dynamic loads. It is also versatile, waterproof, heat resistant and UV resistant. Its use is advisable in extreme conditions.

Resin-based adhesives are in demand in furniture production. The main advantage of the composition is its resistance to chemically aggressive agents, so its use requires the use of protective equipment (gloves).

Clinker and gypsum tiles

For cladding with decorative gypsum tiles, a gypsum mixture is used. It has many advantages, among which it is worth highlighting:

- ease of preparation of the solution;

- increased strength;

- economical consumption;

- long service life.

If necessary, you can also use polyurethane foam, but since it expands when hardening, the parts should be additionally secured with dowels.

Drywall

When fixing drywall, 2 types of glue are most often used. The first type is aerosol. It is applied over the entire area of the slab every 25-30 cm, after which it is fixed in the desired position. The advantage of the aerosol composition is its rapid setting. Disadvantage: intolerance to temperature changes.

Classic mounting adhesive is cheaper. It is produced in dry form, so it requires dilution with water. Using plasterboard slabs you can level walls, door and window openings, as well as ceilings. Self-tapping screws will provide more reliable fixation of gypsum fiber boards.

Plastic

Plastic is widely used today in almost all industries. Products made from it are somewhat fragile, but can be easily repaired using the following types of glue:

- PVA;

- contact glue (Moment and BF-2);

- reaction glue (Second);

- hot melt adhesive.

If everything is clear with the first two types, then the reaction adhesive is made on the basis of epoxy resin. This type of glue has good water resistance. There are one-component and two-component varieties. The first ones dry quickly, the second ones are more durable.

Hot-melt adhesive is applied using a special device - a glue gun. It works great on plastic surfaces, as well as wood, metal and textiles.

Wallpaper

Despite the wide range of interior design possibilities, wallpaper is still the most popular means of wall decoration. When working with them, universal glue is most often used. Depending on the type of wallpaper (paper, vinyl, textile), the instructions for diluting it change. Light materials require a liquid composition; for dense wallpaper you will need to prepare a thicker mixture.

Iron

In situations where the integrity of metal parts cannot be damaged, a special type of glue is used - epoxy. It is sold complete with a hardener and, to increase the strength of the seam, requires thickening - adding metal shavings or silicate chips to the composition.

Another option is “cold welding”. It consists of a base and a catalyst, which, upon reacting with each other, harden. You can lock the threads on the metal and seal the flanges using machine glue or an anaerobic adhesive. In the absence of oxygen, the acrylic base of the adhesive polymerizes and sets tightly.

Rubber and PVC

Rubber parts and things, such as boots or a bicycle tire, can be repaired with a special adhesive compound - rubber glue. It is created on the basis of polychloroprene rubber, organic solvent and synthetic resins.

This variety is highly adhesive. With its help you can repair a tent, a PVC boat, shoes or children's toys. For the latter, it is better to choose brands based on natural rubber.

A second of adhesive gel will help you quickly repair a small tear. He will help out with a punctured tire and other minor troubles. However, it must be remembered that it has extremely low water resistance.

Glass

Glass is present not only in window structures. Decorative items, dishes, jewelry, lighting fixtures and furniture elements - you can find this beautiful but fragile material almost everywhere.

You can glue a broken vase using one-component varieties made on the basis of organic silicon. Unlike BF or Moment, this glue is more aesthetically pleasing and invisible on the surface of parts.

Polymer glue is actively used in restoration work, repairing jewelry, making stained glass and even expensive jewelry. It requires the use of UV radiation, so the polymer variety is rarely used in everyday life.

Silicone glue is environmentally friendly and non-toxic, so it can be used to repair dishes and other items that come into contact with food or drinking water. Silicone glue perfectly repairs not only glass, but also ceramics.

The main thing when selecting glue is to correlate its properties with the goals and tasks that it must accomplish. This is the key to an excellent result.

How to choose

If you choose the right textile glue for the appropriate fabric, this will simplify and speed up the work as much as possible, and create a strong, high-quality, clean and durable connection.

The most popular substance, which received the maximum number of positive reviews, was silicone fabric adhesive “liquid thread”. It is great for any materials, even felt and coconut, and is actively used in handicrafts to create applique on fabrics and clothes, to mask minor defects, holes, cuts on pants, jackets, sweaters.

For gluing synthetic materials, “Dubok” glue is suitable - a universal and waterproof material. If things are actively worn, often ironed and washed, then choose the “Secunda” universal glue, which is resistant to wear and mechanical stress.

It dries instantly and is suitable for working with leather items and shoes, foam rubber, even porcelain. Using it, you can find original ways to disguise damage. In the manufacturer’s line you can find varieties of narrow specialization that allow you to eliminate serious damage. In this case, the gluing efficiency will be much higher, as will the cost of the substance itself.

Moment or PVA glue is suitable for gluing fabric.

Professional substances, which have several advantages compared to conventional compounds, increase the quality of finished work:

- No stains on materials.

- No unpleasant aroma.

- Transparent composition.

- Optimal consistency that does not allow the glue to spread.

- Resistant to washing, ironing, and aggressive detergents.

Glues with the listed qualities are also ideal for needlework and creating crafts, including decoupage and applique.

To choose the optimal textile adhesive for fabric, you need to pay attention to the following criteria:

- Resistance to moisture, water and heat, since the glued area on fabrics and clothes will most likely be subject to washing and ironing.

- Formation of an elastic film, which will create a strong bond. Even after stretching the material, the integrity will not be compromised.

- A significant drying time, thanks to which you can correct minor defects and perform gluing carefully.

- A universal composition that allows you to work with absolutely any artificial or natural materials, including cotton, wool, and synthetics.

On video: Decoupage glue: special or PVA? Which one and how to choose?