Wood and metal processing

Manual musical instruments are used for cutting steel sheets with a thickness of 0.5 - 1.0 mm and non-ferrous metals up to 1.5 mm.

Hand scissors are made with straight and curved cutting blades. According to the location of the cutting edge of the blade, hand scissors are divided into right and left.

Right-handed scissors are those in which the bevel on the cutting part of each half is on the right side. Using right scissors, cut along the left edge of the product in a clockwise direction.

Left-handed scissors are those in which the bevel on the cutting part of each half is located on the left side. These scissors are used to cut along the right edge of the product counterclockwise.

When cutting a sheet with right-handed scissors, a mark is always visible on the metal being cut. When working with left-handed scissors, in order to see the mark, you have to bend the cut metal with your left hand, passing it over your right hand, which is very inconvenient. Therefore, sheet metal is cut in a straight line and along a curve (circle, rounding) without sharp turns with right-handed scissors.

The scissors are held in the right hand, grasping the handles with four fingers and pressing them to the palm; The little finger is placed between the handles of the scissors.

The clenched index, ring and middle fingers unclench, straighten the little finger and, with its effort, move the lower handle of the scissors to the required angle. Holding the sheet with your left hand (Fig. 2, b), feed it between the cutting edges, directing the upper blade exactly in the middle of the marking line, which should be visible when cutting. Then, squeezing the handle with all fingers of the right hand, except the little finger, they cut.

In Fig. 2, c, d shows techniques for working with scissors.

For straight cutting of metal of small thickness, hand scissors are used, one handle of which is clamped in a vice.

Chair staves differ from manual ones in their larger sizes and are used when cutting sheet metal up to 3 mm thick. The lower handle is firmly clamped in a bench vice or fastened (hammered) onto a table or other rigid base. For cutting sheet steel up to 3 mm thick, chair scissors with a stationary fastening are used (Fig. 3, c).

Chair shears are low-productive and require significant effort when working, so they are not used for cutting large batches of sheet metal.

Manual small-sized power music books. Innovator A. N. Vasiliev created small-sized power shears for cutting sheet steel up to 2.5 mm thick, rods, bolts (studs) with a diameter up to 8 mm. The dimensions of these scissors do not exceed the dimensions of standard hand scissors (Fig. 4). For cutting, the handle is secured in a vice, and the handle (working) is activated. The working handle is a system of two levers connected in series. The first lever, on one arm of which the knife is fixed, is connected to the handle with a screw.

The second arm of the lever, which is the handle of ordinary scissors, is shortened and ends with a hinge, or the scissors handle itself. The end hinge of the handle is connected to the handle using a double-hinged link. This lever system approximately doubles the cutting force compared to conventional scissors of the same size. The scissor blades are replaceable and attached to the levers with hidden rivets.

These scissors also have a device for cutting rods with a diameter of up to 8 mm. The device has discs with holes mounted on scissor arms and is a regular scissors, but with specially shaped knives (hardened bushings). These knives are replaceable and are inserted into the disk socket. For cutting bolts (piles). in the bushings of one of the disks there is a groove (several threads), which protects the threads of the bolts from being crushed during cutting.

Small-sized power shears provide good cutting quality.

Lever shears (Fig. 5) are used for cutting sheet steel up to 4 mm thick, aluminum and brass up to 6 mm. The upper hinged knife is driven by a lever. The lower knife is stationary.

The knives are made from U8 steel and hardened to a hardness of HR.C 52 - 60. The sharpening angles of the cutting edges are 75 - 85°.

Before work, check whether the rubbing parts are lubricated, whether the lever moves smoothly, and whether there is a gap between the cutting edges.

When cutting metal, grab the handle of the lever with your right hand and smoothly move it to the upper position, while the upper knife 3 moves upward. Then the sheet is laid so that the left hand holds it in a horizontal position, and the cut line is in the field of view and coincides with the blade of the upper knife. By moving the hand, lower the lever with the knife down until part of the metal is cut through, after which the lever is moved to the upper position. Next, slightly lift sheet 4 with your left hand, move it along the line along the cutting edge of the upper knife and repeat the cutting technique until it is completely cut. The scissors provide a cut without dents, cuts along the edge and sufficient accuracy.

Fly shears are widely used for cutting sheet metal with a thickness of 1.5 - 2.5 mm with a tensile strength of 450 - 500 MPa (45 - 50 kgf/mm2) (steel, duralumin, etc.). These scissors cut metal of considerable length. Lever shears have a cast iron frame and table. A lower stationary knife is built into the table, and an upper movable knife with a curved cutting edge is fixed in a knife holder. The upper movable knife has a counterweight that balances the knife holder with the knife.

