DIY walk-behind tractor repair

Unfortunately, it doesn’t matter what kind of equipment breaks down from time to time, so its owner needs to be able to troubleshoot problems on his own. Obviously, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs free of charge.

Often, damage to a cultivator or walk-behind tractor occurs due to improper operation - when they fill in bad fuel, allow huge loads, or do not replenish the loss of lubricating water in time. Then the car begins to stall, stall, pick up speed poorly (especially if it has an electric motor), or even stops starting altogether. But, knowing the structure of the unit and the principle of operation of its devices, you can identify the cause of the damage yourself and carry out repairs perfectly.

Malfunctions of different types of walk-behind tractors

Today, many companies produce various types of walk-behind tractors.

Let's look at some of the most popular models and get acquainted with their common problems.

- "Belarus-09N" / "MTZ" is a heavy and powerful unit. Most often, its owners have to repair the clutch. Often the gear shift system is also “lame”.

- “Ugra” is a Russian motorcycle with a power take-off shaft. It is characterized by a number of design flaws, which cause problems with oil leakage and unpleasant vibrations. You may even encounter a failure of unit control.

- Equipment from Chinese manufacturers, for example, the Garden Scout GS 101DE model, often experiences rapid wear of important parts. What makes the situation worse is that the service for Chinese walk-behind tractors is rather poorly developed.

Why does a walk-behind tractor engine have difficulty starting when hot?

The equipment may stall when heated. This problem can be resolved relatively easily. This is often caused by excess air being supplied to the carburetor. It is mixed with gasoline and motor oil and acts as a carburetor coolant. So the temperature of the latter is much lower than the temperature of the walk-behind tractor engine.

To fix the problem, you need to follow a certain algorithm. It is important to start the engine. To do this, perform the following steps:

- When starting the engine, the throttle trigger is squeezed halfway;

- You should not regularly press the gas trigger, as this may cause the engine to flood;

- After starting the engine with the throttle trigger pressed halfway, you need to throttle it thoroughly. Afterwards you can continue working.

Simple actions will prevent an increase in the load on a heated engine; the main elements and systems are not subject to increased wear. The listed methods will allow you to eliminate any malfunctions with the unit. They are equally effective for owners of the following brands: Agro, Honda, Neva, Cascade.

Why won't the walk-behind tractor start?

Repair of a walk-behind tractor will be successful if you correctly diagnose the walk-behind tractor.

The reasons for unit failure are very different:

- The hole in the gas tank is clogged;

- The fuel supply channels are clogged with debris;

- The air filter blocks the entry of clogged air;

- Carburetor failure.

Gasoline and diesel walk-behind tractors must be carefully prepared for seasonal work.

It is important to make sure that all structural elements are in place and securely fastened

Installed Subaru engines or engines of other brands may not start after a long period of inactivity, especially in winter. Incorrect storage conditions for equipment also have a negative impact.

The following malfunctions may occur:

- The contacts in the electrical wiring have oxidized;

- Water has entered the oil or fuel;

- The integrity of the wire insulation has been compromised;

- Debris has accumulated in the carburetor jets.

Before starting the walk-behind tractor, you need to look at all the connections in the units of the device, check the integrity and connections of the throttle, reverse and clutch cables. If clamps or kinked cables are found, this must be corrected in order to start the unit.

It is necessary to check the amount of oil in the crankcase. Lack of lubrication can negatively affect the piston group. A diesel or gasoline walk-behind tractor may not start if there is not enough oil. Some models have low-level protection installed; if it is not there, you need to constantly monitor the volume of lubricating fluid.

It is important to take into account the quality of the gasoline being poured. The walk-behind tractor must be refilled with the brand recommended by the manufacturer, then the unit will work without interruption

Two-stroke engines operate on separately prepared fuel: gasoline and oil. It is important to maintain a strict ratio of substances.

Why does the tractor run intermittently?

There are other issues to consider:

- The walk-behind tractor engine reverses. The cause is often the use of bad fuel. It is not enough to replace the fuel. Flushing the pump and fuel hoses;

- The equipment is working. The engine does not warm up completely. The engine must be turned off, wait until it cools down completely. After rebooting and warming up for at least ten minutes;

- The engine does not pull because the engine power is reduced. The filter system has been checked and cleaned. This problem may cause magnetic annealing wear. In this case, the part is replaced.

READ Chainsaw Does Not Gain Speed and Stalls Reasons

Owners of equipment such as gasoline and diesel may encounter such problems. Regardless of the specifics of the breakdown, you must immediately stop using the device and fix the problem.

