USSR lathes are still used in enterprises. New equipment is almost impossible to find. But the old one has retained all its characteristics; it is enough to replace some components to get the result.

Since the 18th century, special machines began to be used instead of manual labor. At first the designs were steam-powered, then they switched to using electric energy; there was no exception for USSR lathes. They have become one of the most important inventions that make modern life easier.

Scope of application of lathes

The purpose of creating equipment is to process various parts on a metal and wooden base. To do this, various operations are performed:

- Cutting.

- Turning.

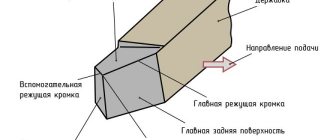

Turning cutters boast the widest functionality if you have the necessary tools and equipment:

- Drilling.

- Trimming, end processing.

- Thread cutting.

- Internal surface treatment.

- Turning grooves, cones and other similar shapes.

- Boring, turning surfaces in the form of cones, cylinders, smooth shaped type.

The machines can be used in both large-scale and small-scale production. Each owner chooses the option that suits him. The choice of models was wide from the very beginning.

Types and types of Soviet lathes

The classification, developed while the Soviet Union was in force, is still used to this day. The following types of metal-cutting equipment are basic:

- Special.

- Automatic, conventional machines for specialized purposes.

- With several cutters for polishing.

- Frontal, screw-cut.

- Carousel variety.

- Cutting group.

- Revolving.

- Semi-automatic, automatic with several spindles.

- Automatic and semi-automatic with one spindle for metal.

The precision with which the work is performed allows the machines to be classified into one of the following classes:

- P – increased.

- A – especially high.

- N – normal.

- B – high.

- S – special.

Information regarding the following characteristics is included in the unit labeling:

- The installations have specific dimensions contained in the third and fourth digits. What is meant here is the height at which the centers are located.

- The second says which class this or that unit represents.

- The first unit is said to be lathe equipment.

Prices of tabletop metal lathes

When choosing a suitable desktop unit for your home workshop, you need to pay attention to its cost. The price of mini-machines depends on several factors, such as:

- brand;

- power;

- performance.

The cost of the machine is determined by its power, productivity, size and brand

Other, smaller characteristics of metal lathes are also reflected in pricing. The price of a mini-unit, the power of which does not exceed 500 Watts, is approximately 15,000-55,000 rubles. Such devices do not differ in functionality, but are more than fully suitable for basic tasks.

Tabletop units with a wider list of capabilities (screw-cutting lathes) cost a little more. For example, a mini-machine of this type with a power of up to 500 Watts can be purchased at a price of 27,000-75,000 rubles.

And finally, turning and milling units are considered the most expensive desktop units. The price range in this case is 65-150 thousand rubles. Depending on the functional features and technical equipment, the price of desktop metal lathes is determined. You can buy the necessary device either in a specialized store or on the Internet by placing an order online.

The most popular companies producing such equipment, as mentioned above, are OPTIMUM and JET. They produce high-quality, wear-resistant units that have a long service life. The price of such devices is quite high, however, they all correspond to the declared quality.

For example, the cost of a desktop lathe Metal Master from the JET company ranges from 50 to 150 thousand rubles. Models from the OPTIMUM brand are even more expensive (from 60 to 330 thousand rubles).

Please note that machines from little-known manufacturers, with similar characteristics, may be significantly inferior in quality and reliability to units of more well-known brands

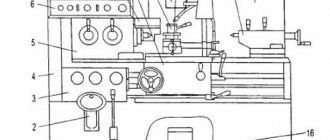

Design of a lathe and photos of its individual parts

The design of this type of equipment always contains the following components:

- Electrical part. We are talking about electric drive motors. Power varies from model to model. The group also includes elements responsible for controlling certain parts of the machine. The main thing is that these parts meet safety requirements.

- Gearbox. In the presence of such a structural element, the machine support receives the energy of movement. Lead screws and rollers act as sources of this energy.

- Caliper. Fastens the cutting elements of the structure. Provides transverse and longitudinal feeding of devices. The design is necessarily complemented by the so-called bottom carriage, or several. Holders for turning tools are fixed on other carriages, at the top.