The size of the workpieces to be cut is pre-marked or limited by an adjustable stop, for which the stop is first set at the required distance from the cutting edge of the lower stationary knife. During cutting, the sheet is tightly pressed with its side edge against the stop, and with the other edge against the spring stop. After this, by turning the handle away from you, the sheet is pressed tightly from above with a clamping bar and, lowering the upper nose with knife holder 6, the workpiece is cut.

When lowered, the knife holder rests against a spring stop. Rearrangement of the stop is carried out using the handle.

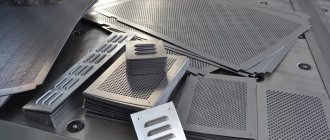

Shears with inclined knives (guillotine) allow you to cut sheet metal up to 32 mm thick, sheets with dimensions of 1000 - 3200 mm, less often strip products, as well as sheet non-metallic materials.

OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

2.1. Before starting work, you should put your work clothes in order:

- tuck clothes in so that there are no hanging parts;

- put on a tight-fitting headdress and tuck your hair under it.

2.2. Adjust the local lighting so that the work area is sufficiently illuminated and the light does not blind the eyes.

2.3. Prepare serviceable and stable equipment for stacking sheets and cut pieces (tables, shelves, etc.), as well as containers for scraps. If there is mechanization of stacking and harvesting of cut strips, strictly monitor the serviceability of the mechanisms.

Sheets to be cut should be placed approximately in the same plane with the scissors table and not far from them.

2.4. By external inspection, make sure that the power wiring and fences of other live parts are in good condition, as well as that there is no break in the protective grounding conductor.

2.5. Make sure that the guards of all moving parts of the transmission mechanism of the drive scissors (pulleys, belts, gears, flywheels, shafts), as well as safety bars or movable clamps and knives are present and securely fastened.

2.6. When using the pedal, check for the presence of a shield protecting the pedal from above. Test the pressing force on the pedal: it should not be very weak, but not strong either (2.5-3.6 kg).

2.7. Check the fastening and correct installation of the knives in accordance with the thickness and hardness of the material to be cut, as well as the correctness of their sharpening.

2.8. On mechanical shears, you should check at idle for the absence of double impacts (the serviceability of the engagement clutch), as well as the reliability of the brake.

2.9. On hand scissors, check the position of the counterweight: it should prevent the knife holder lever from being lowered arbitrarily and return it to the upper position when the lever is lowered.

2.10. Rigidly secure the stops that secure the sheet to be cut in accordance with the work to be done. The length of the cut strips should be less than the distance between the guide rods of the stop.

2.11. Prepare the tool required during work, provided by the technology, check its serviceability and place it on a special bedside table near the scissors in an order convenient for use.

§ 31. Cutting with hand scissors

Hand scissors are used for cutting steel sheets with a thickness of 0.5 - 1.0 mm and non-ferrous metals up to 1.5 mm. Hand scissors are made with straight (Fig. 110, a, 6) and curved (Fig. 110, c) cutting blades.

According to the location of the cutting edge of the blade, hand scissors are divided into right and left.

Right-handed scissors are those in which the bevel on the cutting part of each half is on the right side. Using right scissors, cut along the left edge of the product in a clockwise direction (Fig. 110, 6).

Left-handed scissors are those in which the bevel on the cutting part of each half is located on the left side. These scissors are used to cut along the right edge of the product counterclockwise (Fig. 110, c).

When cutting a sheet with right-handed scissors, a mark is always visible on the metal being cut. When working with left-handed scissors, in order to see the mark, you have to bend the cut metal with your left hand, passing it over your right hand, which is very inconvenient. Therefore, sheet metal is cut in a straight line and along a curve (circle, rounding) without sharp turns with right-handed scissors.

The length of the scissors I1 is 200, 250, 320, 360 and 400 mm, and the cutting part I2 (from the sharp ends to the hinge) is 55 - 65, respectively; 70 - 82; 90-105; 100 - 120 and 110 - 130 mm. Well-sharpened and adjusted scissors should cut paper.

The scissors are held in the right hand, grasping the handles with four fingers and pressing them to the palm; the little finger is placed between the handles of the scissors (Fig. 111, a).