Walk-behind tractor design

An important driving part of the described device is the engine, which can operate on both gasoline and diesel fuel. This piece of equipment can be either two-stroke or four-stroke. A characteristic feature of these motors is that they are equipped with specially designed speed controllers that can simplify the work process. Engine power can vary from five to ten liters. It is also worth noting that specialists encounter the greatest difficulty during repairs in this part of the walk-behind tractor.

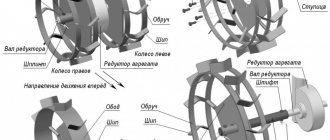

The next element of the device is the transmission

, which has a number of variations:

- Serrated.

- Gear-worm.

- Belt-gear-chain.

- Hydrovolumetric.

An important component of the described device is an aggregated system, thanks to which it becomes possible to attach additional agricultural implements to the walk-behind tractor.

The control of this mechanism can be located either on its handles or on the steering rods. And also in this place the clutch and gas are located. In some complex designs you can sometimes find a brake.

The walk-behind tractor does not develop speed: the reason

Auto mechanic, practicing on agricultural equipment

Two-wheeled, mechanical devices such as a walk-behind tractor or cultivator are in great demand among farmers, gardeners and loaf growers. They minimize human physical labor and help cultivate the soil, remove grass or snow, and transport small loads.

Like any other mechanical unit, a walk-behind tractor can fail and cause a huge amount of inconvenience to the owner. Careful care of the device and adherence to all operating rules indicated in the instructions for use can minimize the possibility of breakdown. But, no matter how high-quality the walk-behind tractor is, there are parts and elements that become unusable earlier than others. And such an element is the engine.

The walk-behind tractor fails for certain reasons

Replacement and adjustment

Quite often, unfortunately, there is a need to completely change the motor on a walk-behind tractor. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about products from Chinese factories have long become irrelevant. To avoid overpaying, you need to carefully analyze how productive the power plant should be. Buying a unit that is too powerful is simply irrational.

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to begin disassembly only after flushing the engine and removing oil from it. Lubricant is poured only when the engine is warmed up after a short run. Next it's time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- screen covering the cylinder.

Motoblock. It won’t start, what should I do?

Then remove the crankshaft pulley. Following the pulley, it is necessary to remove the fan, reflectors, and insulating flywheel casings. Unscrew the cover, removing the rings and coupling bodies. When the washer is removed, you can press out the flywheel using a wooden block.

READ Walk-behind tractor does not start Reasons

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is gained, remove the oil sprayer and locknut. After repairing and replacing damaged parts, reassemble the engine in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Replacing damaged valves for a gasoline walk-behind tractor occurs after removing:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

Often there is a need to replace rings. But be done in the process of more serious repairs. An isolated change of rings in itself is irrational both economically and technically. Additionally, a high quality ring group will usually have the same lifespan as a cylinder. They are changed at the same time.

Installation with an elastic band is advisable if a Chinese motor is installed on domestic walk-behind tractors. Rubber cushions are often used as a platform. They can be used as parts of the front shock absorber from a classic car. Along with the need to rearrange individual parts of the walk-behind tractor engine, many people have a need to install an electric starter themselves. This starter will have to be properly connected to the battery.

Walk-behind tractor engine will not start

The crown is attached only to the removed flywheels. First remove all interfering parts of the motor. To remove the flywheel, in many cases you cannot do without a special key. A generator and its magnets are installed in the flywheel assembly. When the terminals and contacts of the battery are aligned, you should conduct a test run of the walk-behind tractor.

Preparing the walk-behind tractor for start-up

In the instructions, manufacturers always indicate how to start the walk-behind tractor correctly. However, not everyone wants to waste time reading long pieces of paper and start work without familiarizing themselves with the operating rules. This is fraught with serious damage. It will not be possible to return equipment that was used for other purposes or broken due to the fault of the owner under warranty. If you never manage to start the engine even after several attempts, the reason may not be a bad part.

To make sure that the walk-behind tractor engine or starting system is faulty, you must try to turn it on, following the instructions exactly. If the reason turns out to be incorrect actions, there will be no need to contact for repairs. Sometimes it happens that the MB does not start and immediately stalls due to a manufacturing defect. In this case, you can safely go to the guarantee center to process a return. When communicating with an employee, it is important to inform that everything was done according to the instructions and a breakdown could not have occurred due to the fault of the owner.

To start the walk-behind tractor:

- Check the oil level, even if it was filled just a day ago. Sometimes sellers convince you that the required amount of liquid has already been poured into the tank. You can’t trust words, because... An attempt to start a walk-behind tractor without oil will lead to breakdown and will not be accepted under warranty.

