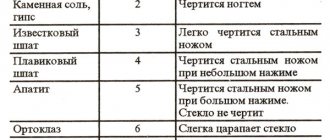

The mineral hardness scale or Mohs mineralogical scale is compiled from reference samples according to the degree of relative hardness from 1 to 10. A qualitative ordinal indicator of the strength resistance of minerals included in this scale is determined by scratching. The mechanical ability of harder materials to scratch softer rocks determines the relative hardness of a particular type of mineral.

The 10 Mohs mineral elements are presented as reference samples and arranged in ascending order, allowing you to visually determine which mineral is harder. For example, talc occupies the first position in the table and is considered the softest among others presented on the scale. On the other side is a diamond, which, according to the “mineral strength” criterion, occupies the very top, that is, the 10th position on the Mohs scale and has no analogues in nature in terms of this indicator.

Determination of mineral hardness

Hardness is determined as follows. A smooth area is selected on the surface of the mineral under study and, taking a mineral from the Mohs scale, it is passed along it at an acute angle with pressure. If a scratch remains on the surface of the sample under study, then its hardness is less than that of the reference mineral. It is necessary to make sure that it is the scratch (indentation) that remains on the test sample, and not the powder of the reference sample.

Using sequential reference minerals from the softest to the hardest, a position is achieved where the test sample is located in its hardness between two reference minerals or the test sample is scratched by the reference one and itself scratches it. In the first case, the hardness of the test sample is estimated to be an average value, in the second case it is equal to the hardness of the reference one. For example, if a mineral is scratched by quartz and not scratched by orthoclase, then its hardness is 6.5. If another mineral is scratched by calcite and itself leaves a scratch on it, then its hardness is 3.

(In the absence of the Mohs scale, the hardness of minerals can be determined in other ways.

Thus, the graphite of a soft pencil has a hardness of about 1. Minerals with such hardness write on paper without leaving scratches on it.

Minerals with a hardness of up to 2 can be scratched with a fingernail; an iron nail and wire have a hardness of 4 (bronze coin 3.5-4), glass - 5, a steel knife, a needle - 6. Quartz, which has a hardness of 7, is widely found in nature)..

It should be kept in mind that individual minerals may have different hardness in different directions. For example, the hardness of disthene along an elongated edge is 4, and perpendicular to it - 6.

To determine the hardness of a mineral, which is a powdery or earthy aggregate, it is necessary to rub the powder on a reference sample.

If the latter is covered with scratches, then the hardness of the standard is less than that of the test sample.

It is important to emphasize that Mohs hardness units are relative. So, for example, a diamond using the indentation method has a hardness of 10,000 kg/mm2, and talc - 43 kg/mm2, i.e. the hardness of diamond is not 10, but 232 times greater than the hardness of talc.

How to apply the hardness scale for metals.

When you decide to buy a product made of a precious metal, but are undecided about which material to choose, the Mohs hardness scale will help.

By comparing the coefficients, you will make a preliminary choice and be able to decide whether this product is also suitable for you in terms of price.

For example, platinum is much more durable than silver, and in general, harder ones last longer with constant wear. However, platinum is also much more expensive than silver, so you need to consider whether you are willing to pay the extra price for durability.

Mohs scale. Mineral hardness

The Mohs scale (mineralogical hardness scale) is a set of reference minerals for determining relative hardness using the scratching method.

10 minerals, arranged in order of increasing hardness, were taken as standards.

Consists of 10 hardness standards: talc - 1; gypsum - 2; calcite - 3; fluorite - 4; apatite - 5; orthoclase - 6; quartz - 7; topaz - 8; corundum - 9; diamond - 10.

Minerals

with an index below 7 are considered

soft

, above 7 -

hard

.

In general, the bulk of natural compounds have a hardness of 2 to 6.

The hardness scale was proposed in 1811 by the German mineralogist Friedrich Mohs.

- this is the resistance that its surface provides when trying to scratch it with another stone or other object

; hardness is a measure of the coherence of the atomic structure of a substance.

The hardness of the same stone can be different in different directions

. It stands out among other minerals by its large difference in hardness in different directions: its hardness varies from 5 to 7, and in some directions the sample can be scratched with a knife, but in others not.

The 1 to 10 scale represents 10 common minerals, from talc to diamond.

.

