From the moment of human development, when he began to actively use his hands in work, the results of his work became more and more complex, more perfect and more beautiful. At first, the purpose of making this or that thing was purely practical; later we began to make objects of art just like that, for aesthetic pleasure, without any hidden use for them.

Forged metal products have always been valued and admired. This is also due to the fact that looking at a high-quality forged item, we involuntarily imagine what a huge amount of work was done. After all, metal is metal and it is not as malleable as, say, wood.

List of materials and tools

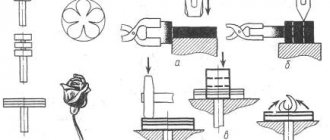

We will need the following devices to make a metal rose with our own hands (a photo of the work being completed is presented in the article):

- Bulgarian;

- angle grinder;

- machine discs: grinding, cutting;

- drill;

- drills of different diameters, up to one centimeter;

- gas heating pad;

- round-nose pliers, flat-nose pliers, long-nose pliers;

- wire cutters;

- hammer;

- pliers;

- anvil;

- file;

- marker;

- welding machine.

Materials you need to stock up on:

- a metal rod (the stem of a future rose);

- sheet metal;

- unused motor oil.

List of parts and their quantity

To make a rose we will need the following parts:

- The first outer leaf has 5 petals.

- The second leaf is slightly smaller in diameter - 4 petals.

- The third leaf of the same diameter has 4 petals;

- The fourth leaf is slightly smaller in diameter - 3 petals.

- Fifth leaf (propeller of slightly smaller diameter) - 4 narrow petals.

- Five leaf star.

- Branches 2-4 pieces.

- Leaves 2-4 per branch.

Forged flower girls

Attention! Promotion: Until March 31, 2016 40% discount on installation for all forged products .

For order amount:

from 50,000 rubles – 5% from 150,000 rubles – 10% from 300,000 rubles – 15%

We will make forged flower bowls according to your sketches.

Use the custom order form. Send us a sketch or photo of the desired product and receive a favorable offer on price and production time.

| Sketch | Name | vendor code | Price / m² |

| Jack | CV-1 | Specify | Order |

| Arrow | CV-2 | Specify | Order |

| Malachite | CV-3 | Specify | Order |

| Dolphin | CV-4 | Specify | Order |

| Athena | CV-5 | Specify | Order |

| Diadem | CV-6 | Specify | Order |

| Assol | CV-7 | Specify | Order |

| Iris | CV-8 | Specify | Order |

Petal drawings

Four or more squares (depending on the volume of the rose) measuring 10 by 10 centimeters are cut out of sheet metal. Rose petals are drawn on them with a marker. A figure similar to a compass rose is drawn on one of the squares. This square will be the template for the sepals of the future flower. To achieve greater realism, you do not need to maintain perfect symmetry.

Use a grinder or a grinder to cut out the rose petals, but do not cut them all the way. After this, the blanks of petals, leaves and sepals are flattened along the edges. This can be done with a hammer on an anvil. With short blows of the tool, the tips of the workpieces are flattened, and then the texture of the leaves is applied to the metal surface with the pointed side of the hammer. It can be done on one or both sides.

If you need to shorten a metal rod, use a grinder. On average, the stem length is 40-50 cm, but this is a matter of taste. Then holes should be made in the petal blanks. They are performed in one of two ways: welding or drilling.

- Welding. The electrode is brought to the center of the petal and the arc is ignited. Its thickness should be approximately three millimeters, pressing into the metal plate, it is pierced through. The set current value is 100 A. The hole is burned quite simply, so you should be especially careful that its diameter is not wider than the size of the stem. In order for the welding to be correct and the strength of the structure not to be affected, it is good if the holes are not perfectly even, since 50% contact is sufficient. To control the process, it is recommended to try the stem to the hole as often as possible.

- Drilling. The hole is drilled strictly in the center. Its size should ideally match the thickness of the metal rod, which is the stem. The rod should fit tightly into the through hole, this will make the further welding process easier. If it turns out to be a little smaller, then drill more holes next to the hole and connect them together, checking the required diameter.

Cutting flowers and petals

After the petals have been given a characteristic structure, the outline is once again outlined with a marker, and the details begin to be cut out. There is no need to try to exactly fall into the line; at further stages of processing, the curvature of the petals will only make them more realistic. Experience has proven that it is easiest to first cut a circle along the contour, and then cut through the petals from the outside to the center. After this, the workpiece is turned over and the remaining sides are cut. Initially it will not be very convenient, since there is no pattern on the reverse side, but in the end everything will work out. Making a rose out of metal with your own hands according to the instructions proposed in our article is not difficult. But remember, the flower will look natural if you do not make all the details symmetrical.

