Very often, in order to ensure maximum comfort in a country house, it is necessary to use various auxiliary equipment.

The most optimal option for water supply units are multi-stage centrifugal pumps.

With the help of pumping equipment of this type, the pressure in water supply systems is effectively increased, which in turn contributes to their effective use, both in private households and in apartment buildings, as well as their industrial use.

Therefore, in this article we will try to disclose in as much detail as possible information about what multistage centrifugal pumps are, what their design and principle of operation are, and we will also talk about the types of this pumping equipment.

- 2 Device

- 3 Operating principle

- 4 Types

Purpose of multistage pumps

The main task that a multistage pump must cope with is to create the maximum possible pressure in the water supply system. In other words, units of this type are designed for pumping water and other non-aggressive liquids, the temperature of which can reach 100 °C.

Other areas of equipment operation include:

- Watering and irrigation of agricultural land;

- Supporting uninterrupted water supply at public utilities;

- Ensuring the operation of fire extinguishing systems in automatic mode;

- Support for drainage in mines;

- Cooling of steam boilers at boiler plants;

- Intake and pumping of non-aggressive substances and compounds in the chemical industry.

From the listed areas of use, we can conclude that pumps of this type are used primarily for water. When working with this liquid, the downhole unit can create the strongest pressure and perform its functions stably for a long time.

Sectional pumps (CNS, TsNSG)

The group of CNS and CNSG pumps presented here is one of the main industrial pumps used in public utilities for hot and cold water supply and heating. The central nervous system pump is a sectional, centrifugal, booster pump. Consists of a cast iron body and rotor. The pump body of the TsNSG and TsNS includes suction and discharge covers, guide vane housings, guide vanes and brackets. The housings of the guide vanes and covers are tightened with coupling bolts. Sectional pumps TsNS and TsNSG are equipped with three-phase asynchronous electric motors of general industrial design. These pumps have a double soft seal. The permissible “leakage” through the seal is no more than 3 l/h. The permissible excess pressure at the pump inlet is no more than 0.35 MPa (3.5 kgf/cm2). Multistage pumps TsNS and TsNSG are designed for pumping cold and hot water, with temperatures from +1°C to +105°C. with a content of mechanical impurities of no more than 0.2 mm.

The structure of the pump designation indicates the type and parameters: pump TsNS300-180 – Centrifugal Pump Sectional for pumping water with a water temperature from +1°C to +45°C and a capacity of 300 m3/hour, a head of 180 m. If the pumping unit pumps hot (up to + 105°C) water – the designation contains the letter “G” (hot) – for example TsNSG38-176. A distinctive feature of CNS type pumps from others is the sectional design of the casing, which allows you to increase or decrease the pump pressure while maintaining the same flow rate. For example, by adding one section to the TsNSG38-176 pump, we, while maintaining a productivity of 38 m3/hour, obtain a head of 198 m and, accordingly, a TsNSG38-198 pump. In addition to TsNS pumps and TsNSG pumps, the industry produces such varieties of pumps of this type as pumps for pumping oil (TsNSN), transformer oil (TsNSM) and pumping water with high mineralization from coal mines (TsNSK series of pumps, the material of the flow part is made of chromium-nickel steel). Typically, pumps in this design are combined with explosion-proof electric motors. The CNSG pump differs from the CNS pump only in the maximum permissible water temperature.

| Model | Supply m3/h | Head m | Engine kW/rpm | Dimensions mm | Weight, kg | Price with VAT | |

| CNS(G) 13-70 | 13.0 | 70.0 m | without frame and engine | 839x420x430 mm | 257.5 | 57,000 rub. | Order |

| CNS(G) 13-70 | 13.0 | 70.0 m | 11.0/3000 | 1387x420x561 mm | 335.0 | RUB 77,800 | Order |

| CNS(G) 13-105 | 13.0 | 105.0 m | without frame and engine | 910x420x430 mm | 294.5 | RUB 65,350 | Order |

| CNS(G) 13-105 | 13.0 | 105.0 m | 11.0/3000 | 1458x420x561 mm | 372.0 | RUR 86,200 | Order |

| CNS(G) 13-140 | 13.0 | 140.0 m | without frame and engine | 981x420x430 mm | 289.0 | RUB 69,700 | Order |

| CNS(G) 13-140 | 13.0 | 140.0 m | 15.0/3000 | 1626x420x621 mm | 415.0 | RUB 97,100 | Order |

