Before using any small arms, they must be sighted. This is required to find out the tactical and technical characteristics of each specific pistol or rifle. Manual sighting, in particular of pneumatic weapons, cannot show fairly accurate results and is performed on special sighting machines.

Target of weapon sighting

In production, weapons are zeroed “cold”, but this is not enough for effective use. Even after the work of a specially hired specialist, the gun can behave completely differently in the hands of the owner. After all, each shooter has his own way of holding a weapon, adjusting it and shooting.

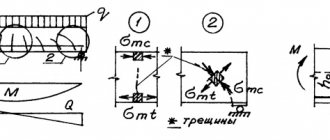

The goal of zeroing is to align the gun's mid-point of impact with the target's sights or crosshairs on an optical sight.

During zeroing, features of the gun are revealed that can interfere or help with its use:

- accuracy of fire;

- the nature of shooting with different types of bullets;

- characteristics of optical sights.

Zeroing a weapon allows you to achieve one hundred percent hits on the target. It is carried out in the following cases:

- when purchasing a new weapon;

- when replacing optics;

- when changing ammunition;

- drying out of wood stock;

- installation of recoil compensators;

- mounting devices on the barrel;

- when repacking the shutter group;

- after the fall;

- with active long-term use;

- after long-term transportation or storage without a cover.

Any change, even wrapping the barrel with camouflage material, leads to increased dispersion and changes in hit accuracy. For zeroing, you should take the ammunition that will be used more often.

According to the rules, zeroing is carried out in two stages: the first on a machine, the second manually, in the field. This is a rather expensive procedure, since a lot of expensive ammunition is consumed, but experts advise carrying it out regularly.

What to fill the shooting rest with?

Shooting bags can be filled with coarse sand. However, this is not the most suitable and optimal option. The fact is that although sand is heavy (which is very important for a high-quality rest), at the same time sand does not give the desired effect for resting during preparation for shooting.

Therefore, such bags need to be filled with more rigid materials. Those shooters who make their own shooting bags use various cereals as filler - buckwheat, oats, rice, wheat, peas, beans. Some people recommend filling such a bag with cut caps from plastic bottles or airsoft balls.

Among the variety of filler options for such stops, you can also name hygienic fillers with large granules for cat litter, wood shavings or sawdust, and gun shot. In general, each shooter chooses the filling for his shooting bag that will be most convenient and comfortable for him while aiming and shooting.

If you make a shooting bag yourself, you need to make sure that the filler does not spill out of such a bag. Ideally, after filling the structure, you simply need to sew up the hole through which you carried out this procedure.

Did you like the article? Subscribe to the channel to stay up to date with the most interesting materials

Source

The role of the machine in zeroing

Beginning shooters try to simplify their task by using “improvised means”: old pillows, plywood, stools and shelves. They are used to make stands for weapons. But such devices wobble, only hindering the shooter. The basis of high-quality zeroing is the equipment of the shooting position. And this means a place for the carbine and a place for the shooter himself.

A reliable support under the butt and fore-end ensure a constant position of the weapon during shooting for any number of shots and the skill of the shooter. It is the uniformity of placement and the constancy of the behavior of the gun that guarantees the effectiveness of zeroing. All necessary conditions are created by the shooting machine.

The machine fixes the carbine rigidly, by the fore-end. Special stops allow the weapon to kick back during a shot. Stops are more popular among professional hunters.

Types of machines

The sighting machine is not a new invention. Various types of them are used in armies to train soldiers. Thus, the 1951 model PS-51 is still in use today. The device allows you to rotate a fixed weapon for aiming.

Almost all companies that produce weapons create their own models of rests and machines. All of them have a single feature: weapon mounting and a rigid base, completely eliminating the impact of any subjective phenomena (human, weather factors). Conventionally, existing models can be divided according to their main properties:

- collapsible and stationary;

- specialized for a specific type of gun or universal;

- allowing only shooting or servicing of guns.

The cost of equipment depends on the size, weight, brand and material of manufacture. A zeroing machine that provides rigid placement on any surface is considered the best and most reliable. It is useful to have a mechanism to determine the height of the barrel. Any machine can be used as a stand when cleaning a rifle.

