04/29/2021 Author: VT-METALL

Issues discussed in the material:

- The essence of metal cutting

- Metal cutting methods

- Metal cutting tools

- Manual and mechanized metal cutting methods

- Possible defects when cutting metal

- Rules for safe work when cutting metal

- Price for metal cutting services

Metal cutting is a process that allows you to solve many different problems, ranging from the banal division of a workpiece into two or more parts and ending with the removal of burrs from a part. That is, this method of metal processing is very, very in demand.

At first glance, the work of cutting metal is not too difficult. However, like any other technology, it has its own nuances. If you don’t take them into account and do everything as you have to, the end result will most likely be completely different from what was originally planned.

The essence of metal cutting

A metalworking operation during which a workpiece is divided into several parts is called metal cutting. The separation of metal products is carried out according to special pre-applied markings. The cutting is performed along or across the workpiece. The advantage of this method of metal processing is that after completion of the process, minimal finishing work is required, which in turn affects the reduction in the cost of the finished part. Although sometimes the ragged edges of the finished product resulting from cutting may need sanding.

Despite some similarities, chopping and cutting metal products should not be confused:

- In the first case, to separate the workpieces, a blow with a sharp cutter is used in a specially designated place. The tool itself is positioned perpendicular to the surface being cut or at a slight angle to it.

- When cutting, parts are separated using special cutting tools (saws, scissors, automated equipment).

Metal cutting technology is used in the processing of pipes, fittings, metal rods of different sections, and sheet iron.

Metal cutting is a common metalworking operation used in cases where it is necessary:

- adjust the workpiece to a certain size;

- level the surfaces of the parts;

- separate scale;

- process the edges of the product;

- remove burrs from the workpiece;

- form edges for subsequent welding;

- cut out parts from metal sheets;

- cut off the mounting heads;

- form grooves and grooves.

Due to its wide range of applications, this operation is used both in small enterprises and in large engineering plants. Primitive cutting of sheet metal and other metal blanks can also be done at home.

Types of hand tools by purpose

During the repair process, a craftsman may need various metal work: bending, chopping, drilling, filing, threading. Solving the listed problems is possible using specialized plumbing tools, which are always at hand. Based on its purpose, it can be divided into several main groups. Below we will look at where each device is used.

Impact and marking tools:

- Machinist's hammers and blacksmith's sledgehammers are used in many technological operations: chopping, bending, straightening.

- Punch punches are used to mark metallic as well as non-metallic materials.

- Chisels are used to cut metal.

- Crosspieces allow you to cut out keyways and grooves. They differ from chisels in having a narrower cutting edge.

- Using scribers and compasses, precise marking work is carried out.

- The bits are designed for punching holes in sheet metal.

In the process of performing plumbing and assembly operations, various pliers are used. This includes pliers, pliers, round nose pliers, tongs, and pliers. A bench vice is used to fix parts for subsequent processing.

Thread cutting tool:

External threads are cut with dies, internal threads with taps. Die holders and wrenches are devices for rotating hand-held thread-cutting tools.

Devices for cutting and machining metal:

Files and needle files are used for filing parts and workpieces. Hacksaws are used to cut sheet and profile metal, and also perform other types of work. Hand shears are designed for cutting sheet metal. Thin layers of material are removed from parts using scrapers. As a result of scraping the mating surfaces, their tight fit and tightness are ensured.

Hole making tool:

- Holes in the workpieces are made using drills. They are made from alloyed carbon steels.

- Reamers allow high-precision machining of cylindrical and conical holes.

- Countersinks are used to process recesses and chamfers of drilled holes for the heads of screws, bolts, and rivets. Using counterbores, the end surfaces are cleaned.

- Countersinks are used to increase the diameters of drilled holes, improve their accuracy and quality.

Tool for assembling threaded connections:

- Spanners. By design, they can be horn or cap, end, hinged, adjustable, ratchet. Choosing the right version ensures ease of work in hard-to-reach places.

- Torque wrenches allow you to adjust the tightening force of fasteners.

- Plumber's screwdrivers for screws and screws with straight or Phillips slots are indispensable in production, construction, and repair.

