A compact radial drilling machine, even with its small dimensions and simple design, allows you to solve many problems associated with the need to produce holes in metal parts. An important quality is the versatility of such equipment, which is used to equip both small repair shops and production workshops of large enterprises.

Radial drilling machine RD 60

Designation

According to the classification, ENIMS are designated as follows: the first number in the marking indicates the group “Drilling and boring machines”, the second - the type - “Radial drilling machines”, the third and fourth - the maximum drilling diameter. Letter – the machine was modernized. For example, 2B56 is a radial drilling machine with a maximum drilling diameter of 60 mm.

Modern imported models of machine tools do not have a designation standard - each manufacturer designates models according to its own standard. For example, Optimum classifies its radial machines into light (RB) and heavy (DR): RB6, RB8, DR5, DR6; Proma stands for heavy machine RV-32; Jet – JRD: JRD-460, JRD-720R, JRD-1100R.

The lack of a standard leads to confusion and complicates the selection of analogues.

Purpose of the drilling machine

The drilling device performs its main function by removing chips with a cutting tool - a drill.

The drilling machine is capable of forming two types of holes, the creation process of which is different:

- Through. Passes through the entire thickness of the workpiece. When working with such a hole, you need to reduce the drill feed in time to keep it operational.

- Deaf. Has a certain depth. Some machines are equipped with automatic spindle feed shutdown when pre-entered parameters. In the absence of such a function, you can use a special chuck or make a mark on the drill, which, of course, has a lower level of accuracy of the operation.

Drilling machines are mainly produced for industrial production, so most of these devices are industrial machines. There are also small models for home use - they have fewer functions. However, all types of machines have common basic elements and operate according to the same principle.

Layout

The equipment has a unique layout: a column and a table are installed on a stove. A traverse is attached to the column, moving along the column in a vertical position, and it also has the ability to rotate relative to the column by 360 degrees. A drilling (spindle) head is installed on the traverse, moving relative to the traverse in the horizontal direction. It is designed as a separate unit. If it needs to be fixed in a certain position, then there is a clamping mechanism for this purpose.

On the market you can find desktop radial drilling machines that are similar in layout to vertical drilling machines. Their main difference from the classic layout is the ability to move the table in the vertical direction instead of moving the traverse.

Vertical drilling machine Enkor Corvette 48

Optimum RB6T

Work and operation

In devices of this type, the gearboxes and operating gears are located in the drill headstock.

Accordingly, all the main organs in units 2m55, 2k52, 2a554, as well as ac2532, 2n55 and 2532l are located directly on its front surface.

Video:

The main movement during which cutting is carried out in devices of this class is considered to be the rotation of the working tool used.

It receives the necessary rotational movement through a transmission directly from the electric motor, which also provides, if necessary, auxiliary movement of the working tool used.

IMPORTANT TO KNOW: Types of metal planing machines

Before starting work, the parameters of the specified processing are set using special handles located on the gearbox.

Feed control occurs in exactly the same way. The main operating characteristics of the unit are described by several indicators.

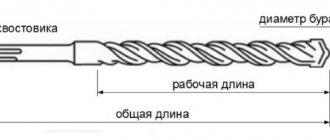

First of all, what matters is the nominal diameter of the maximum value that can be processed with a drill.

The main number of the attached cone, which is located inside the spindle, is also taken into account.

The greatest movement of the spindle itself is also taken into account.

These devices also provide a different range of revolutions at which the spindle can rotate.

When operating drilling machines of this class, the number of steps responsible for the working rotation in the spindle must be taken into account.

Video:

The functionality of the machine is greatly influenced by the power of the electric motor used.

It is also worth noting that the cost of devices from this category is influenced, first of all, by the functional set, all its technological capabilities, as well as the technical condition.

Repair of a drilling machine should be carried out by professional craftsmen who are well versed in the structure and operating principle of units of this class.

When operating the unit, it is imperative to carry out regular maintenance.

This will help extend the life of the device and make it safe to use.

A prerequisite for working on devices of this class is strict adherence to safety regulations that every operator must follow.

In any case, a tabletop drilling machine of this class is considered reliable and quite functional equipment, with which you can perform high-quality processing of various metal surfaces.

Types of machines

Depending on the operating conditions and the specifics of production, radial drilling machines are divided into several types:

- general purpose;

- general purpose with rotation of the drilling unit;

- on the guides of the bed;

- mounted on rails;

- portable (mobile);

- wall-mounted

General purpose radial drilling machine General purpose radial drilling machine with rotating drill assembly Radial drilling machine on bed guides Radial drilling machine mounted on rails Portable radial drilling machine Wall mounted radial drilling machine

General purpose machines are used in repair shops and metalworking industries. They are stationary - they are installed once on the foundation and are no longer transferred during operation. The workpiece is placed on a table or on a foundation slab. The base plate contains a coolant tank with a pump to supply it to the cutting zone. The spindle head moves along the traverse in a horizontal plane, and the traverse moves in a vertical plane and around the column. Equipment with a spindle turning relative to a horizontal transverse beam in an angular direction belongs to the second type.