The clenched index, ring and middle fingers are unclenched, straightened by the little finger and with its effort the lower handle of the scissors is moved to the required angle. Holding the sheet with your left hand (Fig. 111, b), feed it between the cutting edges, directing the upper blade exactly in the middle of the marking line, which should be visible when cutting. Then, squeezing the handle with all fingers of the right hand, except the little finger, they cut. In Fig. 111, c, d shows techniques for working with scissors.

Rice. 110. Hand scissors: a - straight left, b - straight right, c - curved left

Rice. 111. Cutting sheet metal up to 0.5 mm thick with scissors: a - position of the fingers on the handle when cutting with scissors, b - right, c - left, d - cutting out the internal curved contour

Rice. 112. Scissors: a - chair scissors, fixed in a vice, b - hand-held, fixed in a vice, c - chair scissors on a wooden base

Rice. 113. Power small-sized scissors

For straight cutting of metal of small thickness, hand scissors are used, one handle of which is clamped in a vice (Fig. 112, b):

Chair scissors (Fig. 112, a) differ from hand scissors in their larger size and are used when cutting sheet metal up to 2 mm thick. The lower handle is firmly clamped in a bench vice or fastened (hammered) onto a table or other rigid base. To cut sheet steel up to 2 mm thick, chair scissors with a stationary fastening are used (Fig. 112, a), which is not always convenient.

Chair shears are low-productive and require significant effort when working, so they are not used for cutting large batches of sheet metal.

Small-sized power shears. Innovator A. N. Vasiliev created small-sized power shears for cutting sheet steel up to 2.5 mm thick, rods, bolts (studs) with a diameter up to 8 mm. The dimensions of these scissors do not exceed the dimensions of standard hand scissors (Fig. 113). For cutting, handle 7 is secured in a vice, and handle 8 (working) is activated. The working handle is a system of two levers connected in series. The first lever 6, on one arm of which the knife 4 is fixed, is connected by means of a screw 3 to the handle 7.

The second arm of the lever 6, which is the handle of conventional scissors, is shortened and ends with a hinge 7, or the scissors handle itself. The end hinge of the handle 8 is connected to the handle 7 by means of two hinged links 2. This system of levers increases the cutting force by approximately two times compared to conventional scissors of the same dimensions. The scissor blades are replaceable and attached to the levers with hidden rivets.

These scissors also have a device for cutting rods with a diameter of up to 8 mm. The device has 5 disks with holes, mounted on the scissors' arms, and is a regular scissors, but with specially shaped knives (hardened bushings). These knives are replaceable and are inserted into the disk socket. For cutting bolts (studs), the bushings of one of the disks have a thread (several threads), which protects the threads of the bolts from being crushed when trimmed.

Small-sized power shears provide good cutting quality.

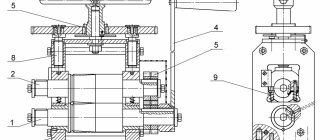

Hand lever scissors (Fig. 114) are used for cutting sheet steel up to 4 mm thick, aluminum and brass up to 6 mm. The upper hinged knife 3 is driven by lever 2. The lower knife 7 is stationary.

The knives are made from U8 steel and hardened to a hardness of HRC 52 - 60. The sharpening angles of the cutting edges are 75 - 85°.

Before work, check that they are lubricated. Are there any rubbing parts, does the lever move smoothly, is there any gap between the cutting edges.

When cutting metal, grab the handle 2 of the lever with your right hand and smoothly move it to the upper position, while the upper knife 3 moves upward. Then lay sheet 4 so that the left hand holds it in a horizontal position, and the cutting line is in the field of view and coincides with the blade of the upper knife 3. With a hand movement, lower the lever with the knife down until part of the metal is cut through, after which the lever is moved to the upper position. Next, slightly lift sheet 4 with your left hand, move it along the line along the cutting edge of the upper knife and repeat the cutting technique until it is completely cut. The scissors provide a cut without dents, cuts along the edge and sufficient accuracy.

Lever (fly) shears (Fig. 115) are widely used for cutting sheet metal with a thickness of 1.5 -2.5 mm with a tensile strength of 45 - 50 kgf/mm 2 (steel, duralumin, etc.). These scissors cut metal of considerable length. Lever shears have a cast iron frame 7 and a table 2. A lower stationary knife 8 is built into the table 2, and an upper movable knife 5 with a curved cutting edge is fixed in a knife holder 6. The upper movable knife 5 has a counterweight 7, balancing the knife holder with the knife.

The size of the workpieces to be cut is outlined by preliminary marking or limited by an adjustable stop 10, for which the stop is first set at the required distance from the cutting edge of the lower stationary knife. During cutting, sheet 3 is pressed tightly with its side edge against the stop 10, and with the other edge against the spring stop 11. After this, by turning the handle 12 away from you, the sheet is tightly pressed from above with the clamping bar 9 and, lowering the upper knife with the knife holder 6, the workpiece is cut.