| CNS(G) 13-175 | 13.0 | 175.0 m | without frame and engine | 1052x420x430 mm | 319.0 | 74,000 rub. | Order |

| CNS(G) 13-175 | 13.0 | 175.0 m | 18.5/3000 | 1697x420x621 mm | 457.0 | RUB 104,700 | Order |

| CNS(G) 13-210 | 13.0 | 210.0 m | without frame and engine | 1123x420x430 mm | 334.0 | RUB 75,700 | Order |

| CNS(G) 13-210 | 13.0 | 210.0 m | 18,5/3000 | 1768x420x621 mm | 494.0 | 110,000 rub. | Order |

| CNS(G) 13-245 | 13.0 | 245.0 m | without frame and engine | 1194x420x430 mm | 389.0 | RUB 87,500 | Order |

| CNS(G) 13-245 | 13.0 | 245.0 m | 22.0/3000 | 1839x420x640 mm | 549.0 | RUB 124,100 | Order |

| CNS(G) 13-280 | 13.0 | 280.0 m | without frame and engine | 1265x420x430 mm | 395.0 | RUB 93,100 | Order |

| CNS(G) 13-280 | 13.0 | 280.0 m | 30.0/3000 | 1935x420x640 mm | 575.0 | RUB 141,500 | Order |

| CNS(G) 13-315 | 13.0 | 315.0 m | without frame and engine | 1336x420x430 mm | 432.0 | RUB 100,800 | Order |

| CNS(G) 13-315 | 13.0 | 315.0 m | 30.0/3000 | 2006x420x640 mm | 612.0 | RUB 149,500 | Order |

| CNS(G) 13-350 | 13.0 | 350.0 m | without frame and engine | 1407x420x430 mm | 469.0 | 110,000 rub. | Order |

| CNS(G) 13-350 | 13.0 | 350.0 m | 30.0/3000 | 2077x420x640 mm | 649.0 | 166,000 rub. | Order |

| CNS(G) 38-44 | 38.0 | 44.0 m | without frame and engine | 839x450x430 mm | 306.0 | RUR 49,600 | Order |

| CNS(G) 38-44 | 38.0 | 44.0 m | 11.0/3000 | 1387x450x578 mm | 382.0 | 71,000 rub. | Order |

| CNS(G) 38-66 | 38.0 | 66.0 m | without frame and engine | 910x450x430 mm | 335.0 | RUB 52,800 | Order |

| CNS(G) 38-66 | 38.0 | 66.0 m | 15.0/3000 | 1555x450x621 mm | 405.0 | RUB 86,300 | Order |

| CNS(G) 38-88 | 38.0 | 88.0 m | without frame and engine | 981x450x430 mm | 376.0 | RUB 56,200 | Order |

| CNS(G) 38-88 | 38.0 | 88.0 m | 18.5/3000 | 1626x450x621 mm | 446.0 | 92,000 rub. | Order |

| CNS(G) 38-110 | 38.0 | 110.0 m | without frame and engine | 1052x450x430 mm | 327.0 | RUB 60,500 | Order |

| CNS(G) 38-110 | 38.0 | 110.0 m | 22.0/3000 | 1722x450x640 mm | 487.0 | RUB 101,500 | Order |

| CNS(G) 38-132 | 38.0 | 132.0 m | without frame and engine | 1123x450x430 mm | 390.0 | RUB 65,200 | Order |

| CNS(G) 38-132 | 38.0 | 132.0 m | 30.0/3000 | 1792x450x640 mm | 570.0 | RUB 119,800 | Order |

| CNS(G) 38-154 | 38.0 | 154.0 m | without frame and engine | 1194x450x430 mm | 439.0 | RUB 71,700 | Order |

| CNS(G) 38-154 | 38.0 | 154.0 m | 30.0/3000 | 1864x450x640 mm | 619.0 | RUB 124,500 | Order |

| CNS(G) 38-176 | 38.0 | 176.0 m | without frame and engine | 1265x450x430 mm | 578.0 | RUR 71,530 RUB 75,300 | Order |

| CNS(G) 38-176 | 38.0 | 176.0 m | 30.0/3000 | 1935x450x640 mm | 758.0 | RUB 127,800 | Order |

| CNS(G) 38-198 | 38.0 | 198.0 m | without frame and engine | 1336x455x430 mm | 546.0 | RUB 82,700 | Order |

