What does a jigsaw consist of?

All variations have the same configuration, and, therefore, a single set of components and what is worth remembering when deciding to make a jigsaw:

- File;

- Tire-connecting rod type assembly;

- Drive unit;

- A special device that allows you to tighten the files;

- Working surface or bed;

- Additional mechanisms (optional).

Main characteristics of a jigsaw

Remember that any option must comply with the established parameters:

- The optimal size of a work surface or table should be between 30 and 40 centimeters. The smaller size is not convenient for processing parts, the larger one represents industrial designs;

- The drive power is equal to 150 Watts. This is the most real value that can belong to a structure made at home;

- The rotational force imparted to the saw is transmitted using a special mechanism. It has a complex name - crank mechanism. Its main task is to change the rotation into a special reciprocating motion;

- The file has a certain vibration limit of one minute. This figure should be between 800 and one thousand movements per minute;

- Jigsaw files have a number of features. The file also has a limit on vertical movement - it should not exceed five centimeters;

- Most models have a speed control function, this allows you to perform work more efficiently and adapt to the different technical qualities of the material with which you interact;

- A jigsaw has a limit on the parameters of the material with which it works. So a manual jigsaw should work with plastic and wood, whose parameters do not exceed ten centimeters in thickness, and the length of the product is not more than thirty-five centimeters;

- Each material (be it plastic or wood) has its own saw. The width of the saw on average can vary from two to ten millimeters;

- Smooth operation is ensured by the tension mechanism.

Note!

- DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

While studying all the features of jigsaws, remember that there are exceptions to the rules. These are industrial designs and variants intended for small-sized figurative work. Most often, their first difference is their high cost.

Device classification

Basically, the classification of jigsaws consists only of the purpose of the tool, so based on this, jigsaws are:

- household - designed to perform small and low-cost work. Machines of this type can have a power of only up to 500 W and run for half an hour, this will be quite enough.

- Professional sawing machines are necessary for work that requires a lot of labor. The power of such a stationary jigsaw is much greater, 700-1500 W, it can be used for 3 hours without a break. It is intended specifically for permanent professional activities.

- The production unit is much larger than previous types; it performs work in the production sector, so the duration increases to 20 hours.

The device can also be classified depending on the cutting material. This is what determines the type of device, as well as the saw used for cutting.

What is the difference?

Each species has its own nuances and advantages over its neighbors. So options with a lower support are the most popular in everyday life. They are the vast majority. The lower frame has several functions at once - a controller, a motor, a main gear, and a button to turn the device on and off.

Models with two (upper and lower) have their own significant advantage. The top has a rail, which is additional to the design. It copes well with cutting small parts and point work. It is important to remember that for this type the thickness of the material during work cannot be more than eight centimeters.

Variations on the suspension do not fix the frame stably. But their advantage is mobility. In this case, the material being processed is fixed and does not move, and the jigsaw itself moves with the help of an attachment behind the master. This variation makes it possible to create very complex and subtle patterns.

The scale and stops are necessary for carpentry masters who work exclusively from drawings. Markings prevent inaccuracies.

Note!

- Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

General information

But in some cases, using a hand tool to perform work is extremely difficult or even inconvenient - poor visibility of the cut line will interfere, it becomes necessary to hold the workpiece with both hands, and so on. But the main problem with a manual jigsaw will be that the file moves to the side, and this is especially evident when cutting materials with a large thickness, as well as a small radius of curvature. In this case, a sawing machine made from a jigsaw will not be superfluous; it is not difficult to make with your own hands and even a novice master can cope with this task.

Area of application of the machine and principle of operation

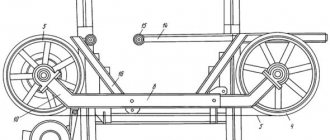

The main structural elements can be called:

- Frame with a tensioned file.

- A crank mechanism that will provide reciprocating motion of the frame.

- Stand and work table.

