Design features of the device

The Izh family of lathes is designed to ensure minimal personnel distraction and guarantee stable operating conditions. Brief description of the features of operation and equipment:

- during turning operations, lubricant is supplied to the lead screw automatically;

- an apron in which the machining mechanics are installed - guarantees high rigidity of the stop, reduces the load on the gearbox mechanism;

- large ranges of caliper movement, feed values, and main shaft revolutions provide high productivity, as well as surface quality;

- a robotic mechanism is used to adjust the rotation speed of the unit’s spindle, and it is also responsible for pre-setting the mode for the next operation;

- the drive belt system and the general design of the main drive gear system provide a high speed of replacement of pulleys and do not require replacement of elements to obtain the desired operating mode;

- The tailstock is designed to provide comfortable handling combined with high rigidity.

- when cutting threads, there is no need to change the wheels of the guitar due to the special design of the mechanics of the feed box;

- The cutter head design uses a backlash-free coupling design. This not only increases the accuracy of installation of the working body, but also ensures high rigidity;

- The feeding operation is controlled by just one handle.

The design of all models in the family is characterized by high strength and durability. All working surfaces are made of wear-resistant chromium-nickel cast iron. All elements are hardened and polished. The layout of the machines is classic, not providing for longitudinal milling operations.

For ease of operation, the equipment is equipped with a work area illumination lamp with variable position.

Security systems include:

- protection against short circuits of the electrical system;

- structure for emergency shutdown of the main engine when the load on the shaft is exceeded;

- blocking devices to prevent simultaneous feeding in two directions;

- system to prevent cases when the roller and screw are turned on at the same time.

The manufacturing company, the legendary IZHMASH plant, offers several equipment modifications that differ in the adjustment of the main drive and other characteristics. In particular, there are systems without a gearbox, in which the spindle rotation speed is changed by modifying the electric motor speed. Machines of this class use a more powerful 5.5 kW drive model.

IZH-250 Universal screw-cutting lathe. Purpose, scope

The universal screw-cutting lathe model IZH-250 has a center height of 150 mm and a distance between centers of 500 mm.

The IZH-250 screw-cutting lathe is one of the first serial machines produced by the Izhevsk Machine-Building Plant in the post-war years. The machine was produced until 1964, when it was replaced by a much more advanced screw-cutting lathe.

The IZH-250 lathe was produced for a relatively short time (1960-1964). The machine has been radically redesigned in relation to its predecessor (model).

Screw-cutting lathes, models IZH-250, are designed for turning on centers, chucks or collets, as well as for cutting metric, modular and inch threads for use in large and small enterprises.

The machines can be used in tool and instrument manufacturing related to the precision processing of small-sized parts.

The IZH-250P machine has an increased accuracy class and is used to perform more precise work.

Design features of the screw-cutting lathe IZH-250

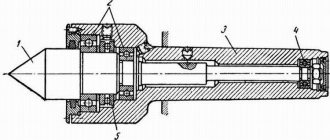

The spindle of the IZH-250 screw-cutting lathe is mounted on three rolling bearings:

- 44. Front double-row roller bearing 70×110×30, 3182114

, accuracy class (A) - 13. Thrust ball bearing 55×78×16, A8111

, accuracy class (A) - 14. Angular contact ball bearing 55×100×21, A46211

, accuracy class (A)

The spindle of the IZH-250P screw-cutting lathe is mounted on bronze split adjustable plain bearings.

The end of the spindle is threaded M68×6. A standard Ø200 mm cartridge is installed on an intermediate (adapter) flange, which is screwed onto the thread until it stops. The diameter of the hole in the spindle is Ø 33 mm for a rod Ø 30 mm. Morse taper 5.

The gearbox is installed in the left cabinet of the machine and is a four-axis gearbox, receiving movement from a flange electric motor. From the gearbox through a V-belt transmission, the movement is transmitted to the spindle. A friction plate clutch and brake are located on the drive shaft of the gearbox. The clutch provides on/off rotation of the spindle, and the brake reduces the spindle rotation time.

The feedbox receives movement through the guitar from the headstock gearbox.

The thread pitch and feed speed are selected using the handles on the front cover of the feed box.

The machine support receives movement from the drive shaft connected to the output shaft of the feed box. When cutting threads, the movement of the caliper is ensured by the lead screw, and the lead shaft should not rotate.

The caliper apron converts the rotational movement of the lead shaft or lead screw into longitudinal and transverse movement of the caliper. The apron also provides manual longitudinal movement of the caliper from the flywheel.

Electrical equipment installed on the IZH-250 machine:

- The electric motor of the main movement drive is asynchronous, two-speed - 1420/2800 rpm, power - 2.6/3 kW, three-phase 380 V, type FT42-4/2.

