For a novice welder, choosing an electrode can be a problem: there are more than two hundred brands with different properties, purposes and characteristics. Moreover, about 100 brands are suitable for manual arc welding with inverter machines. It’s impossible to talk about everyone, and to begin with, it’s not necessary. Let’s just briefly describe the main types and which electrodes for inverter welding are most suitable for beginners. We will also talk about what diameter to take and what current to set for welding metal of different thicknesses.

What is an electrode and what is the coating for?

An electrode is a piece of metal wire with a special coating - coating. During welding, the core melts due to the temperature of the arc. At the same time, the coating burns and melts, creating a protective gas cloud around the welding area - the weld pool. It blocks access to oxygen contained in the air. As the coating burns, part of it turns into a liquid state and covers the molten metal with a thin layer, also protecting it from interaction with oxygen. So the coating ensures good quality of the seam.

The welding electrode consists of a core and a protective coating

Before starting welding, any electrode is inspected: the coating should not be chipped. Otherwise, you will not achieve uniform heating and a high-quality seam. Also pay attention to the tip of the electrode: the thickness of the coating should be the same on all sides. Then the arc will come out in the center. Otherwise it will be displaced. For experienced welders this is not a big deal, but for beginners it can create significant problems.

It is necessary to monitor the moisture content of the coating. Some of them ignite very poorly in high humidity (for example, SSSI). Due to such “capriciousness” of the coating, they need to be stored in a dry place, ensuring as airtight packaging as possible. You can put the box in a bag, and also put in a few bags of salt that come in shoe boxes.

You should not buy wet electrodes: they can, of course, be dried, but their characteristics will decrease. If it does happen that the electrodes become damp, you can dry them in a regular household oven at low temperatures (they are usually indicated on the packaging). The second way is to put it in a dry, well-ventilated area for a long time.

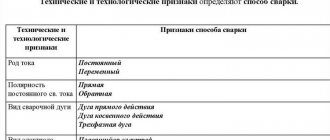

Coating (protective coating) of electrodes can be: basic, rutile, cellulose and acidic.

Types of coating and their characteristics

There are only four types of coatings:

- Basics.

- Rutile.

- Sour.

- Pulp.

Basic (USSI) and cellulose coatings are only suitable for DC welding. They can be used on critical seams: they create a strong, elastic seam that is resistant to impact loads.

There are more than 200 brands of electrodes for welding, about 100 of them can be used in manual arc welding

The other two (rutile and acidic) can work with both alternating and direct current when welding. But acidic coating is very toxic: you can work indoors only if the workplace is equipped with forced exhaust.

Rutile coating has a greenish or blue tint, the electrodes are easy to ignite. They ignite well even if the inverter has a low open circuit voltage (for reliable ignition of the main coating, a good current-voltage characteristic is required; how to choose an inverter welding machine, read here.). When welding with rutile electrodes (MP-3), the metal hardly splashes, but there is a lot of slag and it is not easy to remove: you have to work with a hammer.

You may be interested in how to weld a gazebo from a metal pipe or how to make a shed on a pipe frame.

How to choose electrodes for inverter welding

First of all, the composition of the core is selected: it must be similar to the type of metal being welded. Structural steel is the most commonly used material in households. The electrodes should be made from the same wire. Sometimes you still have to cook stainless steel. Then the core should also be made of stainless steel, and for highly alloyed and heat-resistant ones it is made of metal with the same characteristics.

You can perform all the work around the house or at a construction site using just a few brands of electrodes:

- MR-3

- SSSI 13/55

- ANO 21

- OK 63.34

They are recognized by many as the best electrodes for beginners who work with inverter welding machines: they are easier to work with, at the same time, they allow you to weld high-quality seams even without significant experience. Below are the characteristics and general application of those consumables that many experts consider good electrodes for an inverter. In any case, they are often recommended for beginning welders to gain experience.

