Machine parts and mechanisms are mainly made of steel. Particularly critical or loaded parts are made of carbon steels with mandatory hardening relative to the original state. The strength characteristics of materials are determined not only by their chemical composition, but also by the structure of the crystal lattice. Metals have different strength and hardness depending on the structure of the crystal lattice.

By heating and cooling metals, you can change the structure, and therefore influence their hardness and strength. The product at the workpiece level must be soft to facilitate machining. It becomes soft after annealing, when it has a pearlite crystal structure.

When steels are heated above the recrystallization temperature (GSE points on the iron-carbon diagram), the metal changes from α (alpha iron) to γ (gamma) iron, this crystal lattice structure is called austenite. If γ iron is quickly cooled, then the majority of the atoms will not have time to rearrange into their usual α lattice. This produces a solid product that has predominantly a martensite structure – i.e. solid solution of carbon in γ iron. The martensite lattice is significantly deformed and changes from cubic to tetragonal. A structure consisting of martensite will have the highest possible hardness.

In practice, finished parts have a martensite and pearlite structure in various proportions. The required ratio between structures, and therefore hardness and viscosity, is obtained using a subsequent heating operation called tempering. When tempered, some of the atoms from the γ lattice are rearranged into their usual α lattice, and internal stresses and, accordingly, hardness are reduced. Moreover, the higher the tempering temperature, the more atoms will rearrange, and the product will be less hard and more viscous.

Martensite and martensitic transformation in steels

Martensite is a supersaturated solid solution of carbon in α-iron (α-Fe). Read what austenite, cementite, ferrite and pearlite are here. When eutectoid steel (0.8% carbon) is heated above point A1, the original pearlite structure will transform into austenite. In this case, all the carbon present in the steel will dissolve in austenite, i.e. 0.8%. Rapid cooling at a supercritical rate (see figure below), for example in water (600 °C/sec), prevents the diffusion of carbon from austenite, but the fcc crystal lattice of austenite will rearrange into the tetragonal lattice of martensite. This process is called martensitic transformation. It is characterized by the shear nature of the restructuring of the crystal lattice at a cooling rate at which diffusion processes become impossible. The product of martensitic transformation is martensite with a distorted tetragonal lattice. The degree of tetragonality depends on the carbon content in the steel: the more it is, the greater the degree of tetragonality. Martensite is a hard and brittle structure of steel. Found in the form of plates, under a microscope they look like needles.

The hardening temperature for most steels is determined by the position of the critical points A1 and A3. In practice, the hardening temperature of steels is determined using steel graders. How to choose the hardening temperature of steel, taking into account points Ac1 and Ac3, read the link.

Cooling during steel hardening

To obtain the required structure, the products are cooled at different rates, which are largely determined by the cooling medium, the shape of the product and the thermal conductivity of the steel. The cooling mode should prevent the occurrence of large quenching stresses. At high cooling rates during quenching, internal stresses arise, which can lead to warping and cracking.

Internal stresses balanced within macroscopic parts of the body are called stresses of the first kind. They are responsible for distortion of shape (warping) and the formation of cracks during heat treatment. The causes of stress are:

— temperature difference across the cross section of the product during cooling;

— multi-simultaneous occurrence of phase transformations in different parts of the product.

To prevent the formation of cracks, it is necessary to avoid tensile stresses in the surface layers of the product. In addition to the cooling mode, the nature of the stress distribution during quenching is also influenced by the heating temperature for quenching. Overheating promotes the formation of hardening cracks and increases deformation.

The cooling mode must also provide the required depth of the hardened layer. Optimal cooling mode: maximum cooling rate in the temperature range 727 –

200 °C, to prevent the decomposition of supercooled austenite in the region of pearlite transformation, and the minimum cooling rate in the temperature range of martensitic transformation 200 - 100 °C, in order to reduce residual stresses and the possibility of crack formation.

Very slow cooling can lead to partial tempering of martensite and an increase in the amount of retained austenite, and consequently to a decrease in hardness.