- Electric motor for driving the lubrication oil pump is asynchronous with a squirrel-cage rotor – 1400 rpm, power – 0.18 kW, three-phase 380 V, type AOL12-4

- Cooling pump drive electric motor – 2800 rpm, power – 0.125 kW

- Irreversible magnetic starter with coil 380V, type PMI-1

- Reversible magnetic starter with a 380V coil for switching the direction of rotation of the main motion electric motor, type PMI-1R

- Two-pole thermal relay for protecting electric motors, type RT-1

Main technical characteristics of the IZH-250 screw-cutting lathe

Manufacturer: Izhevsk Machine-Building Plant Izhmash. Serial production began in 1960.

- The largest diameter of a Disk-type workpiece processed above the bed is Ø 250 mm

- The largest diameter of the Shaft type workpiece processed above the support is Ø 125 mm

- Distance between centers – 500 mm

- Center height – 150 mm

- Electric motor power – 2.6/3 kW

- Total weight of the machine – 1.5 t

Spindle of screw-cutting lathe IZH-250

- Spindle end – threaded M68x6

- Internal (tool) spindle cone – Morse 5

- The diameter of the through hole in the spindle is Ø 33 mm

- The largest diameter of the processed rod is Ø 30 mm

- Limits of direct spindle revolutions per minute (22 steps) – 16..2000 rpm

Feeds and threads of a screw-cutting lathe IZH-250

- Limits of longitudinal feeds – 0.07..2.17 mm/rev

- Transverse feed limits – 0.01..1.08 mm/rev

- Limits of metric thread pitches – (24 pcs) 0.2..6 mm

- Limits of modular thread pitches – 0.2..6 modules

- Limits of inch thread pitches – 24..3.5 threads per inch

Screw-cutting lathe 250ITV F1 with digital display

The screw-cutting lathe 250ITV F1 is designed for performing a variety of turning operations on centers, collet or jaw chucks, as well as for cutting metric, modular, and inch threads. The machine is equipped with a digital display system (DDS).

The equipment of the SDI machine allows:

- display dimensions in mm or inches with discreteness from 0.1 to 100 microns;

- carry out linear compensation for errors in the mechanical elements of the machine, for example, wear of guides;

- introduce compensation for tool wear.

Peculiarities:

- A wide range of speeds and feeds ensures productive machining with good surface quality.

- Preselective control of spindle speeds allows you to prepare the subsequent switching on while the machine is running and quickly implement it at the right time.

- Mnemonic feed control is provided by one handle, the direction of activation of which coincides with the direction of the selected movement of the support with the cutting head.

- Backlash-free fixation of the cutting head ensures high rigidity and precision of installation.

- The lead screw is automatically lubricated when cutting threads.

- The design of the spindle unit allows you to quickly change drive belts without disassembling the unit.

- The machine bed is made of chromium-nickel cast iron, the guides are hardened by high-frequency currents and ground.

- The stopping mechanism located in the apron protects the feed mechanisms from overload and also allows you to work against a hard stop when turning.

- The main movement is driven by an electric motor through a twelve-speed gearbox, V-belts and poly-V-belts.

- When the flywheel is turned, a certain combination of holes is created in the two selector discs for the fixing fingers of the levers that switch the gear blocks.

- After this, pulling the handle towards you first slows down the rotating gears, and then switches them.

- The headstock contains a take-up pulley, a spindle, a 1:8 ratio, and a thread-pitch increasing link.

- To accurately measure transverse movements, a vernier mechanism is provided, allowing movements of 0.005 mm/rev.

- The feed box provides a wide range of cut thread sizes, longitudinal and transverse feeds.

- To cut precise threads, a direct connection of the lead screw to the guitar is provided, bypassing the feed box mechanism.

- The closed-type apron provides longitudinal and transverse feeds of the caliper manually and mechanically from the lead roller, as well as thread cutting using a lead screw.

- Feed control is carried out with one handle.

- The direction in which the handle is turned on coincides with the direction in which the caliper moves.

- The presence of a locking device eliminates the possibility of simultaneous activation of the lead screw and the lead roller, as well as longitudinal and transverse feeds.

- The machine is equipped with electric motors and equipment designed for a voltage of 380 V three-phase alternating current with a frequency of 50 Hz, and a local lighting voltage of 36 V.

- The machine is connected to the electrical network using a packet switch.

Information about the manufacturer of the screw-cutting lathe 250ITVM

The manufacturer of the 250ITVM lathe is the Izhevsk machine tool plant Izhmash, founded in 1807.

The history of machine tool building at the Izhevsk Machine-Building Plant begins on July 28, 1930, after the issuance of Order No. 181 on the creation of a machine tool department.

The first machine-tool production product at the plant was a lathe with an external transmission.

The most popular models of universal lathes produced at different times were “Udmurt”, “Udmurt-2” (161-AM), IZH-250, 1I611P, 1IS611V, 95TS, 250ITVM, 250ITVMF1 and the IT42 CNC lathe.

