To know how much paint will go on a pipe of a given length, you need to make several calculations. It is necessary to calculate the area of the pipe over the entire section, then multiply it by a coefficient describing paint consumption and introduce various corrections. This can be done manually, but you will have to spend a lot of time, because not everyone remembers the geometry formulas that they studied at school. The calculator will help you determine the area of the pipe to be painted much faster than manually, which will save time and nerves, because you won’t have to check the calculations and recalculate some parts of the equation.

Painting the pipe

Why do we need calculations of pipe parameters?

In modern construction, not only steel or galvanized pipes are used. The choice is already quite wide - PVC, polyethylene (HDPE and LDPE), polypropylene, metal-plastic, corrugated stainless steel. They are good because they do not have as much mass as their steel counterparts. However, when transporting polymer products in large volumes, it is advisable to know their weight in order to understand what kind of machine is needed. The weight of metal pipes is even more important - delivery is calculated by tonnage. So it is advisable to control this parameter.

What cannot be measured can be calculated

It is necessary to know the outer surface area of the pipe to purchase paint and thermal insulation materials. Only steel products are painted, because they are susceptible to corrosion, unlike polymer ones. So you have to protect the surface from exposure to aggressive environments. They are used more often for the construction of fences, frames for outbuildings (garages, sheds, gazebos, cabins), so the operating conditions are difficult, protection is necessary, therefore all frames require painting. This is where the area of the surface to be painted is required - the outer area of the pipe.

When constructing a water supply system for a private house or cottage, pipes are laid from the water source (well or borehole) to the house - underground. And still, to keep them from freezing, insulation is required. You can calculate the amount of insulation by knowing the outer surface area of the pipeline. Only in this case it is necessary to take material with a substantial margin - the joints must overlap with a substantial margin.

The cross-section of the pipe is necessary to determine the throughput - whether this product can carry the required amount of liquid or gas. The same parameter is often needed when choosing the diameter of pipes for heating and plumbing, calculating pump performance, etc.

What and how to paint?

After the area of the surface to be painted and the material consumption have been calculated, you can select the coloring composition. The following types of paints are used for painting pipes:

- Acrylic based enamel. It contains organic solvents. A durable shiny coating is formed on the surface.

- Alkyd enamel. Features a wide range of colors. Allows you to create a durable coating that does not crack or wear off.

- Water-dispersed compositions. Dries faster than other dyes. In addition, they do not have an unpleasant odor. Before using such substances, a primer must be applied to the surface of the pipes.

- Oil paint. It is used extremely rarely for such purposes.

The first layer is to apply a primer. It will protect the surface from rust and increase the strength of the connection with the paint. After the primer has dried, apply two coats of paint.

Calculating paint consumption manually is not so easy - for this you will have to remember several geometric formulas. Before starting calculations, it is necessary to take measurements of the structure. To make the process easier, you can use ready-made tables or a pipe surface area calculator.

Inner and outer diameter, wall thickness, radius

Pipes are a specific product. They have an internal and external diameter, since their wall is thick, its thickness depends on the type of pipe and the material from which it is made. Technical specifications often indicate the outer diameter and wall thickness.

Pipe inner and outer diameter, wall thickness

Having these two values, it is easy to calculate the internal diameter - subtract twice the wall thickness from the external one: d = D - 2*S. If you have an outer diameter of 32 mm, a wall thickness of 3 mm, then the inner diameter will be: 32 mm - 2 * 3 mm = 26 mm.

If, on the contrary, there is an internal diameter and wall thickness, but an external one is needed, we add double the stack thickness to the existing value.

With radii (denoted by the letter R) it is even simpler - this is half the diameter: R = 1/2 D. For example, let’s find the radius of a pipe with a diameter of 32 mm. Just divide 32 by two, we get 16 mm.

Vernier caliper measurements are more accurate

What to do if there are no technical data for the pipe? To measure. If special accuracy is not needed, a regular ruler will do; for more accurate measurements, it is better to use a caliper.

Why paint pipes?

Making a pipe look aesthetically pleasing is the most obvious function of painting. But she is far from the only one. First of all, pipes are painted to make them corrosion resistant. Previously, water pipes were made of steel without a special protective coating. This approach allowed for significant savings.