Electrodes with rutile coating MP 3

MP-3 is perhaps the most popular welding electrodes for inverters among beginners.

Most often, beginners are advised to start mastering welds with MP-3 electrodes. They light up easily, even with a not very good current-voltage characteristic of the welding machine, provide good protection for the weld pool, and make it quite easy to control its position. If the electrode does not ignite, calcine it at a temperature of 150-180° for 40 minutes.

They are used in devices with alternating current (welding transformers) and direct current (welding rectifiers and inverters). Inverters are usually connected with reverse polarity (+ on the electrode). Suitable for any type of seam, except vertical from top to bottom.

Read about the types of welding machines here.

MP 3 electrodes are not picky about the quality of the surfaces being welded. They can be used even on untreated, rusty and wet parts. Welding is carried out with a medium (2-3 mm) or short arc.

The MP 3 feature is very important for novice welders: they “hold” the arc well and are easy to work with. This is why not all professionals love this brand: they call them sparklers. They cook too softly: slow movements are necessary for good heating. What the pros don't like, is just what beginners need. Try to start learning welding with MP3. Everything should work out for you.

| Electrode diameter LEZ MR-3, mm | Length, mm | Recommended welding current, A | Pack weight, kg | Price, rub |

| 2,0 | 250 | 40-60 A | 1,0 | 146 |

| 2,5 | 300 | 60-100 A | 1,0 | 120 |

| 3 | 350 | 70-100 A | 1,0 | 95 |

| 4 | 450 | 80-170 A | 1,0 | 91 |

| 5 | 450 | 130-210 A | 1,0 | 91 |

UONI 13/55 with basic coating

Electrodes preferred by professionals for the UONI 13/55 inverter (click on the picture to enlarge the size)

These are, perhaps, the most widespread and popular electrodes with a basic coating. They are recommended for welding carbon and low-alloy steels. Suitable for connections of critical structures. The seams are resistant to shock loads and ductile, and withstand low temperatures well.

The disadvantage of these electrodes is that they ignite well only when the idle value of the inverter is sufficiently high (above 70 V). The second significant drawback: high requirements for stripping and processing of welded metals. If rust, dust, oil or other contaminants remain on the edge, the seam will be porous.

You can work with UONI 13/55 only on DC welding machines, including those with inverters, with reverse polarity (+ applied to the electrode), and with a short arc (keep the tip of the electrode closer to the surface to be welded). Minimum open circuit voltage 65 V.

| Electrode diameter UONI 13/55 (manufacturer: Mezhgosmetiz) | Electrode length, mm | Recommended welding current, A | Retail price of a pack, rub |

| 2,0 | 250 | 30-60 A | |

| 2,5 | 300 | 40-70 A | 127 RUR |

| 3 | 350 | 80-100 A | 116 RUR |

| 4 | 450 | 130-160 A | 111 rub. |

| 5 | 450 | 180-210 A | 110 rub. |

ANO 21

This type of rutile-coated electrode is designed to work with thin carbon steels. (Read about welding thin metals here.) When using them, the arc is easily ignited (including when re-igniting), the weld is fine-scaled (made up of small waves), and the slag is easily separated. ANO 21 electrodes can be used for welding water or gas pipes.

Try ANO 21 electrodes to work on the inverter

They work with both alternating and direct current of any polarity. Before welding, heat treatment is required: they are calcined at a temperature of 120°C for 40 minutes.

| Diameter, mm | Low electrode position | Vertical electrode position | Ceiling electrode position |

| 2 | current 50-90 A | current 50-70 A | current 70-90 A |

| 2,5 | current 60-110 A | current 60-90 A | current 80100 A |

| 3 | current 90-140 A | current 80-100 A | current 100-130 A |

Stainless steel electrodes OK 63.34

If you need to weld stainless steel, try OK 63.34. They can also cook structural steel. This produces a seam with a small wave with a smooth transition to the main surface of the metal. The amount of slag is small and can be easily removed.

