Pipe area is a concept used when calculating three different product parameters - external surface, internal surface and cross-section. When carrying out calculations related to a section, in some cases it is necessary to deal with the so-called live section. By calculating the area, it is possible to determine the amount of materials required and the level of costs required for the installation and full functioning of the pipeline.

Calculation of such an indicator as pipe area may be necessary during the construction of a pipeline, as well as its insulation, painting and other activities.

Why are geometric calculations needed?

Before you begin to measure or find out the original dimensions, you need to understand for what purposes the calculations made will serve.

There are several such goals:

- Calculation of thermodynamic parameters of the system . The formula for the surface area of a pipe is necessary when calculating the heat transfer of an individual pipe, section of pipeline or, for example, a heated floor. In order to find out these parameters, it is necessary to calculate the total area of the product or system from which heat is transferred to the environment.

- Calculation of heat loss in the direction “heat source-heating device” . In this case, the greatest loss of thermal energy occurs in the longest section with the largest area of contact with the environment, that is, again in the pipes. Therefore, as in the previous case, having learned the heat transfer surface area, it is possible, based on this value and the amount of heat generated at the starting point, to plan the number and size of heating devices in the future system.

Why is this necessary?

Let's start by once again listing the main situations when we need to calculate the area of a pipe - its surface or cross-section.

- The pipe area formula will be useful if we need to calculate the heat transfer of a register or a heated floor . Both values are derived precisely from the total area that transfers heat from the coolant to the air in the room.

Its heat transfer depends linearly on the surface area of the register

- The opposite situation often occurs - when you need to calculate heat losses on the way to the heating device . In order to be able to make a decision on the number and size of radiators, convectors or other appliances, you need to know how many calories we have. It is derived again taking into account the surface area of the pipe that transports water from the elevator unit.

- Calculation of the pipe surface area is needed in order to purchase the required amount of heat-insulating material . If the length of the heating main is measured in kilometers - and this is exactly what happens - an accurate calculation can save the company huge sums.

Here heat transfer must be reduced to a minimum. To calculate the amount of heat-insulating material required, you need to find out the surface area that needs to be protected from heat loss

- Costs for anti-corrosion coating or paint are in the same category . The area of steel pipe to be painted, together with the paint consumption per square meter, will give us the exact volume of necessary purchases. At the same time, in this case it will be very clear to see, let’s say politely, the inappropriate use of the material: if paint or bitumen varnish is used one and a half times more than the calculated amount, the company should stop theft.

Paint manufacturers indicate its consumption in grams per square meter of surface

- Calculation of the cross-sectional area of the pipe is necessary in order to find out its maximum permeability . Yes, you can simply install a pipe that is obviously larger than necessary; but when drawing up a standard project, according to which many houses will be built, the cost overrun in this case will be large.

Important: in the case of a private house, the budget overrun if you simply take the pipe one step larger is small. But heat losses will increase noticeably. Unclear? Remember: the larger the surface of the pipe, the more heat is dissipated on it.

In addition, between the moments when a hot water tap is opened, the entire volume in the corresponding water supply cools down pointlessly.

The larger the diameter of the pipe, the more water will stand in it, the more heat you will spend on aimlessly heating the room.

The thicker the pipes, the more hot water cools down aimlessly after each opening of the tap.

Calculation of cross-sectional area

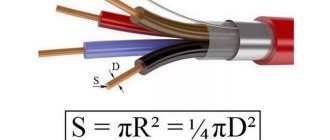

The cross-section of the pipe is, subject to correct cutting, when the ends are perpendicular to the longitudinal axis of the product, a regular circle.

The area of a circle is calculated using the formula:

S=πR^2=π D^2/4,

where π=3.1415926, R is the outer radius of the circle, D is its outer diameter.

Taking into account the thickness of the pipe walls, the pipe area is calculated using the formula:

S=〖π(Rl)〗^2=〖π(D/2-l)〗^2,

where l is the pipe wall thickness.