At the end of the last century, the situation was complicated by the fact that there was no control over construction companies as such. And difficult financial conditions have forced companies to resort to austerity.

Therefore, to set up utilities, the cheapest steel pipes with thin walls, which were designed for the installation of gas pipeline systems, were most often used. Such water pipelines literally fell into disrepair within ten years. Painting in this case could extend their service life.

At the moment the situation has improved, but not much. And now steel pipes are most often used in household heating and water supply systems. You can extend the service life of such structures if you carry out painting work (read: “Which paint to choose for heating pipes - possible options, characteristics”). First you need to calculate the paint for the pipe.

Recommendation: galvanized pipes do not require full painting with an anti-corrosion compound. But the threaded area needs protection, since the zinc layer on it is often destroyed. Therefore, the threads in galvanized pipes must be painted.

Calculation of pipe surface area

The pipe is a very long cylinder, and the surface area of the pipe is calculated as the area of the cylinder. For calculations, you will need a radius (internal or external - depends on what kind of surface you need to calculate) and the length of the segment that you need.

Formula for calculating the side surface of a pipe

To find the lateral area of the cylinder, we multiply the radius and length, multiply the resulting value by two, and then by the number “Pi”, we obtain the desired value. If desired, you can calculate the surface of one meter, which can then be multiplied by the desired length.

For example, let's calculate the outer surface of a piece of pipe 5 meters long, with a diameter of 12 cm. First, let's calculate the diameter: divide the diameter by 2, we get 6 cm. Now all values must be reduced to the same units of measurement. Since the area is calculated in square meters, we convert centimeters to meters. 6 cm = 0.06 m. Next, we substitute everything into the formula: S = 2 * 3.14 * 0.06 * 5 = 1.884 m2. If you round it up, you get 1.9 m2.

How it's done

Several geometric formulas will help you calculate paint consumption. They will differ depending on the type of pipe.

Cylindrical

The area of a cylindrical product is calculated using the following formula: S = 2 * π * R * L. The quantities indicated in it are:

- π – number “pi”;

- R – outer radius of the pipe in millimeters;

- L – length in meters.

For example, if the length of the pipe is 10 m and its diameter is 60 mm, the surface area will be 1.88 m2. Calculations for commonly used pipe diameters can be found in the corresponding tables or use our calculator.

Knowing the surface area to be painted and the properties of a particular paint, you can easily determine its consumption.

Cylindrical sewer

The area of such products is calculated using the above formula. The only difference is the larger sizes. The calculation is based on a height of 90 cm. These are the rings that are most often used for sewer installations. The outer diameter can vary from 70 to 200 cm. Here are some examples:

- With a diameter of 70 cm, the area will be 1.99 m2.

- If the diameter is one meter, the area will be 2.83 m2.

- For the largest products (diameter - two meters), the surface area for painting will be 5.65 m2.

Profile

To determine the area of a profile pipe required for painting, you need to know its dimensions:

- H – height of one side;

- W – height of the other side;

- L – length.

For calculations, the following formula is used: S = 2 * H * L + 2 * W * L. If the length of the product is the same 10 meters, and its sides are 5 and 10 cm, the total area will be three square meters.

Cone shaped

For the most part, such structures are a truncated cone. The area of its lateral surface can be calculated using the following formula: S = π * (

R11+ R2

) *

L. It consists of the following quantities:

- R1 – radius of the smaller circle;

- R2 – radius of the larger circle;

- L – generatrix of a truncated cone: the length of the wall from the narrow to the wide part of the pipe.

With the structure measuring ten meters, three and six centimeters in diameter, the painting area will be almost one and a half square meters.

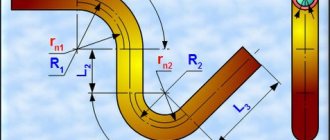

Corrugated

Calculating the area to paint a corrugated pipe is the most difficult thing to do. Experts recommend entering all values obtained during the work into a table.

So, first you need to decide on the following dimensions:

- rounding radius – A;

- projections of straight sections onto length and diameter (B and D);

- pitch of corrugated part – C;

- bevel angle of the flat part – E;

- height of the corrugated section – F;

- the line along which the product can stretch is G.