A mineral's hardness is measured by finding the hardest reference mineral it can scratch; and/or the softest reference mineral that scratches the given mineral. Everything is very simple. For example, if a mineral is scratched by apatite but not by fluorite, then its hardness is in the range of 4 to 5.

Intermediate degrees of stone hardness are expressed as fractions. Thus, the number 8 1/2, referring to chrysoberyl, means that it scratches topaz in much the same way as it scratches itself with corundum.

Pyrope garnet is slightly harder than quartz (7) and slightly softer than beryl (7 1/2), so its hardness is designated as 7 1/4.

It is important to remember that cryptocrystalline, finely porous and powdery varieties of minerals have false low hardnesses

.

For example, hematite in crystals has a hardness of 6, but in the form of red ocher it is less than 4.

Every owner of a diamond ring knows that a diamond easily scratches window glass.

Diamonds are used to cut glass. If we try other precious stones, we will find that they also scratch glass, but not so easily, and then topaz scratches window glass, but the topaz itself is scratched by corundum, which in turn gives in to the all-powerful and hardest diamond.

Samples of the same minerals obtained from different places differ from each other in the complexity of the cutting and polishing process.

It is said of diamonds from Kalimantan and New South Wales that they are considerably harder than those from South Africa and other places and that they are difficult to cut.

Ceylon sapphires are harder than rubies, while Kashmir sapphires are softer.

The Mohs scale is intended for a rough comparative assessment of the hardness of materials according to the softer-harder system. The material being tested either scratches the standard and its hardness on the Mohs scale is higher, or it scratches the standard and its hardness is lower than the standard.

Thus, the Mohs scale only informs about the relative hardness of minerals

.

In addition to the Mohs scale, of course, there are other methods for determining the hardness of minerals, but the different hardness scales cannot be unambiguously correlated with each other

.

Several more accurate systems for measuring the hardness of materials have been adopted in practice, none of which covers the entire spectrum of the Mohs scale.

Table with comparison scale

Comparison of the strength characteristics obtained using various methods with the Mohs table is useful in the practical use of stones. Absolute values of hardness are determined by other estimates; a comparison of the criteria can be seen in the table.

| Minerals and rocks | Mohs grading | According to Schreiner, MPa | Strength on the Knoop scale, units | Grinding hardness in water according to Rozival | Strength according to microhardness tester PMT-2, PMT-3, kg/mm² |

| Talc | 1 | 250―400 | 12 | 0,03 | 2,4 |

| Gypsum | 2 | 32 | 1,25 | 40 | |

| Calcite, marble, anhydrite | 3 | 950―1400 | 135 | 4,5 | 110 |

| Fluorite, dolomite | 4 | 2500―3200 | 160 | 5 | 190 |

| Apatite, granite | 5 | 3000―3700 | 400 | 6,5 | 530 |

| Orthoclase, basalt | 6 | 3900 | 500 | 37 | 790 |

| Quartz, diabase | 7 | 6300 | 1250 | 120 | 1120 |

| Topaz | 8 | 1550 | 175 | 1430 | |

| Corundum | 9 | 1900 | 1000 | 2060 | |

| Diamond | 10 | 8300 | 140000 | 10060 |

The reason for the hardness of granite lies in its complex mineral composition, where the main components, quartz and mica, are classified into different categories - 7 and 2. Their quantitative ratio determines the properties of the rock.

The Mohs scale is also used to compare the hardness of metals - this is convenient when choosing a setting for a precious stone.

| Name | Tin | Gold Silver | Copper, bronze | Nickel | Platinum | Palladium | Titanium | Tungsten |

| Value by gradation | 1,5 | 2,5―3 | 3 | 4 | 4,5 | 4,7 | 6 | 7,5 |

The table shows which metals can scratch others. This circumstance is important to consider when storing jewelry together.

Household hardness measuring instruments

Sometimes to determine hardness you have to use the tools that are at hand

, although in some cases

they are not accurate enough

(pencil -1, table salt - 2, fingernail - 2.5, copper coin - 3, iron nail - 4, glass - 5, steel knife - 6, file - 7).

When determining hardness, a fresh mineral surface should always be tested.

good to remember:

- the nail leaves a scratch on plaster and softer substances

- regular window glass is slightly softer than feldspar

- The steel blade of the knife is slightly harder than feldspar, approaching quartz in hardness, and scratches glass easily.

