Threaded connections are one of the main methods of joining elements of pipelines; sometimes when installing lines with pipes with your own hands, you may encounter different types of them. Therefore, when selecting materials and components for independent installation of pipelines, it is useful to know the difference between metric and pipe threads.

According to accepted standards, pipe threads are measured in special and ordinary inches; there are several types of them, which, depending on their purpose, differ in certain parameters. When doing independent manual or mechanical cutting on lathes, these differences must be taken into account in order to correctly select the sizes that provide the highest quality joints for certain operating conditions.

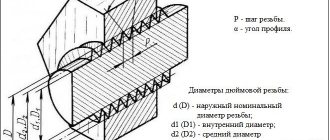

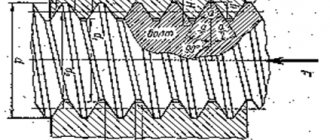

Fig.1 Profile dimensions of tapered thread

Why in inches?

Although the metric measurement system is ubiquitous in countries around the world, and the thread pitch is tied to a millimeter, all modern plumbing, pumping, heating equipment and other systems using pipelines are designed for the inch measurement system.

This is due to the fact that the non-metric system, along with all the equipment, came to us from developed countries of the world, where all industry since the 15th century was oriented towards the English inch, approximately equal to the width of the thumb of 25.4 mm. A system with a basic dimensional unit of 1 meter, which appeared much later in the 19th century, is used everywhere, but was never able to displace inches from the measurements of equipment elements, gas and water mains.

This happened partly because counting tenths of millimeters is too inconvenient and accuracy suffers, while threaded elements of half an inch, three-quarters, one and a half, and so on are easier to designate and produce. In the manufacture of household plumbing, the standard inch pitch is 1/4″ - this is 6 times more than a millimeter and allows you to significantly reduce the number of standard sizes of connecting pipes for plumbing fittings.

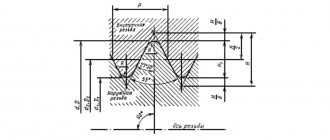

Fig.2 Cylindrical profile and its dimensions

Thread parameters

Any thread is determined by the following indicators:

- Outside diameter. Corresponds to the distance from the tops of the ridges on different sides and is equal to the circumference of the cylinder on which the cutting is made.

- Inner diameter. The distance between the depressions of diametrically located profile ridges.

- Step or move. The distance between the vertices of the thread profile. In pipe knurling, it is measured in turns per inch.

- Profile angle. The angle of the tapered ridge, measured in degrees.

- Depth. The height of the ridge from the top to its base.

Pipe threads used in everyday life

Domestic GOSTs regulate two main types of pipe threads: conical and cylindrical, the main difference of which is the profile of the workpiece. In the first case, it is conical in shape (taper 1 to 16); in the second type, the base is a cylindrical blank.

There are also known American varieties of inch pipe knurling standards NPSM and NPT, the main difference of which is the profile angle of 60 degrees. The domestic analogue of the American NPT standard is GOST 6111-52 for a conical thread with a flange cone angle of 60 degrees.

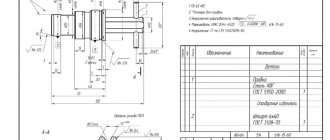

Rice. 3 Table of conical pipe threads

Tapered pipe thread according to GOST 6211-81 and its markings

Threaded connections of this type are designed to work under high pressure conditions; they are used in hydraulic systems of mobile tools driving heavy mechanisms (hydraulic stations), for connecting flexible hoses and couplings designed for pressures of 700 bar or more. This type of threaded connection has the following features:

- GOST regulates not only the maximum outer diameter of 6″, but also the cutting length, which is divided into the full length and the working part.

- The cone slope has a ratio of 1:16 along the entire length, the thread stroke includes four positions and is tied to the outer diameter.

- The marking includes the nominal thread diameter in inches and the type of product, which is designated by the Latin letter R with additional symbols C and P, meaning internal conical or internal cylindrical thread. The direction is indicated for left-hand execution and is symbolically designated LH.

Types of threaded notches

Threaded notches are rows of notches arranged in a spiral. The application of helical relief can be performed on elements in the shape of a cylinder or cone. In this case, the same pitch and diameter must be maintained throughout. This thread is used to create screw connections. The main areas of use are automotive and communication systems.

Helical relief can be of two types:

Pipe notching is considered a separate type. It is made on elements made of metal and polymer materials. Most often, pipe notches are used when assembling domestic systems, such as water supply and heating.

The difference between metric and pipe threads

The main indicators of thread knurling are their diameter and pitch, which are regulated by relevant standards.

The widespread metric thread, used in all areas of industry, differs from pipe threads in the following parameters:

Dimensions. The pipe has an outer diameter that is a multiple of a special fixed pipe inch (33.24 mm) and its tenths, while the inch is not a multiple of units of measurement in millimeters. It is clear that an element with an inch cut cannot match the dimensions of a product made according to metric standards. In pipe threads, the pitch is measured in the number of threads per inch - it follows that the thread pitch in millimeters will not coincide with the inch pitch.