Water at various temperatures, technical oils, solutions of salts and alkalis, and molten metals are used as cooling media for hardening.

Water has a significant drawback: a high cooling rate in the martensitic transformation range leads to the formation of hardening defects. As the water temperature increases, its hardening ability deteriorates.

Cold rooms have the highest and most uniform cooling capacity. 8…12 %

aqueous solutions

of NaCl

and

NaOH

. They instantly destroy the steam jacket and cooling occurs more uniformly and at the nucleate boiling stage.

Increased cooling capacity is achieved by using jet or shower cooling, for example, with surface hardening. For alloy steels with high austenite resistance, mineral oil (petroleum) is used. It provides a low cooling rate in the martensitic transformation temperature range and constant hardening ability. The disadvantages of mineral oils are increased flammability, low cooling ability in the temperature range of pearlite transformation, and high cost.

When choosing a cooling medium, it is necessary to take into account the hardenability and hardenability of the steel.

Hardenability –

the ability of steel to acquire high hardness when hardened. Hardenability is determined by carbon content. Steels with a carbon content of less than 0.2% cannot be hardened.

Hardenability - the ability to obtain a hardened layer with a martensitic and troostite-martensitic structure with high hardness to a certain depth. The depth of the hardened zone is taken to be the distance from the surface to the middle of the layer, where the structure contains equal volumes of martensite and troostite. The lower the critical quenching rate, the higher the hardenability. Enlargement of grains increases hardenability.

If the cooling rate in the core of the product exceeds the critical one, then the steel has through-hardenability. Insoluble particles and heterogeneity of austenite reduce hardenability.

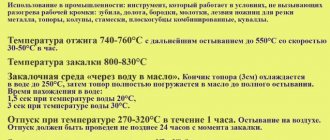

Steel hardening modes

Figure 3.4 — Steel hardening modes

Depending on the shape of the product, the grade of steel and the desired set of properties, various hardening methods are used.

Quenching in one cooler (V1).

The part heated to the required temperature is transferred to the cooler and completely cooled. The following is used as a cooling medium:

- water - for large products made of carbon steel;

- oil - for small parts of simple shape made of carbon steels and products made of alloy steels.

The main disadvantage of this type of hardening is significant hardening stresses.

Quenching in two environments or intermittent (V2).

The heated product is pre-cooled in a sharper cooler (water) to a temperature of ~ 300 oC and then transferred to a softer cooler (oil).

Intermittent hardening provides the closest possible approach to the optimal cooling regime. Mainly used for hardening tools.

Disadvantage: difficulty in determining when to transfer a product from one environment to another.

Step hardening (V3).

The product heated to the required temperature is placed in a cooling medium, the temperature of which is 230 - 250 ° C and maintained for the time necessary to equalize the temperature over the entire section. The isothermal holding time does not exceed the stability period of austenite at a given temperature.

Molten salts or metals are used as a cooling medium. After isothermal exposure, the part is cooled at a low rate.

The method is used for small and medium-sized products.

Isothermal hardening (V4).

It differs from step hardening by the duration of exposure at temperatures above 200 ° C, in the region of intermediate transformation. Isothermal holding ensures the complete transformation of supercooled austenite into bainite. During the intermediate transformation of alloy steels, in addition to bainite, residual austenite is retained in the structure. The resulting structure is characterized by a combination of high strength, ductility and viscosity. At the same time, deformation due to quenching stresses decreases, and phase stresses also decrease.

Molten salts and alkalis are used as a cooling medium. Used for alloy steels.

Hardening with self-tempering.

The heated products are placed in a cooling environment and kept until completely cooled. After removing the product, its surface layers are reheated due to internal heat to the required temperature, that is, self-tempering is carried out.

It is used for products that must combine high hardness on the surface and high viscosity in the core (impact tools - hammers, chisels).