- Fill with fuel. The method for opening the tank varies depending on the model, so you need to read the instructions. For some types of engines, gasoline must be mixed with oil. The proportions are also indicated in the technical book.

- Open the petrol tap. Before doing this, you must move the pump lever to the “Start” position. The name varies depending on the manufacturer.

- Pump fuel from the tank using the starter and turn on the ignition. Then you need to pull the starter and move the choke lever to the “Operation” mode. If everything is done correctly, the walk-behind tractor will start.

The described scheme of action is relevant for a gasoline engine without an electric starter, for example the Lifan model. To start a diesel walk-behind tractor, you will have to spend more time. The main problem of such equipment is its instability to frost. When the outside temperature drops, the fuel freezes, so the MB has to be warmed up before starting. The first attempt to turn on may fail if you do not bleed the system with the starter, because Everything inside is airy. Then pump the decompressor several times. Some models indicate the exact time of such preparation. Usually it is enough to do this 5-6 times, and then pull it to the starting position. If all the steps are completed correctly, to start the walk-behind tractor, just press the decompressor and turn on the starter.

Attention!

If it was not possible to clean the air-filled system by bleeding the starter, you can unscrew the fuel valve and loosen all the supply connecting elements one by one. When the fuel flows out, everything must be returned to its original state.

Engine malfunctions

The engine does not start. If we are talking about a gasoline engine, when troubleshooting, it is necessary to consistently check all possible causes of problems, namely:

- Turn on the ignition.

- Availability of fuel in the tank.

- Opening the fuel tap.

- The condition of the carburetor air damper (it should be closed when starting a cold engine).

- Fuel entering the carburetor. To do this, you need to fill the float chamber by pressing down the float button (fuel should start pouring out of the hole in the float chamber cover), or disconnect the fuel hose from the carburetor and check whether gasoline flows freely. If the fuel flows in too thin a stream or does not flow at all, this may indicate a dirty fuel filter in the tank or a clogged air valve in the tank cap. Repairing a walk-behind tractor in this case will come down to cleaning the filter or valve.

The supply of fuel to the engine cylinder may be indicated by the condition of the spark plug, which in any case must be checked when troubleshooting the ignition system. The spark plug is unscrewed from the cylinder cover, having previously disconnected the wire, and inspected.

https://www.youtube.com/watch?v=VN0Lyts7frs

If it is dry, this means that the fuel mixture is not supplied to the cylinder. And if before this it was established that gasoline is entering the carburetor, then the reason for the engine not starting may be in the carburetor - contamination of its filter mesh, clogging of the nozzle or some other malfunction.

A wet spark plug indicates that fuel is entering the cylinder. Sometimes the walk-behind tractor does not start due to an excess of fuel mixture, so if there is too much gasoline on the spark plug, you need to dry the cylinder by thoroughly “pumping” the engine with a manual starter with the spark plug turned out. Before doing this, you need to shut off the fuel supply.

If the spark plug is contaminated with carbon deposits, it should be cleaned with gasoline and fine sandpaper. It is also necessary to check the gap between the electrodes and, if necessary, adjust it in accordance with the requirements of the operating manual. Typically the gap should be about 0.8mm.

After this, you need to check for the presence of a spark - attach a wire to the spark plug, press its metal part to the cylinder cover and simulate starting the engine with a starter. If the spark plug is working properly, a spark will occur between the electrodes. Sometimes it happens that a spark occurs, but it is so weak that it is not enough to ignite the fuel. If you have doubts about the strength of the spark, you need to check the operation of the engine with a new spark plug.

The absence of a spark may mean a faulty spark plug, lack of contact in the electrical circuit, a violation of the gap between the ignition coil and the magnetic circuit, or a malfunction of the electronic ignition coil. All these elements must be checked. A faulty spark plug and ignition coil must be replaced.

If the walk-behind tractor is equipped with an electric starter, the engine may not start due to a discharged battery, a blown fuse, or a faulty starter. You need to check the battery charge, replace the fuse, repair or replace the starter.

The engine does not develop power. If the walk-behind tractor engine starts but does not develop power (runs intermittently, stalls or does not gain speed under load), the following malfunctions may be possible reasons for unsatisfactory operation.

The air filter is dirty, resulting in insufficient air entering the carburetor, and the fuel mixture is over-rich. Proper maintenance of a walk-behind tractor involves periodically cleaning the air filter, however, very dusty work may require more frequent cleaning.