All of the above means that in practice you cannot screw a metric nut onto a bolt with an inch knurl - the parts will not match in stroke and diameter.

Profile angle. Pipe threading, regulated by domestic GOST 6211-81, 6357-81, has a profile of an equilateral triangle with a conical ridge angle of 55 degrees, while in metric this figure is 60 degrees. It is clear that in addition to different diameters and pitches, these threaded connections will not be able to work in pairs due to the different angles of the conical ridges.

Rice. 6 NTPS thread

Knurling. Pipe thread rolling is carried out on workpieces, taking into account the thickness of their walls and external dimensions - this allows you to obtain the most durable joining of products, depending on their physical and mechanical characteristics of the workpieces. Pipe threads differ from metric threads in that according to the standard, each diameter has its own pitch - this allows, subject to compliance with the standards, to provide the threaded joint with high and pre-calculated strength.

Marking and designation. In state standards, the main pipe thread dimensions are pegged to the inch (indicated by one or two slashes), while the metric ones are given in millimeters. The main difference between the types is in the indication of the stroke - in the inch version the number of threads per 1″ is indicated.

Why is this important to know?

Every car owner who repairs a car with his own hands has at least once encountered a situation where a nut of the same size does not fit onto a bolt of a suitable diameter. The reason lies in the fact that the thread applied to the “problem” part differs from the one cut on the product being screwed on.

This confirms that the carvings on them are different from each other. Therefore, for trouble-free tightening, you will need to select a screw or nut with the same thread.

Do-it-yourself pipe threading

Like metric, pipe threads can be external or internal, and are performed manually or mechanically. To create cuts manually, taps (for internal notching) and dies (for cutting external surfaces) are used.

Independent thread cutting on the pipe inside and outside is carried out in the following order:

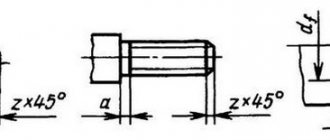

- Before cutting, grind the outer or inner edges, making a small chamfer - this helps to install the cutting tool without distortions. You also need to have machine oil on hand, which will lubricate the surface of the pipe and the cutting tool during the work process.

- The pipe is securely fixed in a vice and lubricated with machine oil, the die is fixed in the die holder, and the tap in the driver, after which the tool is put on or inserted into the pipe.

- By rotating the die or tap, screw them into the workpiece to the required depth. Rotational movements are performed in one direction and the other; for large cutting depths, the die or tap is periodically removed and cleaned of chips along with the surface of the part.

Fig.8 Manual method of creating threads

For high-quality execution of cut threads, two types of dies and taps are used: roughing and finishing, the first, more developed ones, are passed at the beginning, after which the penetration is completed with finishing ones.

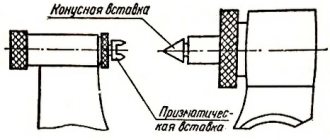

If there is a lathe in the household, a mechanical cutting method is used, and the work performed consists of the following operations:

- The pipe is fixed in the chuck of a screw lathe, and a special cutter is installed in its support.

- Turn on the machine, set the specified modes of spindle rotation speed and movement of the support with the cutter, as well as the immersion depth of the cutter. Cutting the outer pipe surface is carried out using lubricating coolant or oil.

- First, a chamfer is cut, then passes are made, with each one gradually increasing the depth of immersion of the cutter. The last pass is performed with minimal metal removal at low speeds.

Rice. 9 Making threads on a lathe

Cylindrical connection

Parts of cylindrical structures are joined by twisting, which gives high strength of joints with ease of execution. If the need for winding (winding up oiled tow) can be considered a disadvantage, then this is the only drawback of such a connection. But, on the other hand, the presence of tow only strengthens the place of twisting and makes it more airtight.

But not only pipes are connected by twisting: it often happens that threaded connections are used on any parts that have a cylindrical shape and thin walls of the product. In cross-section, a pipe screw thread looks like an isosceles triangle with an upper angle of 550 (not to be confused with 600 in metric threads). The main characteristic of a cylindrical screw thread is the nominal nominal diameter dy, which characterizes the build quality of plumbing units, in contrast to the outer and inner diameters, which reflect compliance with standards.

The term “conditional diameter” should mean a value that determines the throughput of a pipe in liters per hour. The diameter itself in the drawings is displayed in inches, and each conventional diameter value must be accompanied by explanations for the values of the outer and inner diameters.

Read also: How to hammer finishing nails

Twisting is often used on threaded pipelines with diameters ≤ 6 inches. If the requirements differ from the original ones, then the products are connected by welding.

Cylindrical threading in the drawings is designated as pipe thread g 1 with explanations for the accuracy class and thread diameter.

To ensure uninterrupted operation of hot water supply and hot water supply, pipes made of cast iron or steel are often used, the body of which has a steel pipe thread cut into it. The threads are coated with a thin layer of steel due to the brittleness of cast iron, and this cutting strengthens the connection, making it much more durable and strong. It is acceptable to cut cylindrical threads on pipe structures and parts with a diameter in the range of 1/16-6 inches.