Machine tools produced by the Izhmash machine-building plant

- 1I611P

- high-precision universal screw-cutting lathe Ø 270 - 1I611PMF3

- high-precision CNC lathe Ø 320 - 1IS611V

– high-precision universal screw-cutting lathe Ø 270 - 95-TV (95TV)

- screw-cutting lathe Ø 250 - 95TS-1 (IS1-1)

- high-precision universal screw-cutting lathe Ø 250 - 161-A, 161-AM (Udmurt-2)

- universal screw-cutting lathe Ø 350 - 250-ITV (IZH 250-ITV)

- high-precision universal screw-cutting lathe Ø 300 - 250-ITP (IZH 250-ITP)

- high-precision universal screw-cutting lathe Ø 300 - 250ITVM (IZH 250ITVM)

- high-precision universal screw-cutting lathe Ø 300 - 250ITVM.01, 250ITVM.03, 250ITVM F1

- high precision screw-cutting lathe Ø 300 - 250ITVM F2

- high precision lathe with operational control system OSU Ø 320 - 1336m

- turret lathe Ø 420, Izhevsk, Kiev - IZH-T-400 (1623)

- universal screw-cutting lathe Ø 400 - IZH-250, IZH-250P

- high-precision universal screw-cutting lathe Ø 250 - IT-42

– CNC lathe Ø 320

How used is the model today?

Despite the rather “ancient” year of launch into mass production, the IZH 250ITVM passport is still of the old USSR type, but its performance is equal to modern modifications of similar equipment. Today it is supplied to private workshops, school classrooms and secondary construction education institutions without major differences from the original model.

Comparing the design of the machine with alternative multifunctional units, the old IZH 250 loses in many respects, but even such competition cannot completely suppress the demand for these models. The 250ITVM passport does not have superior characteristics, but the accuracy of work on this device can amaze even an experienced modern master of parts processing.

The model lags behind its competitors in terms of ergonomics, number of manufactured parts, lack of computer control and other indicators. But every review of devices capable of thread cutting cannot do without this basic representative of the class.

Read also: Varistors types and markings

Design features of the structure

Machine components

List of components

The 250ITVM series turning machine has quite unique design drawings. The structure of the machine allows us to highlight a lot of technological features:

- Changes in feed parameters and current spindle speed are made over a wide range, which increases functionality.

- The apron of this model is equipped with a well-thought-out stopping mechanism; thanks to this innovation in the structure, the main elements of the device (gearbox, drive, electrical circuits) are protected from loads.

- The basis for adjusting the spindle operation is preselective control technology. Its essence lies in the advance configuration of this node for the next time it is put into operation.

- The cutting of several thread options is determined not by the sequential change of gears, but by the versatility of the gearbox.

- The resistance parameters of the bed have extremely high numerical values. During manufacturing, the main material for this part is a special grade of chromium-nickel cast iron.

It is possible to regulate feeds on the machine using a lightweight scheme - a special handle is used. The feed direction completely corresponds to the movement of the handle.

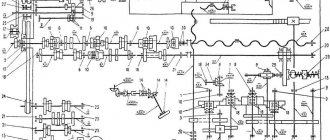

Kinematic diagram of the machine

Machine design and modifications

Appearance

The functional purpose of lathes model IZH-250 is wide. With their help, you can process workpieces using the rotation method. In this case, the part is mounted in a collet, centers or chuck. Additionally, it is possible to form threads of various types.

The design of the equipment is standard, but has a number of features. These include a wide range of gear shifts and cutting tool feeds, the ability to pre-set an operating mode that will turn on in a certain period of time. For ease of control, a mnemonic mechanism is provided. The lead screw is automatically lubricated during thread formation.

In addition, there are several types of machine modernization, which differ in technical and operational qualities, as well as equipment.

- IZH-250ITVF1. Equipped with a digital display unit. With its help, you can significantly increase labor productivity, since the worker does not waste time measuring the actual dimensions of the workpiece;

- IZH-250ITP. Designed for rough processing. This model is produced by special order only.

All types of equipment have a twelve-speed gearbox. High-reliability V-belts are used for drive. The gear block switches when the disks, which have holes for the locking pins, are displaced.

Increasing the accuracy of thread formation is carried out using a vernier mechanism installed on the IZH-250 machine. Additionally, a diagram for connecting the guitar to the lead screw is provided. It allows you to improve processing accuracy.

The machines of this series have gained the greatest popularity for completing production lines specializing in instrument making. This is due to the possibility of individual configuration and changing some machine parameters when ordering from the manufacturing plant.

Technical capabilities of the machine model IZH-250

The IZH-250 machine was created by Izhmash specialists for processing small-sized parts. That is why instrument-making and tool factories were actively equipped with it.

The machine of this model is capable of providing high precision processing for a long time if semi-finishing and finishing turning operations are performed on it. To carry out more crude technological operations, during which significant loads are placed on the unit components, it is better to use a modernized version of this machine model - 250ITP.

