Granite stone is a natural material, during the processing of which certain rules must be followed. The peculiarity of the material is that it is fragile and hard at the same time. In order to properly process a slab, you need to know how to drill granite, what are the methods and rules for drilling this non-metallic material. With this knowledge, you can drill without damaging the stone or compromising its integrity.

How to drill granite - basic rules

Holes in granite stone are made only at the first or second speed of the power tool. The rotation speed of the granite drill (the number of revolutions per 1 minute) is set depending on its size (diameter):

- For a drill with a diameter of 6 mm, the rotation speed is 2000 rpm;

- For a drill whose diameter is 12 mm – 950 rpm;

- For a drill diameter of 20 mm, 700 revolutions should be performed in 1 minute.

As the diameter of the crown (tubular drill) increases, its rotation speed decreases.

Beginners who do not yet know how to drill granite are recommended to practice beforehand. To do this, you can use a small piece of granite stone that was rejected or simply not needed.

Marking of a polished granite slab is done using masking tape, which is first glued to the material, after which the drilling locations are marked on it.

It will not be possible to make pencil marks directly on the slab - the pencil simply will not leave marks on the polished surface of the stone. This method is quite suitable for porcelain stoneware, but not for natural granite stone.

There are the following methods for drilling granite stone:

- The drill is positioned at a slight angle to the plate, after which a test groove is drilled. Next, the drill is smoothly adjusted to a perpendicular position. This is an important rule, failure to comply with which will result in the crown dangling on the polished surface of the material and not moving deeper into the slab.

- Inaccurate centering of the drill on granite and marble, as well as a lack of practical experience on the part of the person doing the drilling, can result in the polished slab being scratched. You can avoid this by first making a hole in the unnecessary granite cuttings. A precisely made test hole will serve as a template for drilling holes already on the main plate.

Four important rules

The rotation speed of the drill or bit should be minimal and selected depending on the diameter of the tool. The larger the diameter, the lower the number of revolutions of the drill should be. So, for example, with a drill diameter of 12 mm, the maximum permissible rotation speed is 950 rpm, and with 20 mm - 700 rpm.

It is necessary to supply water to the drilling site, which will cool the cutting tool and wash away the slag formed during operation. Using water prevents the drill from jamming and increases its service life. In addition, the water will cool the granite, resulting in smooth and neat edges of the hole.

Set of working tools and materials

Drilling granite stone does not require special and complex equipment. The main tool is an electric drill with adjustable rotation speed. Also during the work you may need:

- Diamond drill of the required size (diameter);

- Clamps (2-3 pcs);

- Masking tape;

- Marker;

- Water.

The diamond-coated drill bit may slip off the polished surface of the material. To avoid this, you need to make a small depression at the treatment site. A regular metal drill will do for this task. It should also be prepared in advance.

What you will need

When asked how to drill granite, many say that this will require some complex specialized tool, but this is not so. A regular electric drill is suitable for the job; it is only important that it has the option of adjusting the speed of revolutions per minute.

In addition to the drill, you will also need:

- a diamond-coated drill having the required diameter;

- plain water.

First of all, you need to fix the granite slab as carefully as possible, making sure that the surface on which it is installed is as flat as possible. Before starting work, you should use a drill to mark the center of the future hole: this will help prevent the tool from sliding along the polishing surface. Install a diamond-coated bit into the drill (remember that using a non-coated bit will not allow you to make a hole).

Drilling should be carried out exclusively at low tool speed without using the punching option. When you turn on the perforation mode, the granite may crack. Regularly rinse the stone and drill with water: as already mentioned, this helps to cool, clean, and neaten the hole itself. In order to add water, you can invite an assistant. Or fill a plastic bottle with water, make a hole in the lid and use such a “sprinkler” to water the drill and hole yourself.

What to do if there is no diamond crown

If you don’t have a diamond bit and you don’t know how to drill granite in this situation, you can carefully stick a plasticine ring 3-5 mm high around the entire circumference of the future hole. Place a little corundum, pobedite powder or diamond dust inside the ring and add water. Attach a copper tube to the drill (you can use a tube from any other non-ferrous metal). Now you can drill granite - also at low tool speeds, without using a hammer drill. You will certainly need water here: first of all, in order to regularly cool the metal tube.

