A rolling machine, which many experts call a rolling machine or simply rollers, is a device that allows you to bend workpieces made of sheet metal. Rolling machines are highly efficient and versatile, which allows such equipment to be successfully used in a wide variety of fields, including construction and repair.

Rolling machine W12-4×2500 rolls mild steel up to 4 mm thick

Purpose and main varieties

Rolling devices, the versatility of which was mentioned above, can be found today in almost any production enterprise. It is with the help of such a machine (which, if desired, you can make it yourself) products of conical, cylindrical and even oval shapes are obtained from rolled sheet metal. The technological operation that allows solving such problems is called rolling. However, it should not be confused with flaring, through which changes in the configuration and dimensions of tubular products are achieved.

Roller machines of the simplest design are also actively used by home craftsmen. Using such equipment, various gutters, air ducts, elements of roofing structures, as well as many other products are produced. Roller machines produced by modern industry can effectively process sheets made of various metals.

Thus, devices of this type, represented by a wide variety of models, can successfully cope with sheet workpieces made of carbon and alloy steels, aluminum, copper and cast iron. Some models of such machines, the rollers of which have a special design, can bend polycarbonate sheets.

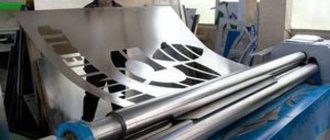

Sheet metal rolling process

Among the rolling equipment, the following categories are distinguished:

- manual machine;

- electromechanical machine;

- sheet metal machine equipped with hydraulic drive.

A manually driven roller machine is the simplest type of equipment, which can be produced in floor-standing (mounted on a stand) or table-top (mounted on a workbench) versions. This manual rolling machine is easy to use, but requires significant physical effort. Meanwhile, the simplicity of the machine’s design ensures that it remains reliable for a long time.

A classic manual three-roll bending machine suitable for rounding metal workpieces up to 3.5 mm thick

Three-roll manual rollers (namely, they are mainly manufactured with this number of working parts) allow processing of rolled pipe and sheet metal with a wall thickness of up to 1.5–2 mm. This type of manual sheet bending machine is easiest to make with your own hands. It has such advantages as:

- compact dimensions;

- insignificant mass;

- high mobility, which makes it easy to move such machines to those places where their use is most in demand;

- savings on electricity costs (a manual rolling machine does not require its use);

- low cost (when compared with the price of electromechanical machines).

Electromechanical three-roll sheet bender FormRoller is used for mass production of workpieces of various geometries

An electrically driven device (electromechanical rolling machine) has a special gearbox in its design, which significantly increases the efficiency of such equipment. An electromechanical rolling machine can be used both for processing sheet metal and for changing the configuration of profile pipe products. As for sheet metal processing, a three-roll machine with an electromechanical drive can be used for processing sheet metal whose thickness does not exceed 4 mm.

The most powerful type of equipment is a hydraulic rolling machine, which is actively used in energy, shipbuilding and machine-building enterprises. A hydraulic three-roll machine or a device with a large number of working parts is many times more powerful when compared with devices of the manual or electromechanical category. Using hydraulic-type rolling equipment, which is often equipped with CNC systems, it is possible to successfully bend sheets of metal whose thickness reaches 8 mm.

The hydraulic drive of this machine easily moves the shafts of impressive dimensions, and the CNC controls their location and the degree of deformation of the sheet

Types, classification and use

Thanks to the various designs and types of rollers, a wide range of products are obtained in various sectors of our economy. They can be classified according to the following criteria:

By number of executive bodies:- two-roll;

- three-roll;

- four-roll.

- By drive type:

- manual;

- mechanical;

- electric;

- hydraulic.

- By bending method:

- segmental;

- drone;

- spring;

- crossbow

- By type of control:

- rune;

- CNC.

Small rollers with two shafts are mainly used by craftsmen in jewelry workshops. Flat or profile blanks are rolled onto them, and rolling is performed.

Twin-roll rollers can also be found in catering establishments. They are used for rolling dough. The canvas is of one thickness and any length.

Typically, such units are manually driven, since large loads are not required. To rotate all rolls simultaneously, a chain or gear drive is used. They are compact, light in weight and secured to the table with a clamp or several bolts.

Electric models have high performance. They are widely used in the manufacture of sheet metal pipes. Pipes are made for air ducts, chimneys, drains and more.

The electric drive and low weight on the frame structure allow you to install such machines directly at the installation site or in a home workshop. More bulky and powerful machines are intended for enterprises.