If in the first formula we take R and D not as external, but as internal diameters, then there is no need to take into account the wall thickness, and the calculation can be carried out using the first equation.

You need to understand that before calculating the cross-sectional area of a pipe, all initial parameters should be converted to the same units of measurement (for more details: “How to calculate the cross-sectional area of a pipe - simple and proven methods”). In principle, if desired, calculations can be carried out in any units - millimeters, centimeters, meters, etc. The main thing when carrying out further computational operations is to bring the area value to a standard form (square meters).

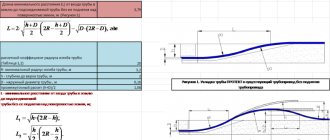

It should also be taken into account that in pressure pipelines the working medium moves throughout the entire volume of the pipe, and in the case of a gravity-flow design, the liquid fills only part of the volume of the pipe - the so-called live section (about

How to calculate the cross section of a pipe

There is a certain nuance here related to the type of pipeline used - pressure or non-pressure. In the case of a pressure pipeline, the calculation is much simpler and you will need to use the formula S = π r2. That is, to calculate the cross-sectional area (S) of the pressure pipeline, in which the transported medium occupies the entire internal volume, the following values are used: π – approximately 3.14; r – radius equal to half the internal diameter or half the external diameter minus double wall thickness.

The situation with similar calculations is more complicated if you have to deal with gravity sewerage or water supply. In such systems, unlike pressure systems, during almost the entire period of operation, the flow of the working medium affects only part of the walls, and not the entire internal volume. Thus, the value of hydraulic resistance is significantly lower.

On a note! When carrying out hydraulic calculations, it is customary to operate with the concept of a live section. It is understood as the part of the cross-section that relates directly to the flow of the working medium, which is located perpendicular to it.

What to do when dealing with a square pipe? To calculate the area of a square or rectangular pipe, you can use an online calculator or use the formula S = Pl. In it, in addition to the values of area (S) and length (l), the value of the perpendicular section perimeter (P) is also used.

Despite the simplicity of calculating the pipe area, it is hardly worth being careless when performing this operation. Errors can result in both an overexpenditure of materials and money, and disruptions in the operation of the pipeline system itself.

Calculation of the outer surface area of the pipe

As in the previous case, you can find the area of the pipe through the diameter. The calculation formula is also quite simple, because the development of the cylinder area is a rectangle, for which the length of one side is equal to the circumference of the outer section, and the second is equal to the length of the pipe section.

Accordingly, the formula for the pipe area is:

S=2πRL=πDL,

where R is the outer radius of the product, D is the outer diameter, L is the longitudinal length of the pipe.

As in the previous case, the calculation must be carried out in the same units (for example, if the pipe diameter is 15 mm and the length is 1.5 m, then when recalculating you need to use either the values of 15 and 1500 mm, or 0.015 and 1.5 m) .

Based on the size of the outer surface area of the pipe, the required amount of coloring materials or heat-insulating substances is calculated.

Calculation methods

Section calculation

Actually, the problem is something from middle school geometry. We need to calculate the area of a circle whose diameter is equal to the outer diameter of the pipe minus the thickness of its walls.

The area of a circle, as we remember, is calculated as S = Pi R^2.

Thus, the formula calculating the cross-sectional area of the pipe is S=Pi*(D/2-N)^2, where S is the internal cross-sectional area of the pipe, Pi is the pi number, D is the outer diameter of the pipe, and N is the wall thickness pipes. Diameter, as we remember, is two radii.

So, we have a formula that calculates the cross-sectional area of a pipe. Let's use it using the example of another spherical horse in a vacuum - a hot-rolled seamless pipe with an outer diameter of 1 meter and walls 10 mm thick.

S=3.14159265*(1/2-0.01)^2=0.754296 m2.

Important: in pressure water pipes, water always fills the entire volume of the pipe.