| CNS(G) 38-198 | 38.0 | 198.0 m | 37.0/3000 | 2059x455x685 mm | 781.0 | RUB 147,900 | Order |

| CNS(G) 38-220 | 38.0 | 220.0 m | without frame and engine | 1407x455x430 mm | 658.0 | RUB 88,600 | Order |

| CNS(G) 38-220 | 38.0 | 220.0 m | 45.0/3000 | 2195x455x685 mm | 913.0 | RUB 153,500 | Order |

| CNS(G) 60-66 | 60.0 | 66.0 m | without frame and engine | 870x525x500 mm | 356.0 | RUB 59,600 | Order |

| CNS(G) 60-66 | 60.0 | 66.0 m | 22.0/3000 | 1540x525x676 mm | 516.0 | RUB 100,900 | Order |

| CNS(G) 60-99 | 60.0 | 99.0 m | without frame and engine | 850x525x600 mm | 442.0 | RUB 62,200 | Order |

| CNS(G) 60-99 | 60.0 | 99.0 m | 30.0/3000 | 1620x525x676 mm | 622.0 | RUB 114,900 | Order |

| CNS(G) 60-132 | 60.0 | 132.0 m | without frame and engine | 1030x525x500 mm | 513.0 | RUB 68,900 | Order |

| CNS(G) 60-132 | 60.0 | 132.0 m | 45.0/3000 | 1818x525x715 mm | 768.0 | RUB 135,000 | Order |

| CNS(G) 60-165 | 60.0 | 165.0 m | without frame and engine | 1110x525x500 mm | 554.0 | RUB 75,200 | Order |

| CNS(G) 60-165 | 60.0 | 165.0 m | 55.0/3000 | 1930x525x731 mm | 890.0 | RUR 151,900 | Order |

| CNS(G) 60-198 | 60.0 | 198.0 m | without frame and engine | 1190x525x500 mm | 578.0 | 82,000 rub. | Order |

| CNS(G) 60-198 | 60.0 | 198.0 m | 55.0/3000 | 2008x525x731 mm | 918.0 | RUB 159,000 | Order |

| CNS(G) 60-231 | 60.0 | 231.0 m | without frame and engine | 1270x530x500 mm | 585.0 | RUB 85,900 | Order |

| CNS(G) 60-231 | 60.0 | 231.0 m | 75.0/3000 | 2190x530x790 mm | 1060.0 | RUB 189,600 | Order |

| CNS(G) 60-264 | 60.0 | 264.0 m | without frame and engine | 1350x530x500 mm | 611.0 | RUB 95,100 | Order |

| CNS(G) 60-264 | 60.0 | 264.0 m | 75.0/3000 | 2270x530x790 mm | 1086.0 | RUB 196,600 | Order |

| CNS(G) 60-297 | 60.0 | 297.0 m | without frame and engine | 1430x530x500 mm | 637.0 | RUB 101,600 | Order |

| CNS(G) 60-297 | 60.0 | 297.0 m | 75.0/3000 | 2350x530x790 mm | 1112.0 | RUB 203,300 | Order |

| CNS(G) 60-330 | 60.0 | 330.0 m | without frame and engine | 1510x560x500 mm | 562.0 | 110,000 rub. | Order |

| CNS(G) 60-330 | 60.0 | 330.0 m | 110.0/3000 | 2470x560x790 mm | 1282.0 | RUR 249,400 | Order |

| CNS 105-98 | 105.0 | 98.0 m | without frame and engine | 1075x425x620 mm | 480.0 | RUB 124,800 | Order |

| CNS 105-98 | 105.0 | 98.0 m | 55.0/3000 | 1893x425x920 mm | 950.0 | 200 300 rub. | Order |

| CNS 105-147 | 105.0 | 147.0 m | without frame and engine | 1170x455x620 mm | 518.0 | RUB 138,000 | Order |

| CNS 105-147 | 105.0 | 147.0 m | 75.0/3000 | 2093x455x930 mm | 1120.0 | RUR 231,000 | Order |

| CNS 105-196 | 105.0 | 196.0 m | without frame and engine | 1265x475x620 mm | 576.0 | RUB 150,600 | Order |

| CNS 105-196 | 105.0 | 196.0 m | 110.0/3000 | 2103x475x940 mm | 1186.0 | RUR 289,000 | Order |

| CNS 105-245 | 105.0 | 245.0 m | without frame and engine | 1360x535x620 mm | 634.0 | RUB 165,000 | Order |

