Is Poxypol cold welding?

You can't cut threads there; there's absolutely no room for a drill or tap. It needs to be taken apart.

If you push this Poxy Pol into the hole and screw the bolt into the uncured mass, will it be able to hold (after it hardens there)?

| QUOTE (ignat @ Mar 18 2022, 17:24) |

| Is Poxypol cold welding? |

You can't cut threads there; there's absolutely no room for a drill or tap. It needs to be taken apart.

If you push this Poxy-Pol into the hole and tighten the bolt into the uncured mass, will it be able to hold?

Rinse/blow out the hole, degrease both surfaces, apply a toothpick from the inside and onto the surface of the bolt, tighten the bolt. It will be ready in 15 minutes, and after a few hours you can load it to full capacity.

Holds better than anything I've ever tried - 100%

| QUOTE (niksam @ Mar 18 2022, 19:33) |

| Instead of a bolt, put a stud on the thread lock until it stops, a couple of turns should remain, and a nut on top. |

| QUOTE (Phil-2000 @ Mar 18 2022, 20:02) |

| Poxypol is a common fast-curing epoxy. If there are temperature changes, it will peel off. There is a solution with anaerobic permanent thread lockers, from Henkel, it seems, |

| QUOTE |

| Or - repair reaming and screwing in the “spring”. |

| QUOTE (niksam @ Mar 18 2022, 20:10) |

| M6 does not need to be tightened much, especially aluminum, about 10 N.m, and the “collapsible” clamp adds +10 N.m |

There this M6 holds a torsion spring, i.e. one of her “shoulders”. The spring is quite tight. It is even possible that I removed the thread not because (or not only because) the bolt went crooked, but also because I “pressed” the spring while tightening the bolt.

Maybe just screw the stud onto the polysol-shaped one, and use the nut for the spring?

| QUOTE (Phil-2000 @ Mar 18 2022, 21:02) |

| Poxypol is a common fast-curing epoxy. If there are temperature changes, it will peel off. |

| QUOTE (Volgogradets @ Mar 19 2022, 08:16) |

| And have you tried? |

Yes, I tried it. Maybe I didn’t degrease it very well, I don’t know.

| QUOTE (Volgogradets @ Mar 19 2022, 08:16) |

| I've had it for about 5 years now and a piece of the intake manifold has not peeled off or fallen off! |

Marvelous! The expansion coefficients of the materials must be completely different!

Ignat, you can also try this hat. They write that you can even unscrew/tighten it after. But I can’t vouch for it, since I haven’t used it myself.

If you don’t need to twist it, you can use this glue. The refrigeration foreman told me that he glues aluminum-copper tubes at the joint, and they last for years. But I can’t vouch for it either, since this is all hearsay.

| QUOTE (ignat @ Mar 18 2022, 21:47) |

| Maybe just screw the stud onto the polysol-shaped one, and use the nut for the spring? |

| QUOTE |

| Poxypol is a common fast-curing epoxy. If there are temperature changes, it will peel off. |

Once upon a time, a piece in the metal CO pipe that runs throughout the engine rotted and fell off. I don’t remember the manufacturer: the plastic tube contained a gray-black substance that had to be cut to the required length and kneaded thoroughly before use! So I covered up this hole with it - at first just to get about 100 km home! But since I had to wait either 7 or 10 days for the ordered part, I drove the same amount around the city during this time. At first I climbed under the hood after almost a couple of kilometers to have a look, then I got the hang of it - this thing held me to death! After replacing the tube with a new one, I tried to tear it off: in the end I tore it out along with the metal! So I wouldn’t dismiss this option right away.

| QUOTE |

| The refrigeration foreman told me that he glues aluminum-copper tubes at the joint, and they last for years. But I can’t vouch for it either, since this is all hearsay. |

But I would not trust such “masters of affairs” without hesitation - they have no interest in doing everything for centuries! And the ALUMINUM-COPPER pair seems to hint at this.

| QUOTE (Michalytsch @ Mar 19 2022, 10:12) |

| I don’t remember the manufacturer: the plastic tube contained a gray-black substance that had to be cut to the required length and kneaded thoroughly before use! |

Something like this, I guess.

| QUOTE (Michalytsch @ Mar 19 2022, 10:12) |

| And the ALUMINUM-COPPER pair seems to hint at this. |

| QUOTE (ignat @ Mar 18 2022, 17:17) |

| The thread in the aluminum part is broken. M6 or M5, bolt length 12 millimeters. |

Try using a self-tapping screw (with a 6-sided head) instead of a bolt.