It is necessary to check the condition of the air filter and, depending on its material, clean it using one of the appropriate methods. The paper filter is cleaned by lightly tapping it on something hard and blowing it with a vacuum cleaner, the foam filter is washed in water with detergent and dried, the mesh filter is blown with a vacuum cleaner, etc. When the filters reach the end of their service life, they must be changed.

Low quality fuel. Bad fuel must be replaced with one recommended by the manufacturer.

The ignition system is faulty. You need to check it as described above. Clean the spark plug and adjust the gap between its electrodes, check for damage in the electrical circuit and the gap between the coil and the magnetic circuit (if this is provided for in the walk-behind tractor repair instructions).

Sometimes the engine cannot develop power due to the muffler being clogged with combustion products. In this case, you need to disassemble the muffler and check its condition, if necessary, wash it in gasoline and clean it with a car wash to remove carbon deposits using detergents.

The non-removable muffler is dried with a hairdryer after washing. Remember that carbon deposits contain substances that are carcinogens, and dry cleaning, which could result in their inhalation, is unacceptable. When removing the muffler, plug the engine exhaust hole with a clean rag.

Dirty or incorrect adjustment of the walk-behind tractor carburetor. It is necessary to remove and clean the carburetor, and then adjust it, if this is provided for in the walk-behind tractor instructions.

A drop in engine power can be caused by a decrease in compression due to wear of the cylinder-piston group, the formation of scoring and scratches on the cylinder and piston, “retraction” in the grooves or breakage of the piston rings. In this case, check the compression by connecting a compression gauge to the spark plug hole and turning the engine shaft with the starter.

Normal compression is characterized by a value of at least 8 atm (normal compression can be indicated in the engine characteristics). When measuring it, you need to take into account that the presence of a decompressor in the engine can affect the readings of the compression meter.

Diesel engine does not start. For most users, repairing and tuning a walk-behind tractor with a diesel engine is a more difficult task than repairing a walk-behind tractor with a gasoline engine. Not so much, perhaps, because of the design complexity of the diesel engine, but because of the lack of experience, since household devices are usually equipped with gasoline engines.

The most common faults or conditions that may prevent diesel engines from starting are outlined in the table below. A detailed list of diesel malfunctions and methods for eliminating them are set out in the operating instructions for specific diesel walk-behind tractors.

| Cause | Remedy |

| The weather is too cold. | Pour hot water into the radiator. |

| The fuel has frozen and lost its fluidity. | Use the correct grade of fuel or heat it up. |

| The nozzle is clogged. | Clean or replace the nozzle. |

| Insufficient injection pressure. | Adjust pressure. |

Insufficient cylinder compression (engine cranks too easily with starter).

|

|

Why does the walk-behind tractor stall under load?

Almost every owner of a walk-behind tractor, regardless of the brand and model of the agricultural machine, has encountered a problem in which the walk-behind tractor starts and stalls after 5 minutes of operation. The main reasons for this breakdown lie in problems with the fuel supply and breakdown of the car’s ignition system.

As practice shows, if a walk-behind tractor stalls during operation, its owner should immediately inspect the parts of the fuel supply system. First of all, unscrew and look at the spark plug - if it is completely dry, this indicates that fuel is not getting into the engine cylinder. After this, you need to make sure that there is a sufficient amount of fuel in the fuel tank. If there is gasoline and there is enough of it for work, inspect the fuel valve - it is quite possible that it is in the closed position. To start the walk-behind tractor, just open the fuel tap and continue working with the unit.

Another reason why the walk-behind tractor starts up and then stalls after 5 minutes of operation is a breakdown of the ignition system. It is quite simple to determine that the unit is faulty for this very reason - look at the spark plugs - if they are wet, it means that the fault has appeared in the ignition system of the walk-behind tractor. The best way out of this situation is to re-adjust the unit’s ignition system. All actions must be performed in this order:

- Remove the cover that protects the elements of the ignition system;

- Turn the motor flywheel until the contacts in the magneto open;

- Using a special feeler gauge, measure the gap between the “anvil” and the “hammer” of the walk-behind tractor’s ignition system;

- After this, turn the flywheel until the piston of the walk-behind tractor compresses. In this case, the latter must reach its highest point;

- Turn the flywheel again until you hear a characteristic knock - this means that the overrunning clutch has engaged;

- Then turn the flywheel in the opposite direction so that the mark on it coincides with the mark on the walk-behind tractor body;

- Set the gap between the interrupting contact and the cam - it should be 0.3 mm;

- At the end, fix the cam with a screw located on top of the part and install the protective cover back into the walk-behind tractor body.

After the above steps, the walk-behind tractor will no longer stall under load. The main thing when similar problems arise in the future is to try to fix the breakdown as quickly as possible, so as not to subject the main mechanisms of the walk-behind tractor to increased wear.