- The spindle head contains the spindle itself. In the inner part there is a gearbox. Woodworking machines are also not devoid of this part.

- Apron. Helps ensure that the movement of the roller is converted into movement of the caliper. The lead screw can also participate in this process.

- Bed. Refers to the load-bearing elements of turning units. Other elements of the machine are mounted on it.

The rest of the elements are supported by two special cabinets included in the set. They have a load-bearing function for equipment. Thanks to this part, the operator is able to select the maximum workpiece height that is most convenient. The cabinets are known for their massive construction.

Brief description of the most common models of Soviet lathes

A wide range of functions have been included with the machines from the very first release. It is enough to look at the most popular brands to be convinced of this.

School lathe TV-4

Created to teach the basics of turning to students and schoolchildren of all ages. Provides access to a large number of work operations, including:

- Multi-start thread.

- Threads of different shapes, pitches: outside and inside, inch, trapezoidal, persistent.

- Boring work for surfaces in the shape of cones and cylinders.

- Carrying out countersinking.

- Boring holes.

- Reaming.

The workpieces rotate inside the centers and chucks - this is the main movement characteristic of the workpieces. The spindle receives energy from the gearboxes. The serve itself is a secondary factor, as is its movement. Thanks to this, even the old cutting tool and the workpiece are brought together.

Capable of processing parts with a diameter from 125 to 200 mm.

0.6 kW - the installation is equipped with electric motors with this average power.

Metal lathe Shkolnik TV-7

Equipment for educational purposes. Designed for training to perform the following operations:

- Countersinking.

- Deployment.

- Processing with a drill.

- Metric thread cutting.

- End processing with different parameters.

- Turning, boring parts.

The belt moves to another pulley pair if the speed is reduced. The main regulator is the handle on the right stand of the device. The result is support for up to four speeds.

Two pairs of gears are located inside the gearbox. The handle allows you to manually adjust the unit. Switching the clutch increases the number of available driving speeds to 8 units. The headstock is not supplemented with handles that simplify the adjustment of the required rotational numbers of the spindle.

The electrical circuit components are located in the right cabinet. The support with the tailstock is placed on the frame guides. Additionally, there are protective elements to prevent operators from being damaged by chips.

The dimensions of the workpiece range from 100 to 300 mm.

School metal lathe TV6

Using this type of equipment, operators gain access to the following operations:

- The workpiece is partially cut off.

- Conical and cylindrical surfaces are bored and machined.

- Metric thread.

- End adjustment.

- Drilling holes.

The machine is distinguished by its original characteristics, which do not allow processing of steel with a hardened surface. The device has the following parameters:

- 350mm distance between centres.

- The spindle maintains 130-170 rpm when rotating.

- 108 mm - at this height there are parts in the center.

- 300 millimeters is the length of the surface to be turned.

- 12 millimeters is the maximum diameter for the workpiece being processed.

The 300-kilogram weight distinguishes the machine, even if the equipment is minimal.

Tabletop metal lathe TV-16

Equipment processing metal parts is characterized by small dimensions. To perform basic operations included in turning operations:

- Making holes.

- Thread with different characteristics.

- Average complexity of operations.

- Carrying out boring and turning.

160 mm is the maximum limit for the size of workpieces in processing if they are above the bed. 90 millimeters is the same size for the location above the caliper. 250 mm – maximum length limit in the central part. The through spindle hole has an increased width when compared with the TV-4 model - it will be 18 mm.

The frame is cast, made of cast iron. It is complemented by three longitudinal grooves that serve as guides. Standard power indicators are in the range of 0.4-0.5 kW. 1400 rpm is an indicator for the rotation speed, which determines how efficient the milling machine will be.

Features of tabletop metal lathes

Such units are suitable for processing metal parts that are small in size. Using such a unit allows you to perform the following operations:

- turning parts in the shape of a cylinder or cone;

- trimming the ends of parts;

- grinding;

- organizing holes by drilling;

- expansion of holes;

- threading (both external and internal).

Helpful information! Processing of various parts on a home lathe is carried out at a much lower speed than on professional equipment. However, this does not in any way affect the quality of the finished product, especially if the operation of the unit is controlled using a computer numerical control (CNC) system.

