A tumbling drum is a device for performing abrasive processing and improving the external qualities of the surface of various parts. The result is achieved through the interaction of abrasive particles and the surface being cleaned. Depending on the type and size of the grinding elements, you can achieve the desired effect: from surface cleaning from traces of corrosion on metal to mirror polishing.

Tumbling is used not only at industrial facilities. A homemade device can be used in many ways at home.

Trough tumbling machine

Trough vibrating tumbling machines are a type of tumbling equipment for grinding and polishing parts. Unlike circular vibratory tumbling machines, they are perfect for finishing critical and large-sized parts in single and small-scale production.

Our electronic catalog contains 6 standard sizes of tray finishing machines of the “Impulse” model and 4 standard sizes of the “Segment” model. We invite you to familiarize yourself with some of their technical characteristics.

Application areas for tumbling drums

With the help of tumbling drums you can perform many operations:

- edge processing;

- removal of burrs and other defects;

- polishing;

- degreasing;

- cleaning from traces of corrosion or acid;

- improving the quality characteristics of the surface.

The listed processing methods are used in the following industries:

- Instrumental. Plumbing tools (drills, dies, taps, reamers).

- Medical. Surgical supplies and other special instruments.

- Processing. Metal blanks, turbine parts, propellers.

- Automotive industry. Separate parts of internal combustion engines, gearbox gears, timing chains and much more.

- Watch production. The body and gears of the mechanism are polished.

- Easy. Cutlery, buttons and sanitary ware items.

- Furniture. Accessories and decorative elements.

- Gas. Shut-off valves, fastening elements.

- Jewelry. Synthetic and natural stones.

As well as other activities that use parts obtained by casting, stamping or turning.

Drums are used to process not only metal products, but also ceramics, glass, plastic, and ferrites.

Characteristics of tray vibrating tumbling machines “Impulse”

| Installation model | Total chamber capacity, l | Working chamber size (WxHxD), mm | Engine power, kW | Installation length, mm | Installation height, mm | Installation width, mm |

| "Impulse"15 | 15 | 180*200*500 | 0,37 | 690 | 570 | 370 |

| "Impulse" 100 | 100 | 320*380*900 | 1,1 | 1090 | 780 | 520 |

| "Impulse" 200 | 200 | 400*500*1100 | 1,5 | 1300 | 895 | 600 |

| "Impulse" 300 | 300 | 440*550*1340 | 2,2 | 1550 | 970 | 680 |

| "Impulse" 500 | 500 | 600*620*1500 | 5,5 | 1720 | 1050 | 820 |

| "Impulse" 50 | 50 | 260*300*720 | 0,55 | 910 | 700 | 450 |

Characteristics of trough vibrating tumblers “Segment”

| Installation model | Total chamber capacity, l | Working chamber size (WxHxD), mm | Engine power, kW | Installation length, mm | Installation height, mm | Installation width, mm |

| "Segment" 800 | 800 | 700*800*1600 | 2* 3,0 | 3030 | 1250 | 940 |

| "Segment" 1000 | 1000 | 750*850*1800 | 2*5,5 | 3370 | 1300 | 1080 |

| "Segment" 1600 | 1600 | 880*1000*2000 | 2*7,5 | 3700 | 1400 | 1250 |

| "Segment" 2200 | 2200 | 1000*1100*2200 | 2*7,5 | 3820 | 1520 | 1370 |

Our specialists can always advise you on what equipment is suitable for your production tasks either by e-mail or by phone.

Technical characteristics and advantages of tray tumbling plants

Trough tumbling equipment has its certain advantages when processing parts.

- The tray shape of the bowl and the possibility of dividing it into segments by partitions completely eliminates the risk of damage to the product during processing.

- Loading and unloading of parts occurs manually, which also reduces the risk of damage to the final product.

- The basic configuration of tumbling machines includes: a tray vibrating tumbling installation, a vibration motor control cabinet, a compound and water supply system.

- The noise-absorbing cover will ensure quiet operation of the vibration tumbling machine.