Forged flower bowls for windows and balconies.

There is no doubt that every person wants to exclusively decorate the space around them. Forged products have become especially popular among connoisseurs of real art. They help create a beautiful environment inside and outside your home. An excellent design solution can be considered a combination of forged objects and living plants.

Forged flower beds for windows and balconies - this is an exclusive transformation of your home or apartment. Made according to individual or standard sketches, they will be an excellent addition to the architectural style of the building. You are guaranteed enthusiastic exclamations from passers-by.

Assembling the rose, giving shape

A few centimeters are removed from the end of the stem and clamped with a vice. Observing the order, string the petals onto the tip through the holes made and weld each subsequent layer to the previous one.

They start with a five-leaf star, then come a five-leaf star, 2 four-leaf leaves one after another, a trefoil and a propeller petal. When all the petals are collected, a rose bud is clearly visible. All that remains is to give it a more natural shape.

Starting from the center, alternately roll the petals into a tube and bend the edges. Next comes the trefoil: the petals are raised up, and their edges at the very edge are bent outward. You shouldn’t get hung up on a certain shape, no two colors are the same, it’s better to play with shape and texture.

Anti-corrosion treatment

In order to preserve the appearance of the rose for a long time, it must be treated with an anti-corrosion compound. This can be paint, special spraying or varnish. However, most often craftsmen use motor oil; this processing technique is called “bluing”.

To do this, you need to heat the rose properly, cover all its components with motor oil and reheat it so that the excess oil burns off. Since the component smokes strongly when heated, it is better to carry out the procedure outdoors or in a well-ventilated area. As a result, the rose will acquire a beautiful shade and will be protected from corrosion.

Forged flower beds on the balcony and under the window

Outdoor forged window flower stands are elegant designs that perform several functions:

- support normal growth of climbing plants;

- decorate the appearance of a balcony or window opening.

Such products are made from durable metal, which is processed using cold or hot forging. During the manufacturing process, various methods of bending rods are used, which gives the structure a unique aesthetic appearance. A special chrome or nickel coating applied to degreased metal protects forged flower beds from precipitation and other external influences. Therefore, they are considered durable structures and are significantly superior in quality and price to similar items made of wood, plastic and other materials.

Rose made of thin tin

If you don’t have a special device, but really want to make a rose out of metal with your own hands, you can also do without welding. To do this you need to take a thin sheet of metal.

To make a rose from thin tin you will need:

- cans;

- pliers;

- metal and regular scissors;

- wire;

- hammer;

- screwdriver;

- nail;

- ruler;

- templates

- Tin cans are cut, unfolded and templates are applied to them. All details of the flower and stem are outlined on the blanks, and then cut out.

- Using a nail and hammer, holes are made in the center of the parts.

- Using scissors, notches are made along the edges of the leaves, and veins are made in the center with a screwdriver.

- Using pliers, the stem and leaves are bent inward, forming a branch.

- The ends of the star are made thinner by turning them inward with pliers.

- I make the inner rose petals from the strips.

- The petals of the flower rise up, forming a basket.

- The wire is cut into pieces: 3 pcs. 25 cm long and 1 pc. 35 cm.

- The ends of three short wires are twisted into a coil, and the longer one is wrapped only on one side.

- All blanks are twisted to form a stem. The curls at the bottom are unrolled, thus making a stand for the flower.

- The stem is tightly wrapped with a thin wire along with the branch, not reaching the end 4-5 cm.

- Finally, the parts are strung together, starting with the star. The end of the wire is hidden inside the flower.

- The finished product is coated with paint from an aerosol can.

As you can see, creating a rose from metal is quite easy. Even with fragile female hands you can make a beautiful flower from a thin sheet of tin. The most important thing to pay attention to is to be careful. Working with a sharp iron is a dangerous activity.

Making decorative [metal products] in the form of flowers and plant figures requires proficiency in several types of tools and welding skills. How to make a rose from iron with your own hands? — step-by-step instructions with photos and videos in this article.

Equipment and tools necessary for making roses from metal:

- welding machine (in fact, if you are smart, you can do without a welding machine, but that will be another story.);

- Bulgarian;

- metal scissors;

- needle nose pliers;

- pliers;

- felt-tip pen / scriber.