Small-sized lathes are used to perform various technological metalworking operations at home

Small devices of this type are capable of performing many functions. They have found their application not only at home, but also in small workshops, as well as in car repair shops. Since Soviet times, such mini-machines have been used to teach turning to schoolchildren and students of professional technical institutions.

Thus, small-sized turning units are used for different purposes. They are indispensable and useful devices that allow technical operations with small parts. You can buy a metal lathe for your home in any specialized store or on the Internet.

Safety rules when working on a lathe

The provisions of the safety rules are as follows:

- Compliance with the original technical specifications is mandatory when performing work. To do this, first obtain a drawing from the master. Or another type of description of the technological process associated with processing.

- Before starting work, be sure to conduct a technical inspection. This is necessary in order to detect and eliminate individual technical faults in a timely manner. If necessary, call a technician.

- Special clothes are fastened with all buttons.

Work cannot be started if any equipment adjustment or other types of maintenance are being carried out. Do not use machines whose centers are heavily worn. The same applies to any tools or clamping materials - you should discard them at the slightest sign of malfunction.

If the breakdown is related to the electrical part, the technicians are prohibited from fixing it themselves.

Partprice.

The main task of any lathe is the mechanical processing of elements with a spherical, cylindrical, or conical surface. With their help, it becomes possible to quickly and accurately cut any type of thread, perform drilling, boring, cutting, and trimming the end part of workpieces.

Modern equipment is highly functional. Manufacturers produce universal models and CNC machines. The second option has recently become increasingly popular due to the higher quality of technological operations.

Where can I buy equipment from those times?

The seller delivers and, if necessary, advises on upgrading the equipment. The main advantage of Soviet equipment is that it can be easily improved, and all main components can be easily replaced, which significantly extends the service life of the machine.

Soviet-made machines are distinguished by reliability and quality of processing, as well as versatility. Most models can be further improved and their functionality expanded. That is why almost all Soviet machines are still used in mechanical engineering and metalworking production.

Main types of lathes

All existing turning equipment can be divided into several groups according to the types of processed materials and parts.

Turning and screw-cutting equipment

Screw-cutting lathes belong to the category of universal units that are widely used in the manufacture of parts in a single copy or as part of mass production. The main task of the equipment is cutting inch, metric, and modular threads. It is also used to perform other metalworking operations.

The basis of the design of a screw-cutting lathe is:

- spindle head with gearbox;

- a frame on which the main structural elements of the equipment are mounted;

- a support designed to fix the cutting tool;

- an apron used to convert the movement of a screw or roller into movement in a given direction of the support;

- tailstock, necessary for fixing the workpiece in the optimal position (in most cases it is equipped with additional tools).

Turret lathes

The turret group equipment is used for processing parts made from calibrated rods. With their help, you can perform a long list of technological operations. They include shaped turning, boring, reaming, threading, countersinking, and drilling.

The tools are mounted on the machine using a special holder. Depending on the modification of the equipment, it can be driven or static (the first option has greater functionality).

Lathe units

The machines are used when it is necessary to process frontal, conical, cylindrical surfaces. Many models do not have a tailstock. An important feature of models of this type is the ability to process heavy parts of short length (this is possible due to the fact that the spindle rotates in a horizontal plane and the presence of sufficient free space). At manufacturing enterprises, when heavy loads are expected to be placed on the lathe, carousel units are used as a replacement.

Vertical lathes

The equipment is used to work with large-sized workpieces. Among their key features, it is worth highlighting the ability to:

- using the machine to form grooves of any configuration;

- thread cutting;

- turning conical or cylindrical surfaces;

- performing end cutting, milling, and grinding operations.

If the machine is equipped with additional equipment, it can be used to grind shaped surfaces using a copier.

During operation of the equipment, the workpiece is fixed on a faceplate, the diameter of which directly determines the overall dimensions of the unit. According to this parameter, there are single-post (up to 2000 mm) or two-post models (more than 2000 mm).

Turning and milling machining centers

The center is a multifunctional device with electronic programmable equipment and complex kinematics.