- Our machines have a simple, rugged design that can withstand heavy duty use with little maintenance or attention.

Tumbling machines

| Price, t. rub. | ||

| Tumbling vibrating machines | ||

| 1 | Tray type tumbling vibrating machine 20/15 L. | 110 |

| 2 | Tumbling post 20/15 L. | 120 |

| 3 | Torus tumbling vibrating machine (octagonal) 30 l. | 150-165* |

| 4 | Tray type tumbling vibrating machine 50/30 L. | 124-135* |

| 5 | Trough type tumbling vibrating machine 50/30 L. (1 kW, 3000 rpm) | 125 |

| 6 | Tumbling post 50/30 L. | 134-135* |

| 7 | Tumbling station 50/30 L. (1 kW) | 135 |

| 8 | Tumbling station 50/30 L. with rotating separator | 260 |

| 9 | Tray type tumbling vibrating machine 150/120 L. | 228-245* |

| 10 | Tray type tumbling vibrating machine 150/120 L. (1.5 kW) | 230 |

| 11 | Tray-type tumbling vibrating machine 150/120 L. for processing car wheels up to R22 | 330-415* |

| 12 | Tray type tumbling vibrating machine 200/150 L. | 270 |

| 13 | Tray-type tumbling vibrating machine 200/150 L. for processing car wheels up to R22 | 370-440* |

| 14 | Tray type tumbling vibrating machine 275 L. | 390-430* |

| 15 | Tray type tumbling vibrating machine 375/250 l. | 450 |

| 16 | Programmable control rack for vibrating machines (universal control cabinet) | 50 |

| Tumbling drums | ||

| 1 | Tumbling drum | 150 |

| Optional equipment | ||

| 1 | Working fluid regeneration station for 50 l. (SRRZh50) | 7-10 |

| 2 | Working fluid regeneration station with a volume of 80 liters with a periodic fluid supply interrupter and a metal tray on wheels (SRRRZh80) | 14 |

| 3 | Adjustable periodic interrupter SRRZH | 2 |

| 4 | Pump for SRRZh50 | 1.5 |

| 5 | Pump for SRRZh80 | 7 |

| 6 | Connecting cable SRRZH | 1 |

| 7 | Polyurethane partition for GVM150/120 and GVM200/150 | 7 |

| 8 | Partition made of corrosion-resistant steel for GVM50/30 | 4 |

| 9 | Set of 8 lattice partitions with fastenings for GVM150 (for positioning flat parts) | 70 |

| 10 | Console for processing car rims up to R22 | 100-170* |

*Equipment prices depend on the configuration.

All equipment is new!

Free delivery of equipment throughout Russia!

Playlist on YouTube: “Processes and results of tumbling.”

Playlist on YouTube: “Equipment”.

Join the VKontakte group: https://vk.com/cnc42

The price depends on the configuration. See more detailed description.

Parts processed on www.CNC42.ru machines from corrosion-resistant steel (stainless steel) grade 12Х18Н10Т (AISI 304, 316, 403)

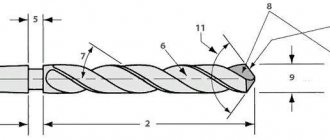

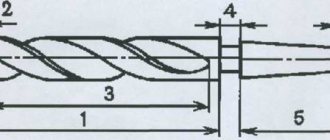

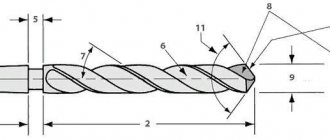

Mirror finishing of drill bits made of 65G black steel and hard alloy

Tumbling station 50 liters with a rotating drum separator April 2022

Operation of the tumbling station in different modes, unloading of parts, processing results

Tumbling vibrator 50 liters 2022

Vibrator operation in different modes, filler unloading

Tumbling vibrator 150 liters 2018

Vibrator operation in different modes, filler unloading

Tumbling station 50/30 liters (new model 2017)

In the video you will see a general view of the machine, start/stop, frequency adjustment, processing, unloading

Tray type tumbling vibrating machine 200/150 liters

In the video you will see a general view of the machine, start/stop, frequency adjustment, processing, unloading, finished parts

Tray-type tumbling vibrating machine 150/120 liters for processing car wheels up to R22

In the video you will see a general view of the machine, start/stop, frequency adjustment, disk installation, processing

Tray type tumbling vibrating machine 20 liters

In the video you will see a general view of the machine, start/stop, frequency adjustment, processing and unloading, at the end there is a small slide show

Tumbling station 50 l.

