Technological operations when surfacing the shaft:

- Selection of surfacing technology and material that will be deposited to repair the shaft seats.

- Mechanical preliminary preparation of the surface of a worn shaft, it includes a selection of defects such as chips, cracks, etc.

- Carrying out surfacing works.

- Control of the deposited coating on a worn shaft.

- Heat treatment after surfacing to relieve residual stresses and prevent the formation of cracks in the deposited layer.

- Final machining of the shaft in accordance with the dimensions indicated in the drawing.

- Shaft measurements and control.

We are ready to perform work on surfacing the working surface of the shaft in St. Petersburg.

If you need to weld a shaft or restore a shaft in St. Petersburg, fill out the order form and send it to us at [email protected] , our engineers will prepare a technical and commercial proposal to solve your problems.

Restoration of parts by metal surfacing

Those who operate various mechanisms sometimes have to face the need to weld metal in one place or another on a part. A broken mounting hole, a surface worn out during operation, a chipped edge of a metal-cutting tool, a worn bearing bushing. In all these cases, you can do without replacing the part by restoring it by welding metal onto the worn part. Surfacing a metal part allows not only to restore the original properties of the product, but also to give it completely new valuable qualities. In particular, by melting a layer of carbide metal onto a low-carbon steel base, you can obtain a wear-resistant working element or cutting tool.

Welded jaws

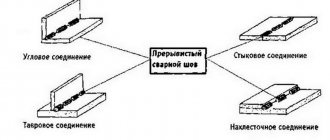

Surfacing is the process of applying one molten metal (called filler) to the surface of another (called base). In this case, the base metal is also melted to a small depth to form a homogeneous compound. The purpose of surfacing can be different: restoring the lost geometry of a part or giving it a new shape, forming a surface layer with specified physical and mechanical properties (such as increased hardness, wear resistance, antifriction, corrosion resistance, heat resistance, etc.), hardening by surfacing.

Surfacing can be done on any surface - flat, conical, cylindrical, spherical. Its thickness can also vary within wide limits - from a few fractions of a millimeter to a centimeter or more.

Basic principles of surfacing

In its main aspects, surfacing technology is similar to welding technology. It faces the same tasks as welding - protecting the deposited metal from gases contained in the air, obtaining a dense weld metal, without pores, cracks and foreign inclusions. Therefore, it is important to read the general article about welding, with articles about welding of relevant metals (copper welding, cast iron welding, aluminum welding, stainless steel welding) and about electrode coatings, otherwise there will be no understanding, for example, why calcinate the electrodes before surfacing and what the consequences will be if it cannot be done, or why the polarity of the electrode connection is important. When surfacing, basic principles must be observed, consisting of a number of requirements:

- It is necessary to strive for minimal penetration of the base metal. This is achieved by tilting the electrode in the direction opposite to the deposition stroke.

- There should be as little mixing of the deposited metal with the base metal as possible.

- We must try to achieve minimal residual stresses and deformations in the part. This requirement is largely ensured by compliance with the two preceding ones.

- It is necessary to reduce allowances for subsequent processing of the part to acceptable values. In other words, you need to deposit exactly as much metal as necessary, and no more.

Various methods of metal surfacing are used - electric arc, gas, electroslag, induction, plasma, pulse-arc, vibrating arc, and powder surfacing. Arc surfacing is most widely used.

Surfacing materials exist in various forms. These can be filler rods, powder mixtures, surfacing coated electrodes, flux-cored and solid wire. Electric arc surfacing mainly uses coated electrodes, filler rods and wire.

Surfacing with coated electrodes

Surfacing with coated surfacing electrodes is one of the main methods used both in industry and in everyday life, due to its simplicity, convenience, and the absence of the need for special equipment.

A large number of brands of electrodes are produced that create a surfacing layer with different characteristics that ensure the required quality of products for operation in certain conditions. Surfacing requires certain skills in operation. It is necessary to melt both components at a minimum current and voltage, so as not to increase the share of the base metal in the deposit. The composition of the metal will determine the type of electrode, and the thickness and shape will determine the diameter of the electrode. The arc voltage determines the shape of the deposited bead; as it increases, the width of the bead increases and the height of the bead decreases, the arc length and the oxidation of alloying impurities, especially carbon, increase. In this regard, they strive for a minimum voltage, which must be consistent with the arc current.