An electric jigsaw can successfully replace the crank mechanism and set the frame with the saw in motion. There are even simpler designs in which the electric jigsaw will simply be attached upside down to the work table, and the file will either hold its position during operation due to its own elasticity, or will be fixed on top by means of guides/spring-loaded bracket that moves with them at work. This will make it possible to reduce power loss during movement on the frame, but it will require the use of an elongated type of saw, which is not very often found on sale.

Advantages

The main advantage of a jigsaw-type machine will be the ability to perform precise cuts, as well as no deviation of the file to the side.

Moreover, the advantages of jigsaw machines over hand tools are:

- More effective control (visual) of the accuracy and direction of the cut.

- Possibility of using guide elements.

- It becomes possible to install special templates, which will make it possible to obtain many identical blanks.

- A narrower file is used, which makes it possible to reduce the radius of curvature and cut out parts of a more complex configuration.

Along with this advantage there will be one more thing - the need to organize a workplace for sawing will disappear, because the machine will be located on a plane appropriate for this.

Basic design and drawings

To make a sawing machine from a jigsaw for wood, you will need a drawing. There are ready-made platforms that make it possible to quickly turn a hand tool into a full-fledged machine tool. But they are usually designed for electric jigsaws from certain manufacturers, and will not fit all other devices. Moreover, the cost of such platforms is often much higher than the cost of the tool.

For this reason, it will be much easier to make the machine yourself. The basis for such a machine will be a desktop. It was experimentally established that tables made of sheet metal were able to demonstrate the greatest efficiency - they are durable, and also provide excellent installation accuracy; frequent replacement and reduction of the working length of the saw blade are not required. The electric jigsaw is attached to the table through holes to the support plane, and if necessary, it will be easy to detach it and use it in the standard way.

The work table must be installed on the bed. It can be made of natural wood, chipboard or other materials. The main requirement will be strength, ease of access to the electric jigsaw and a size convenient for the master, or rather height. A rocker arm should be installed at the end of the table, to which the second end of the saw blade with a tension device will be attached.

There are two options for tensioner designs:

- A rigid rocker arm and a spring-type block at the end with a movable saw blade fastening unit.

- A movable rocker arm, which has a spring at the opposite end and a rigid unit for attaching saw material.

Both the first and second options are popular, have their own advantages and disadvantages, and the choice is usually made in favor of the option that is simpler and technically accessible.

How to make a jigsaw with your own hands?

The easiest option is to make a machine. A homemade jigsaw is probably a better solution. There are a great many variations and drawings, they are easy to find on the Internet. This is all a consequence of the desire to create a unique and inimitable instrument. However, the operating principle will always be absolutely the same.

Step-by-step instruction

To create a jigsaw with your own hands, you don’t need to have superpowers:

- We make a work table that will serve as a support. For this you need a sheet of wood or metal. Lay the size of the base, which will be approximately four times the size of the saw;

- At the bottom of the support we attach the factory device. Cap screws can be used for fastening;

- The structure is mounted on a table.

The trick is that a manual jigsaw is cheaper, but it’s more convenient to work with it on a stand. This will avoid unevenness and shifts when working with the material.

A do-it-yourself jigsaw is a real help for single people who have no one to hold part of the element being cut.

Description of equipment

Cutting machines are the simplest design with a rigidly and immovably fixed frame, which is made of lumber or a welded angle and a movable head with a circular saw working body.

With equal success, such a machine can cope with cutting lining, block house, planed boards and thin logs, which allows it to be used for preparing firewood. READ Do-it-yourself angle grinder table

Today on sale you can choose various types of cutting machines and stationary grinders for cutting metal, which will differ in the power of the electric drive, their design, purpose and a number of other characteristics. The simplest models, which are made on the principle of a rising and falling circle, can be easily assembled yourself.

Such self-made units are not inferior in terms of functionality to industrial models, while they are compact in size, cope well with all the functions assigned to them, and the manufacture of such equipment is not particularly difficult.