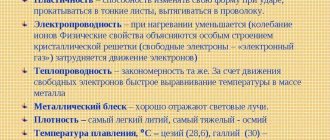

Steel tempering

Tempering is the final heat treatment. The purpose of tempering is to increase toughness and ductility, reduce hardness and reduce internal stresses of hardened steels.

With increasing heating temperature, strength usually decreases, while ductility and toughness increase. The tempering temperature is selected based on the required strength of a particular part.

There are three types of vacation:

Low tempering with heating temperature 150...300 oC.

As a result of this, the quenching stresses are partially relieved.

The structure obtained is tempered martensite.

Carry out for tool steels; after hardening with high frequency currents, after carburization.

Average tempering with heating temperature 300...450 oC.

Get the structure – leave troostite,

combining high hardness 40...45HRC with good elasticity and viscosity.

Used for products such as springs and leaf springs.

High tempering with heating temperature 450...650 oC.

A structure is obtained that combines sufficiently high hardness and increased impact strength (an optimal combination of properties) - tempered sorbitol.

Used for machine parts subject to shock loads.

A complex of heat treatments, including hardening and high tempering, is called improvement .

Tempering brittleness

Typically, as the tempering temperature increases, the impact strength increases, and the cooling rate does not affect the properties. But for some steels, a decrease in impact strength is observed. This defect is called temper brittleness (Figure 3.5).

Figure 3.5 - Dependence of impact strength on tempering temperature

Type I temper brittleness is observed during tempering in the temperature range of about 300 °C. It does not depend on the cooling rate.

This phenomenon is associated with the uneven transformation of tempered martensite. The process proceeds faster near grain boundaries compared to volumes inside the grain. There is a concentration of stress at the boundaries, so the boundaries become fragile.

Type I temper brittleness is “irreversible,” that is, the same parts are not observed upon repeated heating.

Type II temper brittleness is observed in alloy steels upon slow cooling after tempering in the range of 450...650 °C.

With high tempering, dispersed inclusions of carbides are formed and separated along the grain boundaries. The border zone is depleted of alloying elements. With subsequent slow cooling, phosphorus diffuses to the grain boundaries. Border zones are enriched in phosphorus, and strength and toughness are reduced. Chromium, manganese and phosphorus contribute to this defect. Molybdenum and tungsten, as well as rapid cooling after tempering, reduce the tendency to type II temper brittleness.

Type II temper brittleness is “reversible,” that is, with repeated heating and slow cooling of the same steels in a dangerous temperature range, the defect may recur.

Steels prone to type II temper brittleness cannot be used for work with heating up to 650 °C without subsequent rapid cooling.

Microstructure of steel after hardening

Most steels after hardening are characterized by the structure of martensite and retained austenite, the amount of the latter depending on the carbon content and the qualitative and quantitative content of alloying elements. For structural steels of medium alloying, the amount of retained austenite can be in the range of 3-5%. In tool steels this amount can reach 20-30%.

In general, the structure of steel after hardening is determined by the final requirements for the mechanical properties of the product. Along with martensite, after quenching, ferrite or cementite may be present in the structure (in case of incomplete quenching). When steel is isothermally hardened, its structure may consist of bainite. The structure, final properties and hardening methods of steel are discussed below.

Partial hardening of steel

Partial quenching is called quenching, in which the cooling rate is not sufficient for the formation of martensite and it turns out to be below critical. This cooling rate is indicated by the blue line in the figure. During partial hardening, the “nose” of the C-curve steel seems to be touched. In this case, in the structure of the steel, along with martensite, troostite will be present in the form of black island inclusions.

The microstructure of partially hardened steel looks something like this:

Partial hardening is a defect that is eliminated by complete recrystallization of the steel, for example, during normalization or during reheating for hardening.

Hardening methods

Since there is no hardening medium that would provide rapid cooling in the temperature range of 650 - 400 ° C and slow cooling above and mainly below this range, various hardening methods are used to provide the necessary cooling regime.

Quenching through water into oil

Quenching through water into oil (quenching in two environments):

1 - normal mode; 2 - underexposure in water; 3 - overexposure in water.

To reduce the cooling rate in the martensitic range, quenching in two environments is used. First, the part is immersed in water and, after a short soak in water, transferred to oil. Therefore, this method of hardening is called water hardening into oil.

Rapid cooling in water prevents pearlite transformation, and subsequent slow cooling in oil reduces quenching stresses in the martensitic range. The most crucial moment is exposure in water, the duration of which is set for each specific product. Both overexposure and underexposure in water can lead to defects.

When underexposed to water, partial or complete decay of austenite occurs and a reduced hardness is obtained, and when overexposed, stronger quenching stresses arise, which can lead to warping and cracking.

Despite these disadvantages, water quenching in oil is widely used in the production of cutting tools made of carbon steel (carbon steel has little hardenability, and cutting tools made from it cannot be quenched in oil).

Quenching in water and hot environments

Quenching in water and hot environments:

1 - hardening in water; 2 - step hardening; 3 - isothermal hardening.

Another way to reduce the cooling rate in the martensitic range is step hardening. The product heated to the hardening temperature is quickly immersed in a bath with a hot medium, and then, after some exposure, it is exposed to air or immersed in cold oil. Hardening in a hot environment was first described by D.K. Chernov.

In 1885, in the famous report “On the preparation of steel armor-piercing projectiles,” D.K. Chernov reported that projectile steel, when quenched in a melt of lead with tin, acquires the same hardness as when quenched in cold water. When choosing a stepwise hardening mode, the C-diagram helps. The temperature of the hot medium (the “step” temperature) is chosen near the martensitic point (20 - 30 °C above it) in the region of high stability of supercooled austenite.

The exposure time in a hot environment (the length of the “step”) should be less than the incubation period at the appropriate temperature. Step hardening is easier to perform than water hardening into oil and gives more consistent results.

Another important advantage of step hardening is the equalization of temperature across the cross section of the product when exposed to a hot environment. The martensitic transformation after this exposure occurs during slow cooling and simultaneously throughout the entire volume, as a result of which the quenching stresses decrease.

Finally, a very significant advantage is that the steel is in an austenitic state at the “step” temperature. After removal from the hot environment, the product is plastic for some time, and it can be corrected to eliminate warping.

This is especially valuable for thin and long products, during hardening of which warping is inevitable even in a hot environment. Editing is often done by hand, but the best results are achieved by editing under pressure. Straightening can continue with cooling below the Mn point, since immediately at the moment of the martensitic transformation (but not after its completion) the plasticity is increased.

The main disadvantage of step hardening is the low cooling rate in a hot environment. Therefore, the use of step hardening for carbon steels is limited to products with a small cross-section (up to 8 - 10 mm thick).

A product with a large cross-section cools slowly in a hot environment, and the austenite has time to undergo eutectoid decomposition. Products made of alloy steels, which have a lower critical cooling rate, are easier to subject to step hardening. For example, step hardening is widely used when processing tools and machine parts made of chromium steel (ШХ16, ХВГ and 9ХС).

A type of step hardening is hardening in a hot environment, the temperature of which is slightly below the martensitic point. The lower “step” temperature provides greater hardenability, and since the amount of martensite is still small, the main advantages of step hardening are retained. But it is no longer possible to edit the product.

During stepwise hardening, three groups of hot media are used: mineral oils, saltpeter melts and alkali melts.

If the length of the “step” located in the temperature range of the bainite transformation is greater than the time of isothermal decomposition of austenite, then the heat treatment operation is called isothermal or bainite hardening. The bainitic transformation is intermediate between pearlitic and martensitic (see Bainitic transformation).

Steel with a lower bainite structure is closer in mechanical properties to martensite-hardened steel than to steel with a pearlite structure. During the bainite transformation, a martensitic γ → α rearrangement occurs. According to the method of practical implementation, the process under consideration differs little from step hardening. Therefore, it is classified as hardening with a polymorphic transformation.

Isothermal hardening is carried out in the same hot environments as step hardening. The holding time in a hot environment should be greater than the isothermal transformation time of austenite, and it can be approximately selected based on the C-diagram. Products with a small cross-section can be subjected to isothermal hardening, since cooling occurs slowly in a hot environment.

When exposed to a hot environment, the temperature across the cross section of the product manages to level out to an even greater extent than during stepwise hardening.

A sharp reduction in quenching stresses and warping is an important advantage of isothermal hardening.

In addition to reducing quenching stresses, isothermal hardening has another advantage. At the same hardness, the viscosity of lower bainite is greater than that of steel tempered after hardening to martensite.

One of the reasons for this is considered to be a more uniform distribution of carbide particles in bainite. During the bainitic transformation, some alloy steels retain a large amount of retained austenite, which does not transform into martensite upon cooling after isothermal holding.

Isothermal hardening of such steels provides high impact toughness and sharply reduces sensitivity to notching and distortion compared to martensite-hardened and tempered steel. Consequently, isothermal hardening makes it possible to increase the structural strength of steel.

Below we compare the properties of 30ХГС steel after conventional quenching and tempering and isothermal hardening:

| σв, kgf/mm2 | σ0.2, kgf/mm2 | an, kgf * m/cm2 | |

| Quenching at 880°C in water + tempering at 520°C | 110 | 85 | 4,5 |

| Isothermal hardening from 880°C in saltpeter at 300°C | 165 | 130 | 6 |

“Theory of heat treatment of metals”, I.I. Novikov

Incomplete hardening of steels

Quenching at temperatures lying between A1 and A3 (incomplete quenching) retains in the structure of hypoeutectoid steels, along with martensite, part of the ferrite, which reduces the hardness in the quenched state and worsens the mechanical properties after tempering. This is understandable, since the hardness of ferrite is 80HRC, and the hardness of martensite depends on the carbon content and can be more than 60HRC. Therefore, these steels are usually heated to temperatures 30–50 °C above A3 (full hardening). In theory, incomplete hardening of steels is not permissible and is considered a defect. In practice, in some cases, incomplete quenching can be used to avoid quenching cracks. Very often this concerns hardening with high frequency currents. With such hardening, it is necessary to take into account its feasibility: type of production, annual program, type of product responsibility, economic justification. For hypereutectoid steels, quenching at temperatures above A1 but below Acm produces excess cementite in the structure, which increases the hardness and wear resistance of the steel. Heating above the temperature Acm leads to a decrease in hardness due to the dissolution of excess cementite and an increase in retained austenite. In this case, the austenite grain grows, which also negatively affects the mechanical characteristics of the steel.

Thus, the optimal quenching for hypoeutectoid steels is quenching from a temperature 30–50 °C above A3, and for hypereutectoid steels – at 30–50 °C above A1.

The cooling rate also affects the hardening result. The optimal cooling medium is one that quickly cools the part in the temperature range of minimum stability of supercooled austenite (in the range of the nose of the c-curve) and slowly in the temperature range of martensitic transformation.

Cooling stages during hardening

The most common quenching media are water of various temperatures, polymer solutions, alcohol solutions, oil, molten salts. When hardening in these environments, several cooling stages are distinguished:

— film cooling, when a “steam jacket” is formed on the surface of the steel;

- nucleate boiling, which occurs with the complete destruction of this steam jacket;

— convective heat transfer.

More details about the cooling stages during quenching can be found in the article “Characteristics of quenching oils”

In addition to liquid quenching media, cooling in a gas flow of different pressures is used. It can be nitrogen (N2), helium (He) and even air. Such quenching media are often used in vacuum heat treatment. Here it is necessary to take into account the fact of the possibility of obtaining a martensitic structure - the hardenability of steel in a certain environment, i.e. the chemical composition of the steel on which the position of the c-curve depends.

Cooling media for hardening

Cooling media for hardening

Cooling during hardening should ensure the formation of a martensite structure within a given cross-section of the product (certain hardenability) and should not cause hardening defects: cracks, deformation, warping and high tensile residual stresses in the surface layers.

A high cooling rate (above: the critical quenching rate) in the temperature range A

1 –

Mn

to suppress the decomposition of supercooled austenite in the region of pearlitic and intermediate transformations and slow cooling in the temperature range of the martensitic transformation

Mn

–

Mk

. A high cooling rate in the martensitic temperature range is undesirable, since it leads to a sharp increase in the level of residual stresses and even to formation of cracks.

At the same time, too slow cooling in the temperature range Mn

-

Mk

can lead to partial tempering of martensite and an increase in the amount of retained austenite due to its stabilization, which reduces the hardness of the steel.

Typically, boiling liquids are used for hardening - water, aqueous solutions of salts and alkalis, oils. When hardening in these environments, three periods are distinguished:

1) film boiling, when a “steam jacket” forms on the surface of the steel; during this period the cooling rate is relatively low;

2) nucleate boiling, which occurs when the vapor film is completely destroyed, observed when the surface is cooled to a temperature below the critical temperature; during this period, rapid heat removal occurs;

3) convective heat exchange, which corresponds to temperatures below the boiling point of the coolant; heat removal during this period occurs at the lowest rate.

Table 2 shows the approximate nucleate boiling temperature range and the relative cooling rate in the middle of this range for various cooling media.

When hardening carbon and some low-alloy steels, which have low stability of supercooled austenite, water and aqueous solutions of NaCl or NaOH are used as a cooling medium.

Water as a cooling medium has significant disadvantages. A high cooling rate in the temperature range of martensitic transformation often leads to the formation of hardening defects; with increasing temperature, the hardening ability sharply deteriorates (Table 1). When quenching products in hot water, due to their slow cooling at high temperatures and rapid cooling at low temperatures, thermal stresses are low, and the most dangerous structural stresses are high, which can cause the formation of cracks. Cold 8–12% aqueous solutions of NaCl and NaOH, which have proven themselves well in practice, have the highest and most uniform cooling ability.

When quenching in aqueous solutions, the steam jacket is destroyed almost instantly, and cooling occurs more uniformly and mainly occurs at the nucleate boiling stage. An increase in cooling capacity is achieved by using jet or shower cooling, which is widely used, for example, in surface hardening.

A further improvement in cooling methods was the use of water-air mixtures supplied through nozzles. Water-air media are used for cooling large forgings, rails, etc.

For alloy steels that have high resistance to supercooled austenite during quenching, mineral oil (usually petroleum) is used.

Oil as a quenching medium has the following advantages: a low cooling rate in the martensitic temperature range, which reduces the occurrence of quenching defects and the constancy of the quenching ability over a wide range of medium temperatures (20–150°).

Disadvantages include increased flammability (flash point 165–300 °C), insufficient stability and low cooling capacity in the region of pearlite transformation temperatures, as well as increased cost.

The oil temperature during quenching is maintained within 60–90 °C, when its viscosity is minimal.

In recent years, instead of water or oil, aqueous solutions of detergents containing surfactants, liquid silicate, and especially synthetic substances, such as aqua-plast, have begun to be used.

Aqua-plast is a concentrate in water of a highly viscous transparent liquid containing water-soluble plastic and a corrosion-protective inhibitor. Solution concentration 0.5–0.7%,

Quenching polymers and detergents in aqueous solutions leads to a decrease in the cooling rate at temperatures below M

n, and as a consequence of this, the formation of cracks is eliminated and warping is reduced.

Table 1

- Relative cooling capacity of quenching media

| Cooling medium | Temperature, °C | Relative cooling intensity in the nucleate boiling range | |

| cooling medium | nucleate boiling | ||

| Water | 20 | 400–100 | 1,0 |

| 40 | 350–100 | 0,7 | |

| 80 | 250–100 | 0,2 | |

| 10% NaCl solution in water | 20 | 650–100 | 3,0 |

| A solution of 10% NaOH in water | 20 | 650–100 | 2,0 |

| Solution of 50% NaOH in water | 20 | 650–100 | 2,0 |

| Mineral oil | 20–200 | 500–250 | 0,3 |

Factors influencing the position of c-curves:

- Carbon. Increasing the carbon content to 0.8% increases the stability of supercooled austenite, and accordingly the c-curve shifts to the right. When the carbon content increases above 0.8%, the c-curve shifts to the left;

— Alloying elements. All alloying elements increase the stability of austenite to varying degrees. This does not apply to cobalt; it reduces the stability of supercooled austenite;

— Grain size and homogeneity. The larger the grain and the more uniform its structure, the higher the stability of austenite;

— An increase in the degree of distortion of the crystal lattice reduces the stability of supercooled austenite.

Temperature affects the position of c-curves through all of the above factors.

Methods of hardening steels

In practice, various cooling methods are used depending on the size of the parts, their chemical composition and the required structure (diagram below).

Diagram: Cooling rates for different methods of hardening steels

Continuous hardening of steel

Continuous hardening (1) is a method of cooling parts in one environment. After heating, the part is placed in a quenching medium and left there until completely cooled. This technology is the most common and is widely used in mass production. Suitable for almost all types of structural steels.

Hardening in two environments

Quenching in two environments (speed 2 in the figure) is carried out in different quenching environments, with different temperatures. First, the part is cooled in the temperature range, for example, 890–400 °C, for example in water, and then transferred to another cooling medium - oil. In this case, the martensitic transformation will already occur in an oil environment, which will lead to a decrease in the leash and warping of steel. This hardening method is used for heat treatment of stamping tools. In practice, the opposite technological technique is often used - first the parts are cooled in oil and then in water. In this case, the martensitic transformation occurs in oil, and the parts are moved into water for faster cooling. This saves time on implementing the hardening technology.

Step hardening

During stepwise quenching (speed 3), the product is cooled in a quenching medium having a temperature higher than the martensitic transformation temperature. In this way, a certain isothermal holding is obtained before the transformation of austenite into martensite begins. This ensures uniform temperature distribution over the entire cross-section of the part. This is followed by final cooling, during which the martensitic transformation occurs. This method produces hardening with minimal internal stress. Isothermal holding can be done just below the temperature Mn, after the start of the martensitic transformation (speed 6). This method is more difficult from a technological point of view.

Isothermal hardening of steels

Isothermal hardening (speed 4) is done to obtain the bainitic structure of the steel. This structure is characterized by an excellent combination of strength and plastic properties. During isothermal hardening, parts are cooled in a bath of molten salts, which have a temperature 50–150 °C above the martensite point Mn, maintained at this temperature until the end of the transformation of austenite into bainite, and then cooled in air.

When hardening onto bainite, it is possible to obtain two different structures: upper and lower bainite. Upper bainite has a feathery structure. It is formed in the range of 500-350°C and consists of lath-shaped ferrite particles <1 µm thick and 5-10 µm wide, as well as thin cementite particles. The structure of upper bainite is characterized by higher hardness and strength, but lower ductility. Lower bainite has a needle-like martensite-like structure and is formed in the range of 350-200 °C. Lower bainite consists of fine particles of ε-carbides located in ferrite platelets. The bainite transformation never goes to completion. The structure always contains martensite and retained austenite. More preferable, in terms of performance characteristics, is the lower bainite structure. Products with such a structure are used in car construction, where parts experience shock-tensile stresses. The bainite hardening technology requires special hardening equipment. Additional materials on this technology can be found in the article “Technology of hardening for bainite.”

Cold treatment (5) is used for steels in which the temperature of the end of the martensitic transformation Mk is below room temperature.

High-speed steels, cemented parts, measuring instruments, and other particularly precise products are subjected to cold treatment. You can read more about this non-standard method of heat treatment in the article “Cold processing of steel parts”

Cooling modes during hardening

The most studied issues in materials science are the relationship between the chemical composition and the structure of the metal at certain temperatures. The most poorly studied area in hardening technology is methods, conditions and cooling modes. Meanwhile, it is in cooling that large reserves for controlling the structure and properties of the metal in finished products lie.