In a gravity sewer, this is not the case: most of the time, the flow wets only part of the walls and, accordingly, the pipe offers less resistance to it compared to a completely filled one.

It is for hydraulic calculations of gravity sewers that such a concept as the open cross-sectional area of a pipe was introduced.

This is the cross-sectional area of the flow in it, perpendicular to the direction of flow.

Sometimes a lot depends on the exact selection of pipe cross-section

Pipe outer surface area

And this is also a purely geometric problem. How to calculate the surface area of a pipe outside?

How can one find the area of the cylinder walls in general?

The surface of a cylinder is essentially a rectangle, one side of which is the circumference of the cylinder, and the other side is the length of the cylinder itself. So?

The circumference, as we remember, is equal to Pi * D, where Pi is the number Pi, and D is the diameter of the pipe.

How to calculate the area of a rectangle? It is necessary to multiply its length by its width.

The area of the coveted rectangle will be: S=Pi*D*L, where Pi is the good old Pi number, D is the diameter of the pipe, and L is its length.

For a heating main with a diameter of one meter and a length of ten kilometers, the painting area of the pipes will be equal to: 3.14159265*1*10000=31415.9265 m2. You will need a little more thermal insulation: it has a thickness other than zero, and the pipe is wrapped in mineral wool with overlapping sheets.

And here an accurate calculation of the surface area was necessary

Pipe inner surface area

Why the inner surface? Are pipes really painted from the inside?

No, the internal surface area can be useful in hydrodynamic calculations. This is the surface area that water comes into contact with as it moves through the pipes. .

There are several nuances associated with this area:

- The larger the diameter of the water supply pipe, the less the influence of the roughness of its walls on the flow rate in it. For large-diameter pipelines with a short length, the resistance of the pipe can be completely neglected;

- For hydrodynamic calculations, surface roughness is no less important than its area . A steel water pipe that is rusty inside and a perfectly smooth polypropylene pipe has very different effects on the flow rate;

- Non-galvanized steel pipes have, so to speak, a variable internal surface area . Over time, they become overgrown with rust and mineral deposits, causing the opening to narrow. If you come up with a strange fantasy of making a cold water supply pipe out of steel, this fact cannot be neglected, since the permeability of a water pipe can drop by half in just ten years.

Overgrowth of non-galvanized steel pipes must be taken into account when calculating the water supply system

Well, what about the formula? It's simple. The diameter of the cylinder in this case, as you can easily guess, is equal to the difference between the diameter and twice the thickness of the pipe walls .

If so, the area of the cylinder walls takes the form S=Pi*(D-2N)*L, where D is still the diameter of the pipe, N is the thickness of its walls, and L is the length.

For a heating main 10 kilometers long from a pipe 1 meter in diameter with walls 10 mm thick, the internal surface area will be equal to: 3.14159265*(1-2*0.01)*10000 = 30787.60797 m2.

Metal pipe weight calculator

Calculation of pipe weight primarily depends on the type of pipe metal. So, when calculating the weight of a round pipe, a completely different formula is used than when calculating profile pipes. Therefore, first of all, indicate the type of profile. Then indicate the name of the alloy or steel and the dimensional characteristics of the rolled product. The result will be calculated automatically.

Note! The result is approximate and cannot be used when calculating structures related to human life. To obtain more accurate figures for the mass of pipes, use the “GOST tables of steel pipe weights” in the reference section

Calculation of the weight of a profile pipe

To calculate the mass of a square pipe, the calculator uses the formula:

where ro is the density of the metal, S is the size of the pipe wall, A is the overall dimension of the side, L is the length of the pipe.

To calculate the mass of a rectangular pipe, the calculator uses the formula:

where ro is the density of the metal, S is the size of the pipe wall, AB is the overall dimensions of the sides, L is the length of the pipe.

Self-calculation

How much does 1 meter of profile pipe weigh

? Sometimes you have to deal with wire without markings. This is not a reason to refuse to use it. First, find out what material the core is made of. They are distinguished by color: white aluminum, red copper, yellow brass. After this, we begin to calculate the cross-sectional area. To do this, find out the diameter of the conductor by first removing the insulation from it; in the case of a multi-core wire, by untangling one core.