Measuring devices include:

- Rulers, roulettes.

- Vernier tool. This includes calipers, height gauges and depth gauges.

- Micrometric instruments, bore gauges.

- Length measures: plane-parallel end, angular prismatic, line.

- Test plates, probes, straight edges, squares.

- Radius and thread templates.

- Instruments for measuring angles: protractors, levels, sine rulers.

- Indicating devices.

Thus, hand tools allow you to solve most problems when working with metal.

Metal cutting methods

Metal cutting is classified depending on:

- the assigned task - they include sawing, cutting, removing a small part, a layer of the workpiece;

- driving force – divided into manual and automated/semi-automated cutting;

- forced fixation - processing using clamps, a vice, a special bed, a press is distinguished;

- directions of movement - distinguish between horizontal and vertical cutting.

When choosing a method for processing metal products, focus on:

- equipment used;

- workpiece thickness;

- the required level of quality of the finished part (are bent edges obtained by manual cutting acceptable, or is a more even and high-quality cut achieved when using automatic equipment necessary);

- productivity (to produce a large batch of parts you need special equipment; purchasing it in order to obtain one or several products is not economically feasible).

Metal cutting tools

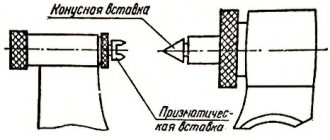

The choice of tools for cutting metal depends on the technology used. For manual processing you will need:

- cutting tool (chisel, crossmeisel, etc.);

- a mechanic's hammer (of suitable weight and with a handle of appropriate length);

- vice;

- metal backing;

- tools for marking.

A bench chisel is used for standard cutting of metal workpieces and consists of:

- shock part;

- holder;

- working (cutting) surface.

The tool can be equipped with cutting surfaces of different shapes, depending on the task to be solved with its help.

The crossmeisel, unlike a chisel for chopping metal, has a narrower cutting edge. The working part of the groover is semicircular to make it more convenient to cut grooves in workpieces. The beard has the shape of a round rod with a cutting part sharpened along the perimeter of the circle. It is designed for cutting holes in sheet metal.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Durable steel is used to produce percussion instruments. They differ in geometric shapes and sharpening angles of the working surface. The top of the chisel is hit with a plumber's hammer. Hammers come with round or square strikers; they differ in the way the handle is attached and in weight.

To cut small metal parts and make holes, fastening equipment or steel substrates are used. Fix the workpieces with a vice.

Marking is carried out using metalwork rulers, squares, marking calipers, and small markers. Marks are applied to the workpiece using various cores, scribers with tips of different shapes, and pencils. Marking tools must meet certain standards.

VT-metall offers services:

Metal cutting at enterprises is carried out using special equipment:

- guillotines;

- hydraulic and mechanical presses;

- press scissors;

- angle cutting machines.

The power and high performance of the equipment allows you to work even with thick-walled metals.

The hydraulic guillotine for cutting metal is controlled using an electronic unit. Processing parameters, type of metal, cutting angle, pressure on the knife, and operating speed are entered into a special program.

Enterprises also use combined equipment:

- Cutting machines (press shears) – for working with profile metal blanks (channels, I-bars, squares), rolled metal, sheet and strip metals. Such equipment allows you to make even holes and grooves of various shapes in workpieces.

- Highly specialized equipment (angle notching machines, presses, stamps) - for angular cutting of workpieces, regardless of the thickness of the metal. A special scale and a properly sharpened chisel allow you to achieve highly accurate results. Presses and dies are equipped with mechanical, hydraulic, pneumatic and electric drives.

What is the essence of metal cutting?

Regardless of the equipment used, the entire cutting process comes down to the following.

The workpiece must be marked - apply the shape of the element to be cut, taking into account the dimensions and tolerances for the thickness of the cut. The latter is often forgotten - meanwhile, for cutting metal, you should plan a cut from one thickness of the workpiece.

When marking, it is important to use the maximum usable area - for this, preliminary planning of placement is optimal. This is especially true for products with complex shapes, and the trajectory of their cutting may be limited in direction and angles.