Also, the utility unit often stalls when tilted. This indicates an insufficient amount of fuel in the fuel tank. If you put the unit in a horizontal position, pull out the starter cable, and the engine starts, it means that you will need to add gasoline to the tank.

Causes of walk-behind tractor malfunctions and ways to eliminate them

Malfunction: walk-behind tractor stalls under load

If the walk-behind tractor operates normally for a few minutes and then stalls, the cause is usually a failure in the fuel supply or problems in the ignition system.

To find out what is the cause of the malfunction of the walk-behind tractor, you must first check how the fuel is supplied:

- take out the spark plug and inspect it - if it is dry, it means there is not enough fuel;

- check whether there is enough fuel in the gas tank of the walk-behind tractor;

- make sure that the fuel tap is open - a closed tap can be a simple reason that the walk-behind tractor stalls.

If the problem is a malfunction of a gasoline walk-behind tractor in the ignition system, it must be re-adjusted as follows:

- remove the cover protecting the ignition system;

- turn the engine flywheel until the contacts in the magneto open;

- using a feeler gauge, measure the distance from the anvil to the hammer;

- turn the flywheel until the piston is compressed to maximum;

- turn the flywheel again until a knock appears, indicating the operation of the overrunning clutch;

- turn the flywheel in the other direction so that its mark coincides with the mark on the body of the walk-behind tractor;

- set the distance from the interrupting contact to the cam to 0.3 mm;

- fix the cam with the screw located above the element;

- install the cover into the walk-behind tractor body.

If the adjustment is made correctly, the walk-behind tractor will not stall during operation.

Malfunction: the walk-behind tractor operates jerkily, intermittently or at reduced power

If a walk-behind tractor with a gasoline or diesel engine begins to work intermittently, you must immediately turn off the unit and begin troubleshooting.

Continuing to work with a faulty walk-behind tractor means leading it to more serious breakdowns.

What to do:

- if the engine of a gasoline walk-behind tractor makes reverse movements, it is necessary to rinse the pump and hoses for supplying fuel and replace the fuel with a higher quality one;

- when the walk-behind tractor operates jerkily due to incomplete warming up of the engine, you need to turn off the engine, let it cool completely, start it and warm it up for ten minutes;

- if engine power has dropped, you need to check and clean the filter system;

- If the ignition magneto wears out, the part must be replaced with a new one.

Malfunction: the walk-behind tractor smokes and stalls, the muffler makes unusual sounds

Possible causes of the malfunction:

- too much motor oil in the fuel;

- the ignition is set incorrectly;

- The fuel in the engine cylinder does not burn completely.

Troubleshooting methods:

- if there is excess oil, drain the fuel, flush the fuel pump and hose system, and add new fuel;

- check that the gap between the electrodes is set correctly;

- if it becomes obvious that the fuel is not completely burned, disassemble the piston system, wash and dry the cylinder, and adjust the carburetor correctly.

Malfunction: the walk-behind tractor starts, but quickly stalls

This malfunction occurs if there are problems with the contacts. What to do:

- clean the candle;

- check the integrity of the wires;

- set the correct distance between the electrodes.

Another reason for the malfunction is that the carburetor is dirty and not enough fuel is supplied. Then you need to replace the fuel and reduce the amount of oil.

Malfunction: the walk-behind tractor stalls when heated

This problem occurs due to excess air entering the carburetor. In case of such a malfunction, the throttle trigger should be squeezed halfway. After starting the engine, you need to give it a good gas before starting work.

If you cannot cope with the malfunctions of the garden walk-behind tractor, the walk-behind tractor stalls, the walk-behind tractor does not start, contact the Alfa-Rost walk-behind tractor repair shop in Rostov-on-Don. We guarantee high-quality repairs of gasoline walk-behind tractors using original components, which are always available in our warehouse.

When your hitherto trouble-free walk-behind tractor begins to act up, it is very annoying. It’s doubly annoying when this happens in a situation where there’s a lot of work and without a walk-behind tractor, it’s like without hands. It seems to start normally, but as soon as you give it a load, it immediately sneezes and stalls. What is the reason for such “betrayal”?

Why does the walk-behind tractor shoot into the muffler?

Sometimes the operation of equipment is accompanied by unusual sounds from the muffler. The walk-behind tractor smokes and stalls. To eliminate such a malfunction, it is necessary to first determine what caused it. Such problems may occur in the following cases:

- Excess motor oil in fuel. The remaining fuel is drained, the fuel pump and hose system are washed, and new fuel is added;

- Incorrectly set ignition. It is necessary to check how correctly the gap between the electrodes is set;

- The fuel in the engine cylinder does not burn completely. In this case, it is necessary to disassemble the piston system, thoroughly wash and dry the cylinder, and adjust the carburetor.