You, as a DIY master, can completely do without one or the other: an angle grinder can replace scissors, pliers can replace thin-nosed pliers. The only difference will be in the labor intensity of some processes.

And since we have discussed the instrument and I touched on the topic of improvisation, I will add that in fact this article is not a panacea, not strict instructions. This is a motivation letter describing technological features! The most important thing when working with a metal rose flower is not to try to replicate me or yourself. Be more relaxed. Let your movements in your work be even slightly careless, the petals crooked, and the bends of different widths. It is these movements that will breathe life into your flower!

My rosebuds consist of the following number of plates with petals:

- outer first leaf - 5 rose petals, circle diameter about 12 cm;

- second leaf - 4 rose petals, slightly smaller in diameter, about 11 -11.5 cm;

- third leaf - 4 rose petals, diameter 11-11.5 cm;

- fourth leaf - 3 rose petals, diameter 10.5 cm;

- fifth leaf - 4 rose petals, narrow like a propeller and about 9-10 cm in diameter;

- five-leaf star - it will serve as a leaf on the outside. Diameter 8-9 cm.

Metal rose leaves look like this:

- For one flower I prepare 2-4 branches of leaves, 2-4 leaves on each. Most often I use 2 branches of 3 leaves. Some average number so that the flower is not empty and does not seem like a whole bush. Again, decide for yourself, try it on, try it.

Forged metal rose stem:

- On average, I take the stem length to be about 50 cm. This makes the flower quite large and beautiful in the end with the size of the bud that I wrote above.

I also made flowers of 30 cm and 60 cm. This is the beauty of working with metal. We have a lot of options for you.

Let's start making a rose from metal.

- First of all, I usually mark out squares for future rosebud petals. I make 3 squares 12x12 cm and 3 squares 10x10 cm. To make it easier to drill a pack of similar shapes later.

- After cutting out these squares, I stack them and mark the center. After which I drill all the workpieces at once to 6-7 mm. Ok, drilled. Since I make quite a lot of flowers, I have ready-made templates so that I don’t have to mark the sides of the petals every time; this is especially tedious when working with cinquefoil.

- I trace the outline and start cutting. I don’t particularly try to get into the line; in the finishing process, all the curvature of the rose petals will turn into their beauty. From personal experience I can say that it is most convenient to first cut out a circle along the outlined outline, then you should cut out one side of the rose petals from the outside to the center. Then turn the workpiece over and cut the remaining sides in the same position. You will immediately understand what I mean when you try to cut the blank along the contour without turning the sheet over. At first it will be inconvenient, because there is no marked outline on the back side. But your hand will get used to it. Mine is used to it.

- Well, the rose petals are cut out. Now let's take on the leaves. I always draw them by hand, since symmetry is not needed there, and I also cut them along the contour with scissors. I will also note here that do not be afraid to bend the metal in your hands when you follow the cut contour with scissors; later we will straighten everything out before further work.

I like to get everything ready first and then start assembling and welding as the final step. Therefore, I also cut the stem to the required length, heat it in different ways: welding, simply. I've tried it all. Everything is working. And I give texture to the rose stem. I crush him mercilessly! After this processing, the rose stem turns out to be of any shape with an interesting pattern. If you continue to bother, you can weld spikes by simply fusing small bumps and processing them with a grinder. I use petal circles for this job. I clamp the grinder in a vice and rotate the stem with my hands. In this way it is possible to sharpen the spikes to a sharp state.

To add texture to the metal rosebud, I use a makeshift anvil, which I scored with the sharp end of a hammer. So I just put the petal on the anvil and tap the back side with a rounded hammer. The texture is perfectly transferred from the anvil to the petals.

I make a notch on the leaves with a chisel and use thin-nose pliers to twist the rose stems into a tube. Many blacksmiths make welded leaves in their practice. The version that we make with you turns out to be more sophisticated and prettier, more lively.

Time to assemble the finished metal rose!

I clamp the rose stem in a vice so that the tip barely rises. And, following the sequence, I assemble the bud, welding each layer through a drilled hole to the stem and the previous layer of petals:

- first I lay out the star-leaf;

- then cinquefoil;

- large quatrefoil;

- large quatrefoil;

- trefoil;

- propeller leaf.

Do you feel like you've almost made a flower? Yes it is! All you have to do is play with the shape of the bud and everything will be finished.