Operation of the tumbling station in various modes: processing, separation, unloading

Tumbling vibrator 150 liters

Vibrator operation in different modes, processing of large and small parts for 4 hours, unloading of filler, at the end of the video there are photographs of parts before and after processing

Porcelain ball processing

Vibrator 50/30 l.

Wood processing (wood finishing)

Vibrator 50/30 l.

What are the advantages of our company

Proizvodstvenny is a leading company in the market of domestic finishing machines and components for them. Trough tumbling machines are universal installations for sliding grinding and polishing of metal and products made from it. They can be used for finishing parts of various sizes, including large ones. These are, for example, metal grids, wrenches, knives, tubes, large body parts, long screws, shafts, etc. Our specialists will always help you choose the necessary equipment according to the shapes and sizes of the parts that need processing.

In addition to comprehensive consultation on the selection of tumbling technology, supply of abrasive materials and compounds of our own production, we also carry out test processing and commissioning work to put equipment into operation. Another area of our activity is the repair and replacement of polyurethane coating of our clients’ finishing equipment.

Advantages and disadvantages

Drum-type tumbling installations have the following advantages:

- Autonomy. After starting the work program, the operator is completely free.

- Reliability and simplicity of design. This type of unit was invented at the dawn of the development of tumbling technology, therefore its structure is not highly technologically complex. The use of modern materials has significantly improved the quality of the design.

- Cheapness. Compared to other tumbling methods, the drum type is considered the most economical.

- Installation dimensions. The dimensions of the device are limited only by the size of the production room and the power of the electric motor.

- Available material. In the production of installations, you can use any type of metal, including ordinary steel.

Flaws:

- Low productivity compared to rotary and vibration type installations.

- Complex separation. After processing, the process of separating the parts and the abrasive takes a lot of time.

- There is no ability to adjust the workflow. For this reason, drum-type devices cannot be used for processing delicate products. In addition, there is no possibility of visual observation of the work cycle.

- Low quality processing. Products with a curved surface are processed unevenly.

- High noise level. To carry out the work, it is necessary to carry out work to ensure sound insulation of the production premises.

How to order our trough tumbling systems

If you are looking for high-quality vibrating tumblers, then contact us urgently! If necessary, our consultants will select the machines that you need.

To directly place an order for the tumbling equipment you like for metal processing, send a request to our e-mail, indicating your contact information. As soon as possible, employees will send you a response letter with a detailed price list, and later contact you by phone to clarify payment details.

Areas of application

Finishing material is in demand in many industries, due to its quality and variety of color palette:

- Jewelry industry. A targeted impact on natural stone allows you to smooth out sharp edges, due to which the material becomes smooth. Elegant stones are used to make bracelets, pendants, pendants, key chains, etc.

- Decoration of facades. This solution is chosen by designers for finishing the facade and basement. Galvanized stone can be used both for exterior decoration and for decorative purposes.

- Interior design. Natural stone processed using special technology is suitable for finishing indoor walls. It is considered a classic option when decorating home fireplaces. An island made of rounded natural stone will harmoniously fit into any style.

- Design of artificial fountains and ponds. Against the background of water, the stone will look even more attractive. An excellent option for creating unique design compositions. It is customary to decorate aquariums with small stones.

- Landscape design. The material is suitable for laying garden paths and finishing fences. Natural material is able to cope with mechanical loads and sudden temperature changes, so there are practically no operational restrictions.

- Construction of coatings. Galvanized stone is used to decorate summer terraces, walking and pedestrian areas. This area is durable, copes well with moisture, and does not require special care.