Rice. 114. Hand lever scissors: 1 - lower knife; 2 — lever; 3 - upper knife; 4 - sheet to be cut

Rice. 115. Lever (fly) scissors: 1 - bed, 2 - table, 3 - sheet, 4, 12 - handles, 5 - movable knife, 6 - knife holder, 7 - counterweight, 8 - fixed knife, 9 - clamping bar, 10 — stop, 11 — spring blow

When lowered, the knife holder rests against the spring stop 11. The stop is moved using the handle 4.

Rice. 116. Scissors with inclined knives

Shears With inclined knives (guillotine) allow you to cut sheet metal up to 32 mm thick. They have a lower fixed and upper movable knife, the upper one is inclined at an angle of 2 - 6°. This ensures a gradual entry of the knife into work, facilitates cutting, and ensures high-quality cutting. The lower knife is attached to the back of the table 2 (Fig. 116), mounted on the frame 7, the upper knife is attached to the slider 7. The crank shaft 4 rotates from the electric motor 6 through a V-belt drive.

Two eccentrics 5 mounted on it impart reciprocating movement to the slider along the guides of the posts 3. The sheet to be cut is placed on the table against bracket 9 and pressed with clamp 8.

Electric scissors

To speed up cutting and make it easier to work with sheet metal, metal tiles and profiled sheets, electric shears are used. They can be of two types:

- Cutting (nibblers);

- Knife.

Cut-in models cut corrugated sheets , so they can be used when arranging a metal roof. They are distinguished by the fact that during work with them, sparks do not fly out, and the roofing covering of the material is not deformed, which happens when cutting with a grinder.

Plunge shears make it possible to cut a sheet not only from the edge, but also from the center. To do this, you need to make a hole where the cutting edge of the scissors is installed.

The principle of their operation can be described by comparing the operation of a hole punch: the moving part - the punch - cuts holes in the metal. Due to the fact that it moves quickly, the edges of the cut come out smooth. This tool is also called punch shears.

Another type of electric scissors is knife scissors. This tool can be splined or sheet .

The design of the sheet ones is similar to the usual ones: two blades are installed. The lower one stands clearly, the upper one moves thanks to the force created by the electric motor. These electric metal shears are also called cutout shears because they can make curved cuts.

Adjusting the scissors consists of adjusting the gap between the two cutting edges. There is no waste or chips when working with this equipment. Their main drawback: they crush corrugated sheets, but cut smooth material well. Their maintenance is very simple, only the lower cutting edge becomes dull and needs to be replaced periodically.

Slotted scissors also have fixed and movable cutting edges , but there are three of them. Two fixed ones are attached at a certain distance from each other, the movable one is in the center, between them. The metal is placed between the fixed and movable knives.

During cutting, chips a couple of millimeters in size appear. It curls into a spiral at the side of the scissors. The cut edge comes out smooth and does not require additional processing. This type of tool can cut both profiled and sheet products, and it is easy to make cuts of any geometry. Slotted shears are also suitable for cutting metal tiles and corrugated sheets.

Cutting sheet metal with hand scissors

Hand scissors are used for cutting sheet metal with a thickness of 0.5-0.8 mm along straight and curved marking lines. Preparation for cutting consists of straightening the sheet, marking cutting lines, performed on clean (galvanized, tin-plated and black) sheets without painting by directly applying marks to the surface of the sheet. Scissors are chosen depending on the nature of the work being performed.

The most commonly used scissors are 250 - 300 mm long. Scissors are selected depending on the conditions of the work being performed: a) for straight cutting - with straight and wide blades; b) for external curved cutting with curved wide blades; c) for cutting along internal curved lines - with curved narrow blades. In addition, depending on the nature of the work, right and left scissors are used. They are distinguished from each other by the location of the bevel of the cutting edge of the lower jaw. If during cutting this bevel is located on the right side, then the scissors are called right, if on the left side - left. When working with scissors, the cutting line should always be in the field of vision of the worker.

The edges of the scissors in the articulated joint should fit snugly against each other and move easily. With a tight move, a lot of friction occurs, causing excessive effort in work and rapid wear of the cutting edges. If there is a large gap between the cutting edges, the material being cut will wrinkle and jam.