Surfacing of steel parts is carried out, as a rule, by direct current of reverse polarity (on the “plus” electrode) in the lower position.

Direct (left) and reverse (right) polarity of electrode connection

Parts made of low-carbon and low-alloy steels are usually welded without preheating. But often preheating and subsequent heat treatment are required to relieve internal stresses. More detailed requirements for surfacing are provided in the documentation for the surfacing electrodes used. For example, for the OZI-3 electrode the following technological features are given: “Cladding is carried out in one to four layers with preheating to a temperature of 300-600°C. After surfacing, slow cooling is recommended. It is possible to surfacing using the bath method at high conditions. Calcination before surfacing: 350°C, 1 hour.”

Before surfacing, the surface of the part is cleaned of oil, rust and other contaminants.

Various layouts of surfacing welds are used. In the case of flat surfaces, two main types of surfacing are distinguished - the use of narrow beads with overlapping each other by 0.3-0.4 of their width, and wide beads obtained by increased transverse movements of the electrode relative to the direction of passage.

Surfacing of metal with narrow beads

Surfacing of metal with wide transverse movements of the electrode

Another way is to lay narrow rollers at some distance from one another. In this case, the slag is removed after applying several rollers. After this, the beads are also fused in the gaps.

To avoid warping of parts, it is recommended to carry out deposition in separate sections, “randomly”, and to begin laying each subsequent roller on the opposite side in relation to the previous one.

Surfacing of a cylindrical surface is carried out in three ways - by beads along the generatrix of the cylinder, by beads along closed circles and along a helical line. The last option (along a helical line) is especially convenient in the case of mechanized surfacing, in which the part is given uniform rotation during the surfacing process.

Metal surfacing on the cylinder

Welded Metal Cylinder

To restore and increase the service life of cutting, stamping and measuring tools, as well as parts of mechanisms operating under intense wear, surfacing of working surfaces with hard alloys is used, which are compounds of metals such as titanium, tungsten, tantalum, manganese, chromium and others with boron , carbon, cobalt, iron, nickel, etc.

In the manufacture of new tools and parts with carbide surfacing, parts made of carbon or alloy steels are used as blanks (bases). In the case of repairing parts with a lot of wear, before surfacing with hard alloys, preliminary surfacing is done with low-carbon steel electrodes.

To obtain better surfacing, prevent the formation of cracks and reduce stress, in many cases it is advisable to heat the workpieces to a temperature of 300°C or higher.

Surfacing of metal-cutting tools and dies

. Metal-cutting tools and dies operating during cold and hot stamping are overlaid with electrodes OZI-3, OZI-5, OZI-6, TsS-1, CI-1M and other grades. The metal deposited with these electrodes is highly resistant to abrasion and crushing at high specific loads and high temperatures - up to 650-850°C. The hardness of the deposited layer without heat treatment ranges from 52 HRC (OZI-5) to 61 HRC (OZI-3). 1-3 layers with a total thickness of 2-6 mm are deposited. Before surfacing, the part is heated to a temperature of 300-700°C (depending on the brand of electrode).

Surfacing of knives

Surfacing of parts exposed to abrasion without impact loads

. If it is necessary to obtain deposited metal of particularly high hardness, you can use electrodes for surfacing T-590 and T-620. They are specially designed to coat parts subject to intense abrasion. Their rod is made of low-carbon steel, but the coatings include ferrochrome, ferrotitanium, ferroboron, boron carbide and graphite. Thanks to these materials, the hardness of the deposited metal can reach 62-64 HRC units.

Due to the fact that the deposited metal is brittle and prone to cracking, products deposited with T-590 and T-620 electrodes are not intended for use under conditions of significant shock loads. Surfacing of carbide metal is carried out in one or two layers. If it is necessary to deposit a greater thickness, the lower layers are deposited with low-carbon steel electrodes, and only the final layers are deposited with carbide electrodes.

Surfacing of parts exposed to abrasion and impact loads

. Parts made of manganese steels (110G13L and similar), operating under conditions of intense surface wear and high shock loads (in particular, working parts of construction and earth-moving equipment), are overlaid with OMG-N, TsNIIN-4, OZN-7M, OZN-400M electrodes , OZN-300M and other brands. When using them, the hardness of the deposited metal in the second layer is 45-65 HRC at high viscosity values.