In the above cases, it is not difficult to repair walk-behind tractors yourself. It is important to strictly adhere to the algorithm of actions.

Doesn't develop speed

If the engine is in good working order, but the walk-behind tractor does not develop speed, then it is possible:

- the air filter is clogged. As a result, not all the air enters the carburetor, and the fuel becomes oversaturated;

- low quality fuel fluid;

- parts of the ignition system have failed. As mentioned earlier, it is necessary to check the spark plug, correct the gap between the electrodes, and pay attention to the mechanical integrity of the electrical circuit;

- if necessary, clean the carburetor and adjust it correctly;

- the operation of pistons and cylinders is interconnected with engine power.

Therefore, pay attention to the condition of the pistons and cylinders. Their external damage can significantly reduce the compression value.

For example, cleaning the carburetor may solve the problem

Engine problems and repairs

There may be several reasons why a motor may break down. In situations where the engine on cultivators does not start at all, you should use the following procedure:

The equipment engine does not provide sufficient power for the following reasons:

- the air filter is clogged: repair measures require thorough cleaning of this part;

- the muffler is clogged: the element must be disassembled and washed thoroughly;

- the carburetor is clogged: the component must be removed, cleaned and adjusted correctly.

What attachments does the walk-behind tractor work with?

Any experienced farmer knows that with the help of a walk-behind tractor, cultivator or other motorized equipment, almost all agricultural work can be mechanized: starting with cultivating the land to prepare it for sowing and ending with transporting the harvested crop. Motor units have become universal due to the possibility of using a variety of attachments. In addition to moldboard and other plows, the following equipment has been created for processing plowed land and cultivating virgin lands:

Harrows are used to plow virgin soil, as well as for pre-sowing (spring) or post-harvest loosening (autumn) of arable soil to a depth of 7-14 cm. Using harrowing with a walk-behind tractor or cultivator, the surface is leveled, moisture is covered, and weeds are destroyed.

The working parts of such agricultural implements are metal teeth or spherical disks. In this video you can clearly see how to properly plow with a walk-behind tractor and a homemade harrow. And also from there you can learn improvements for the harrow.

The hiller is used to hill up potatoes, cut furrows for sowing seeds, backfill planting material, and also sprinkle weeds directly in the row area. Hilling devices come in single-row and double-row, with fixed and adjustable working widths, distinguishable both by their design and their efficiency. Here is a video of how the Neva MB2 motor cultivator performs processing with a mounted two-row weeder-hiller.

With a rotary cutter you can plow virgin soil, carry out pre-sowing and basic cultivation of plowed land. This agricultural implement allows you to mill, cultivate the land and qualitatively prepare it for sowing. It is capable of not only plowing the soil, but also mixing it with fertilizer, crumbling large layers, crushing stubble particles, and leveling the sown area.

A flat weeding cutter helps to trim weeds, split and cut grooves without turning the formation, plow and crush the soil. Flat cutters come in all possible working widths and processing depths, which allows you to choose them for specific processing conditions of agricultural plots and crops.

In addition to the listed removable tools designed to plow virgin soil and cultivate arable land, rakes, wood splitters, seeders, shredders, cultivators, rotary and segment mowers, shovels, sprayers, sweeping brushes, snow blowers, etc. are used with the motorized unit.

Having a basic set of mounted agricultural implements, you can use a walk-behind tractor or a powerful cultivator to perform all kinds of economic tasks, in particular, pre-sowing plowing, sowing and planting crops, applying fertilizers, inter-row cultivation of crops, harvesting root crops, and seasonal harvesting of green fodder.

Service

Maintenance of the walk-behind tractor involves regularly performing the following operations:

- adjusting;

- washing;

- fastening;

- control;

- lubricants;

- gas stations and other works.

The frequency of such manipulations ranges from 5 hours to 1 time per season. Let's consider the classification of periodic work by frequency of execution.

Every 5 hours the following manipulations are carried out:

- cleaning the area around the muffler, the entire cultivator, wiping it dry;

- cleaning the outer surfaces of the cylinder head and the cylinder itself;

- replacing oil in the motor gearbox (after the first 5 hours of operation);

- inspection of fastening connections of the chassis and engine;

- monitoring the oil level in the chassis and gearbox;

- monitoring the tightness of chassis and engine gearboxes, carburetor, gas tank and fuel line.