Rice. 82. Position of fingers on the handle when cutting with scissors

The scissors are held in the right hand, grasping the handles with four fingers and pressing them to the palm; the little finger is placed between the handles of the scissors (Fig. 82). The clenched index, ring and middle fingers unclench, straighten the little finger and, with its effort, move the lower handle of the scissors to the required angle. Holding the sheet with your left hand (Fig. 83), feed it between the cutting edges, directing the upper blade exactly in the middle of the marking line, which should be visible when cutting. Then, squeezing the handle with all fingers of the right hand (except for the little finger), cutting is carried out.

Rice. 83. Method of cutting with scissors according to direct risks

When cutting straight, you should use left-handed scissors and adjust the opening of the scissors to such an extent that they can grab the sheet to a size of no more than 30 mm along the straight line. The cutting edges should not be fully opened, since they do not cut, but push out the sheet.

Rice. 84. Reception and direction of cutting along curved external marks with right-handed scissors

Rice. 85. Reception and direction of cutting along curved external marks with left scissors

When cutting external curved contours, the sheet is turned so that the scissors do not cover the cutting line. In Fig. Figure 84 shows the cutting direction with right scissors, and Figure 85 shows the cutting direction with left scissors. The fingers of the left hand supporting the sheet from below should be in such a position that they do not fall into the cutting zone of internal curved contours with scissors with curved narrow cutting edges (Fig. 86).

Rice. 86. Cutting a round hole

It is used to cut metal with hand scissors while clamping one handle in a vice (Fig. 87). This technique is used for straight cutting of thick metal.

Rice. 87. Cutting with scissors clamped in a vice

The quality of cutting is determined by checking the cutting lines for marks, the absence of cuts, dents and burrs.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. You should stop working, turn off the equipment you are using, and report the incident to the work manager if at least one of the following malfunctions occurs:

- loosening of the guillotine shear knives;

- malfunction of the safety device of knives and clamps;

- malfunction of the counterweight on manual shears;

- brake malfunction on mechanical shears;

- faulty fastening of guards on all moving parts of the transmission mechanism of the drive shears;

- malfunction of devices;

- faulty power wiring;

- break of the protective grounding conductor;

- the occurrence of a situation involving a lack of lighting.

4.2. In case of an accident you should:

- take measures to free the victim from the traumatic factor;

- provide the victim with first aid depending on the type of injury;

- inform management about the incident;

- preserve the situation as much as possible if this does not lead to an accident or injury to other people;

- if necessary, call an ambulance by calling 103 or help transport the victim to a medical facility.

4.3. In the event of a fire:

- stop working;

- turn off electrical equipment;

- call the fire department by calling 101 and inform the management of the organization;

- begin to extinguish the fire using available fire extinguishing equipment.

4.4. In case of electric shock, you should:

- turn off electrical equipment;

- free the victim from live parts;

- provide the victim with first aid;

- inform the head of the organization about the incident;

- if necessary, call an ambulance by calling 103 or help transport the victim to a medical facility.

Cutting sheet metal with hand scissors

You can cut sheet metal into separate parts, cut holes in parts, make parts with a curved contour, and perform other similar work using hand scissors. Depending on the location of the cutting edge of the scissors blade (to the right or left of the lower blade), they are called right (Fig. 47, a) or left (Fig. 47, b). Hand scissors are made with straight (Fig. 47, a, b) and curved (Fig. 47, c) cutting blades.

Rice. 47. Hand scissors: a, 6 - with straight cutting blades; c - with curved cutting blades; g - special design; d - geometry of cutting blades

Hand scissors with straight cutting blades are used for cutting sheets, strips and strips of steel up to 0.7 mm thick, and non-ferrous metals up to 1.5 mm thick along straight lines. Scissors with curved cutting blades are used when cutting sheets, strips and tapes from steel up to 0.6 mm thick, and from non-ferrous metals up to 1.2 mm thick along curved lines or when cutting out parts with a combination of curves and straight lines.

Hand scissors in accordance with GOST 7210-54 are manufactured in lengths of 200, 250, 320 and 400 mm; in this case, the width along the outer circumference of the handles in the closed position, corresponding to the total length, is 40, 40, 50, 55 mm.

Scissors consist of two halves, which are made in one piece or in parts with welded blades. Solid halves of scissors are made of carbon steel 65, 70. Handles of welded scissors are made of carbon steel not lower than grade St. 2, and the blades are made of tool carbon steel U7 with heat treatment to a hardness of HRC 52-58. The cutting edges of the blades are sharpened sharply at an angle of 70-75° (Fig. 47, (3). The blades and surfaces of the scissors should be free of blockages, snatches, crumbled places, burrs, shells, caps, hairs, nicks and cracks.