If there is neither a crown nor a tube, what to do?

In this case, craftsmen suggest using an emergency and risky drilling method - using a Pobedit drill, at high speed with a constant supply of water. During this process, you will need to constantly sharpen the drill because it will stop from time to time. Sharpen the drill with a semicircular file, very carefully, without overheating its teeth. Otherwise, the drill will soften and become dull even faster.

Helpful advice: if you are processing granite with a pobedite drill, it should be sharpened at least every 20-40 seconds of work.

Drilling on granite is a very difficult and painstaking job. It requires certain knowledge and skills. But if you wish, you can always purchase them by seeking advice from more experienced craftsmen. In order to practice, first use fragments of stone: this will help both “get your hands on” and prevent damage to a high-quality new workpiece.

How do you like the article?

Granite Drilling Guide

The granite blank is placed on a flat surface and secured with clamps. To avoid damaging the polished surface of the natural material, wooden planks are placed under the clamps. Masking tape is applied to the places where the holes will be made. After gluing, the center and outline of the future hole are marked on it.

A diamond bit (drill bit for marble and granite) is inserted into the drill. In this case, the central guide is installed in the marked center of the hole. If there is no guide, it is necessary to make a wooden template of the required diameter and fix it on the surface of the slab. It will serve as a guide during the work process.

Granite and basalt are the hardest stones on our planet.

Basalt is less common in nature and less used in construction.

Since granite products are more popular and are found everywhere, we have to deal with granite drilling more often.

If you follow the rules, then drilling granite is quite accessible even at home, unless we are talking about a large diameter hole.

The main thing is to follow the instructions and then it will be almost impossible to split granite when drilling or damage the cutting tool.

Recommendations for drilling granite stone, especially Siberian granite.

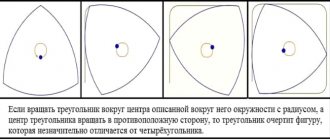

- To drill granite, a special emulsion is used, or if there is none, then ordinary water. The emulsion is of course more preferable, since it also helps to cool the cutting tool more effectively. Drilling granite stone is usually done with diamond-coated drills or a drill made of carbide metal. A granite slab or any other granite product is a porous material, so if you drill it dry, the pores become clogged with dust and the drilling tool gets jammed, and in this case When drilling, the stone overheats and it begins to crack, so the edges are not even. The emulsion solution helps remove this dust from the drill hole and cools both the stone and the drill. If possible, it is better to make the emulsion supply constant, or by constructing a bath from a plastic material, such as plasticine, you can pour the emulsion into it and thus carry out drilling, as shown in the figure below. Bath for drilling granite

- When drilling granite, be sure to use a drill with a low number of revolutions, preferably from 100 to 800 revolutions per minute. If the revolutions are high, the drill will overheat and its cutting edges will become dull. It must be remembered that the larger the diameter of the required hole, the lower the speed should be; this is necessary so that the cutting edge of the drill has time to extract a sufficient amount of material and does not become dull from overheating. If your drill has a diameter of 4-6 mm, then choose a speed of 1200-1500 per minute, if the diameter of the drill is from 9-12 mm, then set the speed to 800 per minute, if the diameter of the drill for granite stone is 20-25 mm, then It is advisable to have a powerful drill of 1500-2000 W and a speed of about 600 per minute. Be patient, just like stone is not metal and drilling into stone takes time. Keep the drill straight while drilling, otherwise after 1-2 cm the hole will begin to move to the side.

- If you have no previous experience of drilling granite stone, try making a test hole on a stone that you do not need or is damaged.

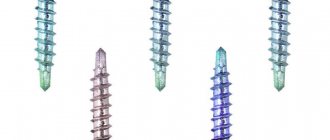

- As a cutting tool, it can be used as standard drills made of HSS metal with diamond coating or hollow tubular core bits with coating. Crowns for drilling granite Drill bit for granite

How to start drilling granite correctly?

The first method of drilling a granite slab, granite stone.