When cutting metal, the first task is to secure the material. This is done using a vice or other clamping device. An ordinary anvil or just a massive piece of metal is popular for this.

Metal cutting

If the work is carried out by mechanization, further operations are reduced to moving the workpiece relative to the lowering knife. When manually cutting, cutting will require at least 2 steps:

- Initially, weak blows are made along the intended line - this is required to establish the cutting contour;

- When the entire line or a separate part of it is ready (if the trajectory is complex), cutting is carried out - powerful blows are applied to the cutting tool.

As a result of this, the cutting edge passes exactly along the desired line of cutting off the excess. Without preliminary marking, the movement of the tip will be difficult, and there is a risk of it reaching the body of the future part.

When the work is done on one side, the sheet is turned over, the process is repeated for the reverse side. With a material thickness of more than 2-3 mm, this is almost guaranteed to be required. If you cut the entire thickness at once, the quality of the edge will be unsatisfactory.

Metal cutting

As a result of the described sequences, metal is gradually removed around the perimeter, and the shape of the part is revealed. In this case, safety is of great importance: individual pieces of material can fly off at high speed.

To prevent injury you must:

- put on locksmith glasses and gloves before starting work;

- try to knock the metal in such a direction that its parts do not fall on people;

- organize the absence of strangers in the work area, for which the use of screens is allowed;

- blows with a hammer - apply without excessive force, try not to hit the vice.

All working tools must be kept intact and in order.

If the work is done without a vice (“horizontal” method), the essence does not change:

- the workpiece is laid flat, it can be pressed so that the cutting line is free (with a heavy object, a clamp);

- the chisel is pre-sharpened until the required degree of sharpness and curvature is obtained;

- felling is carried out in 2 stages (preparatory-basting and power), with a continuous line in one direction;

- When bending the workpiece, if this interferes, its flatness is periodically restored (with hammer blows).

Manual and mechanized metal cutting methods

- Manual cutting of metal.

The sequence of manual cutting of metal, performed horizontally or vertically, will be as follows. The workpiece is fixed with a vice. If this is not possible due to the thickness of the part, then it is placed on a special table. To minimize the sliding of the product, rubberized pads or screws screwed into the edges are used. After this, prepare the necessary tools: hammers, crosscutters or chisels.

Then you need to strike the workpiece. The impact can vary in strength, but is not necessarily severe. Initially, a notch is made on the surface of the metal part, which in the future will not allow the blade to move to the side. If you immediately apply full force, you can deform the workpiece and damage the tool. In the future, the impact force affects the cutting speed and the quality of the cut edges.

Depending on the swing, there are three types of strikes:

- carpal (lightest);

- elbow (medium in impact strength);

- shoulder (heaviest blow).

The longer the handle and the heavier the hammer, the stronger the blow.

Possible defects when cutting metal

If metal cutting rules are not followed, there is a possibility of defects occurring, the most common of which are:

- curved cut edge;

- lack of parallelism of both edges of the resulting product;

- torn cut edge, burrs, roughness.

The causes of defects vary from person to person, but most often their appearance is caused by:

- unreliable fixation of the workpiece;

- displacement of parts and markings;

- incorrectly selected impact force.

To avoid deformation, before starting to cut metal, you should check:

- reliability of workpiece fixation;

- accuracy of combination of parts and markings;

- working tool sharpening parameters.

When cutting grooves, the following defects are also possible:

- torn edges;

- different groove depths;

- chips at the end of the groove.

To avoid defects during operation, it is necessary to act in accordance with the standards and procedures developed for specific equipment. The part, equipment and chopping tools must be prepared for work in advance. If the preparation for cutting and the operation itself are performed correctly, the edges of the part will be smooth, without defects or chips.

Rules for safe work when cutting metal

Before starting work, you must carefully inspect the equipment and check that it meets certain requirements:

- Hammers must fit firmly to the handles and be wedged into the hole using steel wedges with ruffs. Particular attention should be paid to the surface of the tool - cracks and chips are unacceptable, the surface should be smooth, slightly convex. The handle should thicken evenly towards the end. Knots, cracks, chips, and nicks on the handle are also unacceptable.