Classification of natural stone materials by hardness

| Solid | Medium hard | Soft |

| Granite, gneiss, diorite, syenite, gabbro, labradorite, teschenite, diabase, quartz porphyry, basalt | Marble (achromatic and chromatic), conglomerate, breccia, limestone, sandstone, volcanic tuff, calcareous tuff, shale | Gypsum, talc |

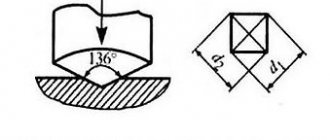

Table of relationships between hardness numbers according to Brinell, Rockwell, Vickers, Shore

Rockwell, Vickers and Shore hardness values indicated correspond to Brinell hardness values determined using a 10 mm diameter ball.

| According to Rockwell | According to Brinell | Vickers (HV) | By Shore | |||

| H.R.C. | HRA | HRB | Imprint diameter | HB | ||

| 65 | 84,5 | – | 2,34 | 688 | 940 | 96 |

| 64 | 83,5 | – | 2,37 | 670 | 912 | 94 |

| 63 | 83 | – | 2,39 | 659 | 867 | 93 |

| 62 | 82,5 | – | 2,42 | 643 | 846 | 92 |

| 61 | 82 | – | 2,45 | 627 | 818 | 91 |

| 60 | 81,5 | – | 2,47 | 616 | – | – |

| 59 | 81 | – | 2,5 | 601 | 756 | 86 |

| 58 | 80,5 | – | 2,54 | 582 | 704 | 83 |

| 57 | 80 | – | 2,56 | 573 | 693 | – |

| 56 | 79 | – | 2,6 | 555 | 653 | 79,5 |

| 55 | 79 | – | 2,61 | 551 | 644 | – |

| 54 | 78,5 | – | 2,65 | 534 | 618 | 76,5 |

| 53 | 78 | – | 2,68 | 522 | 594 | – |

| 52 | 77,5 | – | 2,71 | 510 | 578 | – |

| 51 | 76 | – | 2,75 | 495 | 56 | 71 |

| 50 | 76 | – | 2,76 | 492 | 549 | – |

| 49 | 76 | – | 2,81 | 474 | 528 | – |

| 48 | 75 | – | 2,85 | 461 | 509 | 65,5 |

| 47 | 74 | – | 2,9 | 444 | 484 | 63,5 |

| 46 | 73,5 | – | 2,93 | 435 | 469 | – |

| 45 | 73 | – | 2,95 | 429 | 461 | 61,5 |

| 44 | 73 | – | 3 | 415 | 442 | 59,5 |

| 42 | 72 | – | 3,06 | 398 | 419 | – |

| 40 | 71 | – | 3,14 | 378 | 395 | 54 |

| 38 | 69 | – | 3,24 | 354 | 366 | 50 |

| 36 | 68 | – | 3,34 | 333 | 342 | – |

| 34 | 67 | – | 3,44 | 313 | 319 | 44 |

| 32 | 67 | – | 3,52 | 298 | 302 | – |

| 30 | 66 | – | 3,6 | 285 | 288 | 40,5 |

| 28 | 65 | – | 3,7 | 269 | 271 | 38,5 |

| 26 | 64 | – | 3,8 | 255 | 256 | 36,5 |

| 24 | 63 | 100 | 3,9 | 241 | 242 | 34,5 |

| 22 | 62 | 98 | 4 | 229 | 229 | 32,5 |

| 20 | 61 | 97 | 4,1 | 217 | 217 | 31 |

| 18 | 60 | 95 | 4,2 | 207 | 206 | 29,5 |

| – | 59 | 93 | 4,26 | 200 | 199 | – |

| – | 58 | – | 4,34 | 193 | 192 | 27,5 |

| – | 57 | 91 | 4,4 | 187 | 186 | 27 |

| – | 56 | 89 | 4,48 | 180 | 179 | 25 |

Threaded holes

Table of drills for holes for cutting cylindrical pipe threads.

Wrench nut sizes

Basic spanner dimensions for hex bolt heads and hex nuts.

Read also: Identification of the spotlight on the diagram

G and M codes

Examples, description and interpretation of L and M codes for creating control programs on CNC milling and lathes.

Thread types

Types and characteristics of metric, pipe, thrust, trapezoidal and round threads.

Drawing scales

Standard scales for images of parts on mechanical engineering and construction drawings.

Cutting modes

Online calculator for calculating cutting conditions during turning.

Threaded holes

Table of drills and holes for cutting metric threads with large (main) pitch.