One by one, fold the first leaf on top and use thin-nose pliers to bend the edges. Then we bend the trefoil and also bend the edges with thin-nosed pliers. And so on... Don't get hung up on one form. Try it, even if you like the rose flower in the form that is in front of you now. Believe me, there are a lot of interesting shapes. They suit different colors and occasions differently.

Metal rose bud on a stem. All that remains is to add the leaves. Add to taste; it’s impossible to overdo it or not. Are you an artist. You know better =)

Often I am asked to paint flowers in classic colors: red bud and green stem. We should not forget that in an attempt to catch up with nature, we can only show the shortcomings of a flower in front of the uniqueness of a living one. It's up to you, but now I've finally given up on painting. I try to highlight the graceful appearance of the metal by displaying it. Sometimes I brass the protruding parts. It turns out to be a very beautiful expensive vintage flower. And if it is practically impossible to give a living flower any shape, then look what you can do with our metal roses, which we made with our own hands! (only a small part of my options for performing work)

Answers to questions asked:

- Why don't I take 2 or 3 mm. ? Many blacksmiths always take on thick metal, belittling the dignity of thin metal. Any execution option has a place to be. But thin metal is both lighter and easier to work with, and therefore, at a minimum, it is easier to learn from it.

- Why tie wire (heat treated)? It can be given texture without heating, since it is much softer than simple steel reinforcement.

- Why is it important to make the outer leaf of a rose with 5 petals? The more outer petals on a leaf, the rounder the rose bud will be. With four petals, the bud turns out to be square. More than 5 - it will no longer look like a rose.

- How to cover a metal rose with brass with your own hands? There is a little trick for which we need a brass drill brush. We heat the metal a little and start working on it with a brush. Brass transfers very well to metal and coats it with a quality brass layer. The more you heat the metal before brushing, the yellower the brass will be. Don't overdo it, or you'll burn it.

All photos and video materials from this article were taken by me, as well as the flowers in them.

Materials, templates and tools

Metal flowers can be easily made from a cold-rolled sheet of steel or fragments of a car body - the hood and wings. The complete list of materials will be as follows:

sheet metal with a thickness of 0.3 to 0.8 mm - thinner ones can be burned through [ welding ], thicker ones will resist more strongly during processing;

reinforcing bars 8 - 10 mm or knitting wire - about half a meter long per flower;

welding machine or autogen, or even better, both options;

light and heavy hammers, pliers and needle nose pliers;

good [ sharpened metal scissors ], drill, grinder for those who know how to handle it when cutting thin metal into rounded patterns.

This is quite enough to make your own rose or flowers from sheet metal in a home workshop. As for templates and drawings, they can be easily made from cardboard and even paper, simply by drawing the contours.

Cutting blanks with petals

You can start working by making blanks for the petals or a rod for the stem of the flower. To make the product look natural, it is worth giving the knitting wire several characteristic kinks. Very important! — in the upper part of the future stem you need to leave a straight section of 20 centimeters, onto which the petal blanks will be planted.

Blanks of metal petals for forged roses

Next, we make blanks for cups with flower petals using simple or [curly cutting] methods. To do this, we take metal squares with a side of 80 - 90 - 100 - 110 cm (depending on the number of layers in the bud). We transfer the templates onto them and immediately make a central hole - this way it will turn out exactly in the middle, without displacement. The diameter of the hole should be selected so that the workpiece fits tightly onto the rod. Now you need to cut out the blanks using metal scissors or a grinder, without trying to make them perfectly even along the marking line. A real flower's petals are never perfect.

Assembling metal flowers and bending petals

You can proceed further in two ways. The first one is for those who have their own forge or a serious workshop with blanks and templates. When making several roses from metal, this can be very useful - blanks heated in a forge or gas welding are placed on pre-prepared cups of different sizes, and the petals are punched with a hammer until they fit.

The second method is piecemeal - the workpiece, placed on a wire and welded, is heated, and the master begins to wrap the petals with pliers or round nose pliers. Very important! — it is recommended to first string all the templates onto the stem, and then twist them, starting from the top. And so that they seem to wrap themselves in each other.

If you took care of the metal leaves using a separate template, then they are put on the stem in advance. The cross-shaped lower element under the flower is wrapped with the petals down, almost to the stem itself.

Each cut piece should be welded before bending. It is better to heat the metal with autogenous heat; it gives a directed flow and a well-defined glow zone. This way you can achieve very interesting volumetric solutions, even create an entire metal bouquet.

