Description and types of wire SV08G2S

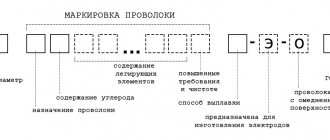

Welding wire SV08G2S is an excellent consumable material for welding. When using it, a product with a perfect, even seam is obtained. It is not difficult to decipher the markings of this wire, although not many people know exactly what all these numbers and letters mean. How is the SV08G2S marking deciphered?

- The first two letters - SV, indicate that this is a welding wire.

- The numbers that follow - 08 indicate the carbon rate.

- G is the manganese present in the composition.

- The next figure is the amount of manganese in the composition, that is, 2%.

- Finally, the letter C stands for silicon. If there is a number behind it, then it indicates the amount of silicon, but in this case there is no number, and this means that there is up to 1% silicon here.

Important!

This type of wire is compatible with any type of welding machine.

Just by the name of this brand you can tell a lot about it. For example, manganese indicates increased bond strength. Silicon improves the mechanical properties of the material after welding.

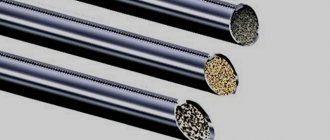

This type of wire is produced in 2 types.

- The first option is with a copper layer. In the marking, there is always a letter O at the end, which means “copper-plated” (SV08G2S-O). It can have a cross-section from 0.8 to 2 mm. Dimensions – 0.8, 1.0, 1.2, 1.4, 1.6 mm.

- The second option is without coverage. Diameter from 0.6 to 6 mm.

Photo welding wire SV08G2S

Distinctive features

When choosing welding materials, both production technologists and home craftsmen are faced with a serious question. He needs to find wire or electrodes that provide high quality seam joints, are unpretentious to welding conditions, and, last but not least, are not too expensive. When compared, SV08G2S wire comes out ahead in many respects.

SV08G2S has the following features compared to other welding materials:

- promotes stability of the electric arc, reduces the risk of electrode sticking to the surface of the workpiece;

- supports a wide range of welding modes;

- compatible with most types of welding machines;

- allows you to minimize the splashing of molten metal;

- facilitates re-ignition of the welding arc;

- helps save other consumables, such as copper tips.

Automatic wire welding

The combination of these features allows us to weld strong and durable seams, with high-quality edge penetration, uniform in composition and with a minimum of porosity and other defects.

Application of wire SV08G2S

Also check out these articles

- Features of making custom magnets

- Types of shower cabins

- What is industrial water treatment

- Materials for making kitchen countertops

In industry, this welding wire is used very often. Moreover, these can be a wide variety of types of industry. It is often purchased for semi-automatic and automatic welding machines. The wire is suitable for welding joints and surfacing.

Most often it is taken:

- when sewing holes between parts of the workpiece;

- to form a bead on the seam.

Often this alloy wire is used as a filler material.

Due to the optimal amount of silicon and manganese in the composition, welding wire SV08G2S is also used for surfacing. It allows:

- obtain a higher level connection;

- reduce the cost of manufacturing welded material;

- achieve a strong seam.

Standard and designation

To carry out high-quality welding work during construction or repair, welding wire GOST 2246-70 is used. It was introduced on January 1, 1973 and is currently in force with amendments and additions. It applies to cold-rolled steel made from low-carbon, alloy and non-alloy steel. Defines technical specifications, grades and classification.

The text provides examples of symbols for welding wire with interpretation. For example, welding wire Sv-08G2S–0 GOST 2246–70.

- It is designed for welding, which is designated “St”.

- It has a copper-plated surface - the letter “O”.

- The number “08” indicates a low carbon content of 0.08%, that is, low carbon.

- “G2” determines the manganese content - 2%.

- “C” - silicon, after which there is no number, this means its share is less than 1%.

- The total amount of alloying elements, that is, elements added to impart certain qualities and properties, is more than 2.5%. In this case, it is considered doped.