At one time, the machine model IZH-250 was produced in several design options:

- ITVM03 – unit with increased distance between centers;

- ITVMF1 – a machine additionally equipped with a digital display;

- ITPM is a model used primarily for turning operations that do not require high precision.

IZH-250 controls

It is worth mentioning separately about the modernized model of the IZH-250 machine - ITVMF1. The latter, due to its digital display, allows processing with high productivity. The operator working on such a unit requires much less time to measure the geometric parameters of the part and perform test passes.

Digital display provides this device with a number of other significant advantages: there is no need to remember dial speeds and calculate certain parameters; Linear compensation for inaccuracies in the interaction of machine components, as well as wear of the cutting tool during processing, is carried out automatically, without human intervention.

The technical capabilities of the machine model IZH-250 make it possible to use it to cut various types of threads (metric, inch, modular) with high accuracy and productivity, so they try to perform such a technological operation on this particular unit.

Differences between modifications

Engineering thought does not stand still, and modified machines have been mass-produced, which have absorbed the best features of the IZH-250, but have also acquired specific features.

IZH 250 ITVM 01 and 03

The machine is distinguished by its increased dimensions of the working space. The center-to-center distance is 700 mm. The diameter of “Shaft” type blanks has been increased to 170 mm.

IZH 250 ITPM

Priority in the machine is given to turning work. Processing class P according to GOST 8–82 is provided. Weight – 1200 kg.

Among the latest modifications, we can highlight the IZH-250 SCI model, equipped with an accurate indication (up to 100 microns in diameter). The machine provides linear compensation for tool wear.

The IZH-250 lathe has been popular for more than 50 years. It is distinguished by fairly high accuracy of parts processing and increased reliability.

Modern modifications are quite competitive with other machines of more recent developments. This equipment can be recommended to both large businessmen and individual entrepreneurs for setting up small production.

Technical characteristics of modifications of the IZH-250 lathe

All the main parameters of the three modifications of the IZH-250 screw-cutting lathe are presented in the table below.

Technical characteristics of modifications of the IZH-250 machine

Device

The passport of the 250ITVM model contains information about the main operating modules of the installation - the drive that provides the rotational torque of the cutter; the second element is the electrical circuit. The latter is used primarily for repair work or as the main means of high-quality installation of additional modules.

Electrical diagram of the machine

The drive operates thanks to a 12-speed gearbox, which allows operation at the required speed with the possibility of pre-setting for subsequent start-up

V-belts have an important purpose, which in this unit can be changed without cumbersome disassembly of the main elements

The smooth gear shift mechanism works according to the following scheme:

- As the flywheel turns, the two selector discs shift.

- Inside the disks, the combination of holes instantly changes, the resulting displacement fully corresponds to the intended gear that the worker wants to engage.

- The holes correspond to locking levers that ensure the required speed is switched.

- The handle is pulled back, which is accompanied by a slight braking of the gears, after which the gear changes.

Technical characteristics of the machine 250ITVM

| Parameter name | 250ITVM.01 | 250ITVM.03 | 250ITVMF1 |

| Main settings | |||

| Accuracy class according to GOST 8-82 | IN | IN | IN |

| The largest diameter of the workpiece processed above the bed, mm | 240 | 240 | 240 |

| The largest diameter of the workpiece processed above the support, mm | 168 | 168 | 168 |

| The largest diameter of the workpiece installed above the bed, mm | 300 | 300 | 300 |

| Maximum workpiece length (RMC), mm | 500 | 750 | 500 |

| Spindle | |||

| Diameter of through hole in spindle, mm | 25 | 25 | 25 |

| The largest diameter of the rod passing through the hole in the spindle, mm | 24 | 24 | 24 |

| Number of stages of direct rotation of the spindle, rpm | 21 | 21 | 21 |

| Spindle direct rotation frequency, rpm | 25..2500 | 25..2500 | 25..2500 |

| Number of spindle reverse rotation stages, rpm | 21 | 21 | 21 |

| Spindle reverse rotation frequency, rpm | 25..2500 | 25..2500 | 25..2500 |

| Size of the internal cone in the spindle, M | Morse 4 | Morse 4 | Morse 4 |

| Spindle end according to GOST 12593-72 | 4 | 4 | 4 |

| Permissible torque on the spindle, Nm | 1051,90 | 1051,90 | 1051,90 |

| Submissions | |||

| Maximum stroke length of the caliper carriage, mm | 500 | 500 | 500 |

| Price for dividing the longitudinal movement dial of the caliper, mm | 0,1 | 0,1 | 0,1 |

| Longitudinal movement per one revolution of the dial, mm | 20 | 20 | 20 |

| Maximum lateral movement of the caliper, mm | 165 | 165 | 165 |

| Dividing value of the caliper transverse movement dial, mm | 0,05 | 0,05 | 0,05 |