| CNS 105-245 | 105.0 | 245.0 m | 132.0/3000 | 2548x535x935 mm | 1609.0 | RUB 319,000 | Order |

| CNS 105-294 | 105.0 | 294.0 m | 160.0/3000 | 2398x330x845 mm | 1571.0 | 460,000 rub. | Order |

| CNS 105-294 | 105.0 | 294.0 m | without frame and engine | 1455x330x620 mm | 715.0 | RUB 183,000 | Order |

| CNS 105-343 | 105.0 | 343.0 m | without frame and engine | 1550x465x620 mm | 775.0 | RUB 207,000 | Order |

| CNS 105-343 | 105.0 | 343.0 m | 160.0/3000 | 2493x465x845 mm | 1635.0 | 465,000 rub. | Order |

| CNS 105-392 | 105.0 | 392.0 m | 200.0/3000 | 2628x465x845 mm | 1786.0 | 513,000 rub. | Order |

| CNS 105-392 | 105.0 | 392.0 m | without frame and engine | 1645x465x620 mm | 836.0 | 220,000 rub. | Order |

| CNS 105-441 | 105.0 | 441.0 m | without frame and engine | 1740x500x620 mm | 897.0 | 236,000 rub. | Order |

| CNS 105-441 | 105.0 | 441.0 m | 250.0/3000 | 2768x500x891 mm | 1906.0 | RUB 599,000 | Order |

| CNS 105-490 | 105.0 | 490.0 m | 250.0/3000 | 2863x500x891 mm | 1971.0 | 610,000 rub. | Order |

| CNS 105-490 | 105.0 | 490.0 m | without frame and engine | 1835x500x620 mm | 958.0 | 248,000 rub. | Order |

| CNS 180-85 | 180.0 | 85.0 m | without frame and engine | 1125x835x715 mm | 629.0 | RUB 187,900 | Order |

| CNS 180-85 | 180.0 | 85.0 m | 75.0/1500 | 2310x835x990 mm | 1308.0 | RUB 305,000 | Order |

| CNS 180-128 | 180.0 | 128.0 m | 110.0/1500 | 2085x645x1000 mm | 1417.0 | RUB 379,000 | Order |

| CNS 180-128 | 180.0 | 128.0 m | without frame and engine | 1230x645x715 mm | 737.0 | RUB 215,000 | Order |

| CNS 180-170 | 180.0 | 170.0 m | without frame and engine | 1335x835x715 mm | 849.0 | RUR 229,000 | Order |

| CNS 180-170 | 180.0 | 170.0 m | 132.0/1500 | 2310x835x985 mm | 1611.0 | RUB 405,000 | Order |

| CNS 180-212 | 180.0 | 212.0 m | 160.0/1500 | 2445x835x985 mm | 1906.0 | 480,000 rub. | Order |

| CNS 180-212 | 180.0 | 212.0 m | without frame and engine | 1440x835x715 mm | 966.0 | RUR 237,000 | Order |

| CNS 180-255 | 180.0 | 255.0 m | without frame and engine | 1545x740x715 mm | 1155.0 | RUB 245,000 | Order |

| CNS 180-255 | 180.0 | 255.0 m | 200.0/1500 | 2555x740x930 mm | 2255.0 | 530,000 rub. | Order |

| CNS 180-297 | 180.0 | 297.0 m | 250.0/1500 | 3060x773x1010 mm | 2740.0 | 670,000 rub. | Order |

| CNS 180-297 | 180.0 | 297.0 m | without frame and engine | 1650x773x715 mm | 1268.0 | RUR 255,000 | Order |

| CNS 180-340 | 180.0 | 340.0 m | without frame and engine | 1755x773x715 mm | 1384.0 | RUB 269,000 | Order |

| CNS 180-340 | 180.0 | 340.0 m | 250.0/1500 | 3165x773x1010 mm | 2859.0 | 680,000 rub. | Order |

| CNS 180-383 | 180.0 | 383.0 m | 315.0/1500 | 3320x773x1010 mm | 3077.0 | 760,000 rub. | Order |

| CNS 180-383 | 180.0 | 383.0 m | without frame and engine | 1860x773x715 mm | 1497.0 | RUR 285,500 | Order |

| CNS 180-425 | 180.0 | 425.0 m | without frame and engine | 1965x773x715 mm | 1610.0 | RUB 307,000 | Order |