Should I paint an iron rose? It is enough to immerse it in oil while it is hot to get the effect of black varnish. For a metal flower, shape and volume are much more important than natural colors, which will peel off later anyway.

A gift made with your own hands is always more memorable and arouses admiration. You invest your time, effort and soul into it. Flowers are beautiful, but short-lived. A handmade iron rose is a wonderful gift that will delight you for many years and make a lasting impression on the recipient.

Forging a rose from metal, process

Naturally, artistic forging of rose metal, and indeed any work of this kind, begins with a drawing of the future product. The principle by which the clover-shaped elements presented below will be cut is that they will be of different sizes, depending on the size of the planned product. If we correspond to the average natural size of a rose, then the first part will be about 80 millimeters, the second 90, and the third 100.

First you need to find thin metal sheets with a thickness of approximately 1 to 1.5 mm. Then make markings of the shape shown in the photo, corresponding to the above dimensions.

You can cut it with a plasma cutter; if you don’t have one, then use either metal scissors (if the sheet lends itself) or carefully cut it out by welding. It is preferable to cut with scissors and choose a sheet of metal that is soft enough for this, this will guarantee the accuracy of the cut.

- After cutting out the elements, their edges must be cleaned. This can be done using a grinder. The end result should be a shape like this.

- On the left is the element after cutting with a plasma cutter, and on the right after cleaning the edges (with a grinder disk).

- The asterisk must be marked on the same sheet. Its diameter will correspond to the largest size of the element, i.e. 100 millimeters. It will look like this.

- The next step is to stamp the texture of the petals using this hammer.

- It turns out that this is the surface on the edges of future petals.

- Now we have come to the most crucial moment. At this stage, the bowl shape of the cut out elements is formed. This is achieved using a special shape and a rounded hammer.

- Due to the fact that the elements are of different sizes, the smaller one should fit freely into the larger one.

- Now the most interesting and creative part of the work: Shaping the petals by folding them. To do this, you need to heat the workpiece and use a hammer or tongs to shape the future rose.

- The final part of the work will consist of bending the base (star) and painting it in the color you want after the product has cooled.

In order to decide on the shape, size, and color of the future product, it would not be amiss to see how other people make forged roses. They may differ in color, be quite dull or, on the contrary, very bright.

For example, this one is made in bronze color with rather large petals.

This forged rose is the exact opposite of the previous one. She has a huge bright red bud on a neat, thin gilded stem. Looks great.

You can make a rose on a solid round stand, as in the next photo.

- The stand can also be made with a recess, in the shape of a plate, so that you can put small things there.

- The gilded color of the forged rose is perfect for a gift. Complete with it you can make a stand for a rose.

- The bronze color of the rose will perfectly decorate the living room.

- Forged candlestick, which is decorated with a bronze rose.

- A gilded bronze color would also be an unusual solution.

- The stand may not be solid, but in the form of a twisted rod. Looks good too.

- A very original idea. A wide twisted rod at the base of the rose with an abrasive pattern on it.

- This type of rose imitates a rose just beginning to fade, thanks to the petals hanging down to the ground at the base.

Good day, brain talents

! You can make a metal rose from sheet copper very quickly and easily, using a minimum of available tools, and now I will tell you exactly how.

I was always interested in working with metal, but never had the time or the right tools to make anything. And when I finally found a cheap, simple, and not requiring special tools way to handle metal, I immediately began “filling” with metal homemade products

my house.

Metal rose crafts

like those in this

brain-teaser

can be a wonderful decoration for your home or an incredible gift for someone worthy of your attention.

For materials, you just need 2 small 22 gauge metal plates (approximately 0.76mm), one copper, the other steel, and a steel rod with a diameter of 6mm and a length of 30cm, and for tools:

- hammer

- pliers and needle nose pliers

- metal scissors

- drill and drill bit 6mm

- chisel

- file

- and a friend with a welding machine.

Step 1: Paper Templates

Print the attached file with templates on an A4 sheet, brain picture

must fill out the entire sheet. Next, we cut out the templates, in those that resemble a propeller, we cut the petals, but do not cut them off from the core (the circle in the center).

Step 2: Metal Petals

Using the cut out petals and sepal (that part of the rose that hangs from the bottom of the bud), we mark the outlines of the petals on the metal plates with a marker, and then cut them out, just as we did with the paper counterparts.

It may be easier to do this if you first roughly cut out each petal blank separately, and then cut the parts along their edges, and if the edges

turn out uneven, they can be processed with a file.