| Transverse movement per one revolution of the dial, mm | 3 | 3 | 3 |

| Maximum movement of the upper slide of the caliper, mm | 120 | 120 | 120 |

| Number of longitudinal feed stages | |||

| Limits of longitudinal working feeds, mm/rev | 0,01..1,8 | 0,01..1,8 | 0,01..1,8 |

| Number of cross feed stages | |||

| Limits of working cross feeds, mm/rev | 0,005..0,9 | 0,005..0,9 | 0,005..0,9 |

| Speed of fast movements of the caliper, longitudinal, m/min | No | No | No |

| Speed of fast movements of the caliper, transverse, m/min | No | No | |

| Number of metric threads to be cut | |||

| Limits of pitches of cut metric threads, mm | 0,2..48 | 0,2..48 | 0,2..48 |

| Number of inch threads to be cut | |||

| Limits of pitches of cut inch threads | 24..0,5 | 24..0,5 | 24..0,5 |

| Number of modular threads to be cut | |||

| Limits of pitches of cut modular threads | 0,2..12 | 0,2..12 | 0,2..12 |

| Number of cut pitch threads | No | No | No |

| DRO resolution in X/Z coordinates. mm | — | — | 0,001/ 0,005 |

| Tailstock | |||

| The size of the internal cone of the tailstock quill according to GOST 25557-82 | Morse 3 | Morse 3 | Morse 3 |

| Tailstock quill center according to GOST 13214-79 | Morse 3 | Morse 3 | Morse 3 |

| Maximum movement of the tailstock quill, mm | 85 | 85 | 85 |

| Rule division price, quill movement, mm | 1 | 1 | 1 |

| Limb division price, quill movement, mm | 0,05 | 0,05 | 0,05 |

| Transverse displacement of the quill, mm | ±10 | ±10 | ±10 |

| Electrical equipment | |||

| Number of electric motors on the machine | 3 | 3 | 3 |

| Main drive electric motor, kW/rpm | 3/ 1410 | 3/ 1410 | 3/ 1410 |

| Lubrication station electric motor, kW/rpm | 0,09/ 1350 | 0,09/ 1350 | 0,09/ 1350 |

| Cooling pump electric motor, kW/rpm | 0,18/ 2730 | 0,18/ 2730 | 0,18/ 2730 |

| Cooling pump (pump) | PA-22 | PA-22 | PA-22 |

| Total power of electric motors on the machine, kW | 3,27 | 3,27 | 3,27 |

| Overall dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1790_810_1400 | 2005_810_1400 | 1790_810_1400 |

| Machine weight, kg | 1180 | 1240 | 1190 |

Bibliography:

Screw-cutting lathe 250ITVM.01, 250ITVM.03, 250ITVMF1. Operating manual 250ITVM.00.000 RE, 2000 Screw-cutting lathe 250ITVM.01, 250ITVM.03, 250ITVMF1. Electrical equipment operating manual 250ITVM.00.000 RE1, 2000

Acherkan N.S. Metal-cutting machines, Volume 1, 1965

Batov V.P. Lathes., 1978

Beletsky D.G. Handbook of a universal turner, 1987

Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1972. (1k62)

Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1979. (16k20)

Modzelevsky A. A., Muschinkin A. A., Kedrov S. S., Sobol A. M., Zavgorodniy Yu. P., Lathes, 1973

Pikus M.Yu. A mechanic's guide to machine repair, 1987

Skhirtladze A.G., Novikov V.Yu. Technological equipment for machine-building industries, 1980

Tepinkichiev V.K. Metal cutting machines, 1973

Chernov N.N. Metal cutting machines, 1988

Related Links. Additional Information

- Classification and main characteristics of turning machines

- Selecting the right metalworking machine

- Multi-start thread. Methods for cutting multi-start threads on a lathe

- Graphic signs for lathes

- Friction clutch of a screw-cutting lathe

- Methodology for checking and testing screw-cutting lathes for accuracy

- Manufacturers of lathes

- Manufacturers of metal-cutting machines

- Directory of lathes

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Universal screw-cutting lathe 250ITVMF1

Screw-cutting lathes models 250ITVM are designed for turning on centers, chucks or collets, as well as for cutting metric, modular and inch threads for use in large and small enterprises.

The machines can be used in tool and instrument manufacturing related to the precision processing of small-sized parts.

In order to maintain long-term processing accuracy, machines should be used only for finishing or semi-finishing operations. The machine model 250ITVMF1 is equipped with a digital display system (hereinafter referred to as DRO), which allows increasing labor productivity by reducing auxiliary time for test passes and measuring parts. The use of a DRO makes the turner’s work easier by eliminating calculations and the need to memorize dial revolutions.

Design features and operating principle of the machine

The design of universal screw-cutting lathes models 250ITVM is made on the basis of the IZH1I611P and 250-ITV (IZH 250-ITV) machine.