The blades of the scissors should overlap each other when closed, and the overlap at the ends should not exceed 2 mm. Both halves must be connected using a screw and nut and ensure a tight fit of the halves without distortions or play. Scissors should cut with any part of the cutting edges; in this case, their STROKE should be smooth without jamming.

In Fig. 47, d shows hand scissors that differ from ordinary ones in the shape of knives. The lower knife is straight and the upper one is curved towards the cutting edge. The lower knife is equipped with a special flange, thanks to which the part of the sheet being cut is bent and the scissors freely pass along the marking line along the entire sheet to be cut. Thanks to this shape of the knives, cutting with these scissors is carried out with less effort. These scissors have handles located at an angle of 30° to the cutting plane, which eliminates the possibility of cutting your hands. These shears cut sheet metal in half the time than regular hand shears.

Sheet metal is cut with hand scissors, usually along marking lines pre-marked on the surface of the sheet metal.

Rice. 48. Working with scissors: a - cutting a sheet into wide strips, b - cutting a sheet with left scissors, c - cutting out round-shaped blanks, d - cutting out a part with curved outlines, e - cutting a hole in a part

When cutting sheets into wide strips, bend the cut strip with your left hand without making sharp bends (Fig. 48, a). This will make it easier for the scissors to advance when cutting and will protect your right hand from getting cut.

When cutting a sheet with the left scissors (Fig. 48, b) into narrow pieces, make sure that they bend forward.

When cutting sheet metal along a curved contour, for example, when cutting a circle with left-handed scissors, cut in a clockwise direction, positioning the scissors so that they do not cover the marking lines with the blade (Fig. 48, c).

Parts with a curved outline are cut out with right scissors counterclockwise (Fig. 48, d).

When cutting, the scissors open approximately 2/3 of the blade length so that they can grip and cut the metal well without much force. Strongly opened blades do not cut, but push metal out.

It is necessary to ensure that the cutting plane is perpendicular to the sheet being cut, since misalignment of the scissors leads to crushing of the metal along the edge of the cut, jamming and the formation of burrs.

When moving the scissors forward, they are pressed tightly against the end of the cut, otherwise burrs will inevitably appear. Cut holes in the parts using scissors with curved cutting blades (Fig. 48, d).

What to consider when choosing metal scissors

Blade arrangement option .

According to this criterion, left and right scissors are separated. With the latter, the lower cutting edge is on the right and this is convenient when you need to cut an arc from left to right. In cases where it is necessary to cut radii in the other direction, scissors with the blade positioned on the left at the bottom are used. Blade shape . The blades are straight (they are equipped with straight mechanical scissors, which make a through and straight cut). The curved shape of the cutting edge will allow you to make curved or shaped cuts, as well as align the edges.

Cutting capabilities . As a rule, two parameters are given for this characteristic, or more precisely: the thickness of stainless and cold-rolled steel (for example, 1.5 and 1 millimeter). It is necessary to select scissors with the appropriate characteristics, taking into account the thickness of the sheets you will need to work with.

From time to time it is necessary to pay attention and adjust the distances between the two blades of the scissors, since if the blades move very tightly, then it will be difficult to cut the metal with this tool, and, conversely, if the blades move very freely, then when cutting the metal will begin to wrinkle, or so to speak, chew. When you need to sharpen your blades, remember that you need to clearly maintain the old bevel angle. Use scissors only for their intended purpose and correctly; in this case, they will serve you for a very long time.

In this case, metal scissors can be electric or manual . In each group there are several types that differ in their scope of use.

Cutting metal with scissors

Cutting with hand scissors. Scissors are used for both manual and machine cutting of metals. According to GOST 7210, hand scissors are manufactured in three types:

- • 1 – straight cutting;

- • 2 - for cutting holes;

- • 3 for shape cutting.

Scissors of all types are manufactured in a left-handed design (the lower blade is located on the left), and upon customer request, in a right-handed design (the lower blade is located on the right). In Fig. 6.33 shows the appearance, and table. 6.1 shows the main dimensions of the scissors.

Table 6.1. Dimensions of hand scissors according to GOST 7210

The connection of the scissor arms in the hinge should not be distorted. It should ensure a tight fit of the contacting surfaces, while the scissors should open and close smoothly, without jamming, with a force applied in the grip area of the handles of no more than 2 N for scissors with a length of 200 and 250 mm and 3 N for scissors with a length of 320 and 400 mm.