Buy several self-tapping screws at once. To differ slightly in the outer diameter of the thread. And in this way: 1. you can cut a new thread (with the self-tapping screw), with minimal effort 2. you can select a self-tapping screw that will “sit” most firmly.

Z.Y. I did this in a desperate situation. Self-tapping screw Holds very tightly (in AL)

Read also: Laser cutting wood products

| QUOTE (kudrik @ Mar 19 2022, 09:45) |

| Try using a self-tapping screw (with a 6-sided head) instead of a bolt. |

Buy several self-tapping screws at once. To differ slightly in the outer diameter of the thread. And in this way: 1. you can cut a new thread (with the self-tapping screw), with minimal effort 2. you can select a self-tapping screw that will “sit” most firmly.

Z.Y. I did this in a desperate situation. Self-tapping screw Holds very tightly (in AL)

The only drawback, perhaps, is that the self-tapping screw may break off when tightening, or if it doesn’t hold, then you’ll have to take everything apart and solve the problem the “correct” way.

Threaded connections are the most widely used today. They are used in various industries. During operation, the working part of the thread may be damaged, resulting in reduced strength and reliability. There are quite a large number of different ways to restore a damaged working part, all of them are characterized by their own specific features.

Technology for restoring internal and external threads

Today, thread restorer is used extremely rarely in work. The most commonly used common tools are:

- A drill is used to change the size of a hole.

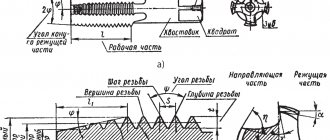

- The tap and die are designed for direct cutting of turns. They are inexpensive and are often used to cut a new surface, but they can also be used to restore a damaged one.

- Spindle or tool for screwing in the insert. It is characterized by the fact that the working part resembles a threaded one; there is a special hook at the end.

- Repair insert, represented by a diamond-shaped spiral. A leash was made at one end, due to which it rotates due to connection with the spindle.

In addition, some technologies involve the use of epoxy glue, cold welding or other materials. The choice is made depending on the specific case

How to fix the screwdriver in the head

The spark plug thread breaks well when replacing spark plugs. One or more candles are simultaneously unscrewed along with the wire. Therefore, it will not be possible to install a new plug without repairing the thread.

If a breakdown occurs in a car service center, the car owner will be offered timely repairs, which will be carried out using a special tool for repairing wires.

If the thread breaks in a field, in a garage or on the street, the car will no longer be able to reach the nearest car service center. We recommend finding a service that has a special tool in its arsenal and agreeing with its employees about on-site repairs.

The plug wire reset tool does not require any special skills to operate it. Therefore, repairs can be done on your own.

Often the thread breaks due to the narrowing of the candle when wound. A malfunction occurs if the spark plug was replaced by an unqualified service worker or an inexperienced car owner.

In addition, the thread may break due to the spark plug being distorted when screwing. This occurs if the wrong tool is used to replace the spark plug.

Additionally, replacing spark plugs while the engine is hot can also cause damage. Therefore, carry out repairs only on a cold engine.

To avoid over-tightening or tilting the spark plug, you need to use a professional socket and torque wrench to check the torque.

There are two ways to restore the thread of the spark plug hole:

- Remove the cylinder head. Drill a hole for the candle, cut the wire larger, cut out special accessories for it, etc.;

- Without disassembling the cylinder head. Repair the spark plug threads using the special tool.

The second option is preferable, since it does not require disassembling the cylinder head. Thanks to this, repairs can be carried out quickly.

Specialty tools include tap set taps and a plug thread reset kit.

The cost of a spark plug well repair kit can be several times higher than the cost of a spark plug tap. Let's try to figure out what this is connected with and in what case it is more appropriate to make a choice in favor of one or another solution.

Thread restoration method

Each thread restoration method is suitable for a specific case. An example is the use of epoxy glue, which can repair minor damage to the coils.