CNC machines

Classification of CNC machines, CNC machines for metal for turning, milling, drilling, boring, threading, reaming, countersinking.

Cutting modes

Online calculator for calculating cutting conditions when milling.

Drawing formats

Table of side sizes of main and additional formats of drawing sheets.

CAD/CAM/CAE systems

CAD computer-aided design systems, 3D programs for design, modeling and creation of 3D models.

Linear hardness

Linear hardness is determined by the absolute hardness scale, not the Mohs scale.

Here is the absolute hardness scale:

Talc - 1 - Can be scratched by a fingernail Gypsum - 3 - Scratched by a fingernail Calcite - 9 - Scratched by a copper coin Fluorite - 21 - Easily scratched by a knife Apatite - 48 - Hardly scratched by a knife Orthoclase - 72 - Scratched by a file Quartz - 100 - Scratched window glass Topaz - 200 — Easily scratches quartz Corundum — 400 — Easily scratches topaz Diamond — 1600 — Not scratched by anything (and at the same time easily scratches corundum)

HardnessMineralAbsolute hardness

| 1 | Talc (Mg3Si4O10(OH)2) | 1 |

| 2 | Gypsum (CaSO4 2H2O) | 3 |

| 3 | Calcite (CaCO3) | 9 |

| 4 | Fluorite (CaF2) | 21 |

| 5 | Apatite (Ca5(PO4)3(OH-,Cl-,F-)) | 48 |

| 6 | Feldspars (KAlSi3O8) | 72 |

| 7 | Quartz (SiO2) | 100 |

| 8 | Topaz (Al2SiO4(OH-,F-)2) | 200 |

| 9 | Corundum (Al2O3) | 400 |

| 10 | Diamond (C) | 1500 |

What's harder than diamond?

Many attempts have been made to create or find in nature a material stronger than diamond. So far they have not been successful: obsidan, titanium, super-hard alloys, all kinds of innovative materials cannot compete with the noble standard. Moreover: many chemists and physicists even argue that substances stronger than diamond (more precisely, harder) cannot exist.

The most famous and scandalous story involves a substance called lonsdaleite, which in a chemical and physical sense is a hexagonal diamond. In the 60s of the last century, this mineral was synthesized artificially, and a little later it was discovered in small quantities in meteorite craters.

In 2009, a group of Chinese scientists published a sensational paper claiming that lonsdaleite is more than half as hard as cubic diamond (as we know it). Unfortunately, these data turned out to be a hoax and were not confirmed even by the calculations in the above work.

The most successful attempt to create a substance harder than diamond was made quite recently, in 2022. A duo of American scientists managed to produce hexagonal diamonds from graphite using targeted explosions. The resulting samples demonstrated better sound conductivity than classic cubic diamond, which theoretically indicates greater hardness.

Unfortunately, it has not yet been possible to test the theoretical calculations of American scientists experimentally. And the disgraced lonsdaleite, obtained from graphite by exposure to colossal pressure, shows a strength of only 7-8 points on the Mohs scale. And it’s unlikely to be used: it consists of crystals visible only under a microscope, and obtaining this substance is fantastically expensive.

Gold pendant with cognac diamonds (go to the SUNLIGHT catalogue)

There are other substances that are not much inferior to diamond in hardness: fullerites, all kinds of boron compounds, carbyne, and so on. They are slightly softer than diamond, but often surpass it in other characteristics: strength, resistance to chemical attack and ultra-high temperatures.

A stronger substance can be created from cubic diamond (for example, using nanoengineering). The Japanese succeeded, but how to process this unprecedentedly hard material?

Imitation stones and hardness testing

Since various types of gemstones are at least as hard as quartz (7), they can be easily distinguished from similar-looking “soft” glass products that imitate gemstones using a file.

This test is especially useful in the case of a diamond, because it, being much harder than any other precious stone, leaves a much deeper scratch on the glass than can be done with a ruby or sapphire.

Before the refractometer was introduced, this was practically the only method for checking cut stones.

If the stone is encased in a setting, it is best to remove it from there and test it on the rim of the stone, since the scratched area can then be completely covered by reinserting the stone into the setting.

For the convenience of testing minerals for hardness, so-called standard points are used, in which pieces of material with a known hardness are inserted into small holders.

General information about diamonds

Do you know the formula of diamond? Even a preschooler who has no idea about chemistry can remember it. It's just C, which means diamonds are pure carbon (ideally, of course).