Every 25 hours or once a season:

- V-belt transmission adjustment;

- cleaning the air filter and monitoring its condition;

- checking the fastenings of threaded connections of the chassis and engine using spare parts tools;

- Changing the oil in the chassis gearbox.

Every 50 hours or every season:

- cleaning spark plugs;

- replacing the filter element in the air filter; this procedure can be carried out more often when working in difficult conditions;

- Changing the oil in the engine gearbox (at elevated ambient temperatures, this is done more often - after 25 hours).

Every 100 hours or every season:

- lubrication of control cables;

- installing a new spark plug;

- cleaning and lubricating the starter;

- muffler cleaning;

- changing the oil in the chassis gearbox;

- cleaning the grooves of the piston rings, piston, cylinder head, and exhaust purge windows of the cylinder from carbon deposits.

Every 300 hours or every season:

- flushing the gas tap and carburetor;

- flushing the fuel tank.

Carrying out diagnostics

This process is considered an important stage of repair. Thanks to it, you can determine the cause of the malfunction that needs to be eliminated when repairing the equipment.

When carrying out diagnostics, you should study the candles very carefully. If there is a large amount of fuel on them, then we can talk about an excess of gasoline in the cylinders. To eliminate this problem, it is recommended to remove all fuel from the cylinder and dry it well, and then you need to adjust the equipment injectors in order to normalize the fuel supply. It is worth noting that before carrying out these manipulations, it is recommended to stop the fuel supply.

The next reason for poor engine performance may be the presence of carbon deposits on the spark plugs. To fix this problem, it is recommended to clean the spark plugs with fine sandpaper and check the distance between the electrodes. Normally it should be from 0.7 to 1 mm.

Before you start replacing spark plugs (if a lack of spark is detected), it is recommended to check the old spark plugs for functionality: you should connect them to the battery using an auxiliary wire. Thanks to this, it is possible to identify problems with the wiring.

Reasons that could cause this malfunction:

Diesel

Repairing a diesel engine is quite difficult due to the fact that a small variety of equipment operates on these low-power devices.

In this case, it is better to entrust repair work to professionals.

Transmission

Manual repair of a walk-behind tractor can also be carried out in case of problems with the transmission:

Problems with the gearbox

It should be noted that the gearbox is the most complex unit, and repairing it is quite difficult.

The causes of problems may be the following:

We should not forget that if a walk-behind tractor malfunctions, it is worth first identifying the cause of the problem. Thanks to this, it is possible not only to correctly repair a broken part, but also to reduce the risk of malfunctions in the future. Repair work on such agricultural equipment must be carried out professionally. In most cases, problems arise due to improper maintenance of the mechanism, which ideally should be carried out according to the instructions for use.

Victor change the spark plug

Sergey Check the fuel supply and compression.

Provided that, of course, the candle is normal. In general, their rescrs are not so hot.

Sasha, he doesn’t have to work while idle, he needs to work

Kirill Blow out the carburetor, wash the filter, reduce the spark plug gap or replace...

Artyom Change the spark plugs

Tags: Why, walk-behind tractor, works, intermittently, video

Starting system malfunctions

If during inspection the spark plugs turn out to be wet, but the engine does not start, then detecting the malfunction will be much more difficult:

- the ignition system may fail;

- due to depressurization of connections, air leaks may occur;

- the air damper in the carburetor may not be closed enough;

- carburetor failure.

A failure of the ignition system is an unpleasant moment, but you should not panic and immediately call a specialist. First, remove and inspect the spark plug. If you find carbon deposits on it, clean it with sandpaper, rinse it with gasoline and let it dry completely. Very often, after such a procedure, the engine begins to work normally.

If the engine still won't start and you feel competent, check the gap between the electrodes. The required value is indicated in the manufacturer's instructions, but due to constant vibration during operation, it may change, and the walk-behind tractor may stall while driving. Adjust the gap to the desired value by bending the side electrode.

It will not be possible to deal with other problems of the ignition system right away. If the insulators of spark plugs or electrical wiring are burnt out, they need to be replaced. You can also short the “STOP” button to ground, and until the short circuit is eliminated, the engine will not start. Also, the reason that the engine does not start may be a violation of the contacts in the spark plug brackets or a violation of the gap between the magnetic shoe and the starter. Finally, the starter itself may be damaged and will need to be replaced.

Another common reason why a walk-behind tractor engine “chokes” or stalls under load is air leaks. If this occurs due to depressurization of the carburetor connections, then you must first tighten the spark plugs and tighten the mounting bolts, and then check and, if necessary, replace the gaskets. The engine will “choke” even when the carburetor air damper is open. To fix the problem, it needs to be adjusted, making sure that it moves freely without distortions or jamming.