The diameter can be determined in several ways, for example:

- using a caliper or micrometer;

- pencil and ruler.

The second method gives an approximate result and is used only as a last resort.

Calipers

You can measure wires of any size using a caliper. To do this, place the wire between the jaws of the caliper and look at the scale divisions. Whole numbers of millimeters are counted on the upper scale, decimal fractions of a millimeter on the lower scale.

Pencil + ruler

If you don’t have a meter at hand, and the length of the bare part of the wire being measured allows you to wind it onto a pencil turn to turn with a length of at least 1 cm, then use this method. The number of turns N that fit on a segment L = 1 cm is counted. The diameter value is obtained by dividing the length of the segment by the number of turns. The measurement accuracy depends on the winding density and its length.

Table

After the diameter is determined by one of the methods, Ssection is determined using a formula or using tables.

The simplest table for wire diameters up to 4.5 mm

| Wire diameter, mm | Section, mm | Wire diameter, mm | Section, mm |

| 0,8 | 0,5 | 2 | 3 |

| 1,0 | 0,75 | 2,3 | 4 |

| 1,1 | 1 | 2,5 | 5 |

| 1,2 | 1,2 | 2,8 | 6 |

| 1,4 | 1,5 | 3,2 | 8 |

| 1,6 | 2 | 3,6 | 10 |

| 1,8 | 2,5 | 4,5 | 16 |

More accurate values can be selected from the tables located in the Rules for Electrical Installation Devices (PUE).

Coolant movement speed

It is immediately worth noting that the minimum speed of water movement in the heating system pipeline cannot fall below 0.2-0.25 m/sec. If the speed at some point turns out to be lower, the coolant will gradually begin to release air - and this, in turn, will cause air locks to appear in the system. Such traffic jams always lead to a decrease in the performance of the system, up to its failure.

Conclusion

Having collected the values of all the necessary parameters, it is enough to substitute them into the formula to find out the required pipe diameter for the heating system. To simplify your work, you should use special tables that indicate formulas for calculations and describe in detail all the indicators used in them.

By simple calculations you can determine the optimal pipe size for a particular situation. A clear understanding of what pipe diameter to choose for heating will allow you to create an extremely high-quality and functional design that will provide the house with sufficient heat.

Comparison of one-pipe and two-pipe systems

We have already found out how to calculate heating pipes and what diameter is needed for both types of systems. For closed circuits, with a room area of 120 m2 or more, this figure is 32 mm for polypropylene. In this case, the nominal bore for products with a nominal pressure of 20 and 25 atmospheres is 21.2 mm. For products with a nominal pressure of 10 atmospheres, the nominal bore is 20.4 mm and the outer diameter is 25 mm.

- Efficiency - definitely, “hitches” heat the room more efficiently than single-pipe ones;

- saving money - all that can be saved on Leningradka is some segment of the contour and that’s it.

The number of tees will be the same, and the same number of taps, but more adapters may be required. Imagine a circuit from which two pipes extend at a short interval. One of them goes to the radiator inlet, and the second returns the coolant back to the system. It turns out that the section between the pipes is a bypass. In order for the circulation in the battery to be better, the bypass must be made of a smaller diameter than the main heating circuit. It follows from this that a couple more units of fittings will be required. It turns out that we spend less money on pipes and more on fittings, resulting in no savings, and the efficiency is lower.

As a result, we can conclude from this that the stories about how good and cheap a single-pipe heating system is are simply unfounded.

Section and pressure

Once upon a time there lived a Swiss man, Daniel Bernoulli, in the glorious 18th century. He lived and lived and in the meantime formulated a law that later laid the foundation for modern hydrodynamics and was named after him.