Surfacing of mill parts (hammers)

Auger surfacing

Surfacing of stainless steels

. For surfacing parts made of stainless steel, electrodes TsN-6L, TsN-12M-67 and other brands are used. The rod of these electrodes is made of stainless high-alloy wire. In addition to high corrosion resistance, the deposited metal also has resistance to scuffing, which makes it possible to use these electrodes for surfacing sealing surfaces in reinforcement products.

When using some electrodes for surfacing stainless steels, it is recommended to carry out preliminary and concomitant heating of the part to a temperature of 300-600°C and carry out heat treatment after surfacing.

Surfacing of copper and its alloys

. Surfacing of copper and its alloys (bronze) can be carried out not only on a copper or bronze base, but also on steel and cast iron. In this case, bimetallic products are created that have the necessary performance qualities (high resistance to corrosion, low coefficient of friction and other valuable properties inherent in copper and its alloys) and at the same time have a much lower cost in comparison with parts made entirely of copper or its alloys

Aluminum bronzes, in particular, which have high anti-friction properties, work very well in friction units, so they are welded onto worm wheels, crackers and other parts that operate under friction conditions.

Surfacing of parts made of technically pure copper can be carried out using Komsomolets-100 electrodes or filler rods made of copper or its alloys. When surfacing copper on copper, preheating to a temperature of 300-500°C is used.

It is advisable to subject the deposited layer to forging at a copper temperature above 500°C.

If surfacing with bronze is required, you can use OZB-2M electrodes, which, in addition to the base copper, also contain tin, manganese, nickel and iron. Products deposited with OZB-2M electrodes have high surface wear resistance.

Surfacing of copper and its alloys is carried out using direct current of reverse polarity in the lower position.

Surfacing in shielding gases

Along with surfacing with coated electrodes, surfacing can also be carried out at home in a shielding gas environment - using the MIG/MAG method (with automated wire feed) or TIG (tungsten electrode) with filler rods.

For protection, various gases can be used: argon, carbon dioxide, helium, nitrogen - depending on the type of metal being deposited. When restoring carbon steel parts by surfacing, you can use cheaper carbon dioxide. Considering the fact that CO2 oxidizes the molten metal, the surfacing wire in this case must have deoxidizing agents (manganese, silicon, etc.).

Surfacing of copper and its alloys can be carried out in nitrogen, which is neutral with respect to copper.

High-alloy steels, magnesium- and aluminum-based alloys are fused in argon, helium or a mixture thereof.

Surfacing with a non-consumable tungsten electrode is carried out in argon and helium. In general, inert gases, especially argon, are universal, suitable for welding and surfacing of almost any metal.

Solid welding wires (Sv-08GS, Sv-08G2S, Sv-12GS) and special surfacing wires (Np-40, Np-50, Np-30KhGSA) are used as materials for semi-automatic surfacing of carbon and low-alloy steels. For surfacing stainless steel, stainless steel wire is used. Surfacing can also be carried out with flux-cored wire, which makes it possible to obtain a deposited layer with special properties.

When restoring parts by surfacing using the MIG/MAG method, a direct current of reverse polarity is used, as in the case of MMA, which ensures less penetration of the base metal. When using a tungsten electrode (TIG method), straight polarity is used to prevent melting of the tungsten electrode. You should try to surfacing with as short an arc as possible to avoid metal spattering.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

other services

Restoration of diesel fuel equipment parts Restoration of plunger surfaces Restoration of bearing seats Surfacing of valves Restoration of parts by spraying Restoration of parts by surfacing Restoration of cast iron parts Restoration of parts by welding Repair of stamps and molds Restoration of parts of printing equipment Restoration of food industry parts Repair of shafts Spraying of shafts Restoration of shafts Restoration of parts and components Restoration of parts by metallization Restoration of parts with repair dimensions Restoration of metal parts Restoration of surfaces of parts Restoration of steel parts Restoration of car parts

"Plasmacenter" offers

- services for restoration of parts, coating, vacuum sputtering, microplasma sputtering, electric spark alloying, plasma processing, coating certification, titanium nitride sputtering, shaft repair, corrosion coating, protective coating, hardening of parts;

- supply of equipment for the processes of finishing plasma hardening, welding, soldering, surfacing, spraying (for example, gas-thermal, gas-flame, microplasma, high-speed and detonation spraying), electric spark alloying, control devices, powder dispensers, plasma torches and other equipment;

- supply of consumables such as welding wire, electrodes, welding rods, spraying powders, surfacing powders, additive manufacturing powders, surfacing wire and other materials for welding, surfacing, spraying, additive manufacturing and hardening processes;

- conducting R&D in the field of surface engineering, coating tribology, plasma processing methods, selection of optimal coatings and methods of their application;

- training, consulting in the field of surfacing, sputtering, hardening, modification, hardening.