Hydraulically driven rollers are heavy duty equipment. Usually their height exceeds human height by several times. And the drive power allows you to roll steel sheets with a thickness of more than 100 mm. The resulting parts reach 6 m in diameter.

To make a cone on a roll bending machine, it is necessary to give the side shafts an additional degree of freedom. This is expressed by the fact that one side of the shaft is movable and, depending on the angle of the cone, can rise to the required height. During such a run-in, the workpiece tends to move out. To prevent the workpiece from moving, a thrust roller is installed.

This category of equipment also includes a rolling machine for sheet metal. Its main purpose is to produce sheet metal of various thicknesses from a hot thick billet by rolling. Steel mills are equipped with machines of this type.

Due to the fact that the workpieces are fed heated to high temperatures, the mill shafts are made of heat-resistant heat-treated steel.

Design and principle of operation

The supporting element of a rolling machine, including a self-made one, is the base frame. It is on this frame, which can be made of cast iron or sheet steel of considerable thickness, that the deforming element of the machine is mounted, which can include two, three or even four rolls. The vast majority of such devices, including those made by yourself, are equipped with three working bodies, since twin-roll rollers are not very efficient.

Rotational motion during the operation of a three-roll machine is communicated only to the two lower working bodies, which, meanwhile, can perform linear movement only in the horizontal plane, which is necessary to change the distance between them. The upper roller of such a device, which is called a thrust roller, rotates due to the friction forces created between its surface and the surface of the workpiece being processed.

Rolling machine device (click to enlarge)

The upper roller, which is equipped with a rolling machine, has the ability not only to move in the vertical direction, which allows it to be pressed with the required force to the surface of the workpiece, but also to tilt to the side. The latter is necessary in order to quickly replace it with a roller designed for processing workpieces with other geometric parameters.

The machine, whose working rollers are equipped with special grooves, can be used for bending pipes, rods and even large-section wire. It should be borne in mind that the additional fourth roll, the use of which significantly increases the load on the drive mechanism of the equipment, can only be installed on an electromechanical or hydraulic rolling machine.

Lower shaft position adjustment unit

A sheet bending machine, the main working parts of which are rollers, operates on the following principle.

- The sheet of metal from which it is necessary to form a cylindrical or conical product is placed on two lower rolls, separated from each other by a certain distance.

- By lowering the upper roll using a special mechanism, the metal sheet is securely clamped between three working bodies.

- When the two lower rolls rotate, which is provided by a manual or electromechanical drive, the sheet of metal being processed is set in motion and begins to bend around the working elements of the rolling machine that clamp it, gradually taking on the required configuration.

The polished surfaces of the rollers do not damage the workpieces, and the slots along the edges allow you to bend the rods

Moving at a certain speed between the rollers, a flat sheet of metal gradually turns into a product of cylindrical, conical or oval shape. Obviously, a machine of this type does not work like a flaring machine, the working part of which rolls out the end of a tubular product, expanding it to the required geometric parameters.

It is not at all necessary to buy a rolling machine, which can effectively bend not only rolled sheet metal, but also tubular products. A rolling apparatus, if high productivity is not required from it, is easy to make with your own hands. Of course, it is easiest to make such a machine with a manual drive, but the power and functionality of this equipment is quite enough to perform work related to construction and repair.

DIY rolling machine: drawings and video

To manufacture a manual rolling machine, you must first find its drawings or develop them yourself, taking the design of any serial model as a basis.

As an example, consider a set of drawings of the USG rolling machine, which are presented below.

Assembly drawing of a serial rolling mill USG (click to enlarge)

So, in order to make a manual rolling machine with your own hands, you need to follow the algorithm presented below.

- From metal sheets, cutting them according to a previously prepared drawing, a device frame is made, in special grooves in which its lower shafts will be fixed. The structural elements of the frame are connected to each other using stiffening ribs, which can be metal pipes or angles.

- To accommodate the upper roll, support posts are welded to the frame of the device. For their manufacture, it is best to use a powerful U-shaped profile. Bearing units are mounted in the support stand, into which the upper roll of the machine is installed.

- A drive mechanism is mounted on the side of the frame, which includes three sprockets, a chain and a device for tensioning it.

- The final stage of manufacturing a homemade rolling machine is installing the handle of the drive mechanism, tensioning the chain and adjusting all structural elements.

Installing the top roll on a homemade machine

Naturally, after final assembly, the homemade machine must be tested (and the operation of all its mechanisms adjusted, if the need arises).