As the scissors close, contact of the cutting edges in the cutting zone must be ensured as it moves along the entire length of the cutting part, for which

Rice. 6.33. Hand scissors

the internal surfaces of the blades are curved relative to the cutting plane: the left blade - to the right, and the right blade - to the left.

In scissors closed all the way, the blades should overlap each other, and the overlap at the ends of the blades should be:

- • 1.0-2.5 mm for scissors 200 and 250 mm long;

- • 1.0—3.0 mm for scissors 320 mm long;

- • 2.0-4.0 mm for scissors 400 mm long.

In plumbing, scissors with a length of 250-300 mm are most often used.

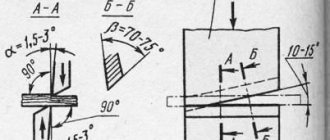

The sharpening angle of the scissors ranges from 65 to 85° depending on the hardness of the metal being cut. For soft metals (copper, etc.) it is 65°, for medium-hard metals 70-75°, for hard metals 80-85°. To reduce the friction of the scissors knives when working on the blades, a rear angle oc = 1.5–3.0° is created (Fig. 6.34). The scissor knives are made of carbon steel U7 and U7A in accordance with GOST 1435 or from steel grade 8HF in accordance with GOST 5950, the axis is made of steel grade 35 in accordance with GOST 1050, the cutting part of the scissors is hardened.

Rice.

6.34. The sharpening angles of the scissors knives: 1 - upper knife; 2 - lower knife

In plumbing, both right and left scissors are used, fig. 6.35. When cutting a sheet with right-handed scissors, a mark is always visible on the metal being cut. When working with left-handed scissors, in order to see the mark, you have to bend the metal being cut with your left hand, passing it over your right hand, which is very inconvenient. Therefore, cutting sheet metal straight

Rice. 6.35. Right (top) and left (bottom) hand scissors and use of right scissors

lines and along curves (circles and curves) without sharp turns is done with right scissors.

The edges of the scissors in the articulated joint should fit snugly against each other and move easily. With a tight move, a lot of friction occurs, causing excessive effort in work and rapid wear of the cutting edges. If there is a large gap between the cutting edges, the material being cut will wrinkle and jam.

Using hand scissors, you can cut sheet steel up to 0.7 mm thick, roofing iron up to 1 mm thick, and copper sheets up to 1.5 mm thick.

When cutting metal, the scissors are not opened completely, but only enough so that they can grab the sheet to a size of no more than 30 mm along the direct line. The cutting edges should not be fully opened, since they do not cut, but push out the sheet.

The scissors are held in the right hand, grasping the handles with four fingers and pressing them to the palm. The little finger is placed between the handles of the scissors, fig. 6.36 a.

The clenched index, ring and middle fingers unclench, straighten the little finger and, with its effort, move the lower handle of the scissors to the required angle.

Holding the sheet with your left hand (Fig. 6.36 b),

feed it between the cutting edges. Guide the top blade exactly in the middle of the marking line, which should be visible when cutting. Then, squeezing the handle with all fingers of the right hand (except for the little finger), cutting is carried out.

Rice.

6.36. The position of the fingers on the handles when cutting with scissors (a), the technique of cutting with scissors using

direct marks (b)

When cutting external curved contours with scissors, turn the sheet so that the scissors do not cover the cutting line. In Fig. 6.37 a

the cutting direction is shown to the right, and in Fig.

6.37 b -

left scissors. The fingers of the left hand, supporting the sheet from below, should be in such a position that they do not fall into the cutting zone.

Cutting out internal curved contours is done with scissors with curved narrow cutting edges, Fig. 6.38p.

It is also used for cutting metal with hand scissors with one handle clamped in a vice, Fig. 6.386. This technique is used for straight cutting of thick metal.

Rice. 6.37. Acceptance and direction of cutting along curved external marks with right (a) and left (b) scissors

Rice.

6.38. Cutting a round hole (a) and cutting with scissors clamped in a vice (b)

The quality of cutting is determined by checking the cut line for marks, the absence of cuts, dents and burrs.

Cutting metal with hand lever scissors. Hand lever shears are used for cutting sheet steel up to 4 mm thick, aluminum and brass up to 6 mm thick. Before work, check the quality of lubrication of the rubbing parts, the smooth movement of the lever, the absence of a gap between the cutting edges and their tight fit to each other. The tight movement of the knives requires a lot of effort in operation and causes premature wear of the cutting edges. A large gap between the cutting edges impairs the quality of the cut, the sheet wrinkles, the knives become dull and break.