If it is possible to change the size of the hole, then a tap is used. It is selected depending on the parameters of the existing turns.

The tool in question is designed to produce turns on metal.

In some cases, it is impossible to increase the diameter, then a screwdriver is used. Such a cylindrical device has coils on the outside and inside with the required pitch.

In some cases, the damage is represented by a hole that can be repaired by welding. After this, thread restoration is also carried out using the most suitable tool.

What is a threaded rod

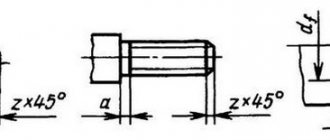

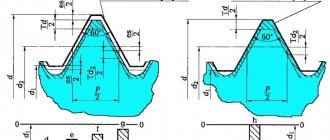

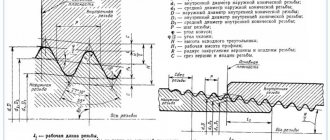

It is impossible to understand the defects of a product if you do not fully understand what the product is. A threaded rod is a metal rod with threads cut on both extreme sides (DIN 938) or along the entire length (DIN 975, 976).

There are two technologies for cutting threads on studs: tapping and rolling. This will help you understand what to do if the thread of a stud is broken.

- cutting is carried out by thread-cutting heads (dies), which cut off part of the metal from the rod and create thread turns.

- Unlike cutting, rolling is carried out using thread rolling heads, not with cutters, but with rolling rollers. The thread is not cut, but extruded. This results in more precise and cleaner threads.

For cutting, hardened dies (dies) are used, which in the first case cut the metal, in the second case they are pressed against the raw rod with the necessary pressure. The cut or extruded metal is forced out and removed through a die.

Application of epoxy glue

Using epoxy glue can significantly speed up the process of thread restoration. Among the features of the restoration work, we note the following points:

- The hole is filled with a special substance, after which you need to wait a little until it hardens.

- The bolt is screwed in to form the required surface, after which the substance hardens.

This method is not suitable when fasteners are used under conditions of high loads or vibration. This is due to the fact that the polymer does not form a durable and hard surface after hardening.

How to secure the screwdriver?

How to secure the screwdriver?

Post by Demige » Jan 22, 2010, 00:04

I’m sure the topic is boyan, but if I can briefly, how to secure the screw in the head?

I fastened it to a pin - the pin is cut off and the screw is still unscrewed and not the candle. In addition, there is a little siphoning through the thread. The spark plug has to be screwed in without a ring, otherwise, due to the screw flange, it turns out deeper than necessary. It is impossible to flare it - it does not stick out into the combustion chamber at all - it is exactly flush with it.

Maybe I think - pin + glue. So the question is - what adhesive should I use?

Post by region47 » Jan 22, 2010, 00:08

Post by Demige » Jan 22, 2010, 00:19

Post by Detonator » Jan 22, 2010, 00:24

Post by region47 » Jan 22, 2010, 00:30

Post by android » Jan 22, 2010, 00:31

Post by Demige » Jan 22, 2010, 00:34

. Dismantling with conventional tools is difficult; heating from 250°C is required. .

The combustion chamber is more than 250″. This thing won't work.

I think I read it - they put it on an asbestos cord + grease, it seems to stick and everything is ok. Has anyone done this? And what about the fact that the candle doesn’t reach if it’s with a ring?

Post by musolini » Jan 22, 2010, 00:36

Post by Detonator » Jan 22, 2010, 00:36

Loctite 270 is a high strength threadlocker that cures only after air is displaced upon contact with metal (anaerobic product). Completely fills and seals threads, preventing corrosion. Used to fix a threaded connection to prevent spontaneous loosening; Fixes more reliably than all mechanical fasteners (spacer rings, cotter pins, etc.) even under high loads. Simultaneously seals and protects against corrosion.

Cold welding

Cold welding can be used instead of polymer glue. It is also applied as a paste, after hardening it forms a strong and hard surface. The recovery process is as follows:

- Both components are mixed to obtain the required paste.

- The paste is filled with the damaged surface, after which you need to wait a little.

- The bolt is screwed in.

Cold welding can withstand a fairly large load, but is easy to use and inexpensive.