Tip: when cutting metal, try not to completely cover the scissors, otherwise if the tips of the scissors close together, you will end up with a very uneven edge.

Drill a hole in the center of the metal blanks of the petals and sepals with a 6mm drill.

Note: I apologize in advance that in the presented photos with the brain process I do not use protective equipment, BUT when cutting out petal blanks and drilling holes, wear PROTECTIVE GLOVES!

Step 3: Applying Texture

Using a chisel and a brain hammer

we punch the edges of all the petals so that they look as if they were scratched in the direction from the center to the edges.

There is no need to completely texture the petals, as only the outer edges of the petals will be visible on the finished homemade product

. We simply make scratches along the outer edge of ¾ of the petal.

Tip: if you have a hatchet, a pointed hammer, or something similar with a pointed edge, you can use them to apply shallow texture scratches. The pointed end of a crowbar is perfect for these purposes.

But to apply the grooves of the sepals you need to be more precise. First, use a marker to draw grooves on the sepal leaves, just as shown in the brain photo

, and having done this, we punch out all these grooves with a hammer and chisel. Then, having erased the marker, we get a finished sepal!

When the entire set of petals and sepals are made, we clean them with a metal brush to restore shine.

Step 4: Stringing Petals and Sepals onto the Stem

Using a hammer, we give one end of the metal rod a square shape to a length of about 4 cm from the edge. This square shape of the rod will tightly fix the brain petals

on the stem and will not allow them to rotate along that stem.

Next, we take the sepal, and on top of it we fold the petals in descending order of size, with all the textured surfaces on top, and string them onto the square end of the stem, about 6mm, the main thing is that they sit tightly on the stem.

Note: I used a small head for threading. I simply placed the notched end of it against the end of the stem and pressed it down onto the petals until they were firmly in place.

After this, all that remains is to cook the petals. You just need to put a few brain welding

to secure the petals and sepals - a couple of points on top and a couple on the bottom. There is no need to weld the petals together.

Step 5: Folding the first 2 layers of petals

The first layer, consisting of only three petals, just needs to be folded up and inside each other. Simply take the right edge of the first petal with needle nose pliers and twist it from the outer edge up to the center. We repeat the same procedure with the two remaining brain petals.

. The end result should be a three-lobed spiral with touching inner edges and protruding outer edges, looking something like a wind-driven pin-wheel toy.

Then we take the protruding left edge of the petal and bend it to the left towards the adjacent petal, and if viewed from above, the shape of the petal folded in this way should resemble the letter “C”. We do the same for the remaining two petals, and as a result the petals should “close” around each other. If they are still spaced apart, then use ordinary pliers to press them into a tight spiral.

We do the same with the second layer of petals. We bend one of the edges of each petal up and inward, and the second edge also inward, forming the letter “C”. However, this time you need to use pliers to bend 3mm of the upper edges and twist them slightly. This will highlight the petals when viewed from above and give the

more realistic look. And you need to complete the manipulations with the second layer of petals by bending the outer edges of the petals a little inward using needle nose pliers, giving the bud a denser appearance.

Step 6: Folding the Three Remaining Layers of Petals

We bend the third layer in the same way as the first two. We bend them up and bend them in the shape of the letter “C”. And we also slightly twist the upper edge of the petals, but now we twist the left and right sides of these upper edges separately. This will give the curled upper brain edge

slightly triangular in shape, which is more natural for a rose than just a twisted petal.

We form the fourth and fifth layers in a similar way, with each layer more clearly showing the sharpness of the curved edges of the petals. The edge of the third layer should be rounded, with just a hint of a point, the edge of the fourth layer should be somewhere between round and triangular, and the fifth should be distinctly triangular.

In addition, we take the petals of the fourth and fifth layers with pliers at a distance of 1.2 cm from the top edge and slightly bend them into an arc so that they do not “grow in a straight line” from the stem. This will give the homemade

volume and, when viewed from above, it will not be too flat.

Step 7: Folding the Sepals

We take the sepal leaves with pliers and bend them in the opposite direction from the bud, closer to the stem. At the same time, we also bend the tips of these leaves so as not to prick ourselves on them when we hold the brain craft

in hand.

Step 8: Polishing

All that remains is to take a metal brush or wire sponge and polish your metal rose craft

. You can also take clear polyurethane and apply it to the surface of your rose to protect it from rust, but this is optional!