Shooting machines

The gun is mounted on a frame (sometimes the butt is held by a special support), aimed at the target with the help of regulatory elements, and firing on the machine is carried out like a heavy machine gun. This is an excellent device for initial shooting, the results of which are subsequently corrected by individual shooting.

The machine for zeroing pneumatics can be metal or plastic. Metal ones are reliable and heavy, they are good for large-caliber weapons. Plastic machines, which are much cheaper than metal ones, work great with calibers up to 7.62. For owners of powerful guns who use them frequently, it is preferable to purchase a metal machine, which is additionally weighted in various ways.

A common mistake when zeroing: different positions of the rifle in the machine or rest. The weapon must be placed on the stand with the fore-end in the same position as the shooter's hand.

Front stops

There are many models of compact front supports, including military ones. More convenient and efficient are expensive models with the ability to be installed in several planes. Military grades do not allow for adjustment and may scratch the forend. Plastic ones are light, simple and inexpensive. They are convenient for rare sightings, as a backup option. But for serious shooters, metal stops with the ability to adjust the height are optimal. There are many more additional adjustments that you can do without: turning the weapon, the table, the amount of tilt. Their price is reasonable and convenient to use. The most expensive models are adjustable with a lever, which makes work easier.

As an additional accessory, many people buy a butt bag, creating an analogue of a collapsible machine. The bag is filled with sand, it smooths out recoil and makes zeroing convenient.

The main criterion when choosing any machine model for sighting is the absence of backlash between parts. All joints must be tightly tightened.

What does the price depend on?

It is not for nothing that a sighting machine is considered a pleasure only for professional hunters or athletes who can afford not only the purchase of a good weapon, but also the purchase of tools for its maintenance. The price of a unit for fixing a rifle or shotgun depends on the following nuances:

- fixture size;

- material of manufacture;

- device weight;

- brand.

The best and most reliable machine is considered to be the one that is capable of securing the weapon on any surface. Therefore, such a tool must be quite heavy (made of metal) and large. As for the brand, Russian and Chinese models are inexpensive, but American and European machines are a pleasure for the rich.

The cost of a machine is influenced by its mechanism, which determines the number of functions available to the tool. For example, some machines can be used as a stand for cleaning a gun, others allow you to raise the rifle to a fairly large height. The more bells and whistles a machine has, the more expensive it will cost the buyer.

Making a shooting machine

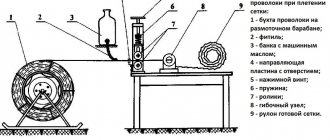

Although buying a suitable device is not a problem, many craftsmen make sighting machines with their own hands. Here is one of the models for zeroing pneumatics, which you can do yourself without welding.

To make it you will need:

- metal pipe of rectangular or square cross-section;

- threaded pin with a diameter of 14 mm;

- 2 bolts with a diameter of 14 mm and a length of 10 cm;

- 1 bolt with a diameter of 14 mm and a length of 15 cm;

- 6 bolts with a diameter of 5 mm with nipple nuts;

- rivet bolts;

- 13 regular nuts;

- 2 wing nuts;

- 10 washers;

- metal plate 6.5x8 cm;

- 3 corners 5.5 x 6.5 cm;

- spray can with black paint.

Types of sighting machine

A sighting machine is a device that allows you to securely fix a weapon and ensure its complete immobility. In this case, such a device can be rotated and deployed in order to ensure it hits the target.

Reliable fixation of the weapon is the main purpose of the sighting machine. It is important in order to prevent any third-party interference in the shooting process, including from humans or adverse weather conditions.

However, the sighting machine may have other functional features. Depending on such features and types of designs, machines are divided into the following types:

- collapsible (a set consisting of a table and a chair can be assembled and disassembled; some hunters prefer this type due to the fact that shooting can be carried out in a sitting position);

- stationary;

- universal;

- specialized (this type is focused on a specific type of weapon; their low weight is an advantage);

- intended only for shooting;

- used when servicing guns.

What is a sighting machine and how to make it yourself

A sighting machine is a useful tool that allows you to fine-tune the sights on your weapon by zeroing it in as precisely as possible. Such a unit will be indispensable when checking the tactical and technical characteristics of a rifle or pistol. That is why it is so valued by shooting range owners and professional hunters. Read on to learn about the different types of machines for zeroing weapons, as well as how to make a tool for zeroing a carbine with your own hands.