What had to happen for carbon to turn into diamond? Many hypotheses have been put forward on this matter. The most convincing of them claims that diamonds are formed at very great depths (over 200 km) and under tremendous pressure - there carbon forms a special cubic lattice inherent in diamonds. During volcanic processes, carbon crystals are carried closer to the surface, where they are discovered by diamond miners.

Gold ring with diamonds (go to the SUNLIGHT catalogue)

This process is very slow: the age of diamonds is measured in hundreds of millions, or even billions of years. So when, during intensive mining, diamond-bearing kimberlite pipes and other rocks are depleted, the reserves of this stone will dry up for a very long time.

According to scientific data, some diamonds are of extraterrestrial origin. They came to us with meteorites or came to us as a result of a supernova explosion. It is assumed that some of them are much older than the solar system!

There are a lot of diamonds on Earth, but only a tiny part of them can be turned into diamonds. The purest and largest diamonds (the so-called “Cape”) are mined in Africa, and Russian reserves of this mineral are concentrated mainly in Yakutia.

Among the most outstanding properties of diamond are the following:

- unsurpassed hardness – 10 on the Mohs scale;

- the highest thermal conductivity among solids – 900–2300 W/(m K);

- vanishingly low coefficient of friction on metal (in air);

- refractoriness and resistance to high temperatures;

- resistance to most aggressive acids and alkalis;

- high refractive index of rays combined with transparency;

- the ability to luminesce (glow) in x-rays and ultraviolet light.

Diamonds are not only white, but also colored. Brown and yellow colors reduce the cost of a diamond, blue, blue, pink, red, green - increase it to sky-high heights.

The main characteristic that decides the fate of a rough diamond is transparency (“clear water”). That is why black diamonds (carbonados) have long been considered exclusively technical. However, occasionally you come across evenly colored black diamonds that retain some transparency and characteristic shine. They are mind-bogglingly expensive.

HARD AND BRIGHT

The next widely used material is mineral (or silicate) glass. Until recently, this was the standard in the watch industry and even expensive and elite models were equipped with it. The basic method for producing glass is to melt a mixture of quartz sand (Si02), soda (Na2C03) and lime (CaO) at temperatures above 1000°C, resulting in a chemical complex with the composition Na20*Ca0*6Si02. The introduction of additional substances into this mixture can significantly change the physical properties of the material, making it suitable for use in various industries. For example, silicon oxide will add elasticity to the finished product, and barium oxide will provide the glass with a fairly high level of radiation protection. To give the glass mass the shape of the finished product, a wide range of methods are used: drawing, rolling, pressing, casting, blowing, etc., the shape is fixed by sudden cooling.

Mineral glass is more fragile than plastic, but more scratch resistant

Compared to plastic, mineral glass is harder and therefore more resistant to scratches and abrasions. But it’s too early to rejoice: mineral glass can easily be scratched by any metal object or stone. Fortunately, just like plexiglass, this material is easy to polish, and “spare tires” made from it are quite inexpensive. Various measures, such as hardening or coating the glass with a more durable material, can improve the mechanical properties of glass to some extent. However, they do not provide a fundamental increase in hardness.

Where are soft stones used?

Low hardness plus other properties determine the areas of use of soft minerals:

- Soft rocks rarely act as independent players, more often serving as raw materials for production processes or as a component of complex substances. For example, rare earth metals are obtained from soft molybdenite; it is added to lubricants and used in radio engineering.

- The best samples become exhibits of mineralogical collections or decorative and ornamental materials.

- The most famous soft ornamental stones are gypsum and its variety selenite. Both are excellently processed with cutting tools.

Soft stones make beautiful boxes, figurines, balls, pyramids, and other small plastic items.

Can a diamond be scratched or broken with a hammer?

Based on the above, we can conclude: it is impossible to scratch a diamond. This makes it possible to quickly identify rough glass counterfeits that are easily scratched by a steel needle or nail file. True, imitation diamonds like cubic zirconia, and even more so carborundum, cannot be recognized in this way.

But there are plenty of substances stronger than diamond - and even steel! This means breaking a diamond is quite possible. Naturally, the stone will calmly survive a fall from a considerable height, and even if you step on it, nothing critical will happen. But if you hit the diamond with force with a hammer, it will crack, otherwise it will crumble into small crumbs.

But you shouldn’t do this: the experiment will be too expensive, and the world will lose another diamond that has been formed over hundreds of millions of years!

19.04.21