If we translate the dry language of formulas into our familiar Russian, then it can be formulated as follows: the flow speed is inversely proportional to the static pressure of the liquid or gas in it.

From a practical point of view, this means that at pipeline diameter transitions, the flow behaves contrary to common sense: an increase in the cross-section causes an increase in pressure, and a decrease and the associated acceleration of the movement of liquid or gas causes an increase.

The relationship between pipe cross-section, flow speed and pressure in it.

Nowadays, this effect is widely used in mechanisms for various purposes.

Let's give a couple of the most obvious examples that any of us has encountered.

- The main element of the heating unit of the house is the elevator. It is a nozzle in which a stream of water with higher temperature and pressure from the supply pipeline is injected into a volume filled with colder water with low pressure from the return line. Due to the drop in static pressure in the jet, it draws part of the water from the return pipeline through a suction designed for this purpose into recirculation. (See also the article How to bend a profile pipe: features.)

Schematic diagram of the operation of the elevator - the main element of the heating unit of the house.

- The spray gun and airbrush use the same effect: a fast air flow, due to the vacuum created in it, pulls the dye out of the tank, crushes it, turning it into an aerosol, and deposits it on the surface to be painted.

Measuring pipes using photography (copy method)

This non-standard method is used when there is complete inaccessibility to a pipe of any size. A ruler or any other object is applied to the pipe being measured, the dimensions of which are known in advance to any master (often in this case they use a matchbox, the length of which is 5 cm, or a coin). Next, this section of the pipe with the attached object is photographed (in addition to a camera, in modern conditions it is also possible to use a mobile phone). The following size calculations are made from photographs: the visual thickness in mm is measured in the photograph, and then converted into real values, taking into account the scale of the photographs.

Table of rolled metal surface areas

Surface area of 1 ton of rolled steel.

Click on the position you are interested in.

| Profile name, number and section thickness, mm | Surface area of 1 ton profile, m2 | Profile name, number and section thickness, mm | Surface area of 1 ton profile, m2 |

| 1. Sheet steel and open bent profiles. The surface is given as a total on both sides. | |||

| Sheet thickness | Square | Sheet thickness | Square |

| 2,0 | 127,6 | 12,0 | 21,5 |

| 2,2 | 115,9 | 14,0 | 18,4 |

| 2,5 | 102,3 | 16,0 | 16,2 |

| 2,8 | 91,2 | 18,0 | 14,4 |

| 3,0 | 85,0 | 20,0 | 13,0 |

| 3,2 | 79,9 | 22,0 | 11,8 |

| 3,5 | 73,0 | 25,0 | 10,4 |

| 4,0 | 63,9 | 28,0 | 9,4 |

| 5,0 | 51,1 | 30,0 | 8,7 |

| 6,0 | 42,7 | 32,0 | 8,2 |

| 7,0 | 36,6 | 36,0 | 7,3 |

| 8,0 | 32,1 | 40,0 | 6,6 |

| 9,0 | 28,5 | 45,0 | 5,9 |

| 10,0 | 23,4 | 50,0 | 5,4 |

| 11,0 | 21,5 | 55,0 | 4,9 |

| 2. Closed bent square, rectangular and pipe profiles. The surface is given on the outside. | |||

| Wall thickness | Square | Wall thickness | Square |

| 2,0 | 65,2 | 12,0 | 10,8 |

| 2,5 | 52,1 | 4,0 | 9,3 |

| 3,0 | 43,5 | 16,0 | 8,1 |

| 3,5 | 37,3 | 7,0 | 7,6 |

| 4,0 | 32,9 | 18,0 | 7,5 |

| 5,0 | 26,5 | 20,0 | 6,7 |

| 6,0 | 22,0 | 22,0 | 6,1 |

| 7,0 | 19,0 | 25,0 | 5,5 |

| 8,0 | 16,6 | 28,0 | 5,0 |

| 9,0 | 14,5 | 30,0 | 4,7 |

| 10,0 | 13,1 | 32,0 | 4,4 |

| 11,0 | 11,8 | 40,0 | 3,5 |

| 3. Angular steel, equal flange. The surface is given as a total on all sides. | |||

| Shelf thickness | Square | Shelf thickness | Square |

| 3 | 86,5 | 14 | 19,0 |

| 4 | 65,0 | 16 | 16,6 |

| 5 | 52,0 | 18 | 14,9 |

| 6 | 44,0 | 20 | 13,3 |

| 7 | 37,0 | 22 | 12,0 |

| 8 | 33,0 | 25 | 10,6 |

| 9 | 29,5 | 28 | 9,6 |

| 10 | 26,3 | 30 | 9,0 |

| 12 | 22,0 |

| 4. Hot rolled channels. The surface is given from all sides. | |||

| Profile no. | Square | Profile no. | Square |

| 5 | 47,1 | 20 | 38,3 |

| 6,5 | 46,4 | 20A | 36,4 |

| 8 | 45,4 | 22 | 36,6 |

| 10 | 44,7 | 22A | 34,9 |

| 12 | 43,1 | 24 | 35,0 |

| 14 | 41,6 | 24A | 33,3 |

| 14A | 39,7 | 27 | 33,2 |

| 16 | 40,5 | 30 | 31,4 |

| 16A | 38,7 | 33 | 29,6 |

| 18 | 39,3 | 36 | 27,7 |

| 18A | 37,7 | 40 | 26,1 |

| 5. I-beams. The surface is given as a total on all sides. | |||

| Profile no. | Square | Profile No. | Square |

| 10 | 44,4 | 27 | 33,0 |

| 12 | 43,1 | 30 | 31,2 |

| 14 | 41,8 | 36 | 26,7 |

| 16 | 40,5 | 40 | 24,9 |

| 18 | 39,1 | 45 | 23,2 |

| 20 | 38,1 | 50 | 21,4 |

| 22 | 36,7 | 55 | 19,7 |

| 24 | 34,4 | 60 | 18,1 |

| 6. I-beams for monorails. The surface is given as a total on all sides. | |||

| Profile no. | Square | Profile No. | Square |

| 24M | 24,0 | 36M | 21,4 |

| 30M | 22,3 | 45M | 19,3 |

| 7. Beams with parallel flange edges. The surface is given as a total on all sides. | |||

| Profile no. | Square | Profile no. | Square |

| 20B | 49,1 | 50B2 | 22,8 |

| 20B1 | 39,4 | 50B3 | 20,9 |

| 20B2 | 36,7 | 55B | 26,7 |

| 20B3 | 33,6 | 55B1 | 22,6 |

| 23B | 45,9 | 55B2 | 20,8 |

| 23B1 | 38,0 | 55B3 | 19,1 |

| 23B2 | 35,3 | 60B | 24,4 |

| 23B3 | 32,0 | 60B1 | 20,5 |

| 26B | 43,2 | 60B2 | 18,6 |

| 26B1 | 35,9 | 60B3 | 17,2 |

| 26B2 | 33,3 | 70B | 21,0 |

| 26B3 | 30,4 | 70B1 | 19,1 |

| 30B | 40,7 | 70B2 | 17,4 |

| 30B1 | 35,4 | 70B3 | 15,9 |

| 30B2 | 33,0 | 70B4 | 14,6 |

| 30B3 | 30,1 | 80B | 19,3 |

| 35B | 37,8 | 80B1 | 17,2 |

| 35B1 | 34,4 | 80B2 | 15,5 |

| 35B2 | 31,1 | 80B3 | 14,2 |

| 35B3 | 28,4 | 80B4 | 13,1 |

| 40B | 34,9 | 90B | 17,8 |

| 40B1 | 30,8 | 90B1 | 15,7 |

| 40B2 | 27,8 | 90B2 | 14,5 |

| 40B3 | 25,5 | 90B3 | 13,2 |

| 45B | 32,3 | 90B4 | 12,0 |

| 45B1 | 27,5 | 100B | 16,7 |

| 45B2 | 24,9 | 100B1 | 14,4 |

| 45B3 | 22,8 | 100B2 | 13,0 |

| 50B | 29,3 | 100B3 | 11,7 |

| 50B1 | 24,8 | 100B4 | 10,6 |

| 8. Wide-panel I-beams. The surface is given as a total on all sides. | |||

| Profile no. | Square | Profile no. | Square |

| 20Ш | 38,9 | 50Ш4 | 14,2 |

| 20Ш1 | 33,8 | 50Ш5 | 12,9 |

| 20Ш2 | 31,2 | 60Ш | 21,4 |

| 23Ш | 37,9 | 60Ш1 | 17,4 |

| 23Ш1 | 30,9 | 60Ш2 | 16,0 |

| 23Ш2 | 27,8 | 60Ш3 | 14,6 |

| 26Ш | 33,2 | 60Ш4 | 13,1 |

| 26Ш1 | 28,6 | 60Ш5 | 11,8 |

| 26SH2 | 25,9 | 60Ш6 | 10,7 |

| 30Ш | 30,1 | 70Ш1 | 15,8 |

| 30Ш1 | 26,0 | 70Ш2 | 14,4 |

| 30Ш2 | 23,4 | 70Ш3 | 13,1 |

| 30Ш3 | 21,1 | 70Ш4 | 12,0 |

| 30Ш4 | 19,4 | 70Ш5 | 11,0 |

| 35Ш | 26,8 | 70Ш6 | 10,3 |

| 35Ш1 | 22,7 | 70Ш7 | 9,5 |

| 35Ш2 | 20,8 | 70Ш8 | 8,8 |

| 35Ш3 | 19,1 | 80Ш | 17,4 |

| 40Ш | 23,2 | 80Ш1 | 14,4 |

| 40Ш1 | 20,4 | 80Ш2 | 13,2 |

| 40Ш2 | 18,9 | 80Ш3 | 12,1 |

| 40Ш3 | 17,9 | 90Ш | 15,7 |

| 40Ш4 | 16,2 | 90Ш1 | 13,1 |

| 50Sh | 22,6 | 90Ш2 | 12,1 |

| 50Ш1 | 19,4 | 90Ш3 | 11,1 |

| 50Ш2 | 17,4 | 100Sh | 14,2 |

| 50Ш3 | 15,7 | 100Ш1 | 12,3 |

| 9. Column I-beams. The surface is given as a total on all sides. | |||

| Profile no. | Square | Profile no. | Square |

| 20K | 32,3 | 35K1 | 19,3 |

| 20K1 | 29,3 | 35K2 | 17,3 |

| 20K2 | 26,1 | 35K3 | 15,6 |

| 20K3 | 23,7 | 35K4 | 14,2 |

| 20K4 | 21,7 | 35K5 | 13,0 |

| 23K | 31,6 | 35K6 | 11,9 |

| 23K1 | 27,5 | 35K7 | 10,9 |

| 23K2 | 25,7 | 35K8 | 10,0 |

| 23K3 | 23,2 | 40K | 19,9 |

| 23K4 | 21,2 | 40K1 | 17,5 |

| 26K1 | 26,1 | 40K2 | 16,0 |

| 26K2 | 23,3 | 40K3 | 14,5 |

| 26K3 | 20,9 | 40K4 | 13,1 |

| 26K4 | 19,2 | 40K5 | 11,8 |

| 26K5 | 17,6 | 40K6 | 10,8 |

| 30K1 | 21,4 | 40K7 | 9,8 |

| 30K2 | 19,9 | 40K8 | 9,0 |

| 30K3 | 18,3 | 40K9 | 8,2 |

| 30K4 | 16,7 | 40K10 | 7,8 |

| 30K5 | 15,2 | 40K11 | 6,2 |

| 30K6 | 14,1 | 40K12 | 5,2 |

| 30K7 | 12,8 | 40K13 | 4,4 |

| 30K8 | 11,7 | 40K14 | 3,7 |

| 10. Round steel, reinforcement, rod. | |||

| Diameter | Square | Diameter | Square |

| 5,0 | 102,0 | 45,0 | 11,3 |

| 6,0 | 84,9 | 48,0 | 10,6 |

| 6,5 | 78,5 | 50,0 | 10,2 |

| 7,0 | 72,8 | 53,0 | 9,6 |

| 8,0 | 63,6 | 56,0 | 9,1 |

| 9,0 | 56,7 | 60,0 | 8,5 |