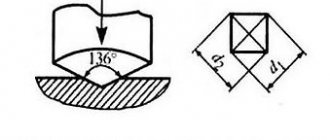

- There should be no cracks or chips on the chisel and crosspiece, the ribs on the sides of the middle part should be rounded and cleaned, the surface of the striking part should be smooth and slightly convex. The striking part of the chisel or crosspiece should be 2.5 cm from the thumb. The cutting edge of the chisel is straight or slightly convex with chamfers of the same width.

Before cutting metal using electrical equipment, you should check:

- Is the wire insulated or damaged?

- whether the ground wire is in contact with the body of the metal processing equipment;

- Are the gloves and mat in the workplace in good working order?

Before starting work on pneumatic equipment, you should check:

- serviceability of hoses;

- tightness of connections between hoses and pipelines and with cutting equipment;

- operation of the starting device.

When working, the mechanic must follow the safety rules:

- use safety glasses;

- To work with wedges or chisels, use sledgehammers and drifts with 70 cm holders; the drifts must be made of soft metal;

- securely fix the workpiece in a vice;

- direct the metal being cut or felled in the direction opposite to yourself;

- When working with sheet metal, use gloves;

- use protective nets (screens) when cutting large-sized workpieces, as well as parts made of hard metal.

Compliance with the listed safety rules is necessary to minimize the risk of injuries and accidents at work.

Metal cutting

Chopping is often classified as a group of cutting jobs, but in fact, completely different tools are used here, and the possibilities they provide are much wider. Unlike the impact action exerted on the cutter in the previous case, pressure is used when cutting.

Manually

To work with various workpieces the following are used:

- for cutting wire - wire cutters,

- circle, square and hexagon are sawed with a hacksaw,

- sheet materials are cut with scissors.

The use of special equipment can expand the capabilities of metalworking several times.

In industry and mass production

Various types of machines are used in production:

- with hacksaw blades or circular saws,

- turning,

- milling,

- installations for plasma/laser/gas cutting.

The scope of application for these installations, like for hand tools, is quite different.

Hacksaws and circular saws are the simplest types of machines. Their only task is to save time when cutting long products. They can also handle thick workpieces with ease.

Lathes can be divided into models:

In the first case, using carbide cutters of various shapes, a worker manually grinds the required part from a horizontally fixed rotating cylindrical workpiece. In the second, all actions are performed automatically when executing a preloaded program.

The easiest way to understand the principle of use is in this video:

Milling machines perform approximately the same function, but can create products of absolutely arbitrary shape. A rectangular, square or cylindrical workpiece is fixed on a movable table, after which a head with a rotating cutter, following the program, begins to cut off the “extra” metal.

The process looks like this:

For thin and thick sheet metal, a separate group of CNC machines is used. The key difference between them is the technology used for cutting.

The blank sheet is placed on a stationary table, after which the cutting head, controlled by a computer, begins to cut parts according to a predetermined program.

The cutting head can be used for:

This technology ensures maximum accuracy and speed of production, which is highly valued in conditions of mass production.

Its main disadvantage is the likelihood of formation of molten metal deposits on the edges of parts and scale, especially when using workpieces of large thickness.

Price for metal cutting services

The cost of cutting metal varies depending on various parameters, including the complexity of the work, the tools used, technology, etc.

Also, the formation of the price is influenced by the material from which the workpiece is made, the labor intensity of the process, the techniques used in the process of cutting metal, the presence or absence of additional work, the timing of the order, etc.

Semi-automatic

Perhaps this name is not entirely correct, but the essence of the method is that various mechanical machines are used to cut the workpiece - guillotines, which speed up and simplify the process and provide a much more accurate cut.

When using them, the processed edge is smooth, there are no nicks and burrs on it, which are common when working with a chisel, and the geometry of the product itself is not disturbed. The absence of unevenness on the resulting edge significantly saves time, since there is no need for further processing.

To use the guillotine, simply place a metal sheet on it and lower the handle. A cutter reinforced with hydraulics, mechanics or pneumatics will easily cut through the entire width of the workpiece.

Such mechanized devices are popular in small industries, but electromechanical guillotines are considered truly productive.