If you want to continue this creative brain process

, then you can cut out a few more leaves from the metal and weld them to the stem, as you like. At the same time, if one leaf is quite large and flat, then you can attach a candle to it, and your rose will thereby turn into a very beautiful candlestick.

So, craft

ready, thank you for your attention!

You need pieces of sheet iron with a thickness of 2-2.5 mm: 120x120 = 2 pieces, 100x100 = 1 piece.

Round rolled O10, square #10. Cut out petal blanks from the sheet.

We heat the rod O 10 and, stepping back from the edge by about 40 mm, we forge a transition to O8.

Then we clamp the workpiece in a vice and press the remaining end to O 12-13. Let's trim the boss and use a backing chisel to make an undercut at a distance of 5-10 mm from the edge - this will be the rod for the rivet.

Pull the rod back to #6-7mm.

When crimping, we roll the rod to Ø 6mm.

Now let's move on to the spikes. To forge a thorn, the stem is forged to 8, leaving part of the rod (l = 10mm).

Then, on the edge of the anvil, with two or three sharp blows of the hammer, we delay the protrusion. You have to hit very accurately.

Then we clamp the workpiece in a vice and install the protrusion through the guide (bar).

The spike is ready. We forge others (as many as planned) and complete the stem.

It's the petals' turn. On the petals you need to lower (make thinner) the edges and mark the veins. Well, it’s possible without veins, but I’ll do it.

Let's form the petals.

And also the lower petals.

And the middle of the corolla.

The time has come to “grow” the leaves. To do this, heat #10, pull the end onto a cone and leaving about 45mm, make a neck for the handle.

We break the workpiece, giving it the shape of a sheet. We apply veins on the leaf.

And we pull back the stalk.

You can collect “to the heap”. Assembly procedure for a forged rose

Let's start assembling the flower. We clamp the stem in a vice, put the rims on the rivet rod and seal them. Let's rivet st.

A gift made with your own hands is always more memorable and arouses admiration. You invest your time, effort and soul into it. Flowers are beautiful, but short-lived. An iron one, created by hand, is a wonderful gift that will delight you for many years and make a lasting impression on the recipient.

Materials and tools for creating an iron rose

- welding machine (semiautomatic or inverter; for an inverter, use electrodes 2 mm thick at a current value of 50-70 A)

- angle grinder or grinder (with cutting and grinding discs; it is better to use a cutting disc with a thickness of 1 mm, and a flap type grinding disc)

- drill with metal drills with a diameter of 0.5 - 1 cm

- iron rod with a diameter of 8-12 mm (for the flower stem)

- sheet iron 0.5 mm thick; (you can use metal from the hoods or wings of a car, its thickness according to GOST is 0.5 - 0.8 mm)

- gas burner, or any other high temperature source

- 300 g motor oil (preferably not used)

- round pliers

- felt-tip pen

How to make an iron rose

Cut 4 squares with a side of 10 cm from an iron sheet. If you want your rose to be more magnificent, prepare 5 squares.

Draw the shape of future petals on the squares, and on one of them - something like a “wind rose”. This will be a blank for the sepals, so don’t try to achieve perfect symmetry - nature makes each of its creations individual.

Next, cut out the petals of the iron rose with an angle grinder, without cutting to the very center, the cutting lines are shown in the photo.

Take an iron rod and, if necessary, shorten it to the required length - this is the stem of the future rose (40-50 cm).

Now you need to make holes for the stem in the cut out petal blanks. There are 2 methods - drilling and welding.

Drilling

Using a drill, drill a hole strictly in the center; the diameter of the hole should correspond to the diameter of the rod. If the diameters do not match, suppose you chose a rod with a diameter of 12 mm, and the thickest drill you have is 8 mm, then drill 3 holes side by side so that you get one hole of the desired size. Bend the inner edges with round nose pliers or thin pliers. The rod must fit tightly into the holes, otherwise it will be difficult to weld.

Welding

Use a 3 mm thick electrode and set the current value to about 100 A. Bring the electrode to the center of the blade and strike the arc. Press the electrode into the metal, piercing it all the way through. Since we are using thin sheet iron, it will burn through easily. But be careful, the hole should not be too large.

Tip: You don't have to make perfectly round holes. They need to be made such that the rod is in contact with them by at least 50% of its diameter. This is a necessary condition for proper welding and strength of the entire structure. While making holes, periodically apply a rod to them, this will allow you to control the process.