Main technical parameters

How to make a sheet bending machine with your own hands? To do this, it is necessary not only to develop drawings of such a device, but also to determine its technical characteristics. It is best to take the design of a serial model as a basis and independently adapt it to your own needs.

Assembly drawing of a factory-made three-roller machine (click to enlarge)

Considering the fact that you are going to install your rollers in a certain room, you should immediately decide on their dimensions. This parameter, which directly depends on the length of the installed shafts, will determine what width of sheet blanks you can process on a device made by yourself. When deciding on the size of hand rollers, you should also take into account the fact that processing sheet blanks with a width of more than 1.2 meters using them will be quite difficult physically. The weight of a homemade machine will affect the ability to move it around the room and transport it.

Drive shaft. Drawing (click to enlarge)

Folding shaft. Drawing (click to enlarge)

Pressing shaft. Drawing (click to enlarge)

Drawing of three-roll plate bending rollers with electric drive (click to enlarge)

In addition to the dimensions and weight of future rollers, it is necessary to determine the following characteristics of such equipment:

- the diameter of the rolls - the main working parts of the device (this parameter, which is quite important, will determine the maximum radius with which you can bend the metal sheets being processed);

- the maximum distance at which the upper thrust roll can be located from the lower ones;

- the maximum distance to which the lower rollers can move apart;

- the speed at which the processed sheet material can move between the rolls.

Studying the technical parameters of factory models will help you decide on the size and design of the machine.

An important parameter that you should pay special attention to when developing a drawing of future rollers is the rigidity of their design. When processing metal sheets, significant mechanical loads are experienced not only by the rolls, but also by all other components - bed, drive mechanism, etc. That is why the choice of the roller operation scheme, as well as the selection of materials for its implementation, should be done with particular care.

Most often they are used for the manufacture of 3-roll rollers, since an increase in the number of working parts of such low-power manual devices leads to an increase in the level of load exerted on its drive mechanism.

Popular models of manual rolling equipment

Manual roller machines, presented on the modern domestic market, allow you to effectively solve technological problems of any degree of complexity. Thus, for an affordable price you can purchase a small-sized table-top rolling device or stationary equipment, the power and performance of which is quite enough to solve the problems facing a small production or repair enterprise.

Among specialists and home craftsmen who prefer to bend metal sheets with their own hands, manual rolling equipment from the following brands is very popular.

Stalex

This company produces reliable and efficient equipment designed for processing sheet blanks of various widths and thicknesses.

Metalmaster

This brand produces reliable, functional and easy-to-use equipment for rolling. On many models from Metalmaster, due to the presence of special grooves on the rolls, it is possible to bend pipes and rods.

Encore Corvette

This is a domestic brand under which inexpensive but fairly reliable sheet metal bending equipment is produced in China. Using such machines, you can bend sheet metal whose thickness does not exceed 1.5 mm.

The Enkor-Corvette-512 model with a manual gear bends rods and sheets, it can be adjusted to a cone

Application of devices

Bending operations for rolling sheet material are performed in production when it is not profitable to buy finished products or the number of orders is quite large. The main consumers of rolling equipment are the metallurgical, chemical industries, construction and many others.

Main directions of use of machines:

- Formation of cone-shaped and cylindrical products.

- Manufacturing of pipes and structures with radial bending.

- Drawing ellipses and other metal shapes.

The decision to purchase such bending rollers will greatly simplify the operations of bending these shapes and designs. And this will allow your enterprise to reach a new level of rolled metal production.

Electromechanical sheet metal bending machines

Electromechanical rolling machines are presented on the domestic market in an equally wide range. So, of the most popular brands of devices of this type, the following are worth noting.

VEM

This is a functional rolling equipment that, due to its high reliability, rarely requires repairs and expensive maintenance. By equipping with additional structural elements, the technical capabilities of machines of this brand can be significantly expanded.

Stalex

Professional-level electromechanical roller machines are produced under this brand. A design feature of such machines is the asymmetrical arrangement of the work rolls, as well as the ability to quickly remove the upper working body, which allows for the rapid removal of the workpiece from the processing zone.

Electromechanical rolling machine Stalex ESR-1300×2.5 (the width and thickness of the processed metal is reflected in the designation of the machine)

Metalmaster

This is a powerful and reliable equipment with convenient foot control, which can be used not only for bending sheet metal, but also for processing tubular products and reinforcing bars .