Radial machines are installed on bed guides for processing heavy and large-sized workpieces. Another variety of this type are machines mounted on a trolley, which is capable of moving along rails due to an electric drive.

Wall-mounted and portable radial drilling machines are used in shipbuilding and heavy engineering, and their main purpose is the processing of hard-to-reach parts with large dimensions: cases and castings.

Design features and technical parameters of radial drilling machines

Radial drilling machines are designed for processing workpieces with large dimensions. They differ from similar equipment models in layout and functionality. Specific application – production areas for the manufacture of large-sized products.

Purpose and design of equipment

Example of a multifunctional radial drilling machine

The main feature of machines of this type is the optional movement of the workpiece along the work table to form holes on it. For this purpose, the design of the machine provides a block for displacing the spindle head in the horizontal and vertical planes.

This type of construction is designed for drilling, countersinking and reaming holes in steel workpieces. To perform these functions, the equipment includes a base plate on which a supporting column is mounted. It is necessary to fix the sleeve along which the spindle block with the electric motor of the main rotational movement moves.

To perform its functions, a radial drilling machine must have the following parameters:

- rigid clamp of the sleeve on the column. This is necessary to reduce vibration and increase the stability of the drill position during processing;

- a simple and reliable mechanism for shifting the sleeve along the height of the column. Most often, a hydraulic system is installed for this. Additionally, a clamp is used for fixation;

- components must be within an accessible area for the worker. Taking into account the specifics of the design, and in particular the height of about 2 m, the equipment layout should provide for ease of repair and maintenance work.

The rotation of the column is carried out due to a small effort of the operator. This reduces labor intensity and increases productivity. To improve these indicators, it is recommended to choose a model with a preselective unit. Thanks to it, you can pre-set a mode change without stopping the equipment.

Additional structural rigidity can be provided by a two-column arrangement. This has a positive effect on processing accuracy, but increases the weight of the structure.

List of main technical characteristics

Arrangement of systems in the machine

Radial drilling machines belong to the class of professional equipment. Their productivity and processing accuracy are due to their complex layout, which entails large dimensions and weight. Therefore, familiarization with the technical and operational characteristics is mandatory.

It is recommended to use special magnetic plates to secure the workpiece. Most often they are not included in the standard equipment. Therefore, they must be purchased separately. It is important that their dimensions match the size of the desktop.

An analysis of the capabilities of a radial drilling machine should begin with familiarization with the main technical characteristics:

- maximum drilling diameter. Depends on the material used to make the part;

- parameters for shifting the working head along the sleeve;

- maximum and minimum sleeve heights;

- angle of rotation of the sleeve along the axis of the column;

- spindle head rotation speed;

- number of spindle speeds and revolutions;

- number of working feeds;

- rated power of electric motors - the main drive and for moving the hose along the column.

Additionally, it is necessary to take into account the presence of devices for clamping the sleeve in the column and the working head. These functions will increase the reliability of the equipment.

The presence of a counterweight facilitates manual adjustment of the parameters of the radial drilling machine. Therefore, his condition must be monitored most carefully.

Features of operation

Radial drilling machine on a production line

Almost all models of radial drilling machines have a large mass - from 3.5 to 6 tons. For their installation, it is necessary to first prepare a stable site. Most often this is a reinforced concrete platform.

Before starting work, it is necessary to check the condition of all components and assemblies. This especially applies to the hydraulic system of clamps and movement of the hose along the column. After this, you can begin to fully operate the equipment.

Rules for working on a radial drilling unit:

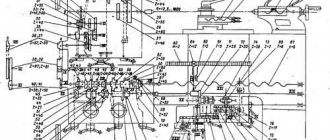

- get acquainted with the principle of operation of the equipment, study its kinematic diagram;

- use drills recommended by the unit manufacturer;

- Follow the safety precautions outlined in the operating instructions.

As an example, you can see the video, which shows how to drill holes in a channel using this equipment:

stanokgid.ru

Kinematics

Spindle rotation is the main movement of the machine.

The movement of the spindle in the vertical direction is the feed movement.

Moving the traverse up and down along the column, moving the drilling head horizontally along the traverse, moving the traverse around the axis of the column - installation movements.

An example of a kinematic diagram of a radial drilling machine 2N55

The machines have a wide range of rotation speeds, drilling head speeds and mechanical feeds.