Using a thread tap

The tap is used to cut grooves, due to which the required geometry is formed. The instrument in question consists of two parts and can be classified according to a large number of criteria. The features of the work carried out include the following points:

- The tool is lubricated with oil. Due to this, the process of forming turns is simplified.

- When working three turns along the way, there are 1.5 turns in the opposite direction. This is done in order to remove chips from the cutting zone.

- The tool must be positioned strictly vertical to the surface.

- After the required surface has been formed, a control bolt is used. The first pass may be under a slight load, but after that there should be no problems.

It takes a relatively short amount of time to form turns. In this case, you can get high-quality and reliable threads that will last for a long period.

Russian Standards

- GOST 9066. Studs for flange connections…

- GOST 22032. Studs M2 - M48, screwed into holes...

©elesant.ru

More articles

- Basic standards for electrical installation work

- Introductory machine. Calculation, selection of an introductory machine for an apartment

- Built-in, overhead and hanging floor panels

- Charging the diesel generator battery

- Paper insulated cables

- Cable metal tray

- How to choose a stylish floor lamp

- How to properly install electrical wiring in a bathhouse

- How to reduce prices for electrical work

- Distribution panel complete set, circuit breakers, connection terminals

Using a screwdriver

When using a screwdriver, a hole is drilled with a suitable drill, after which a tap of the appropriate diameter is selected. A screwdriver is installed in the hole, the upper part is cut off if necessary.

Screwdriver for thread restoration

After this, notches are made on the boundary using a core. This is done so that the screw does not unscrew from the hole. There are a wide variety of screwdriver options on sale, so there will be no problems with selection.

How to fix the screw in the cylinder

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

lucky you. because anaerobic fixative is complete bullshit. it’s like spreading office glue)

DCH

DCH

Slavyansk Donetsk region?

I am also a builder Uzhachi Kalega

Try to find a bolt with a thread like a candle and a nut for it, screw it into a screw and tighten it over the nut, and then try to unscrew it all

I used to live in Gorlovka, I was born there

Typically, such things are designed for use in a certain temperature range. When the range limits are exceeded, the material is destroyed. Since it is more difficult to cool in a home (garage) environment than to heat, you should try heating. The only thing is that the metal itself is not damaged. Therefore, you need to run to the store (the packaging most likely has not been preserved), look at the packaging to see what is written on the temperature and.

Source

The use of footwear

Such fasteners can also be restored by using futorka. This type of threaded connection is a bushing that has a large outer diameter and a smaller inner diameter.

Read also: Do-it-yourself mushroom cutting drawings

The scope of application of futorks is very large. An example is the manufacture of furniture or the connection of various pipes, fastening paired wheels.

In some cases, when it is possible to change the diameter of the connection, futorok is used when the turns are damaged.

With repair insert

In the case where the above method is not suitable, a repair insert or foot will help out.

The operating procedure is as follows:

- We prepare a footer of the required size.

- Using a tap whose size corresponds to the outer diameter of the insert, we cut a hole for screwing in the fitting.

- After thoroughly cleaning the chips, install the insert and secure it with a retaining ring. As a result, the hole will look like in the photo and will be completely identical to the old one.

If you follow all the details of installing an insert with a double-sided thread, then the reliability of this repair method will be the highest. The only disadvantage of this type of repair is the need to have a lot of inserts of the required diameter and a tap in stock.

How to repair the expansion tank cap yourself and why it is important

There are many reasons for thread damage on aluminum parts.

One careless movement or too much force to tighten becomes the beginning of a new problem. But it can be solved very easily if you know and correctly apply the repair methods used by experienced car enthusiasts and professional car mechanics

Education: secondary specialized. Specialty: car mechanic. Professional diagnostics, repair, maintenance of passenger cars of foreign production 2000-2015. Extensive experience working with Japanese and German cars.

2 comments

- Denis says: I don’t understand why you need to go through the trouble of making a tap out of a bolt when you can take a ready-made tap.

- skivko1 says: This advice will be useful to someone. In Russia we are used to repairing cars ourselves.

Selecting Cold Weld for Threads

There are various types of the substance in question on sale. When choosing, the following points are taken into account:

- Recommended area of application.