The essence of zeroing

Sighting is a completely incomprehensible process for novice gun owners and people completely unrelated to firearms. However, it is almost impossible to do without this when purchasing a new weapon.

Experienced hunters know that it is better to carry out shooting on their own, without the help of professionals. Each person has his own way of holding a weapon, pressing it and firing.

The essence of zeroing is precisely to align the point of average hits with the target. When carrying out such a procedure, the owner of a pneumatic or firearm:

- learns to feel the features of weapons;

- determines the difference between firing different types of bullets.

If the process is carried out correctly, the hunter will be able to ensure a guaranteed hit on target with every shot.

The need for shooting occurs in several cases:

- when purchasing a new weapon;

- in case of replacement of optics;

- when using new ammunition;

- when installing additional components (recoil compensators, devices on the muzzle);

- if the rifle has been dropped;

- in case of improper storage or prolonged stay in transit during transportation;

- if the wooden bed has dried out.

It is important to understand that any change provokes a change in the accuracy of the hit when firing a weapon. It is for this reason that hunters carry out shooting even in cases where they simply wrapped the barrel with material, for example, camouflage, to disguise the weapon.

According to the rules, this procedure is carried out in two stages. The first involves shooting on a machine, and the second - in the field. Unfortunately, you won't be able to avoid the costs. Sighting is carried out only with those ammunition with which you plan to go hunting. Accordingly, it will not be possible to replace them with a cheaper analogue when testing a gun.

The hand will not tremble: an assistant for marksmanship on the hunt

The culmination of any hunt (of course, if it is not a quiet mushroom hunt) is a shot. The hunter must make every effort to be accurate and not be ashamed of an offensive mistake. Sometimes you have to watch how perplexed a shooter is when he missed while shooting at a moose from a distance of 25–30 meters.

How could this happen?

After all, the rifle has been sighted and the hunter shoots perfectly.

And this could be due to many factors: excitement, adrenaline or fatigue accumulated during the transition or waiting.

One of the options for solving this problem is the use of stops and stands of various designs.

But after our hunters began to go hunting in other countries (and abroad, especially in Africa, the use of rests is almost the norm), they realized that a regular rest sharply increases shooting efficiency.

Without taking up space in your equipment, a small monopod will serve its owner well.

Today we can safely say that if you are going on a group hunt, say for an elk in a pen, two people in your team will use one type of rest or another. To understand which emphasis is best for you, let's take a closer look at them.

On African hunts, the use of stops is almost mandatory. PHOTO TOPSIMAGES.COM

A distinctive feature of bipods is their attachment to a weapon, which is why compact models have become widespread, which when folded do not interfere with movement.

The attachment of the bipod to the weapon can be rigid (and then the horizontal rolls are removed by different lengths of the right and left legs) or with a “rocking” (and then making adjustments is much easier and faster).

The positive qualities of bipods are their compactness and low cost, but for hunters who shoot from a standing position, bipods are still less convenient.

The next type is pods that are not attached to weapons. For example, a monopod, a single stop, most often telescopic, looking like a ski pole with a flyer on top.

The telescopic stop is most convenient, especially in a monopod, since the shooter has no other way to adjust the height.

photo: Semina Mikhail

Despite its apparent simplicity, a monopod makes life very easy for the shooter: when walking it can be used as a stick, and when shooting it makes aiming much easier.

Monopods come in different designs, two-, three- and four-piece. It is interesting that their prices are much higher than their analogues - walking poles sold for tourists, monopods for photographers, which is apparently due to lower demand and the specifics of the market.

Bipod is a stand consisting of two sticks, which can be either telescopic or non-telescopic. When walking, they are usually connected together and used in a similar way to a monopod.

With the latter, when shooting, the height is adjusted by the width of the placed sticks. A bipod is noticeably more stable and does not require as much control as a monopod, but it is less convenient to transport.

Using a stop increases the distance to confidently hit a target. PHOTO BY ANTON ZHURAVKOV

A tripod is the most stable design of the above, similar to a photographic tripod.

The price to pay for stability is heavy weight and bulkiness. By the way, any tripod can be turned into a tripod by installing a flyer on it, which is sold separately and is not very expensive.

I would also like to mention homemade stops. Often watching videos from Africa, I notice that hunters simply use three or two poles tied together.