| CNS 180-425 | 180.0 | 425.0 m | 315.0/1500 | 3425x773x1010 mm | 3313.0 | 780,000 rub. | Order |

| CNS 300-120 | 300.0 | 120.0 m | 160.0/1500 | 2580x1050x1145 mm | 2600.0 | 520,000 rub. | Order |

| CNS 300-120 | 300.0 | 120.0 m | without frame and engine | 1365x1050x830 mm | 1150.0 | 270,000 rub. | Order |

| CNS 300-180 | 300.0 | 180.0 m | without frame and engine | 1485x970x830 mm | 1300.0 | 300,000 rub. | Order |

| CNS 300-180 | 300.0 | 180.0 m | 250.0/1500 | 2900x970x830 mm | 3000.0 | 725,000 rub. | Order |

| CNS 300-240 | 300.0 | 240.0 m | 315.0/1500 | 3065x970x1170 mm | 3243.0 | 820,000 rub. | Order |

| CNS 300-240 | 300.0 | 240.0 m | without frame and engine | 1605x970x830 mm | 1460.0 | 340,000 rub. | Order |

| CNS 300-300 | 300.0 | 300.0 m | without frame and engine | 1725x1370x830 mm | 1650.0 | RUB 387,000 | Order |

| CNS 300-300 | 300.0 | 300.0 m | 400.0/1500 | 3285x1370x1565 mm | 5250.0 | RUB 1,300,000 | Order |

| CNS 300-360 | 300.0 | 360.0 m | 500.0/1500 | 3200x1370x1565 mm | 5400.0 | Price on request | Order |

| CNS 300-360 | 300.0 | 360.0 m | without frame and engine | 1845x1370x830 mm | 1750.0 | 430,000 rub. | Order |

| CNS 300-420 | 300.0 | 420.0 m | without frame and engine | 1965x1370x830 mm | 1950.0 | 450,000 rub. | Order |

| CNS 300-420 | 300.0 | 420.0 m | 500.0/1500 | 3405x1370x1565 mm | 6300.0 | RUR 1,645,000 | Order |

| CNS 300-480 | 300.0 | 480.0 m | 630.0/1500 | 2085x1370x830 mm | 6500.0 | RUB 1,765,000 | Order |

| CNS 300-480 | 300.0 | 480.0 m | without frame and engine | 2085x1370x830 mm | 2150.0 | 500,000 rub. | Order |

| CNS 300-540 | 300.0 | 540.0 m | without frame and engine | 2205x1470x830 mm | 2310.0 | RUB 537,000 | Order |

| CNS 300-540 | 300.0 | 540.0 m | 800.0/1500 | 3810x1470x1670 mm | 6660.0 | RUB 1,950,000 | Order |

| CNS 300-600 | 300.0 | 600.0 m | 800.0/1500 | 4175x1160x1440 mm | 6820.0 | RUB 1,954,500 | Order |

| CNS 300-600 | 300.0 | 600.0 m | without frame and engine | 2325x1470x830 mm | 2470.0 | 580,000 rub. | Order |

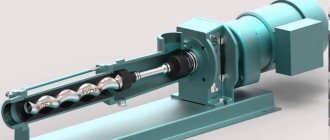

Multistage pump design - what does the unit consist of?

These types of pumps have a simple design. They consist of the following elements:

- Housing made of corrosion-resistant materials;

- Suction pipe that receives liquid;

- Discharge pipe - through it water is supplied under pressure into the system;

- Main shaft;

- Impellers;

- Bearings with self-lubricating function;

- Seals at the ends of the device prevent water leaks from the working chamber.

The simple design of pumping equipment greatly facilitates its maintenance and troubleshooting. This helps save money on specialist services.

Operating principle of multistage pumps

A centrifugal multistage pump is a sectional device and operates in a specific order. First, the liquid enters the first section through the suction pipe, in which the impeller is located. After creating the necessary pressure, the water passes through the discharge pipe into the second section, where it is again affected by the centrifugal force generated by the second impeller. After this, the liquid under pressure flows from the pump into the outlet hose.

In other words, as each section of the pump passes, the fluid is exposed to greater pressure, which is created by the impellers. From this we can conclude that the pressure in a multistage pump is equal to the sum of all pressure indicators created in each individual section.

It is worth noting that with an increase in the diameter of the impeller and the speed of its rotation inside the unit, the pressure of the liquid leaving the pump will also increase.