- Features of manufacturing the working mixture.

- Operating conditions: temperature, humidity and some other points.

Restoring threads by cold welding

Most versions are represented by two components that are mixed to obtain a paste. It is worth considering that the substance does not remain in a plastic state for long.

Disadvantages and advantages

Each method has its own advantages and disadvantages. Let's take the following as an example:

- Cold welding and polymers can be used when the hole diameter cannot be changed. However, the resulting coils are characterized by low strength.

- The tap is used only when the hole can be slightly enlarged. This produces high-quality and durable coils.

- Inserts allow you to expand the range of application of the cutting tool, but the restored thread is also not designed for heavy loads.

In general, we can say that there are simply a huge number of ways to restore fasteners. The choice is made depending on where it is used and what the load is.

If you find an error, please select a piece of text and press Ctrl+Enter.

They write that: since many people use equipment with a gasoline two-stroke engine, due to design features, they often have to unscrew the spark plug from the block head, which leads to damage to the threads in the spark plug channel. The spark plug has a strictly defined thread diameter (M14) and therefore it will not be possible to drill a mounting hole or use a screwdriver for restoration. In most cases, the block head material is aluminum; the metal is quite soft and thread repair by passing it with a tap does not bring the desired result.

In such cases, the so-called liquid thread will help you - a polymer composition that is intended for repairing spark plug channels. You can use the reconditioned threaded connection after 24 hours of polymerization. Also, the connection remains completely removable, and the composition has less adhesion to steel than to aluminum. This means that with some initial effort you should be able to remove a spark plug or bolt from a remanufactured aluminum housing.

Who used it? How was it ? Your opinion?

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: STORM (—.95-54-233-131.dynamic.murmansk.avangarddsl.ru) Date: 09-03-13 10:34 |

All my adult life I have been scratching the threads on a candle with a soft pencil, applying graphite, the candle always unscrews normally without damaging the thread. This is advice on how to prevent it, not how to eliminate it.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomato (—.qwerty.ru) Date: 09-03-13 11:00 |

I usually use graphite lubricant.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author (—.pppoe.avangarddsl.ru) Date: 09-03-13 11:36 |

Me too, but it needs fixing.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomat (—.qwerty.ru) Date: 09-03-13 12:14 |

Then a pinwheel or spiral insert.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author (—.pppoe.avangarddsl.ru) Date: 09-03-13 12:19 |

I understand that ETA does not inspire?

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomat (—.qwerty.ru) Date: 09-03-13 12:23 |

Maybe, of course, something has already been invented, but I haven’t heard it yet.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Bubble67 (Cheerful Village) (—.broadband.corbina.ru) Date: 09-03-13 12:23 |

This is all nonsense. I tried to use similar crap on the trimmer, and in the end the spark plug shot past my friend’s ear immediately when starting it up. Well, not in the eye. There are special kits with a tap and screws (futures), as in the photo. It costs a little, but it really helps.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: HUNTER-1 (—.opera-mini.net) Date: 09-03-13 13:15 |

Not impressive at all.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: STORM (—.178-65-207-246.dynamic.avangarddsl.ru) Date: 09-03-13 14:15 |

I think that such gadgets exist as an emergency/temporary measure, such as getting to the service.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Garlic (92.240.136.—) Date: 09-03-13 14:29 |

I make screws for people from bronze, outer diameter m18 pitch 1.5, never had any complaints. For some reason, mostly on Gazelles. But there is no faith in this chemistry, since the engine has a very large temperature difference. Metal does not hold up, but polymer is doubtful.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

Read also: Inverter motor operating principle

| Author: Gorynych (195.135.239.—) Date: 09-03-13 19:14 |

In general, some magical properties are often attributed to epoxy compounds, although almost any of them loses strength at 70-90 degrees.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Alexander 13 (—.kirov.comstar-r.ru) Date: 09-03-13 19:27 |

“since many people use equipment with a two-stroke gasoline engine, due to design features, they often have to unscrew the spark plug from the block head, which leads to damage to the threads in the spark plug channel.” - Did the bathhouse fall out of the blue? With the right hands, unscrew it at least a million times, screw it to the light bulb absolutely, but with crooked hands you’ll ruin the girl’s mono the first time