In our conditions, it is not easy to find three thin, but strong and, most importantly, straight poles, but to buy an aluminum tube with a diameter of 16 or 18 cm in a repair store for a penny and make yourself a bi- or tripod that is in no way inferior to the African one or even superior to it, quite possible.

With proper fastening, this structure can always be disassembled and obtained poles for an awning or tent or a holder for a pot.

The rest can be used for both shooting and observation. PHOTO BY ANTON ZHURAVKOV

But there are lightweight designs that are mounted on a tripod and are quite suitable for transportation during hunting. Such designs make it possible to minimize errors when shooting.

Old school hunters (at least ours) did not use special equipment. In the literature, a method of shooting often found is when a backpack is simply placed on a fallen tree or stump and they shoot from it.

In connection with the latter, I remember an incident: one old hunter on the chase had a small pillow made of two strips of felt. The essence of the design was not very clear to me, so I asked.

It seemed to me that it increases the area of the shoulder strap and prevents sliding, but it turned out that, in addition to these useful functions, the cushion is placed under the carbine when shooting from a hard surface (wood, stone) and prevents bouncing, maintaining a constant STP point.

In this position, the carbine is securely fixed, has a large sector both horizontally and vertically, but it cannot be removed quickly, which, in my opinion, is not very good.

In general, the conclusion can be drawn as follows: when shooting, it is best to use a rest. Let it be a tree or something else, but the main thing is that shooting will become more effective than shooting simply with your hands.

In conclusion, I would like to say that, of course, no stops or machines can compensate for a person’s low shooting training.

The emphasis can compensate for minor errors that appear from fatigue, but if the shooter does not know how to take the lead correctly or simply has little experience, then the emphasis in this case is powerless.

So the best decision will be our desire to improve our shooting skills.

Source

Good day to all!

It was evening, there was nothing.

And I decided to make a comfortable pillow-rest for shooting and sighting in particular.

So let's go: we have 1 * 1.5 meters of camouflage fabric, a pair of zippers, in my case 20 cm, 0.5 meters of sling, a mischievous attitude and patience are desirable.

Let's quickly sketch out the pattern and get:

So, imagining ourselves to be a great tailor, we cut it all out and sew it together in a sequence convenient for everyone.

There are no photos of the cut out flaps and the sewing process, it was late and I was in the heat of work, sorry. And there is nothing interesting there.

Preparation of materials

Anyone can build a homemade machine, since the creation process does not involve performing complex actions. No welding work is required either.

Before starting the practical work, it is recommended to read the step-by-step instructions and look at the finished sample in the photo. This will avoid technical issues that arise during device assembly.

The workshop always has a set of tools for home craftsmen. To create a sighting machine, you only need a drill, a grinder and a screwdriver.

You should choose only high-quality materials, since the functionality of the machine will depend on this.

Attempts to get away with improvised means and save on the manufacture of the machine do not give the desired result. Usually a stool, pillow or shelves are used for this, considering that such objects can act as an acceptable stand. It is impossible to ensure their immobility during shooting, which means that the quality of the shooting will not meet the standards.

For this reason, it is better to spend time, but make a machine that can last for more than one year.

For its construction you need:

- pipe, plate, metal corners;

- wooden blocks;

- pin (thread diameter 14 mm);

- fastening materials (bolts, nuts, washers);

- spray paint.

What to fill the bag stops with?

What will those who know the question or link say? What filler should I fill the bag stops with? What is their optimal shape and size? Sincerely.

Fall asleep. See the form on the websites. Go to the varmint thread, there is a detailed post on this topic.

I use 1 kg. packed rice enclosed in a cover made of thick, durable and soft fabric fastened with two magnetic rivets.

As I understand it, cereal is the best option? But this is probably not entirely practical, because... Due to its hygroscopicity, it quickly loses its desired properties and requires frequent replacement. Or will its low price solve this problem? I assumed that there could be synthetic or other types of fillers. Sincerely.

You can try granulate from plastic production, but you will be a pioneer. Don’t forget to write the result here later

Do you mean plastic raw materials in granules for the production of bottles or other products? Original! Sincerely.

Buckwheat goes well. In this case, the bag can be given different shapes.

Where can you buy good bags online?

In. Buckwheat also rolls, but regarding plastic raw materials, just a fleeting thought came to mind, I’ll have to try it myself