Step back 2 cm from the end of the rod. Now put the blanks with petals on it, starting with the sepals. Arrange each layer of petals so that the petals are criss-crossed. Secure each layer by welding. Be careful - thin metal burns quickly, so melt more rods than petals.

Bend the leaves of the bottom layer down.

Now the most interesting part of the work is the formation of the petals. Heat the still flat petals with a gas burner. It is not necessary to get it red hot, just a little heat is enough. Under the influence of temperature, the metal becomes ductile, easier to form, and the likelihood of unwanted deformations is reduced.

Using thin pliers or pliers, bend the 2 central petals so that they are wrapped in each other. Fold the remaining petals around them.

Layer by layer, bend all the petals, bending the tips in the opposite direction.

Now you need to make the rose leaves. Draw their outlines on a metal sheet. They may not be the same either.

Cut out the leaves with a grinder.

Make notches on both sides of the leaves, as shown in the photo.

Carefully! Hold the leaves only with pliers, never with your hands.

Change your grip as you make cuts. Hold the sheet by one edge and make notches on the other, then vice versa.

Bend the leaves with your hands and attach them to the rose stem using weld points. Be careful not to burn them.

The rose is ready. But untreated metal will rust over time, and corrosion processes must be prevented. There are many options - spraying, varnishing, you can even paint a rose in the colors of a living flower.

I preferred to do the bluing. To do this, you need to heat the rose, cover it with motor oil and heat it again so that the excess oil burns off. Work should be carried out only in a ventilated area, or better yet, in the open air, since the oil will smoke when heated.

Heat the rose properly (again, not red-hot), and you will get a beautiful coating that protects the product from corrosion. If you encounter difficulties during your work, the article “Basics of Sheet Metal Working Techniques” may be useful.

Cutting without sewing, technical stages of work

The process of creating a rose:

Making a solid forged rose.

- From sheet metal we cut out four or five, if we want a larger rose, square templates with a side length of 10 cm. In each square we draw a schematic flower with four petals, try to draw them symmetrical, but precision to the millimeter is not needed here. On the last square we draw a sepal that looks like a compass rose; exact symmetry is not necessary here either.

- If you want to make a tea rose - wide open, with numerous petals, it is better not to be lazy and prepare the templates in the following order:

- The sepal is a five-pointed star with a diameter of 7–8 cm.

- The first outer blank consists of five petals with a diameter of 11 - 12 cm.

- The second and third blanks each have four petals with a diameter of 10–11 cm.

- The fourth blank is made of three petals with a diameter of 10 cm.

- The fifth is made of four narrow petals with a diameter of 9 cm.

- We cut out the blanks with metal scissors or, if available, with an angle grinder. We do not cut to the center of the figure.

- We draw on the metal a couple or three blanks for green leaves on the stem. The size must be different. We cut out the leaves with scissors or a grinder.

- Let's take the stem. If it is a rod, shorten it to 40 - 50 cm.

- We drill holes in the blanks to attach them to the stem. The diameters of the holes and the stem blank must match. The rod or wire should fit tightly into the petals.

- Welding stage: weld the workpieces to the stem. The optimal thickness of the electrode is 3 mm, the current strength is from 70 to 100 A. The holes in the petals do not have to be made round, the main thing is that the stem touches them with at least half of its circumference. In this case, the seam and the structure itself will be strong. You need to melt more rods than petals - it’s easy to burn through thin metal.

You need to plant the workpiece on the stem, starting with the sepals. The petals should be placed crosswise, two centimeters below the upper tip of the stem. Each layer must be secured by welding - similar to a puff pastry.

Metal roses: finished products.

- Now comes the most exciting and artistic part of the work: forming the rose petals! We bend the leaves of the sepals of the lower workpiece down. Turn on the gas burner and begin to gradually heat the flat petals. At this stage, moderate heating is sufficient - there is no need to heat it red-hot. We use pliers to wrap the two petals as if we were wrapping them into each other. We wrap the remaining two petals around the first two. We work like this with each layer. At the same time, bend the tips of each petal outward - in the opposite direction. At this stage, it is important to have a “free” hand: the petals should be crooked, their bends in the opposite direction should be unequal, the serifs and marks should be asymmetrical. This is the only way the flower will turn out alive and real: there are no strict geometric shapes in nature.

- Let's start with the leaves on the stem. We make small notches on each edge of the leaves. The leaves should not be flat; it is enough to bend them with your hands. We weld it to the stem carefully at the weld points.

- In principle, the rose is ready. But only in principle!