It is used when working with automatic and semi-automatic devices, as a rule, in ship, aircraft, mechanical engineering and construction. It is also used for gas-shielded arc welding.

Characteristics of welding wire SV08G2S

Steel welding wire SV08G2S GOST 2246-70. The chemical composition of this material is described in the table below.

| Element | Quantity (%) |

| Nickel | Up to 0.25 |

| Chromium | Up to 0.2 |

| Sulfur | 0,025 |

| Manganese | 2 |

| Silicon | Up to 0.95 |

| Carbon | 0,08 |

| Phosphorus | 0,03 |

Copper-plated welding wire - SV08G2S-O - is deservedly popular. The copper layer promotes increased conductivity due to reduced resistance at the point of contact. This property significantly increases the stability of the electric arc and increases the strength and, most importantly, durability of the suture material.

Copper in the copper-plated type can be up to 0.3%, taking into account the coating itself, which is not less than 0.1 microns. When the wire is made to order, its composition may include: vanadium, titanium, molybdenum, at the request of the customer.

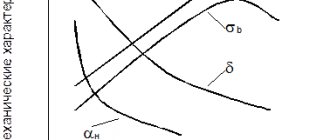

Now directly about the characteristics of the SV08G2S wire.

- Vel. tensile strength for material with a cross section of up to 1.5 mm – 882-1372 MPa.

- Vel. tensile strength for a material with a cross section of 2 mm is 686-1029 MPa.

- The relative elongation indicator is from 30%.

- Yield strength – 415-440 MPa.

Important!

SV08G2S wire enhances the stability of the welding arc and thanks to this, the electrodes stick less.

- Impact strength at 40 degrees Celsius is 56 J/cm², and at 20 degrees Celsius – 69 J/cm².

- High deposition rate.

- Heat treatment of wire marked O is possible.

- A soapy, lubricating film often appears on the surface of this material, but this is allowed even according to GOST.

Photo welding wire SV08G2S-O copper-plated

mechanical characteristics

Manufacturers are required to conduct strength tests. Each batch of welding wire 08g2s must meet the following standards:

| Diameter, mm | Tensile strength, kgf/mm2 | |

| surfacing | Welding | |

| Less than 1.5 | 89-136 | — |

| 1,6 | 89-136 | 69-101 |

| 2,0 | 79-121 | 69-101 |

| Over 2 | 69-106 | 64-96 |

The relative elongation coefficient is at least 30%. The yield strength of the product should fall in the range of 415-440 MPa. The value of the impact strength of the material measured at 40 °C is 56, and at 20 °C is 69 J/cm2.

GOST standards also standardize some other characteristics of SV08G2S.

Deposition factor

We recommend reading our other articles

- Online wallpaper store: 3 roll designs that transform a room

- Simplicity and convenience of repair using special tools

- Instrumentation for determining air humidity

- Stylish chandeliers - selection criteria

During surfacing, the welder must know the welding coefficient of the wire that he is using. After all, this indicator depends on:

- quality of the final product,

- loss of the weld due to evaporation, oxidation, spattering,

- amount of melting of the base material, etc.

Important!

Works with SV08G2S wire in most welding modes.

This coefficient indicates the value that describes the metal deposited in the allotted time at a specific current strength. Wire SV08G2S has a deposition rate within 8.5 g/A*h, however, it may differ for different materials, because this value is influenced by:

- components used during wire creation;

- polarity and type of current used in the work;

- product coating.

BRANDS AND CLASSIFICATION

1.1. The wire must be made of the following grades:

low-carbon - Sv-08, Sv-08A, Sv-08AA, Sv-08GA, Sv-10GA and Sv-10G2;

alloyed - Sv-08GS, Sv-12GS, Sv-08G2S, Sv-10GN, Sv-08GSMT, Sv-15GSTYUTSA (EP-439), Sv-20GSTUA, Sv-18KhGS, Sv-10NMA, Sv-08MH, Sv-08KhM , St. -08ХН2М, Sv-10ХН2ГМТ (ЭИ-984), Sv-08ХН2ГМТА (EP-111), Sv-08ХН2ГМУ, Sv-08ХН2Г2СМУ, Sv-06Н3, Sv-10Х5М;