Contact us by phone: +7 (812) 679-46-74, +7 (921) 973-46-74, or write to us by email.

Our managers will tell you in detail about the technologies we have for coating, hardening, restoring, imparting surface properties, as well as the cost of the company’s services.

Features of internal combustion engine production

To repair internal combustion engines, there are dozens of different methods that can bring them back to life. Modern motors are produced in factories specializing in the production of only these products.

Using several basic powertrain products, different car manufacturers produce different models with their own brand. Externally, cars may differ noticeably from each other, but the power unit inside these vehicles will be the same.

- Motorists produce more than one type of engine; they have a line of internal combustion engines, differing in the intake system, the number of valves, the presence or absence of turbocharging, and the presence of certain options. Most often, the block and a number of body elements are practically the same.

- Cases and covers arrive from the foundry for further processing in the machine shop area. Parts are made from blanks on metal-cutting machines.

- Assembly areas assemble components and assemblies. Future products are being completed.

- The main conveyor carries out final assembly.

- Then the finished products are sent to the running-in area. Here the engine is installed on a running stand.

- During the first two hours the engine does not start. Cold rolling is performed. As a result, the mating parts grind in. Check for imbalance in the crankshaft and other mechanisms.

- Then fuel is supplied. The engine starts. He is allowed to work in different modes for an hour.

- The used engine oil is drained and the cleaning filter is replaced.

- A new filter is installed and fresh oil is poured into the engine crankcase. It is packaged for sale to a car manufacturing plant.

Spray surfacing

A promising way to restore crankshafts is to spray titanium oxide onto the surface of the journals. Spraying is performed with a powder having a granule size measured in microns.

A potential difference is created, as a result of which a stable process of attraction is formed between the powder particles and the body of the part being restored. To increase the intensity of the process, a jet is created in which the potential difference reaches tens of thousands of volts. At the same time, the jet heats up, the temperature rises to 4000…6000 ⁰С. The process takes only a few fractions of a second. The powder flow is directed to the surface. Diffusion occurs between the particles and the body of the part. The particle is soldered to the surface.

Gas flame spraying of titanium oxide:

Attention! The hardness of titanium oxides reaches up to HRC 65...75. Such hardness is unattainable in steel and its alloys. Therefore, the wear of powder coating on crankshafts can reach millions of vehicle runs. The restored part “runs” several times longer than the planned life of a new crankshaft.

Motor repair

Operational repairs are reduced only to adjustments of individual components. Maintenance is carried out, during which filter elements and consumables are replaced.

They check the performance of power supply, sparking, cooling, and lubrication systems. Modern internal combustion engines are equipped with sensors that record existing deviations from nominal values. Using appropriate diagnostic instruments, a rapid analysis of all internal combustion engine systems is carried out. If possible, restore adjustments and debug operating modes.

Engines with regular maintenance can be guaranteed to operate for ten years or more. To carry out major repairs, manufacturers provide measures to restore functionality.

The following are subject to the greatest wear:

- ICE cylinders. The combustion process takes place inside them. The temperature of flammable gases reaches up to 2200…2500 ⁰С. Some of the metal may burn out. Scores form on the inner surface and the cylinder mirror is damaged.

- Pistons wear out; they make millions of reciprocating movements. The result is wear on the outer surface. Sealing is achieved using compression and oil rings made of ductile iron. The grooves in which the rings are installed wear out.

- The load from the pistons is received by the connecting rods. They rest on the piston pins and connecting rod journals. Wear occurs in the contact area. The clearance in the pins and crankpins increases.

- The crankshaft is mounted on supports; after making several tens of millions of revolutions, the main journals wear out. The gaps are increasing. Engine oil stops flowing to the connecting rods and flows through the leaks back into the crankcase.

Engine section:

1 – camshaft; 2 – piston; 3 – cylinder; 4 – main journal of the crankshaft; 5 – connecting rod journal of the crankshaft.

Many parts are replaced quite easily. ICE manufacturers, in addition to basic parts, produce an additional batch of components manufactured with repair dimensions:

- New pistons are installed in place of worn pistons.