Models with vertical or horizontal spindle rotation are available.

In the first case, it is possible to process workpieces with high weight and size parameters. Such machining centers are equipped with an external cooling system, due to which the productivity of the machine is significantly increased by increasing the speed of rotation of the parts.

Most models with vertical spindle rotation have an automatic cutting tool change function. When positioned horizontally, centers are often equipped with tilt-rotary or rotary tables. Belt-type mechanisms are used to change tools.

Such machining centers are distinguished by the presence of a vibration damping system, the ability to use up to 120 tools in operation, thanks to the tracked mounting system.

Automatic longitudinal turning

For small-scale production of parts, automatic longitudinal turning machines are widely used (equipment productivity can be up to 40 finished parts per minute). In this case, a shaped profile, wire, calibrated or cold-drawn rod can be used as blanks. There are models with movable and fixed spindle head.

Multi-spindle lathes

The equipment is used for processing workpieces with complex geometries, which are made from pipes, cold-drawn rods of any cross-section, as part of mass production.

High performance is ensured by high drive power.

When developing models of multi-spindle lathes, the use of structures of increased rigidity is envisaged. The equipment is capable of performing several technological operations simultaneously.

CNC machines

Numerical control allows for high precision machining of workpieces and increased productivity. Automation of all processes greatly facilitates the operation of equipment.

Work processes are managed in one of three ways:

- contour (the machine operates continuously in accordance with the parameters specified by the user);

- along a rectangular contour (relevant when it is necessary to process step-shaped parts; the transverse and longitudinal transmission in them is switched automatically);

- positionally (in this case it is envisaged that the mechanism will initially be located at a given starting point, only after which processing begins).

CNC machine tools use self-adjusting, closed-loop or open-loop systems. They differ from each other in the principle of receiving information, reading and measuring mechanism.

Pipe cutting units

The machines are highly specialized equipment used only for cutting steel pipes. They are widely used in geological exploration, gas and oil production, and other industries.

The operation scheme of CNC units is as follows: first, the workpiece is fixed in the chuck, then a program is installed for automated elimination of defects.

If it is necessary to perform additional operations, the machine is equipped with the required type of cartridges, a turret, and a cutter.

Types of lathes for metal processing

The main factor that influences the choice of such equipment for the home is its purpose. Before purchasing such a small machine, you need to know exactly what it will be used for.

Depending on the purpose, all turning units are divided into three main types:

- desktop;

- semi-professional;

- professional.

In production, powerful metal-working units are used; smaller models are more suitable for domestic purposes.

Desktop devices for private use at home are distinguished by their small dimensions and, accordingly, weight. The minimum weight of such micro-machines is 13 kg, and the maximum does not exceed 100 kg. In turn, semi-professional floor options, which are also often used in home workshops, can weigh up to 400 kg. The power of the desktop unit reaches 400 watts.

Semi-professional machines are also used in small industries and are distinguished by higher power (up to 1000 watts) and functionality. As a rule, such units combine, in addition to turning functions, two more: drilling and milling. This expansion of capabilities significantly increases the functionality of the machines.

Professional units are installed in large and medium-sized industries. They are often controlled by software. They are large in size and weight.

Only the first type of machine is suitable for use at home. Depending on the method of processing parts, they are divided into three main types:

- turning and milling;

- screw-cutting lathes;

- combined.

Each type of machine has its own set of functions and technical characteristics

Metal turning and milling machines are used, as a rule, for removing chamfers from workpieces, as well as for organizing holes and facing. The second type of desktop devices is used for sharpening parts and applying threads to them. In turn, combined devices used at home are capable of performing all of the above functions.

Tips for choosing equipment

Metalworking machines

The choice of a metal cutting machine is always based on the characteristics of its future application. This is what its performance characteristics depend on (power, electrical parameters, list of available functions, accuracy, overall dimensions).

Particular attention should be paid to the following factors:

- Functional. It is worth considering in advance the list of technological operations that will be required to complete production tasks.

- Level of automation. The higher it is, the more expensive the equipment will be. But with an increase in the level of automation, the accuracy of the operations performed, their complexity and speed also increases.