Essentially, a corrugated pipe is the same cylinder that can be extended along the G line.

The calculations look something like this.

- Let us assume that the value of A is 3 mm. The rounded part is calculated using the formula 2 x π x A. In this case, it will be 18.84 mm.

- The value of D must be doubled. Let it be equal to 20 mm.

- If we take into account the above data, we can determine that the stretched corrugation will be equal to 38.84 mm.

- If you remove the bevel angle, you can calculate the value of E. It is equal to twice the diameter, or 12 mm.

- As in previous cases, the length of the product is 10 m. Knowing this, you can calculate the number of folds. To do this, the length must be divided by step. It turns out 866 pieces.

- Knowing all these dimensions, you can calculate the stretched length of the product. To do this, 866 must be multiplied by 38.84 mm. It turns out that the length of the stretched corrugation will be 33.64 m.

- If the diameter of the stretched corrugation is, for example, 52 mm, the area for painting will be equal to 54.92 m2.

Weight calculation

When calculating the weight of a pipe, everything is simple: you need to know how much a linear meter weighs, then multiply this value by the length in meters. The weight of round steel pipes is in reference books, since this type of rolled metal is standardized. The weight of one linear meter depends on the diameter and wall thickness. One point: the standard weight is given for steel with a density of 7.85 g/cm2 - this is the type recommended by GOST.

Round Steel Pipe Weight Table

In table D - outer diameter, nominal diameter - inner diameter, And one more important point: the weight of ordinary rolled steel is indicated; galvanized steel is 3% heavier.

Weight table for profiled square pipe

Where to begin

Paint consumption depends not only on the size of the pipe, but also on the material used to make it and on the shape.

Most often you can find pipes in the shape of a cylinder. But there are other types:

- In the shape of a rectangle. Outwardly, they look like ordinary timber. Otherwise called profile.

- Cone-shaped. The name speaks for itself. Very rarely used. Their scope of application is pressure injection systems.

- Corrugated.

- For sewerage equipment. They are large cement rings.

The dimensions of pipes of each type correspond to the requirements stated for them in special documents.

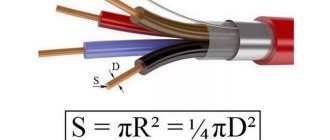

How to calculate cross-sectional area

Formula for finding the cross-sectional area of a round pipe

If the pipe is round, the cross-sectional area should be calculated using the formula for the area of a circle: S = π*R2. Where R is the radius (internal), π is 3.14. In total, you need to square the radius and multiply it by 3.14.

For example, the cross-sectional area of a pipe with a diameter of 90 mm. We find the radius - 90 mm / 2 = 45 mm. In centimeters this is 4.5 cm. We square it: 4.5 * 4.5 = 2.025 cm2, substitute it into the formula S = 2 * 20.25 cm2 = 40.5 cm2.

The cross-sectional area of a profiled pipe is calculated using the formula for the area of a rectangle: S = a * b, where a and b are the lengths of the sides of the rectangle. If we consider the cross-section of the profile to be 40 x 50 mm, we get S = 40 mm * 50 mm = 2000 mm2 or 20 cm2 or 0.002 m2.

Calculation of cross-sectional area

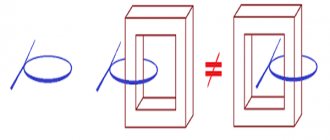

The cross-section of the pipe is, subject to correct cutting, when the ends are perpendicular to the longitudinal axis of the product, a regular circle.

The area of a circle is calculated using the formula:

S=πR^2=π D^2/4,

where π=3.1415926, R is the outer radius of the circle, D is its outer diameter.

Taking into account the thickness of the pipe walls, the pipe area is calculated using the formula:

S=〖π(Rl)〗^2=〖π(D/2-l)〗^2,

where l is the pipe wall thickness.

If in the first formula we take R and D not as external, but as internal diameters, then there is no need to take into account the wall thickness, and the calculation can be carried out using the first equation.

You need to understand that before calculating the cross-sectional area of a pipe, all initial parameters should be converted to the same units of measurement (for more details: “How to calculate the cross-sectional area of a pipe - simple and proven methods”). In principle, if desired, calculations can be carried out in any units - millimeters, centimeters, meters, etc. The main thing when carrying out further computational operations is to bring the area value to a standard form (square meters).

It should also be taken into account that in pressure pipelines the working medium moves throughout the entire volume of the pipe, and in the case of a gravity-flow design, the liquid fills only part of the volume of the pipe - the so-called live section (about

How to calculate the volume of water in a pipeline

When organizing a heating system, you may need a parameter such as the volume of water that will fit in the pipe. This is necessary when calculating the amount of coolant in the system. For this case, we need a formula for the volume of a cylinder.

Formula for calculating the volume of water in a pipe

There are two ways: first calculate the cross-sectional area (described above) and multiply it by the length of the pipeline. If we calculate everything according to the formula, we will need the internal radius and the total length of the pipeline. Let's calculate how much water will fit in a system of 32 mm pipes 30 meters long.

First, let's convert millimeters to meters: 32 mm = 0.032 m, find the radius (divide in half) - 0.016 m. Substitute into the formula V = 3.14 * 0.0162 * 30 m = 0.0241 m3. It turned out = a little more than two hundredths of a cubic meter. But we are used to measuring the volume of the system in liters. To convert cubic meters into liters, you need to multiply the resulting figure by 1000. It turns out 24.1 liters.

Why else is it necessary to determine the pipeline area?

During construction or repair work, it is necessary to take into account such a factor as the cost of man-hours to perform any action. After all, this affects not only the cost of the work, but also the number of workers required to complete the task. If you have to paint a couple of pipes 5–10 meters long, then no special calculations are required, because one person will complete this work in a day and will spend one or two cans of paint. If the number of pipes is in the hundreds, and the total footage is in kilometers, the calculator will determine the area of the pipe for painting hundreds of times faster than you would calculate manually. This fully applies to both profile (rectangular) and round pipes.

Large diameter pipes

The principle of painting pipes

If you plan to paint cold water supply pipes, they must first be dried. First, prepare enough water to last you 24 hours. Do not open the cold tap during this time. Within 24 hours, the water supply will heat up to room temperature, and at the same time all condensation will disappear. If you plan to paint the cold water riser, you will have to use a fan to dry it. All moisture should disappear from it.

When drying is complete, you can proceed to surface preparation. Pipes must be thoroughly cleaned and degreased. Using a knife is usually all you need to remove paint to get the job done.

If it doesn't lag behind, try heating it with a hair dryer or a gas torch. But watch the temperature, overheating can lead to leakage of threaded connections. Now you will need to clean the surface with a wire brush. There should be no layers of paint or other materials left on the pipe.

You can move on to priming work, then painting begins. It is advisable to apply two layers, although then the paint consumption on the pipe will be higher. It is preferable to choose liquid paint. If it is too thick, then it needs to be diluted. Otherwise, untidy smudges will form, and such a coating will take much longer to dry.

A special case

Many people are interested in whether it is possible to paint hot pipes. Anyone can complete this task. But there are certain nuances that need to be taken into account.

Features of painting hot pipes:

- It is worth understanding that applying paint with a brush is not the best option. Since the pipe is hot, the coating will dry quickly, even before it is completely rubbed. Because of this, the painted product will look unsightly and have marks from the brush. Therefore, it is advisable to purchase spray paint. You can also use a spray gun.

- It is extremely important to calculate the painting of the pipe in advance and buy material in reserve. After all, the leftovers can be used in the future. But if there is a lack of paint, many difficulties will arise.

- The paint will emit a pungent odor when dry. Inhaling it will make a person feel unwell and will negatively affect his health. Therefore, it is advisable to think about the issue of ventilation in advance and perform work in a respirator.

- It is necessary to carefully approach the issue of choosing paint. Experts recommend using heat-resistant enamel that is resistant to high temperatures. Low quality paint will quickly change color.

Recommendation: It is highly undesirable to cover the wall with newspaper; there will most likely be smudges on it. It is best to use plastic film. It must be secured in such a way that it simultaneously grasps the section of the wall and the floor from below.