- Honing machines polish the inner surface of the cylinders and restore their shape. Attention! Some manufacturers do it simpler; they equip the engines with new removable cylinders. All that remains is to purchase a repair kit and replace the piston group.

- The piston pins are replaced and the mounting holes in the connecting rod head are pre-bored.

- Grind the connecting rod and main journals of the crankshaft. Most manufacturers provide 3…4 repair sizes of liners. Therefore, the actual service life can be extended by 3...4 times compared to the base one.

After all operations are completed, the engine is assembled. They put it on their original car.

Crankshaft diagnostic diagram:

In theory, everything looks pretty great. With proper use, the heart of a car can work for decades. But reality often proves that after a relatively short mileage, problems may arise that are difficult to eliminate using simple methods. It is necessary to restore the most complex unit - the crankshaft. This is the most expensive part in the engine. She is the most stressed out. Therefore, complex and expensive repairs are necessary.

Detonation spraying

The most promising way to restore crankshaft parameters is detonation spraying. In this process, the acceleration of the powder flow from the storage hopper to the surface occurs due to the energy of the explosion produced inside the gas flow.

A detonation gun is used. It has a water-cooled barrel at one end. It is filled with a gas mixture, which can explode when the desired concentration is reached.

As a result of the explosion, a jet appears in a limited space, the speed of which is 1000...1200 m/s. When colliding with a hard surface as a result of an impact in the contact zone, the temperature rises to 2000...2200 ⁰С. The contact zone is instantly heated and the particle forms a rigid bond with the body. It is extremely difficult to destroy mechanically. Microwelding connects dissimilar powder and steel surface.

Detonation spraying of solid powders:

After the “shot,” the barrel is purged with non-flammable gas. The flow not only hits the barrel, it is directed to the welding zone, cooling it to 20...30 ⁰С. Then the process resumes. Another shot occurs. Another certain amount of powder is fed to surfacing.

This method of surfacing (spraying) surpasses any other option in its parameters.

Attention! Detonation spraying can be carried out not only on metals. The powder flow is welded onto plastics, ceramics, glass and other refractory materials.

Currently, individual high-tech equipment can be designed and manufactured by order of interested enterprises. Of course, the price for it can be quite high. The high quality of restored parts will allow you to recoup your investment.

Video: crankshaft restoration.

Electric spark powder spraying

Plasma spraying causes noticeable heating of the part. In order not to overheat the entire crankshaft, a different method of organizing the soldering of particles is provided. The supplied powder is rolled with a roller.

A potential difference is created between the roller and the part. It is small, the current strength is important here. It reaches tens of Amperes. As a result, the temperature in the contact zone increases to 1900…2200 ⁰С. At such values, a strong diffusion bond is formed between the particles and the powder. Now the coating will be held quite firmly.

In practice, it has been verified that the resulting surface does not represent an ideal mirror. When examined under a microscope, small dots are visible. It turns out that the free space is filled with lubricant. As a result, wet contact occurs between the mating surfaces.

Installation for electric spark spraying:

Attention! It has been established that a regular VAZ 2106 engine (1600 cm³) has traveled more than 1,200,000 km. It was installed in three car bodies. They worked until they were completely worn out, and after disassembly the engine itself showed that the wear of the main and connecting rod journals did not exceed 0.01...0.02 mm. With these parameters, regrinding to the next repair size is not required.

How to repair an engine crankshaft?

The crankshaft is installed on the machine. Diagnostics are performed using indicator heads. An analysis of surface runout and wear is carried out:

Most manufacturers provide the possibility of grinding the shaft journals to repair sizes. Usually they differ from the nominal value by 0.25...0.50 mm. After regrinding, new bearings are installed to suit the new value. They are the ones who compensate for changing the parameter to a new one. For grinding, combinations of machines are used: lathe and center grinder.

Signs of wear are visible on the surface:

- The crankshaft is installed on the lathe in the centers. Two installations are possible: in the main center of the shaft or centered on the connecting rods.

- Then the runout is checked. Indicator heads are used here.

- After clarifying the actual dimensions, the possible dimensions after grinding are clarified.

- The machine is turned on, lubricating coolant (coolant) is supplied. The process is running. All necks of the same type are ground to their size.

- After completing the work, check the values. If the expected result is obtained, the order is given to the customer.

Crankshaft after surface grinding:

Surface polished:

Possible option for polishing the surfaces of the crankshaft journals: