Equipment for detailed processing of products

All this is special equipment for manual sharpening and finishing of various types of tools:

- The floor-standing grinding and grinding machine model 3K634 is equipped with two grinding wheels, type PP 400×50×203, PV 400×50×203.

- With a diameter from 110 to 450 mm or more, depending on the type of equipment and manufacturer.

- The height of the incisors to be sharpened should be in the range of 6–100.

- The permissible sharpening angle of the drill is from 70 to 140 degrees.

- Parts are processed with a universal wheel for detailed polishing of products H – 55 mm, D – 400 mm, Dpos – 50 mm.

- The spindle operates at a maximum speed of 30 m/min and a permissible rotation speed of 1.44 thousand revolutions per minute.

- Machine dimensions – 1000×665×1230 mm.

- The weight of the machine reaches 425 kg depending on the type of unit.

The equipment is mainly used for processing certain batches of parts; manipulations are carried out for finishing and repairing products for subsequent full-fledged work.

This is interesting: How to flare a brake pipe with your own hands: instructions, tools, video

3K634 Floor-mounted grinding and grinding machine. Passport, diagrams, characteristics, description

The grinding and grinding machine model 3K634 is produced by the Mukachevo Machine Tool Plant named after. Kirov is currently Mukachevo Machine Tool Plant, OJSC.

The 3K634 sharpening and grinding machine model replaced the 3B364 model machine.

Synonyms: sharpening machine, electric sharpener, emery, grinding machine.

Sharpening and grinding machines are designed for manual sharpening and finishing of metal-cutting woodworking and other tools (drills, cutters, knives) with abrasive, diamond and CBN wheels. Grinding and grinding machines can be used for deburring, chamfering, cleaning and stripping parts, and manual grinding.

Depending on their purpose, sharpening machines can be divided into three groups:

- small desktop sharpening and grinding machines with grinding wheels with a diameter of 100-175 mm, used for sharpening and grinding small tools

- medium floor-mounted grinding and grinding machines with grinding wheels with a diameter of 200-350 mm, used in mechanical engineering for sharpening the main types of cutters

- large industrial grinding machines with wheels with a diameter of 400 mm or more, used mainly for manual grinding of parts, and also as roughing and grinding machines.

Sharpeners can be equipped with devices for sharpening drills, and grinding machines can be equipped with devices for belt grinding, polishing and dressing wheels.

By installing a polishing pad, grinding machines allow polishing.

The sharpening and grinding machine with two wheels model 3K634 is designed to perform the following operations:

- sharpening of high-speed cutters equipped with carbide plates with a height of up to 100 mm;

- sharpening drills with a diameter of 6 - 60 mm;

- sharpening of metalwork tools;

- removal of burrs, chamfers and other metalwork works;

- grinding parts with an abrasive belt;

- polishing parts

It is not recommended to use the machine for stripping cast and welded parts.

3K634 General view of the grinding machine

3K634 machine design

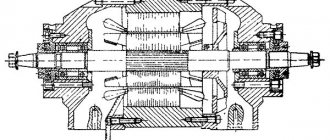

The main part of the machine is the head (Fig. 5). A two-speed electric motor is mounted in the head, the shaft of which is the spindle of the machine. The stator, rotor and fan impeller are located in a housing with two covers, which house the ball-bearing spindle supports (Fig. 6).

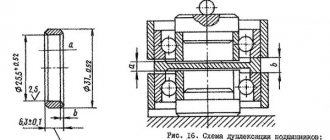

Ball bearing supports are double high-precision angular contact ball bearings No. B36209L with selected axial play. Axial labyrinth seals are made on the outer sides, and fatty grooves on the inner sides.

The electric motor is cooled by air circulation, for which the head support covers have windows connecting the internal cavities of the frame and the head. For fastening protective covers and some devices (for polishing, belt grinding, etc.) there are two trunnions on the head covers. The head is fastened to the frame using pins.

The frame is a cast iron with an electrical cabinet housed in it. A panel with electrical equipment is reinforced inside the frame. Access to electrical equipment is possible due to the presence of an opening in the front wall, hermetically sealed with a door.

Grinding wheels of types 1-400 x 50 x 203 (flat straight profile) and 5-400 x 60 x 203 (flat with recess) are installed on the machine. The circles are mounted on adapter flanges mounted on the conical part of the spindle. The adapter flanges on the outside have three crackers, with the help of which the grinding wheels are balanced.

Grinding wheels are protected by protective covers made of sheet steel.

On the front wall of the casing there is a gap for access to the grinding wheel. In the upper part of the throat there is a visor, with the help of which a gap of no more than 6 mm is maintained between the visor and the grinding wheel, in the lower part of the throat there is a retractable flap for dust suction. When installing a device for sharpening drills, the flap is completely pushed into the casing. The side wall of the housing is hinged to the housing and can be quickly removed for replacement and inspection of the grinding wheel.

At the bottom of the casing there is a dust collector, which collects up to 40% of the dust sucked from the operating area of the machine. The dust collector must be cleaned of accumulated dust at least once per shift.

The casing is equipped with a pipe for connection to the exhaust system. A bushing for fastening the protective screen is welded to the top of the casing.

The protective screen (Fig. 9) is made integral with the lamps. For ease of use, the screen can be rotated about the horizontal axis by 15°. The lamps are equipped with two 41.6 W lamps, providing good illumination.

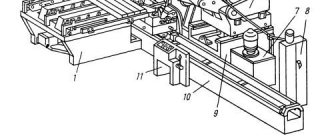

For sharpening cutters and cleaning parts, the machine is equipped with a rotary table (Fig. 10) and a tool rest (Fig. 11). The turntable is a steel plate screwed to a cast iron bracket that can move along a curved guide. Thus, the table can occupy an inclined position relative to the end of the grinding wheel. The table guide is attached to a bracket, which, in turn, is attached to the bed. As a result of two movements of the table in the horizontal plane, wear of the circle along the end and side surface is compensated.

The tool rest is a steel part with two working surfaces: flat and curved. It is recommended to use a flat working surface when grinding parts that have a supporting plane. If you need to grind the curved surface of a part in the absence of a good reference plane or if you need to frequently readjust the angle of the tool rest, you need to use a curved working surface of the tool rest. The attachment of the hand rest to the bracket is made in such a way that it can move in a circle, vertically and rotate around an axis. It is necessary to ensure that the gap between the circle and the tool rest is no more than 3 mm.

3K634 Floor-mounted grinding and grinding machine. Video.

Parameter name 3B634 3K634 TSh-3

| Grinding wheel | |||

| Number of grinding wheels | 2 | 2 | 2 |

| Type of grinding wheels | PP 400x50x203 PV 400x50x203 | 1-400x50x203 5-400x50x203 | GOST 2424-83 |

| Outer diameter of the circle, mm | 400 | 400 | 400 |

| Circle height, mm | 50 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 127 |

| Diameter of worn circle, mm | 240 | ||

| Unbalance class | 1, 2 | ||

| Height of centers from base, mm | 900 | 900 | 950 |

| Recommended height of sharpened cutters, mm | 6-100 | 6-100 | |

| Diameter of sharpened drills, mm | 6-60 | 6-60 | |

| Drill tip angle, degrees | 70-140 | 70-140 | |

| Rear angle, degrees | up to 20 | up to 20 | |

| Rotation angle, degrees | +20..-1 | +20..-1 | |

| Contact roller diameter, mm | 400 | 400 | |

| Sanding belt width, mm | 80 | 80 | |

| Sanding belt length, mm | 3000 | 3000 | |

| Sanding belt tension force, N | up to 1000 | up to 1000 | |

| The largest diameter of the polishing wheel, mm | 400 | 400 | |

| Maximum height of the polishing wheel, mm | 55 | 55 | |

| Polishing wheel hole diameter, mm | 50 | 50 | |

| Spidel | |||

| Rotation speed, 1/min | 720/ 1440 | 1440 | 950 |

| Maximum cutting speed, m/s | 15/ 30 | 30 | 20 |

| Grinding spindle end (diameter/length), mm | 40/ 40 | 40/ 40 | |

| Electrical equipment | |||

| Drive electric motor, kW | 3,2/ 5,3 | 4 | 3,0 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1000 x 665 x 1230 | 1000 x 680 x 1230 | 660 x 600 x 1670 |

| Machine weight, kg | 425 | 358 | 220 |

Related Links. Additional Information

Directory catalog of sharpening machines

Data sheets and manuals for sharpening machines

Directory of woodworking machines

Buy a catalog, directory, database: Price list of information publications

stanki-katalog.ru

Purpose of the grinding unit

Grinding and grinding machine 3b634

The grinding machine brand 3B 634 is capable of:

- carry out manual finishing and grinding of metal-cutting equipment;

- remove chamfers and burrs;

- perform additional functions for cleaning the edges of small parts.

It is worth noting that the technical characteristics of the model allow you to install a polishing washer on the machine. Then it will be possible to carry out belt grinding and straightening of metal wheels.

General description of the model

Grinding and sharpening machine - passport 3b 634. It is based on an electric motor with 2 speeds and located in the inside of the working head. The protruding shaft is a spindle designed to perform rotational movements.

The main components of the structure include:

- frame with cast iron;

- an electrical cabinet located inside the frame, accessible through an opening in the front part;

- hermetically sealed door in the opening;

- grinding wheels, size 40x60x203, attached to the conical part of the adapter flanges and rotating due to crackers (3 pcs.);

- spindles that help balance grinding wheels;

- pipe connected to the hood;

- a bushing in the upper part of the casing as a mount for a protective screen;

- a dust collector located in the lower part of the casing with the ability to collect dust up to 48% and absorb debris from the working area of the equipment;

- turntable;

- a tool rest with the ability to move vertically along the grinding wheel and around its axis.

Grinding and grinding machine Intertool WT-0815

The model also has a special visor located at the top of the equipment on the left, the function of which is to maintain a gap of 6 mm between the built-in lamps and light bulbs (41.6 W) to provide better lighting.

A turntable in the form of a steel plate, attached to cast iron brackets, rotating along curved guides. Thus, when moving horizontally, the table performs a compensation function and does not lead to wear of parts during grinding.

The main thing, when working at the machine, is to ensure that there is no gap between the tool rest and the grinding wheels, the diameter of which must be at least 2.8 mm.

Application of the 3b634 grinding and grinding machine and its main characteristics

The grinding and turning machine 3b 634 is a convenient and reliable device to use, produced at the Mukachevo Machine Tool Plant back in Soviet times. But the technical characteristics allow them to be successfully used in many industries today. Today, an improved brand of machine model with a passport is already known - TK 634.

Purpose of the grinding unit

Grinding and grinding machine 3b634

The grinding machine brand 3B 634 is capable of:

- carry out manual finishing and grinding of metal-cutting equipment;

- remove chamfers and burrs;

- perform additional functions for cleaning the edges of small parts.

It is worth noting that the technical characteristics of the model allow you to install a polishing washer on the machine. Then it will be possible to carry out belt grinding and straightening of metal wheels.

General description of the model

Grinding and sharpening machine - passport 3b 634. It is based on an electric motor with 2 speeds and located in the inside of the working head. The protruding shaft is a spindle designed to perform rotational movements.

The main components of the structure include:

- frame with cast iron;

- an electrical cabinet located inside the frame, accessible through an opening in the front part;

- hermetically sealed door in the opening;

- grinding wheels, size 40x60x203, attached to the conical part of the adapter flanges and rotating due to crackers (3 pcs.);

- spindles that help balance grinding wheels;

- pipe connected to the hood;

- a bushing in the upper part of the casing as a mount for a protective screen;

- a dust collector located in the lower part of the casing with the ability to collect dust up to 48% and absorb debris from the working area of the equipment;

- turntable;

- a tool rest with the ability to move vertically along the grinding wheel and around its axis.

Grinding and grinding machine Intertool WT-0815

The model also has a special visor located at the top of the equipment on the left, the function of which is to maintain a gap of 6 mm between the built-in lamps and light bulbs (41.6 W) to provide better lighting.

A turntable in the form of a steel plate, attached to cast iron brackets, rotating along curved guides. Thus, when moving horizontally, the table performs a compensation function and does not lead to wear of parts during grinding.

The main thing, when working at the machine, is to ensure that there is no gap between the tool rest and the grinding wheels, the diameter of which must be at least 2.8 mm.

Technical specifications

Thanks to the 3b634 grinding and sharpening machine, you can sharpen drills, metalwork tools and cutters. If you wish, you can familiarize yourself with the full list of operational parameters by reading the passport attached to it. If it is not available or it is not possible to purchase it due to the discontinuation and discontinuation of production of this grinding and grinding model, then the main technical characteristics are as follows:

- GOST machine – 8–82;

- power – 4 kW;

- grinding wheels (2 pcs.) PP size 400x40x203;

- distance between grinding wheels – 550 mm;

- equipment dimensions – 925x650x1440;

- equipment weight – 365 kg;

- height from the floor of the centers of the grinding wheels – 864 mm;

- voltage – 380 V, frequency 50 Hz;

- spindle speed – 1440 rpm;

- cutting speed – 30 m/s;

- sanding belt when installed, length – 300 cm, for sharpening it is recommended to use a height of up to 6 m.

If necessary, sharpen the drills, the frame can be installed at an angle at the top - 70-140 degrees, and at the rear - at an angle of 20 degrees.

The grinding machine is adapted to use cutters with different cutting edges, but their height should not be higher than 100 mm, and when using drills, the permissible diameter is 60 mm.

If you need to chamfer or polish a part, you need to take into account the diameter of the grinding wheels for installation and choose the optimal operating mode of the machine.

The 3B634 sharpening and grinding machine is more intended for repair work. The kit includes a special attachment necessary for sharpening drills. Taking into account the characteristics of the equipment, it is quite possible to make the nozzle yourself or buy it separately in the store.

Design and equipment of the unit

The 3b634 sharpening machine has quite high functionality. The design includes:

- 2 working circles for performing rotational movements;

- electric motor with 2-speed modes, mounted in the inside of the head;

- a motor shaft with a protrusion on both sides of the cover, which acts as a spindle in the equipment.

The main features of this model include:

- the presence of a rotary table with a tool rest and 2 working surfaces (curvilinear, flat), for grinding parts;

- the ability to move the table horizontally to avoid rapid wear of the working circle;

- the right hand rest is equipped with a rotating mechanism and you can change the angle of inclination of the supporting surface if necessary;

- the presence of openings in the protective covers for better access to the workpiece and the surface of the working circle;

- moving the rotary table along curved guides to install the machine at an angle relative to the ends of the working circle.

Rotary table of grinding and grinding machine 3B634

Equipping the machine with transparent protective screens is necessary for safer and freer observation of the entire process and work performed.

The presence of powerful lamps with the ability to rotate 15 degrees horizontally, which is convenient when working with this sharpening and grinding equipment.

Model features

Electric motor of grinding and grinding machine 3B634

On the sharpening and grinding machine 3b 634 you can not only sharpen products, but also carry out roughing and polishing work, and belt grinding. To ensure greater functionality, additional devices can be attached at any time by placing them on the trunnions mounted on the covers of the working head.

These are excellent assistants that not only firmly fix the sharpening machine casings, but also serve to secure the working head on the frame in the form of pins attached to the equipment.

It is worth noting that the electric motor of this brand of machine quickly overheats and therefore requires cooling. Although the design provides an air duct through which air circulates through the external cavity and unhindered penetration into the working head through a window in the supporting part.

One of the design features of the machine is the presence of built-in ball bearing supports, which provide stability to the protruding parts of the electric motor shaft and give them rotational accuracy. These are quite high-precision, persistent ball bearings with sealing elements, grease and axial labyrinth grooves placed on both sides.

Each element in the design of the sharpening machine is firmly fixed to a cast-iron frame, the inner part of which is hollow, where it is located in the electrical equipment. For unobstructed access, there is an opening in the front of the frame, as well as a sealed lid for closing.

Related video: Sharpening and grinding machine TCH-350

promzn.ru

Device

The sharpening and grinding equipment is installed on a steel vertical stand in a prepared room of a small repair shop or in utility rooms, and is powered by a single-phase AC mains voltage of 220 V.

The working tools for the machine are abrasive wheels made of CBN, technical corundum, and electrocorundum. Diamond bonded discs can be used for sharpening various cutting tools - knives, cutters, drills, chisels.

The kinematic diagram of the machine provides for the transmission of torque to both ends of the output shaft, to which two abrasive wheels are connected. They can have different grain sizes, so on a 3K634 type sharpening and grinding machine you can perform both rough and fine grinding. Range of technological capabilities of 3K634 equipment:

- Sharpening;

- Polishing;

- Ripping;

- Descaling (for small-sized castings);

- chamfering;

- Edge preparation;

- Finishing of carbide plates.

Mounting holes are used to install the machine. 3K634 includes units:

- Cast iron body with mounting bosses for fastening studs.

- Horizontally located electric motor with two stages of rotor rotation speed.

- Support shaft rotating in double ball bearings designed for significant axial loads.

- The top cover, inside of which a ventilation device with an impeller is mounted for continuous cooling of the drive.

- Built-in cabinet with elements of the electric drive system.

- Housing with control buttons.

The working tools on the 3K634 are abrasive wheels, which are installed on the output parts of the shaft and covered with protective covers. A protective screen made of durable acrylic glass is installed in the slot of each casing, behind which the worker can carry out the necessary grinding or turning operations without the risk of injury or damage. For sharpening, the sharpening and grinding equipment is equipped with a movable shutter, which can move left and right. The side walls of the casing are quick-removable, which is used when it is necessary to visually inspect the periphery of the abrasive disc and to replace it.

3K634 design features and capabilities

At the bottom of the casing there is the possibility of connecting a dust bag, which collects small metal waste, as well as turning chips. For intensive processing of workpieces, this equipment can be connected to the hood of the exhaust system of a workshop or workshop.

Proper sanitary and hygienic operating conditions of the grinding machine are ensured by the presence of a built-in lamp, the characteristics of which are designed for the use of lamps with a power of 40 W and a voltage of up to 36 V inclusive (it is not safe to buy used equipment without a lamp!). The lamp leg can be rotated at an angle of up to 15°, which provides good lighting conditions when grinding various parts.

Before purchasing a 3K634 machine for grinding work, it is worth remembering that the equipment must be equipped with a rotary-type tool table. The table is attached to the equipment body and allows movement along a curved path, which is convenient when sharpening twist drills. Thus, with a fixed axis of the grinding disk, the sharpening surface can vary within the required limits. Moving the table on 3K634 allows you to take into account the wear of the working edge of the circle.

Technical characteristics of model 3K634

The basic model has the following technical parameters:

- The largest outer diameter of the grinding wheels used is up to 400 mm.

- The maximum thickness of the circle is up to 50 mm.

- The height of the shaft at the centers is 900 mm.

- The range of sizes of sharpened turning tools is 6-100 mm.

- The range of sizes of sharpened drills is 6-60 mm.

- The shape of the working part of the drill is conical, with a cone angle of 70-140 mm.

- The highest technological grinding force is 1000 N.

- The spindle shaft speed is 1440 min-1.

- The radial rotation speed of the spindles is 30 m/s.

- The length of the free part of the spindle for tool installation is 40 mm.

- Electric motor power 4 kW.

- Overall dimensions in plan: 1000×630×1230 mm.

- The mass of the assembled machine, but without tooling, is 358 kg.

3B634 Floor-mounted grinding and grinding machine. Passport, diagrams, characteristics, description

The grinding and grinding machine model 3B634 was produced by the Mukachevo Machine Tool Plant named after. Kirov is currently Mukachevo Machine Tool Plant, OJSC.

The model 3B634 sharpening and grinding machine is no longer produced and has been replaced by the more advanced machine model 3K634.

Synonyms: sharpening machine, electric sharpener, emery, grinding machine.

Sharpening and grinding machines are designed for manual sharpening and finishing of metal-cutting woodworking and other tools (drills, cutters, knives) with abrasive, diamond and CBN wheels. Grinding and grinding machines can be used for deburring, chamfering, cleaning and stripping parts, and manual grinding.

Depending on their purpose, sharpening machines can be divided into three groups:

- small desktop sharpening and grinding machines with grinding wheels with a diameter of 100-175 mm, used for sharpening and grinding small tools

- medium floor-mounted grinding and grinding machines with grinding wheels with a diameter of 200-350 mm, used in mechanical engineering for sharpening the main types of cutters

- large industrial grinding machines with wheels with a diameter of 400 mm or more, used mainly for manual grinding of parts, and also as roughing and grinding machines.

Sharpeners can be equipped with devices for sharpening drills, and grinding machines can be equipped with devices for belt grinding, polishing and dressing wheels.

By installing a polishing pad, grinding machines allow polishing.

The sharpening and grinding machine with two wheels, model 3B634, is designed to perform the following operations:

- sharpening of high-speed cutters equipped with carbide plates with a height of up to 100 mm;

- sharpening drills with a diameter of 12 - 50 mm;

- sharpening of metalwork tools;

- removal of burrs, chamfers and other metalwork works;

- grinding parts with an abrasive belt;

- polishing parts

It is not recommended to use the machine for stripping cast and welded parts.

3B634 machine design

The main part of the machine is the head (Fig. 5). A two-speed electric motor is mounted in the head, the shaft of which is the spindle of the machine. The stator, rotor and fan impeller are located in a housing with two covers, which house the ball-bearing spindle supports (Fig. 6).

Ball bearing supports are double high-precision angular contact ball bearings No. B36209L with selected axial play. Axial labyrinth seals are made on the outer sides, and fatty grooves on the inner sides.

The electric motor is cooled by air circulation, for which the head support covers have windows connecting the internal cavities of the frame and the head. For fastening protective covers and some devices (for polishing, belt grinding, etc.) there are two trunnions on the head covers. The head is fastened to the frame using pins.

The frame is a cast iron with an electrical cabinet housed in it. A panel with electrical equipment is reinforced inside the frame. Access to electrical equipment is possible due to the presence of an opening in the front wall, hermetically sealed with a door.

Grinding wheels of types PP 400 x 50 x 203 (flat, straight profile) and PV 400 x 60 x 203 (flat with recess) are installed on the machine. The circles are mounted on adapter flanges mounted on the conical part of the spindle. The adapter flanges on the outside have three crackers, with the help of which the grinding wheels are balanced.

Grinding wheels are protected by protective covers made of sheet steel.

On the front wall of the casing there is a gap for access to the grinding wheel. In the upper part of the throat there is a visor, with the help of which a gap of no more than 6 mm is maintained between the visor and the grinding wheel, in the lower part of the throat there is a retractable flap for dust suction. When installing a device for sharpening drills, the flap is completely pushed into the casing. The side wall of the housing is hinged to the housing and can be quickly removed for replacement and inspection of the grinding wheel.

At the bottom of the casing there is a dust collector, which collects up to 40% of the dust sucked from the operating area of the machine. The dust collector must be cleaned of accumulated dust at least once per shift.

The casing is equipped with a pipe for connection to the exhaust system. A bushing for fastening the protective screen is welded to the top of the casing.

The protective screen (Fig. 9) is made integral with the lamps. For ease of use, the screen can be rotated about the horizontal axis by 15°. The lamps are equipped with two 41.6 W lamps, providing good illumination.

For sharpening cutters and cleaning parts, the machine is equipped with a rotary table (Fig. 10) and a tool rest (Fig. 11). The turntable is a steel plate screwed to a cast iron bracket that can move along a curved guide. Thus, the table can occupy an inclined position relative to the end of the grinding wheel. The table guide is attached to a bracket, which, in turn, is attached to the bed. As a result of two movements of the table in the horizontal plane, wear of the circle along the end and side surface is compensated.

The tool rest is a steel part with two working surfaces: flat and curved. It is recommended to use a flat working surface when grinding parts that have a supporting plane. If you need to grind the curved surface of a part in the absence of a good reference plane or if you need to frequently readjust the angle of the tool rest, you need to use a curved working surface of the tool rest. The attachment of the hand rest to the bracket is made in such a way that it can move in a circle, vertically and rotate around an axis. It is necessary to ensure that the gap between the circle and the tool rest is no more than 3 mm.

3B634 General view of the grinding machine

Photo of sharpening and grinding machine 3B634

3B634 Arrangement of components of a grinding machine

Arrangement of components of the grinding and grinding machine 3B634

3B634 list of components of a grinding machine

- bed

- head

- PP wheel mount (straight profile flat grinding wheel)

- fastening the PV wheel (flat grinding wheel with a recess on one side)

- left casing

- right casing

- screen

- rotating table

- left hand rest

3B634 Specification of components of a grinding machine

- Bed ZB634.10A.000

- Head ZB634.22.001

- Fastening the circle PP ZB634.30.002

- Mounting circle PV ЗБ634.31.002

- Left casing ZB634.40.001

- Right housing ZB634.41.001

- Screen ZB634.42A.001

- Right rotary table ZB634.54B.001

- Left hand rest ZB634.56.001

- Electrical equipment ЗБ634.80.000

- Control panel ZB634.88.000

- Accessories ZB634.90.000

3B634 Location of controls for a grinding machine

Location of controls for the sharpening and grinding machine 3B634

3B634 list of controls for a grinding machine

- input switch

- push-button station “Start”, “Stop”

- light switch

- speed switch

3B634 Electrical circuit of a grinding machine

Electrical circuit of the grinding grinding machine 3B634

3B634 electrical equipment of the machine

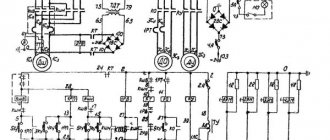

The electrical equipment of the 3B634 grinding and grinding machine (Fig. 12 and 13) is designed for connection to a three-phase alternating current network. The lighting circuit is made at a voltage of 12 V and is powered by a step-down transformer TO. A built-in two-speed 1M electric motor is used as an electric motor drive.

The machine control is push-button and is performed from the control panel located at the workplace (on the front wall of the bed).

The remote control contains “Start” and “Stop” buttons, light switches, and an engine speed switch. The rest of the electrical equipment is located in the niche of the frame.

The choice of engine rotation speed is made by the PS switch before turning on the machine by pressing and turning its handle to the required position.

The machine lighting is interlocked with the operation of the electric motor and turns on when the 1KU “Start” button is pressed.

The engine is turned off when the 2KU “Stop” button is pressed. It is not recommended to turn off the engine with a 1A circuit breaker.

The electrical interlocking of the starter K disconnects its coil using a normally closed block contact when the PS switch handle is switched.

The 2M engine and automatic ZA are supplied with a ventilation unit upon special order.

3B634 Installation drawing of the grinding machine

Installation drawing of grinding and grinding machine 3B634

3B634 Floor-mounted grinding and grinding machine. Video.

Parameter name 3B634 3K634 TSh-3

| Grinding wheel | |||

| Number of grinding wheels | 2 | 2 | 2 |

| Type of grinding wheels | PP 400x50x203 PV 400x50x203 | PP 400x50x203 | GOST 2424-83 |

| Outer diameter of the circle, mm | 400 | 400 | 400 |

| Circle height, mm | 50 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 127 |

| Diameter of worn circle, mm | 240 | ||

| Unbalance class | 1, 2 | ||

| Height of centers from base, mm | 900 | 900 | 950 |

| Recommended height of sharpened cutters, mm | 6-100 | 6-100 | |

| Diameter of sharpened drills, mm | 6-60 | 6-60 | |

| Drill tip angle, degrees | 70-140 | 70-140 | |

| Rear angle, degrees | up to 20 | up to 20 | |

| Rotation angle, degrees | +20..-1 | +20..-1 | |

| Contact roller diameter, mm | 400 | 400 | |

| Sanding belt width, mm | 80 | 80 | |

| Sanding belt length, mm | 3000 | 3000 | |

| Sanding belt tension force, N | up to 1000 | up to 1000 | |

| The largest diameter of the polishing wheel, mm | 400 | 400 | |

| Maximum height of the polishing wheel, mm | 55 | 55 | |

| Polishing wheel hole diameter, mm | 50 | 50 | |

| Spidel | |||

| Rotation speed, 1/min | 720/ 1440 | 1440 | 950 |

| Maximum cutting speed, m/s | 15/ 30 | 30 | 20 |

| Grinding spindle end (diameter/length), mm | 40/ 40 | 40/ 40 | |

| Electrical equipment | |||

| Drive electric motor, kW | 3,2/ 5,3 | 4 | 3,0 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1000 x 665 x 1230 | 1000 x 680 x 1230 | 660 x 600 x 1670 |

| Machine weight, kg | 425 | 358 | 220 |

Related Links. Additional Information

Directory catalog of sharpening machines

Passports and manuals of metal-cutting machines

Directory of woodworking machines

Buy a catalog, directory, database: Price list of information publications

stanki-katalog.ru

Complete set of machine TSH-2.10

The machine is delivered assembled, in special packaging (allows for its transportation and long-term storage)

The set and price of the machine includes:

- Grinding wheels 2 pcs: 300x40x76, 25A F46 K-L٭ 1700 (GOST P52588-2006), 300x40x76, 64C F46 K-L٭ 1700 (GOST P52588-2006);

- Work area protection: circle fencing 2 pcs., protective screens 2 pcs.;

- Work area lighting: local lighting lamp 1 pc;

- Electrical control: push-button, with zero protection.

Included with the machine:

- Operating manual 1 copy;

- Technical documentation for equipment;

- Equipment installation drawings;

- A certified copy of the GOST ISO 9001 equipment certificate;

- Certified copy of the security certificate

- Certified copy of the customs declaration

The TSh-2.10 machines are not equipped with a device for shutting off the electric motor when the protective screen is raised, only the TSh-2.20 modification. The warranty period for the equipment is 12 (twelve) months from the date of commissioning, but not more than 18 (eighteen) months from the date of sale.

This is interesting: Fittings for metal-plastic pipes: types and installation features

What technological operations can be performed on the 3B634 machine

Due to its technical characteristics and design features, the 3B634 machine, which belongs to the equipment of the sharpening and grinding group, allows you to perform the following technological operations:

- sharpening of cutters up to 100 mm high, made of high-speed steels or equipped with carbide cutting inserts;

- sharpening drills with a diameter from 12 to 50 mm;

- sharpening of various tools used to perform plumbing work;

- cleaning operations - removing burrs, forming chamfers on the surface of a part and other types of metalwork;

- grinding of parts, for which an abrasive belt is used;

- polishing operations.

The high functionality of the 3B634 sharpening and grinding machine is also ensured by the fact that its design provides two working wheels at once.

Grinding and grinding machine - TSh 2 - TSh 1 - 3k634 and others

Sharpening grinding machines are used in production for sharpening and finishing the working part of tools used to process products made of metal, wood and other materials. Drills, cutters, knives, scissors - all tools that have a cutting edge (blade) can be sharpened quickly and efficiently only on such a machine.

Benchtop grinding machine DeWALT DW-753

- A grinding machine is also used in cases where it is necessary to remove burrs, chamfer the finished contour of a product, clean or peel (remove) rust, paint, or a small layer of excess material from the surface of a part or workpiece.

- It is possible to use such a machine for manual grinding or polishing of finished metal products.

about the types and features of Energomash sharpening machines.

Varieties

The operating principle and basic structural layout of devices of this type are almost the same for all models. The division into separate groups, according to purpose and application, can be done in the following form:

- small tabletop - has a grinding wheel with a diameter of 100 to 175 mm. Used when working with small tools and parts;

- medium floor - the grinding wheel on such a machine in diameter corresponds to parameters from 200 to 350 mm. The main purpose is sharpening of various types of cutters at industrial enterprises;

- large industrial - grinding wheel with dimensions of 400 mm and larger. Mainly used for roughing and stripping, as well as for grinding and polishing parts.

Equipping the machine with special equipment

The 3K634 machine is equipped with additional equipment - a support table, which is used to sharpen drills with an allowable diameter from 6 to 60 mm. It is also possible to carry out operations for chamfering and polishing workpieces with a preliminary selection of the operating mode of the machine.

Basic parameters for processing workpieces:

- Processing of the workpiece using the optional 300 cm sanding belt.

- Sharpening of cutters with parameters from 6 to 100 mm.

- Use of abrasive wheels with indicators: D- 400 mm;

- D-400 mm;

- permissible processing speed – 30 m/min.

The 3K634 machine is used mainly for processing individual small batches of parts and when carrying out repair work.

3K634

3K634 is a sharpening and grinding machine, which replaced the 3B634 model. This unit is also a floor-mounted structure, which can be found in many large enterprises involved in the metalworking industry. Like its “predecessor”, this unit boasts the following functions:

- Sharpening of cutters made of hard alloys;

- Sharpening drills with a diameter from 6 to 60 millimeters;

- Maintenance of metalwork tools;

- Removing burrs and chamfers;

- Polishing and grinding of metal products.

Like its predecessor, the 3K634 sharpening and grinding machine is equipped with 2 grinding wheels of the PP 400x50x203 type. Most of the technical parameters of this coincide with the characteristics of 3B634. The main difference is the built-in 4-watt motor with improved performance characteristics. In addition, the 3K634 sharpening and grinding machine has slightly larger dimensions, which are 1000x680x1230 millimeters.

However, the increased dimensions did not affect the weight of the unit, which is only 358 kg, which is 67 kg less than the 3B634 model. In all other respects, this unit is almost completely identical to the previous series.

Results

Machine tools that were once produced by the Mukachevo plant are now very popular on the used market in all corners of the post-Soviet space. Easy to maintain, affordable and reliable in operation, they are in deserved demand among professionals. Today, if you are looking for how to equip your own workshop at minimal cost to your budget, consider purchasing one of the units described above. If you manage to find a car in excellent condition, you can count on it to serve you for many more years. Today, grinding machines 3K634 and 3B634 are able to seriously compete with many modern units, primarily in price. For this reason, experts recommend that you become more familiar with the specifics of this technique.

Advantages

The 3K634 sharpening and grinding machine has the following advantages:

- simplicity of design;

- multifunctionality;

- versatility;

- quality of equipment and its components;

- ease of installation and operation;

- accuracy of work;

- safety;

- attractive price;

- reliability and strength;

- long service life.

Design and equipment of the unit

The 3b634 sharpening machine has quite high functionality. The design includes:

- 2 working circles for performing rotational movements;

- electric motor with 2-speed modes, mounted in the inside of the head;

- a motor shaft with a protrusion on both sides of the cover, which acts as a spindle in the equipment.

The main features of this model include:

- the presence of a rotary table with a tool rest and 2 working surfaces (curvilinear, flat), for grinding parts;

- the ability to move the table horizontally to avoid rapid wear of the working circle;

- the right hand rest is equipped with a rotating mechanism and you can change the angle of inclination of the supporting surface if necessary;

- the presence of openings in the protective covers for better access to the workpiece and the surface of the working circle;

- moving the rotary table along curved guides to install the machine at an angle relative to the ends of the working circle.

Rotary table of grinding and grinding machine 3B634

Equipping the machine with transparent protective screens is necessary for safer and freer observation of the entire process and work performed.

The presence of powerful lamps with the ability to rotate 15 degrees horizontally, which is convenient when working with this sharpening and grinding equipment.

Features of the machine 3B634

To impart rotational motion to the working circles of the sharpening and grinding machine of this model, a two-speed electric motor is used, which is installed in the inner part of the working head. The electric motor shaft protruding from both sides of its covers simultaneously plays the role of an equipment spindle.

View from the machine spindle side

To ensure the stability of the protruding parts of the electric motor shaft and give them precise rotation, ball bearing supports are mounted in the covers of the working head. The main structural elements of such supports are high-precision angular contact ball bearings, in which axial play is additionally selected. There are sealing elements on both sides of the bearings: axial labyrinth (on the outside) and with grease grooves (on the inside).

The electric motor of sharpening and grinding equipment is subject to strong heating during operation, so it must be effectively cooled. In the 3B634 machine, such cooling is provided by air that circulates through the internal cavity of the frame and freely penetrates into the working head through the windows in its supporting part.

The characteristics of the sharpening and grinding machine of this model provide for the possibility of using it not only as sharpening equipment, but also for performing belt grinding and polishing work.

In order to provide such functionality, the 3B634 design provides for the possibility of attaching additional devices, for which special trunnions are mounted on the covers of the working head. With the help of such trunnions, in addition, the fixation of the protective casings of sharpening and grinding equipment is ensured. To securely fix the working head on the equipment frame, studs are used.

Machine Specifications

All structural elements of the grinding and grinding machine of this model are fixed on its frame, which is made of cast iron. The inner part of the frame is hollow; it houses electrical equipment mounted in a separate cabinet. Access to the electrical equipment of the grinding and grinding machine is provided by an opening in the front part of the bed, closed with a sealed lid.

To perform sharpening and other metalworking operations on the machine, wheels with a flat straight profile (400x50x203) and flat wheels with a recess (400x60x203) can be used. To fix the working wheels, adapter flanges are used, which are fixed to the machine spindle, which has a conical shape.

Working wheels on sharpening and grinding machines must be balanced after they are installed; for this purpose, there are three crackers on the outer part of the adapter flanges.

To ensure the safety of performing work on a grinding and grinding machine of this model, its working circles are protected with special casings made of sheet steel. In addition, the design of the machine includes special dust collectors connected to an exhaust system, which makes it possible to collect up to 40% of the dust created during work.

The machine is equipped with an exhaust system

Access of the workpiece to the surface of the working circle is ensured by the presence of openings in the protective covers. Transparent protective screens attached to the top of the casings make it possible to safely observe the processing process. Such screens, made integral with powerful lamps, can be rotated 15 degrees relative to the horizontal axis, which further increases the convenience of working on the sharpening and grinding equipment of this model.

The machine in question is very convenient for sharpening turning tools, since its design includes a rotary table and a tool rest. Thanks to movement along curved guides, the rotary table of a sharpening and grinding machine can even occupy an inclined position relative to the end of the working wheel. The movements of the rotary table, which occur in the horizontal plane, make it possible to easily compensate for the wear of the working circle.

The tool rest for sharpening and grinding equipment of this model has two working surfaces – flat and curved. They are used, respectively, when grinding parts with a flat and curved reference plane.

The right hand rest of the machine is equipped with a rotating device that allows you to change the angle of inclination of the supporting surface

Operating rules

Before using the machine, you must perform the following steps:

- Install the equipment on a level surface, without additional elevation.

- Provide the room with a 380 V electrical network; it is operational for 3K634.

- Take care of forced ventilation.

- When connecting, check the correct rotation.

- Check the functionality of the circuit breaker, which provides overload protection.

Before operating the machine, the operator must undergo appropriate training. Since the electrical part wears out during long-term operation, personnel must periodically check these elements of the machine.

When starting up new equipment for the first time, wipe it with a rag soaked in acetone or gasoline to remove the anti-corrosion coating. After checking the serviceability of all elements, specialists launch it.

It is imperative to balance the abrasive wheels, which, when rotating, should not create a feeling of beating.

Device control system

The operation of the grinding and grinding machine of this model is controlled using the following technical elements:

- a switch that turns on the electrical power of the machine;

- buttons for turning on (“START”) and switching off (“STOP”) equipment;

- a switch responsible for supplying power to the machine lamp;

- equipment speed switch.

Machine controls

Structural elements of the 3B634 machine

The design of the grinding and grinding machine of this model includes the following elements:

- supporting frame;

- working head;

- device for fixing circles PP type;

- device for fastening circles type PV;

- two protective covers – left and right;

- transparent protective screens;

- turntable;

- handyman

Machine components

Safety precautions

To safely use the 3K634 roughening, grinding and grinding machine, the following rules must be observed:

- Installation of equipment is carried out only on a level basis.

- The place where the machine works must be equipped with forced ventilation.

- The unit must be grounded.

- The machine must not be left unattended while the engine is running.

- You should leave the room only after the engine has completely stopped.

- Periodically, all equipment mechanisms are cleaned of abrasive dust.

Technical characteristics of the grinding grinding machine 3B634

| Parameter name | 3B634 | 3K634 | TS-3 |

| Grinding wheel | |||

| Number of grinding wheels | 2 | 2 | 2 |

| Type of grinding wheels | PP 400x50x203 PV 400x50x203 | PP 400x50x203 | GOST 2424-83 |

| Outer diameter of the circle, mm | 400 | 400 | 400 |

| Circle height, mm | 50 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 127 |

| Diameter of worn circle, mm | 240 | ||

| Unbalance class | 1, 2 | ||

| Height of centers from base, mm | 900 | 900 | 950 |

| Recommended height of sharpened cutters, mm | 6-100 | 6-100 | |

| Diameter of sharpened drills, mm | 6-60 | 6-60 | |

| Drill tip angle, degrees | 70-140 | 70-140 | |

| Rear angle, degrees | up to 20 | up to 20 | |

| Rotation angle, degrees | +20..-1 | +20..-1 | |

| Contact roller diameter, mm | 400 | 400 | |

| Sanding belt width, mm | 80 | 80 | |

| Sanding belt length, mm | 3000 | 3000 | |

| Sanding belt tension force, N | up to 1000 | up to 1000 | |

| The largest diameter of the polishing wheel, mm | 400 | 400 | |

| Maximum height of the polishing wheel, mm | 55 | 55 | |

| Polishing wheel hole diameter, mm | 50 | 50 | |

| Spidel | |||

| Rotation speed, 1/min | 720/ 1440 | 1440 | 950 |

| Maximum cutting speed, m/s | 15/ 30 | 30 | 20 |

| Grinding spindle end (diameter/length), mm | 40/ 40 | 40/ 40 | |

| Electrical equipment | |||

| Drive electric motor, kW | 3,2/ 5,3 | 4 | 3,0 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1000 x 665 x 1230 | 1000 x 680 x 1230 | 660 x 600 x 1670 |

| Machine weight, kg | 425 | 358 | 220 |

Grinding machine

Products / Metalworking machines, KPO, forging equipment / Grinding and grinding machine

Rough grinding machine Proma BKS-2500

The roughing and grinding machine BKS-2500 is made in a desktop version. The machine is used for sharpening various machine and hand tools, as well as roughing, cleaning metal workpieces, removing burrs and chamfers.

Available on a special stand for this grinding machine. Machine base with holes diameter 12 mm for attaching the machine to a working surface, for example to a workbench

| Parameter name | Meaning |

| Grinding wheel (D/d/B), mm according to GOST 2424-83, mm | 250/32/32 |

| Grinding speed circle, rpm | 2950 |

| Power/voltage, main drive, kW/V | 1,1/380 |

| Noise level value, dB | 92,3 |

| Dimensions, mm | |

| Weight of the machine with stand, kg | 46 |

| Price including VAT, rub. | 30 500 |

Grinding and grinding machines models STSh2/2, STSh2/2D and STSh3/2 are designed for roughing and removing burrs and chamfers during metalwork using abrasive wheels installed on the machines. Grinding and grinding machine STSh2/2, STSh2/2D and STSh3/2 used for sharpening hand and machine tools, including diamond wheels. The machines are reliable and easy to use. Operation of the machines should be carried out at a humidity of no more than 75% and an ambient temperature of +5..+45°C. The price/capability/reliability ratio is at a high level.