| 10,0 | 50,9 | 65,0 | 7,8 |

| 11,0 | 46,3 | 70,0 | 7,3 |

| 12,0 | 42,5 | 75,0 | 6,8 |

| 13,0 | 39,3 | 80,0 | 6,4 |

| 14,0 | 36,3 | 85,0 | 6,0 |

| 15,0 | 33,9 | 90,0 | 5,7 |

| 16,0 | 31,8 | 95,0 | 5,4 |

| 17,0 | 30,0 | 100,0 | 5,1 |

| 18,0 | 28,3 | 105,0 | 4,9 |

| 19,0 | 26,8 | 110,0 | 4,6 |

| 20,0 | 25,4 | 120,0 | 4,2 |

| 21,0 | 24,3 | 125,0 | 4,1 |

| 22,0 | 23,2 | 130,0 | 3,9 |

| 24,0 | 21,2 | 140,0 | 3,6 |

| 25,0 | 20,4 | 150,0 | 3,4 |

| 26,0 | 19,6 | 160,0 | 3,2 |

| 28,0 | 18,2 | 170,0 | 3,0 |

| 30,0 | 17,0 | 180,0 | 2,8 |

| 32,0 | 15,9 | 190,0 | 2,7 |

| 34,0 | 15,0 | 200,0 | 2,5 |

| 36,0 | 14,2 | 210,0 | 2,4 |

| 38,0 | 13,4 | 220,0 | 2,3 |

| 40,0 | 12,7 | 240,0 | 2,1 |

| 42,0 | 12,1 | 250,0 | 2,0 |

Name of the profile, number and section thickness, mmSurface area of 1 ton of profile, m2

Calculation of pipe area for painting

Both savings in money and time resources depend on taking this into account. The first point is that a correct analysis will allow you to purchase the required amount of paint without overpaying for its excess. The second is characterized by the absence of the need to spend additional time traveling to the store for additional purchases.

The whole procedure should begin with a pipe analysis. After all, V of coloring matter depends not only on its dimensions, but also on the material, shape and S.

How to calculate the paint area of a pipe, knowing its diameter and shape? To get a solution, we will consider each point separately. This will help you better understand the formulas and apply them in practice in the future.

What types of pipes are there?

It is necessary to paint metal products, or rather, steel ones. Cast iron ones are much more resistant to rust, while copper or brass ones are not susceptible to corrosion at all. In addition, their appearance is excellent without any paint. Steel needs protection, and the polymer layer that the paint forms has excellent water resistance.

Gas pipes

The area of pipes to be painted depends on the length of the product, diameter, material and, of course, shape. Based on the latter characteristic, pipe rolling is divided into several groups:

- round cross-section is the most common type and is used in the construction of water pipes, sewers, and smoke structures. Calculating the size of the surface for painting is not difficult if you know the outer diameter of the steel product;

- with a section of rectangular, square, triangular and even hexagonal - profile. Calculating the surface area here is easy. Profiles are more often used in the construction of frames;

Profile pipes

- cone-shaped - very specific products, as a rule, are not used in everyday life. In production they are used in the construction of pressure injection systems;

- corrugated - the most difficult to calculate, as they have a variable cross-section. Paint consumption in this case is the greatest;

Corrugated pipes

sewer - for large highways and wells. These are concrete rings with a variable inner surface.

Sewage well