high-alloy - Sv-12Х11НМФ, Sv-10Х11НВМФ, Sv-12Х13, SV-20Х13, Sv-06Х14, Sv-08Х14GNT, Sv-10Х17Т, Sv-13Х25Т, Sv-01Х19Н9, Sv-04Х19Н9, Sv-08Х16Н8М2 (EP-377) . 9Н10М3Т, Sv-08Х19Н10М3Б (EI-902) Sv-07Х25Н13, Sv-08Х25Н13БТУ (EP-389), Sv-13Х25Н18, Sv-08Х20Н9Г7Т, Sv-08Х21Н10Г6, Sv-30Х25Н16Г7, Sv-10Х16Н25AM6, Sv-09Х16Н25М6AF (EI-981А), Sv-01Х2 3N28M3D3T (EP-516) , Sv-30Х15Н35В3Б3Т, Sv-08Н50 and Sv-06Х15Н60М15 (EP-367).

(Changed edition, Amendment No. 2).

1.2. According to purpose, the wire is divided into:

for welding (surfacing);

for the manufacture of electrodes (symbol - E).

The purpose of the wire must be specified in the order.

1.3. Based on the type of surface, low-carbon and alloy wire is divided into:

non-copper-plated;

copper-plated - (O).

Special requirements for copper plating of the wire surface (including the total copper content) are established by technical specifications approved in the prescribed manner.

The need to supply wire with a copper-plated surface is specified in the order.

(Changed edition, amendment No. 2).

1.4. At the consumer's request, the wire must be made from steel smelted by electroslag (SH) or vacuum-arc (VA) remelting or in vacuum induction furnaces (VI). In this case, additional requirements for the wire metal (tightening standards for the content of harmful and foreign impurities, introducing restrictions on the content of gases, non-metallic inclusions, etc.) are established by agreement of the parties.

Price and release form

Welding wire SV08G2S is made in accordance with GOST 2246-70. The permissible cross-section is from 0.3 mm. It is collected into coils (bundles) weighing 5 and 15 kg. Large-section material is sold in coils and coils weighing 80-250 kg. If the wire is copper-plated, then the coils are most often produced rectangular, up to 50-90 mm in height. Internal diameter – 100-400 mm, external – 175-600 mm.

If there is a certain permission, SV08G2S alloyed wire can be supplied in cassettes or reels. It is wound carefully so that there are no breaks in the thread. The wire is wound in straight rows, one to one, to eliminate the chance of unwinding and tangling during transportation.

The price is affected by the size of the skein, coil, type of wire, and it can range from 100 rubles per kilogram. If you take packs with a large weight, then, for example, wire weighing 250 kg is sold on average for 30,000-40,000 thousand rubles. And, of course, this material can be purchased in bulk. It will be much cheaper, but such a purchase is practiced only in large productions.

Decoding wire markings and its main advantages

The abbreviation Sv-08G2S only at first glance is an incomprehensible set of numbers and letters. It is easy to decipher: the two letters at the beginning of “Sv” mean that this is a welding material. “08” indicates the C content in hundredths of a percent; the letter “G” is established by GOST to indicate Mn. Manganese was added to streamline the crystalline structure of the weld. The following number “2” indicates the content of this element as a percentage. The letter "C" stands for Si, the absence of numbers means that the Si content is less than one percent. This element is added to improve physical and mechanical properties.

Maintaining the proportion of Si to Mn at 0.83 to 1.95 makes it possible to achieve stability of the chemical composition against the background of increased strength and durability of the weld.

Download GOST 2246-70

The wire also contains the other chemical elements mentioned above, such as nickel, chromium, copper, sulfur and phosphorus. According to GOST requirements, since their content is less than one percent, they are not reflected in the designation.

Material Sv-08GS Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells Sv-08GS material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, Sv-08GS material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.