The main question of hardening is how intensely to cool? It would seem that if you cool it as quickly as possible, you will get maximum hardness, but at the same time, increased internal stresses will lead to the formation of cracks in the parts. The so-called hardening cracks, which are well known to all thermal experts. By cooling slowly, you will not achieve the required hardness and the part will need to be annealed and then undergo repeated heat treatment. Each brand has its own “critical” cooling rate, which ensures maximum hardness and will not lead to cracking. For example, 45X steel, depending on the type of coolant, can be hardened to HRC 45 or HRC 60. In order to “squeeze out” the maximum hardness, it is necessary to cool at a rate as close as possible to the critical speed, for a specific steel grade and workpiece geometry. From this we can draw a simple conclusion that the intensity of temperature reduction must be adjustable. There are only two widely used speeds: the cooling speed in water and in oil. Even taking into account that the intensity, in a small range, can be adjusted by temperature and circulation, the critical hardening rate may still not be obtained.

Water and oil media may only provide "critical" hardening rates in some applications. In addition, while working with water is relatively simple, oil hardening has specific features and disadvantages:

- insufficient cooling intensity for some brands;

- the ability to ignite, emit harmful vapors, smoke, coke on the walls of air ducts, etc.,

- good wetting of surfaces and, as a result, large removal of oil from workpieces, evaporation;

- changes in chemical composition under the influence of high temperatures;

- the need to wash the workpieces in detergents with further regeneration of oil films.

The disadvantages of traditional hardening options have contributed to the search for more optimal hardening mixtures and hardening methods, at least for some variants of workpieces and alloys. As a result, several options for hardening technologies and compositions have emerged that are better suited for certain types of products. The most widely used are liquid polymer concentrates combined with water. This technology first appeared in the Soviet Union in 1980.

Characteristics of water-polymer media

These compositions are a mixture of water and polymers in certain proportions

. Polymers are chemical compounds formed by long chains of macroparticles obtained by combining microparticles - monomers. This reaction is called polymerization. Mixing allows you to obtain a stable liquid with adjustable heat capacity, and therefore cooling capacity.

The basis of the composition of the liquid is water, even with altered properties. Therefore, there are restrictions on the use of water-polymer liquids. These environments are not recommended for hardening high-alloy tool and die steel grades, as well as parts of complex shapes or with variable cross-sections.

Polyacrylic iron salt is used as the initial polymer concentrate

brand PK-M. This polymer turned out to be cheap and had advantages over other polymers of similar composition. Polymer coolants were originally designed to replace oil to eliminate flammability. Soon they developed materials that were superior to oil in efficiency for some products. Other advantages of water-polymer media have also been discovered.

Average cooling results in various environments

| Characteristic | Oil I-20 | PC-M environment |

| Hardness | (HB ≤ 363) | 302 – 311 |

| Twist factor | (ext. 66-89) | 76 – 82 |

| Tensile strength (additional load 34-41 tf) | 34,6 – 36,0 | 35,4 – 37,4 |

| Tensile strength along the oblique washer (additional 34-42 tf) | 34,6 – 36,4 | 36,2 – 37,0 |

| Relative elongation (not less than 8.0) | 14 – 17 | 9,6 – 12,0 |

| Relative narrowing (not less than 40.0) | 53 – 59 | 50 – 53 |

| Impact strength (not less than 0.5 MPa) | 6,6 – 7,3 | 5,5 – 6,7 |

Dependence of martensite hardness on carbon content

The hardness of steel after quenching depends on the hardness of martensite, which in turn depends on the carbon content. As the carbon content increases, the hardness after hardening of the steel also increases. The graphical dependence is shown in the figure.

Graph of martensite hardness versus carbon content

Solvent for alkyd enamel - https://www.dcpt.ru