How to improve the design?

Of course, a manual jigsaw is not perfect, but it can be modified and brought to perfection.

- A rocker is being made. This type of structure will be tensioned using springs on one side and secured to the file on the other.

- We fasten the file between two rollers. Their function is to be guides.

- We use a factory jigsaw as a drive. A file is pulled between it and the rocker.

Note!

Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

- Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

- Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

How to use a sewing machine?

It's hard to believe, but it can also be converted into a jigsaw. How can this idea be brought to life?

- We remove the part that ensures weaving of threads (the lower part of the machine).

- We remove the cotter pin and drive shaft.

- We remove the upper part, which protects the mechanism from mechanical damage.

- We expand the part for the needle for the file.

- Let's modernize the file. The file should not be longer than the needle.

Such a device perfectly replaces a jigsaw for shaped work on plywood and will become a homemade jigsaw that can surprise all your friends and acquaintances.

It allows you to create even the most complex patterns and turns. However, this design has its drawbacks:

- The leg may get tired from working with the pedal;

- Vibrations may occur that complicate work.

If it is not possible to purchase an expensive design, you can get by with small losses. A jigsaw - a machine made independently can be an excellent solution. The main thing is to follow the instructions exactly when working and conscientiously fasten all the elements together.

Consider a table base so that it becomes a reliable support for the mechanism. It is important that the table does not rock or vibrate when the mechanism is running.

The more static all elements are in the end, the easier it will be to work, avoiding unnecessary movements and mistakes. And mistakes in such a matter are most often not acceptable.

A slight change in the angle or position at which you work, and the part may not fit into place or lose its shape. In any carpentry, the most important thing is the accuracy and measuredness of all actions.

A homemade jigsaw machine with your own hands is not such a complicated story as it might seem at first. After studying the article, understanding the basic elements and how to create your own tool, you can get to work.

It is worth noting that very often such a homemade machine is much more convenient than a purchased one. This saves money, but most importantly, this table is personalized. It will perfectly suit your workplace, your height and weight.

Such a design will fully meet the objectives, because the most convenient mechanism can be created only by the person who will use it in the future. In addition, in case of minor breakdowns, it will be clear how to repair and what can be fixed.

For a purchased sample, you will have to look at the instructions and study forums in search of a specific model and its characteristics. Have fun creating, and let the new jigsaw give you confidence and the desire to start a new renovation!

Working with a tabletop jigsaw

A jigsaw, like a hand tool, allows you to work with wood, plywood, thin plastic or plexiglass. Homemade products made using this device are distinguished by high accuracy and complex shapes. Using a jigsaw, holes for sockets are cut out in wooden panels, and materials are cut into shapes.

When working with a jigsaw, you need to protect your eyes.

There are a number of rules used when working with this tool:

Do not apply excessive force to the material. The saw must cut at optimal speed, otherwise it will not be possible to avoid breakage of the blade or the entire tool. For different jobs you should use blades of different widths. For example, for long, even cuts, a wide file is used. For cutting thin materials, a plywood backing is used. This way the future product will be protected from damage. It is necessary to use eye protection, as during operation the jigsaw throws a large amount of small sawdust into the air. When working with sheet plastic, the saw speed should be set to minimum. At high speeds, the material overheats, causing it to begin to melt. When cutting round holes, first make a small hole in the plywood with a drill, after which a saw blade is threaded through it and secured in clamps. Rectangular holes are made according to the same principle, but right angles are not cut out immediately. To begin with, they are made rounded, and after passing the saw along the entire perimeter, the remaining triangular fragments are cut out. To prevent the plywood from vibrating when working with it, the material must be held securely with both hands, pressing it against the table

It is important to ensure that no sharp turns of the material occur during cutting, otherwise the saw may simply jam and break off. In places where there are turns, the plywood should be held in place for a few seconds, giving the tool time to expand the space for action, and then move on.