We start drilling at a slight angle. This is necessary because the material is hard and not completely smooth, so it will be easier for the drill to catch on the protrusion to start drilling. It is impossible to core the drilling site, as the granite may crack or break off at the core site. Next, when the drill catches on the surface and the formation of a hole begins, we level our drill. If you have a special machine that allows you to rigidly fix the drill and the surface when drilling, you do not need such a procedure, and you can safely start drilling at a right angle. Those who have drilled on the surface of smooth metal know that if the drill is not fixed or caught, the drilling site begins to wander, both from the density of the material and from the vibrations and movement of the drill.

Another option is to use an invoice template. This can be a piece of wood, you can use or buy a granite slab in which a hole has already been made. Or use a piece of metal with a pre-drilled hole. This template needs to be fixed on the surface of the granite stone; this can be done with a vice, clamps or other fixing tool. A cooling-lubricating emulsion can be applied to the same surface of the template.

A quick guide to drilling granite slab or granite stone.

- For drilling, you need a drill with a low number of revolutions, ideally up to 600 revolutions per minute, with a power of 1.5 -2 kW, you can use a drill with adjustable speed. We only recommend checking whether your drill can operate for a long enough time at the minimum number of revolutions.

- You will need diamond-coated drills or bits made from hard tool HSS alloy. You can also try drilling with drills with a Pobedit tip (like those used in rotary hammers). Remember that drill bits with pobedit leave a rougher drill mark and may chip or partially chip the granite when drilling.

- The quality of drilling into granite will depend on how well you have secured the tool and the surface of the stone.

- Clamp the drill bit very well in the drill chuck. Do not allow the drill to rotate while drilling.

- Start drilling at the lowest speed, then you can slowly increase the speed if you see that the drill does not start to burn and drilling occurs without noise (whistle, grinding, etc.). Select the optimal number of revolutions.

- If you use a hammer drill, do not turn on the impact mode when drilling a granite slab. The impact mode can be selected only if the drilling is a piece of granite stone and a sufficiently large thickness. Otherwise, the stone will split.

- Make a bath for the emulsion. You can make it from plasticine or similar material. You can buy ready-made. You can use plastic bottles by first cutting off the top part of them.

- Add water or emulsion as it evaporates and is consumed. There shouldn't be a lot of it. The drill should only be wetted where it comes into contact with the granite stone.

- You can drill intermittently.

Replacement for diamond tools

How to drill into granite if you don’t have a diamond-coated drill? In addition to a diamond drill, holes in granite can be made using pobedit drills, diamond dust or corundum. These tools are inferior in quality to a diamond drill and make the drilling process longer, but with their help you can achieve the desired result.

To make a hole in a granite slab using corundum, diamond dust or ground pobedite, you need a tube made of copper or brass and fixed in a drill. The diameter of the hole marked on the slab is protected by a side that is 4-5 mm high and made of plasticine or putty with quick-drying properties.

Abrasive material is poured inside the side and drilling is performed with a tube at a minimum rotation speed of the drill. During the drilling process, you need to add water from time to time.

To work independently with granite stone, you must have the appropriate skills and tools, and perform the work carefully and accurately. To understand how to drill through granite without damaging it, it is recommended that you first practice drilling using scraps of granite.

How else can you form a hole in granite?

A stone drill, which is used to form a hole in granite, can be made from a tube made of non-ferrous metal. This method, compared to the option that uses diamond drills, is more technically complex.

How to drill granite correctly using a non-ferrous metal tube?

- Around the center of the future hole on the surface of the granite, it is necessary to form a side with a height of at least 5 mm, for which you can use ordinary plasticine or the middle part of a plastic bottle.

- Diamond dust, corundum or pobedite powder must be poured into the inner part of the formed side.

- Water is poured into a bath formed by the side and filled with abrasive powder. To constantly replenish the water level in such a bath, it is necessary to prepare a separate vessel in which it will be contained in sufficient quantities.

This method is far from the most effective and is only suitable for shallow holes of small diameter

Drilling granite using this method alone is problematic, so you will need the help of another person who will ensure that the tray formed around the hole is constantly filled with water. Drilling when using this technology is also performed at low speeds.