Types of centrifugal pumps

Units can be classified according to the following distinctive features:

- By number of steps:

- single-stage units;

- two-stage;

- multi-stage.

- What is the number of fluid flows:

- single-threaded;

- with two streams;

- multithreaded.

- By what principle is liquid supplied to the impeller?

- with spiral outlet;

- along an annular outlet, with a guide vane;

- What is the design of the impeller:

- closed impeller;

- open impeller.

- How the drive is made:

- using a coupling;

- through the gearbox.

- By shaft location:

- vertical;

- horizontal.

- Glandless rotor pump. In this case, the engine rotor moves directly the fluid. The engine stator, which is constantly under voltage, is separated from the rotor by a special sleeve, 0.1 to 0.3 millimeters thick, made of stainless steel. The rotor bearings are lubricated by a liquid medium, which also performs the function of cooling the rotor. The pump shaft is mainly horizontal.

- Dry rotor pump. Here the motor rotor does not come into contact with the liquid medium that is being pumped. They usually have a large fluid supply.

Advantages and disadvantages of centrifugal pumps

Compared to other types, centrifugal pumps have advantages:

- In a wide range of flows Q, fairly high values of efficiency and pressure H are maintained, as a result of flat characteristics H = f(Q) and η = η (Q.

- Increased rotation speed, which allows the pumps to be driven by electric motors and turbines.

- The power change N has a smooth shape, which allows the pump to be started with the outlet valve closed or the check valve closed.

- They have good stability in the operation of the devices and expansion of the technical values of H and Q with parallel and series connection of pumps, when working on one pipeline.

- Transient processes occur smoothly when operating modes of hydraulic systems change.

- The pumps are located above the liquid level in the flow tank.

- Due to various factors, the performance of pumps H, Q, η changes. These factors are:

- turning the diameters of impellers;

- change in rotation speed;

- change in frequency of power supply.

- The low price of the pump, which is associated with the use of relatively inexpensive structural materials in the product:

- become;

- cast iron;

- polymer materials.

- Easy to maintain and operate.

- High reliability during operation.

- Large fluid supply Q.

- Liquid flows with small, uniform pressure pulsations.

- They work successfully on “contaminated” liquids.

The disadvantages of centrifugal pumps are:

- The unit must be primed before starting it up.

- They have a tendency to cavitation.

- Reduced efficiency when pumping viscous liquids.

- Low efficiency value with small liquid supply Q.

- Centrifugal pumps are best used in the area of large water supplies Q and low and medium pressures H.

Advice: You cannot use such devices without first filling them with water.

Types of multistage pumps - classification of market models

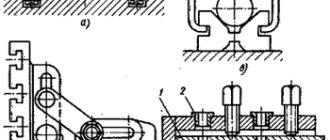

Modern multistage pumping equipment is divided into the following types:

- Vertical units - pumps of this type are installed in a vertical position. Among the advantages of a vertical unit, one should highlight the generation of very high liquid pressure, the ability to pump liquid at a temperature of 100 °C and long service life without failures;

- Horizontal multistage pumps are the optimal equipment for arranging water supply in a country house. The working planes of such a pump are performed in a horizontal position. This makes it possible to obtain water under high pressure with low device productivity.

Depending on the areas of application, the following units are distinguished on the market:

- Industrial high-pressure pumps – have larger dimensions and higher power. Each industrial pump has a special coating that protects it from chemicals;

- Household devices - these units have smaller dimensions and light weight. They are much easier to maintain and repair, they consume less electricity and make less noise. At the same time, they do not produce as high a pressure as equipment of the first type.

When buying a multi-stage unit, you must remember that industrial devices are characterized by fairly high electricity consumption. Because of this, it is better not to buy them even for servicing large farms. Instead, you can purchase two household pumps, which in total will consume much less energy than is required to operate one industrial unit.

How the pump works

Centrifugal forces act on the fluid so that it is directed towards the periphery of the wheel. In this area, through a ring-shaped channel (also called a snail), water is supplied to the pressure pipe (diffuser). And the purpose of this part is to convert some part of the dynamic energy into static energy.

A multistage pump is a newer unit, the design of which has a number of impellers and stages. These steps are located one after another. When choosing a centrifugal pump, you need to consider how the shaft is sealed. New models have a difference and this difference lies in the mechanical seal, while older models have a gland load. The first option maintains the tightness of the device and prevents leaks. If the pump operates with any vibrations or its shaft is not significantly displaced, this will not cause a leak.