If the walk-behind tractor does not gain power normally, it is worth checking its muffler. Over time, fuel combustion products clog the muffler, forming a thick layer of soot on its walls, so it needs to be cleaned periodically. To do this, the muffler must be removed, plugging the outlet hole with a clean rag, washed first in gasoline, then cleaned of carbon deposits by washing with detergents, and finally dried with a hairdryer.

Sometimes the walk-behind tractor stalls during operation due to simple overheating. If, with the throttle fully open, you press the throttle, and the engine, instead of accelerating, loses speed, then this is a clear sign of overheating. The walk-behind tractor must be stopped and allowed to cool completely, and then started again.

This is not the entire list of reasons why your recently perfectly serviceable walk-behind tractor may stall even under light load. Almost all components of the walk-behind tractor are subject to significant loads during operation, so minor malfunctions and breakdowns are not uncommon. Therefore, if you discover that there is something wrong with the walk-behind tractor: extraneous noise, twitching, strong vibration, etc. - Turn off the engine immediately. And only after the engine has cooled down can you begin troubleshooting. But this is a topic for another conversation.

The walk-behind tractor starts and stalls

This problem most often occurs due to engine malfunctions. The heart of a walk-behind tractor can “stop” for many reasons

It is important to determine at what stage the problem occurred. For example, the MB may stall only under load or turn off a few minutes after startup

Then the “diagnosis” will be significantly different from cases when the equipment goes silent immediately after starting up.

One of the reasons may be a failure in the ignition system. For example, the engine will not work if the electrical wires are broken or the contacts on the boards are loose. It is not always possible to find out this on your own, so the first diagnostic measure will be to check the spark plug. Its condition will immediately tell why the walk-behind tractor stalls:

- Dry. The problem is in the carburetor. No gasoline gets into it, which causes the filter to become clogged with debris. A separate jet may also be damaged.

- Wet. The reason is an excess of fuel. It prevents the engine from developing speed.

- Carbon deposits on the surface. The spark plug has failed and cannot produce an ignition spark. If such a problem is detected, additionally check the part using electrodes.

The engine is dependent on fuel, so it may stall due to its lack or poor quality. Most often, this problem occurs among owners of walk-behind tractors, which require mixing oil and gasoline. Incorrect proportions or debris that has entered the liquid prevent the engine from working and it dries out. In this case, the fuel tank must be removed and thoroughly washed. An additional measure would be to check the carburetor. Debris often gets into gasoline from this part.

In regions where temperature changes are more than 5°C per day, MB cannot be stored outdoors. Changes in weather may cause the fuel tank to burst. Depressurization prevents it from working and the walk-behind tractor stalls. If there is no garage on the site, make sure that the container is empty when the equipment is not in use. It can also be insulated by wrapping it in scrap fabric. Moisture should not be allowed to enter if frost is expected soon. An icy tank will quickly fail.

Cold weather negatively affects not only gasoline walk-behind tractors. More often, the problem occurs among owners of equipment with diesel engines. Such a motor may not start even at a temperature of -1°. The problem is easy to solve: just pour hot water into the radiator. If fuel is added before each use, it should be stored in a warm place. This is especially true for those who rarely turn on a walk-behind tractor.

Sometimes the engine stalls due to a fault in the gearbox. This breakdown can be determined by the characteristic sound that appears in the gearbox area. Due to a lack of lubricant, the cultivator is unable to develop speed and begins to knock. It is difficult to repair such a breakdown on your own. If you have no experience, it is better to take the MB for a technical inspection.

Why does the walk-behind tractor stall under load?

A breakdown can be determined by the moment the engine stops working. Sometimes malfunctions occur 5 or 10 minutes after startup. If the walk-behind tractor stalls under load, the reason may lie in the air filter. Check it and clean it. To do this, you only need a vacuum cleaner or compressed air. The quality of oil and gasoline also affects performance. The easiest way to diagnose the problem is by the condition of the spark plug.

Most elements in the walk-behind tractor can be repaired independently. This is provided by the manufacturer and indicated in the instructions. If the equipment stalls even from the slightest load, check:

- Muffler. Due to debris, the engine does not develop speed. To get rid of combustion products, soak the muffler in water with special products. Then it needs to be rinsed and dried completely.

- Carburetor. Although the factory settings are generally correct for all parts, they need to be checked. The procedure is described in the walk-behind tractor instructions.

- Cylinder piston parts. If this element breaks down, the walk-behind tractor does not gain momentum. To check for this problem you will need a compressor.