- Tooling of the machine. It is important to take into account the minimum and maximum dimensions of the workpieces being processed, the amount of movement along the axes, the maximum diameter above the support and frame, and the spindle rotation speed.

- Software. When purchasing a CNC metalworking machine, the ability of the equipment to work in conjunction with other devices and its compatibility with CAD/CAM technologies becomes fundamentally important.

- Manufacturing company. When choosing any equipment, it is important that the manufacturer provides full warranty and service maintenance; during operation, there are no problems with the supply of components or consumables.

Which metal lathe to buy: recommendations for choosing

When choosing a benchtop lathe, you need to pay attention to a number of important parameters. Mini-machines for home use for processing metal workpieces can have different weights. The minimum weight of such a unit is 13 kg, and the maximum is 400 kg. Accordingly, the higher the mass of the device, the larger it is.

Note! Experts recommend choosing mini-machines for home workshops that have the least weight (up to 50 kg). Such models are compact and versatile, and they are also very convenient to install. In addition, if necessary, it will not be difficult to change the location of such a small-sized unit.

Another important parameter that is worth considering when choosing a desktop mini-machine is its power. For small units this figure is no more than 2.25 kW. Separately, it is worth saying that there are devices that are commonly called “low-power”. They include a drive with a power of 0.15 kW.

Before choosing how much power you want to purchase a small-sized lathe, it is recommended to decide on its purpose. For processing small workpieces made of non-ferrous metals, less powerful tabletop metal lathes are suitable. Mini-units with higher power are suitable, in turn, for large parts made of durable material (for example, steel).

Low-power models are suitable for processing products made of non-ferrous metals

Even desktop devices intended for home workshops are complex, from a technical point of view, structures. Therefore, when choosing a mini-machine, it is also recommended to pay attention to the quality of its components. The material from which the structural elements of the device are made is of no small importance.

Experts recommend paying special attention when choosing a small-sized machine to its following components: bed and support. These elements must be made of durable metal. The outer surface of the material must be carefully sanded.

Today you can find many units of this type. To buy a mini metal lathe that is suitable for use in your case, it is recommended to study the technical characteristics of popular models of these devices on the Internet.

Woodworking machines

Modern manufacturers offer a wide selection of woodworking machines. General-purpose installations, special models for the production of similar parts, or specialized devices for certain types of wood processing are produced.

To ensure that the equipment fully meets your expectations after purchase, we suggest using the following tips.

- Optimal power depends on the characteristics of the work and the list of operations that will be performed on the selected machine. Household models are considered to be models with a power of up to 3 kW/h, connected to a 220 V network; industrial models are units with higher productivity, which are also distinguished by a greater depth of cut, planing width, and a wider range of functions.

- The bed should be heavy and rigid (cast iron would be the ideal material for its manufacture).

- It is desirable to have a chuck on the headstock or the ability to install it. In the future, this will make it possible to process workpieces that are secured at only one end.

- The ability to install a drill chuck on the tailstock, which will greatly facilitate the task of sharpening blind holes.

- The presence of a spindle speed controller is a convenient feature that will help improve the quality of many technological operations.

- Universal models are equipped with a saw blade, drill, milling cutter, planing shaft with 3 or 4 knives.

Advantages of mini lathes

Units of this type have a number of advantages over large-sized, professional devices. For example, to operate such equipment, a standard household electrical network with a voltage of 220 V is sufficient. If desired, the mini-machine can be adapted to connect to a network with a voltage of 380 V (three-phase).

Another important advantage of a home turning unit is that it consumes a small amount of electricity during operation. The shelf life of micromachines of this type can reach several decades. How long it will serve you directly depends on two factors: proper use and timely maintenance.

To extend the service life of the metalworking unit, technical inspections and maintenance should be carried out regularly.

Due to its compactness, such a micro-machine can be placed in any suitable room (room in an apartment, garage, etc.). Units of this type allow novice turners to quickly learn how to process metal parts. It’s also worth saying that the cost of lathes for home use is more than affordable for most people.

And finally, an important advantage of such devices is that they can be equipped with additional devices. This allows them to be used for milling metal parts, which significantly expands their operational range.