The machine model 250ITVM is the base model for the machines 250ITVM.03, 250ITVMF1, 250ITPM.

The machine model 250ITVMF1 is additionally equipped with a digital display device (DDU).

The 250ITPM machine (accuracy class P according to GOST 8-82) is used to perform rougher and less precise work and is manufactured to special order.

The design of the machine model 250ITVM.03 differs from the basic model 250ITVM by its large center-to-center distance (500 mm and 750 mm)

The main movement is driven by an electric motor through a twelve-speed gearbox, V-belts and poly-V-belts. When the flywheel is turned, a certain combination of holes is created in the two selector discs for the fixing fingers of the levers that switch the gear blocks. After this, pulling the handle towards you first slows down the rotating gears, and then switches them. The headstock contains a take-up pulley, a spindle, a 1:8 ratio, and a thread-pitch increasing link. The machine model 250 ITVMF1 is equipped with a digital display system (DRO).

The equipment of the lathe 250ITVM.F1 DCI allows you to:

- display dimensions in mm or inches with discreteness from 0.1 to 100 microns;

- carry out linear compensation for errors in the mechanical elements of the machine, for example, wear of guides;

- introduce compensation for tool wear.

To accurately measure transverse movements, a vernier mechanism is provided, allowing movements of 0.005 mm/rev. The feed box provides a wide range of cut thread sizes, longitudinal and transverse feeds. To cut precise threads, a direct connection of the lead screw to the guitar is provided, bypassing the feed box mechanism.

The closed-type apron provides longitudinal and transverse feeds of the caliper manually and mechanically from the lead roller, as well as thread cutting using a lead screw. Feed control is carried out with one handle. The direction in which the handle is turned on coincides with the direction in which the caliper moves. The presence of a locking device eliminates the possibility of simultaneous activation of the lead screw and the lead roller, as well as longitudinal and transverse feeds.

The machine is equipped with electric motors and equipment designed for a voltage of 380 V three-phase alternating current with a frequency of 50 Hz, and a local lighting voltage of 36 V.

The machine is connected to the electrical network using a packet switch.

Accuracy class of machines 250ITVM V according to GOST 8-82

The machines are intended for use in conditions of UHL4 GOST 15150-69.

The machines used inventions according to copyright certificates 173094, 312739, 249142, 28M05, 288496, 583912, 831503, 1199461.

The machines are certified. Certificate of conformity No. ROSS RU.AYA04.V10876, valid until 06/17/2006.

Design Features:

- A wide range of spindle speeds and feeds provide productive processing with good surface quality.

- Preselective control of spindle speeds allows you to prepare the subsequent switching on while the machine is running and quickly implement it at the right time.

- The universal feed box makes it possible to cut all metric threads and common inch and modular threads without changing gears on the guitar.

- Mnemonic feed control is provided by one handle, the direction of activation of which coincides with the direction of the selected movement of the support with the cutting head.

- Backlash-free fixation of the cutting head ensures high rigidity and precision of installation.

- The lead screw is automatically lubricated when cutting threads.

- The design of the spindle unit allows you to quickly change drive belts without disassembling the unit.

- The machine bed is made of chromium-nickel cast iron, the guides are hardened by high-frequency currents and ground.

- The stopping mechanism located in the apron protects the feed mechanisms from overload and also allows you to work against a hard stop when turning.

- It is possible to design the machine without a gearbox with spindle speed control.

Technical characteristics of screw-cutting lathe 250ITVM

| Parameter name | 250ITVM.01 | 250ITVM.03 | 250ITVMF1 | 250ITVMF1.03 |

| Main settings | ||||

| Accuracy class according to GOST 8-82 | IN | IN | IN | IN |

| The largest diameter of the workpiece processed above the bed, mm | 240 | 240 | 240 | 240 |

| The largest diameter of the workpiece processed above the support, mm | 168 | 168 | 168 | 168 |

| The largest diameter of the workpiece installed above the bed, mm | 300 | 300 | 300 | 300 |

| Maximum workpiece length (RMC), mm | 500 | 750 | 500 | 750 |

| Spindle | ||||

| Diameter of through hole in spindle, mm | 25 | 25 | 25 | 25 |

| The largest diameter of the rod passing through the hole in the spindle, mm | 24 | 24 | 24 | 24 |

| Number of stages of direct rotation of the spindle, rpm | 21 | 21 | 21 | 21 |

| Spindle direct rotation frequency, rpm | 25..2500 | 25..2500 | 25..2500 | 25..2500 |

| Number of spindle reverse rotation stages, rpm | 21 | 21 | 21 | 21 |

| Spindle reverse rotation frequency, rpm | 25..2500 | 25..2500 | 25..2500 | 25..2500 |

| Size of the internal cone in the spindle, M | Morse 4 | Morse 4 | Morse 4 | Morse 4 |