When cutting metal with hand lever scissors (Fig. 6.39), grab the lever handle with your right hand and move it to the upper position (the upper knife rises). The sheet is then placed on the cutting edge so that the left hand holds it in a horizontal position, and the cutting line is in the field of view and coincides with the blade of the upper knife. The lever with the knife is lowered down until part of the metal is cut through, then the lever is raised. With your left hand, lift the sheet, move it along the line along the cutting edge of the upper knife and repeat the cutting technique.

Rice. 6.39. Sheet cutting with hand lever shears

The quality of cutting is characterized by the absence of dents and the cutting accuracy of the marks.

Cutting sheet material with hand-held electric scissors. Electric shears (Fig. 6.40 and Fig. 6.41) are hand-held portable power tools and are designed for cutting sheet material along a straight or curved contour with a thickness of the steel sheet being cut up to 2.7 mm. Before you start work, you must study and follow the “Standard labor protection instructions when working with hand-held power tools” (RD 153-34.0-03.299/4—2001). Besides,

Rice. 6.40. Electric scissors for cutting (left) and cutting (right)

Rice. 6.41. Electric nibblers (left) and knife scissors (right)

It is necessary to check the sharpness of the electric scissors knives - the cutting edge should be sharp without dents or chips.

The insertion of the scissor knives should be approximately 4 mm, fig. 6.42 a.

Too much insertion of the knives makes it difficult to cut along a curve, and if there is no overlap, the scissors stop cutting metal along their entire length, fig. 6.425. The entry of the knives is set using adjusting screws. The gap between the knives depends on the thickness of the material being cut.

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. Workers over 18 years of age who have undergone a medical examination, completed an introductory briefing on labor protection upon hiring and initial briefing at the workplace, as well as repeated and, if necessary, unscheduled and targeted briefings on labor protection, are allowed to work on metal cutting with scissors, have mastered safe techniques for cutting metal with scissors and have passed a knowledge test of labor protection requirements.

1.2. Employees allowed to perform work must comply with the internal regulations established by the organization.

1.3. When working with scissors, you should follow a work and rest schedule. Relaxing and smoking are allowed in specially designated and equipped areas.

1.4. It is allowed to work only with those scissors that are indicated in the technological map for performing this operation, and to perform only the work that is assigned by the employer.

1.5. During work, when cutting metal with scissors, a worker may be exposed to the following dangerous and harmful production factors: noise, dust, unfavorable microclimate parameters, the danger of hand cuts when placing sheets on the table and the possibility of workers’ fingers getting caught under knives and clamps.

1.6. Workwear, special footwear and other personal protective equipment are issued to employees in accordance with current standards and the work performed.

1.7. Workwear, safety shoes and other personal protective equipment should be stored in specially designated areas in compliance with storage rules and used in good condition.

1.8. Workers must comply with fire safety rules, know fire warning signals, the location of fire extinguishing equipment and be able to use them.

1.9. In the event of an accident, stop work, notify management and seek medical attention.

1.10. In the event of an accident with another employee, first aid should be provided and sent to a medical facility.

1.11. Workers performing work with scissors must observe personal hygiene rules (wash hands with soap or take a shower).

1.12. If any questions arise during the work related to its safe performance, you should contact the employee responsible for the safe performance of work.

1.13. Employees who do not comply with the requirements of this instruction are liable in accordance with the current legislation of the Russian Federation.

How to choose scissors, their prices

It is difficult to say how necessary these tools are in everyday life; it depends on the household and the amount of work that needs to be done. When the metal work is one-time, for example, you need to make a roof from metal tiles, then hand-held shears for cutting metal are quite suitable. This tool costs from 50 to 2000 rubles .

More expensive professional scissors made of forged steel using alloy metals. This tool can cut black sheet steel up to 1 millimeter, stainless steel up to 0.5 millimeters.

Mechanical hydraulic shears will obviously be needed when cutting reinforcement. You can, of course, cut the rod using a grinder, but not every facility has electricity. Then this tool will help. Their price is about 1.8-2.8 thousand rubles . By and large, this is a multi-purpose tool, therefore, even then, during the further construction of a bathhouse or other building, or the arrangement of a site, there will definitely be work for them.

With electric scissors - slotted or mortise, you can cut metal tiles or corrugated sheets without much effort and very quickly. They create a smooth edge and do not harm the coating of the material. There is a very wide range in the cost of power tools, in this case you need to look at the description and photo. It, like everything else, is divided into professional and household. The latter are inexpensive, but have a short operating time due to the use of cheap materials.