| Spindle end according to GOST 12593-72 | 4 | 4 | 4 | 4 |

| Permissible torque on the spindle, Nm | 1051,90 | 1051,90 | 1051,90 | 1051,90 |

| Submissions | ||||

| Maximum stroke length of the caliper carriage, mm | 500 | 500 | 500 | 500 |

| Price for dividing the longitudinal movement dial of the caliper, mm | 0,1 | 0,1 | 0,1 | 0,1 |

| Longitudinal movement per one revolution of the dial, mm | 20 | 20 | 20 | 20 |

| Maximum lateral movement of the caliper, mm | 165 | 165 | 165 | 165 |

| Dividing value of the caliper transverse movement dial, mm | 0,05 | 0,05 | 0,05 | 0,05 |

| Transverse movement per one revolution of the dial, mm | 3 | 3 | 3 | 3 |

| Maximum movement of the upper slide of the caliper, mm | 120 | 120 | 120 | 120 |

| Number of longitudinal feed stages | ||||

| Limits of longitudinal working feeds, mm/rev | 0,01..1,8 | 0,01..1,8 | 0,01..1,8 | 0,01..1,8 |

| Number of cross feed stages | ||||

| Limits of working cross feeds, mm/rev | 0,005..0,9 | 0,005..0,9 | 0,005..0,9 | 0,005..0,9 |

| Speed of fast movements of the caliper, longitudinal, m/min | No | No | No | No |

| Speed of fast movements of the caliper, transverse, m/min | No | No | ||

| Number of metric threads to be cut | ||||

| Limits of pitches of cut metric threads, mm | 0,2..48 | 0,2..48 | 0,2..48 | 0,2..48 |

| Number of inch threads to be cut | ||||

| Limits of pitches of cut inch threads | 24..0,5 | 24..0,5 | 24..0,5 | 24..0,5 |

| Number of modular threads to be cut | ||||

| Limits of pitches of cut modular threads | 0,2..12 | 0,2..12 | 0,2..12 | 0,2..12 |

| Number of cut pitch threads | No | No | No | No |

| DRO resolution in X/Z coordinates. mm | — | — | 0,001/ 0,005 | 0,001/ 0,005 |

| Tailstock | ||||

| The size of the internal cone of the tailstock quill according to GOST 25557-82 | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Tailstock quill center according to GOST 13214-79 | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Maximum movement of the tailstock quill, mm | 85 | 85 | 85 | 85 |

| Rule division price, quill movement, mm | 1 | 1 | 1 | 1 |

| Limb division price, quill movement, mm | 0,05 | 0,05 | 0,05 | 0,05 |

| Transverse displacement of the quill, mm | ±10 | ±10 | ±10 | ±10 |

| Electrical equipment | ||||

| Number of electric motors on the machine | 3 | 3 | 3 | 3 |

| Main drive electric motor, kW/rpm | 3/ 1410 | 3/ 1410 | 3/ 1410 | 3/ 1410 |

| Lubrication station electric motor, kW/rpm | 0,09/ 1350 | 0,09/ 1350 | 0,09/ 1350 | 0,09/ 1350 |

| Cooling pump electric motor, kW/rpm | 0,18/ 2730 | 0,18/ 2730 | 0,18/ 2730 | 0,18/ 2730 |

| Cooling pump (pump) | PA-22 | PA-22 | PA-22 | PA-22 |

| Total power of electric motors on the machine, kW | 3,27 | 3,27 | 3,27 | 3,27 |

| Overall dimensions and weight of the machine | ||||

| Machine dimensions (length width height), mm | 1790_810_1400 | 2005_810_1400 | 1790_810_1400 | 2005_810_1590 |

| Machine weight, kg | 1180 | 1240 | 1190 | 1050 |

Standard equipment 250ITVM:

- 3-jaw chuck (Ø 160 mm)

- Longitudinal stop

- Tailstock center (Morse 3)

- Headstock Center (Morse 4)

- Set of replacement gears for threading: metric, modular, inch

- Quick-change tool holder SWH 3-E consisting of: - eccentric quick-change head type E; — 3 replaceable cartridges 20×100 mm type D (for cutters with a square holder) for the tool holder SWH 3-E — 1 replaceable cartridge 30×100 mm type H (for cutters with a round holder) for the tool holder SWH 3-E

Additional equipment (for a fee):

- Rear tool holder

- Drive chuck

- Faceplate with grooves

- 4-position tool holder

- Rotating center (Morse 3) for tailstock

- Longitudinal stop 4 positions

- Fixed steady rest (Ø 6…70mm)

- Movable rest (Ø 6…50 mm)

- Vibration-isolating support OV-31M (4 pcs.)

- Precision quick-change drill chuck with Morse 3 conical shank, clamping tool diameter 0.3 – 16 mm.

- Collet chuck type 3911 from BISON (Poland), with mounting on the spindle through an adapter flange. Clamping the part using a key. Set of collets with a diameter of Ø 3-25, pitch 1 mm (or 0.5 mm)

- Collet chuck type 2912-M125/5C from BISON (Poland) with manual drive using a lever

- Set of collets with a diameter of Ø 3-25, pitch 1 mm (or 0.5 mm)

Device

The IZH 250 lathe is equipped with a powerful electric motor that transmits movement through a 12-speed gearbox. The built-in motor is designed to operate in 380 V mode. Its rated power is 3 kW.

The unit is equipped with a closed apron. The caliper is fed in both directions by a master manually or using a roller. The closed apron also allows for efficient and accurate thread cutting via the lead screw. In this case, the master controls the feed using the handle. The direction of activation of the handle and the direction of movement of the caliper are identical. A significant advantage of the design is that the drive shaft and screw cannot be started at the same time, which is ensured by a built-in locking device.

If the IZH 250 machine is equipped with a digital display system, this greatly expands its functionality. This option allows you to control dimensions in inches or millimeters with an accuracy of 0.1-100 microns. SDI increases the accuracy of parts processing, as it makes it possible to linearly compensate for errors in the mechanical parts of the unit. This could be, for example, wear on the guides.

The IZH 250 lathe model has a special feed box, which provides a significant range of thread variations. If the master needs extremely precise cutting, the lead screw can be directly connected to the guitar, which will allow him to achieve the desired result.

Screw-cutting lathe Plant 250ITVM.F1

Machines of the 250ITVM series are universal equipment and have accuracy class B (according to GOST 8-82), so they are ideal for a wide range of precision turning operations.

Machines of modification 250ITVM.F1 are equipped with a digital display device (DID), which allows increasing labor productivity by reducing auxiliary time for test passes and measuring parts. The use of a DRO makes the turner’s work easier by eliminating calculations and the need to memorize dial revolutions.

Screw-cutting lathes are designed for performing a variety of high-precision turning operations on centers, collet and jaw chucks, as well as for cutting metric, inch and modular threads.

Product Modifications

- 250ITVM.F1 – basic modification of the machine with a digital display device (DRO).

- 250ITVM.03.F1 – with increased distance between centers.

Product Features

- Accuracy class – B (according to GOST 8-82)

- Solid cast frame providing a high level of vibration damping and rigidity

- Availability of a digital display device (DRO)

A wide range of speeds and feeds ensures productive machining with good surface quality.

Preselective control of spindle speeds of the machine 250ITVM.01 allows you to prepare for subsequent switching on while the machine is operating and quickly implement it at the right moment. Mnemonic feed control is provided by one handle, the direction of activation of which coincides with the direction of the selected movement of the support with the cutting head. Backlash-free fixation of the cutting head ensures high rigidity and precision of installation.

The lead screw is automatically lubricated when cutting threads. The design of the spindle unit allows you to quickly change drive belts without disassembling the unit.

The bed of the 250ITVM.01 machines is made of chromium-nickel cast iron, the guides are hardened by high-frequency currents and ground.

The stopping mechanism located in the apron protects the feed mechanisms from overload and also allows you to work against a hard stop when turning.

The main movement of the machine is driven by an electric motor through a twelve-speed gearbox, V-belts and poly-V-belts. When the flywheel is turned, a certain combination of holes is created in the two selector discs for the fixing fingers of the levers that switch the gear blocks. After this, pulling the handle towards you first slows down the rotating gears, and then switches them.

The headstock contains a take-up pulley, a spindle, a 1:8 ratio, and a thread-pitch increasing link.

The machine model 250ITVM.F1 is equipped with a digital display system DRO.

EQUIPMENT OF THE LATHE 250ITVM.F1 DCI ALLOWS:

- display dimensions in mm or inches with discreteness from 0.1 to 100 microns;

- carry out linear compensation for errors in the mechanical elements of the machine, for example, wear of guides;

- introduce compensation for tool wear.

To accurately measure transverse movements, a vernier mechanism is provided, allowing movements of 0.005 mm/rev. The feed box provides a wide range of cut thread sizes, longitudinal and transverse feeds. To cut precise threads, a direct connection of the lead screw to the guitar is provided, bypassing the feed box mechanism.

The closed-type apron provides longitudinal and transverse feeds of the caliper manually and mechanically from the lead roller, as well as thread cutting using a lead screw. Feed control is carried out with one handle. The direction in which the handle is turned on coincides with the direction in which the caliper moves. The presence of a locking device eliminates the possibility of simultaneous activation of the lead screw and the lead roller, as well as longitudinal and transverse feeds.

The machine is equipped with electric motors and equipment designed for a voltage of 380 V three-phase alternating current with a frequency of 50 Hz, and a local lighting voltage of 36 V.

The machine is connected to the electrical network using a packet switch.