This electrode is good for welding vertical seams in metal 6-8 mm, passing from top to bottom. Suitable for multi-pass welding of butt and overlap joints. Works with direct and alternating current of any polarity, minimum open circuit voltage is 60 V.

Welding electrodes OK 63.34

For welding you will also need a mask. To make your work easier, take a chameleon welding mask.

Alternative Methods

In addition to inverters, a semi-automatic welding method is also well suited, especially when working with car bodies. The advantage is that there is no need to change the electrode, since the wire is fed continuously. This significantly speeds up the entire process for large projects. The distance between the product and the heating pad is easier to control since there is no combustible part of the electrode. This method is easier for beginner welders to master.

Semi-automatic welding allows you to work with even thinner sheets of steel due to the use of 0.8 mm wire. But such equipment is not always available in everyday life, so the inverter method remains in demand. After considering these tips, it becomes clear how to properly weld thin metal. Additional videos about working with an inverter and semi-automatic machine will help you consolidate your knowledge and start practicing.

How to choose the diameter of the electrode, how to connect it and what current strength to set

Choosing the brand of electrodes for the inverter is not all. Even if you have made your decision, at least three questions remain:

- what electrode diameter to use when welding;

- what current to set;

- Which output “+” or “-” should the electrode be connected to?

First things first. Let's start with what diameter of the electrode is needed for welding. In general, it is recommended to proceed from the thickness of the metals being welded: for small thicknesses, an electrode is taken with a diameter of the same size as the metal. If you are welding metal 3 mm thick, then use electrodes of a similar size. If you are cooking something thicker, take 4 mm accordingly. But large electrodes will be difficult for beginners to work with. Start mastering welding with a metal thickness of 3-4 mm. To do this, use 3 mm electrodes, or as they say “three”.

General recommendations for choosing the diameter of the electrode depending on the thickness of the metal

Regarding how to connect the electrodes to which output. The technical specifications on the package most likely indicate what polarity the electrode is intended for. When connecting in reverse, an electrode is connected to the positive output, and a clamp is connected to the negative output, which is attached to the part. With direct polarity, a plus is placed on the part, and a minus is applied to the electrode. How it looks on a welding inverter is shown in the photo.

Direct and reverse polarity of connection on the welding inverter

How are these two connection types different? The flow of electrons has different directions. As you know, electrons move from minus to plus. Therefore, when welding, it turns out that the element that is connected to “+” heats up more. By changing connection modes you can control the intensity of metal heating.

Let's consider several situations. For example, you have a 3 mm electrode, 2 mm metal. If you apply “+” to a part, burnout may result. Therefore, in this case it is better to use reverse polarity, at which the electrode will heat up more. If you want to weld 6 mm metal with the same three, it is better to do it with direct polarity: this way the heating of the metal will be deeper and the weld will be stronger.

Read how to choose an inverter welding machine here. You might be interested in building a fence from corrugated sheets.

Welding current

In general, when installing an electrode, the welding current strength for the inverter is set depending on the diameter of the electrode used. In general, there are recommendations on each pack, but you can do without them: take 20-30 Amperes of current for each millimeter of diameter. It turns out to be a fairly wide range, but then you also need to consider how you will lay the seam: with or without tearing. For welding without separation, lower currents are used, for welding with separation, higher currents are used.

What current should be used to cook with different electrodes (general recommendations, carefully select experimentally)

For example, for an electrode with a diameter of 3 mm, the calculated current is from 60 A to 90 A. They actually work in the range from 30 Amperes to 140 Amperes. When welding without separation, the current is set to about 70-90 A, with separation - 90-120 A. These parameters can “walk” in both directions: it also depends on the speed of movement of the tip of the electrode, on the grade and “fluidity” of the steel being welded, on the position of the seam (for vertical and horizontal seams they put a little less, for the ceiling - even less).

In general, even the currents recommended by the manufacturer are far from a requirement. Start with them, and then select them so that it is convenient for you to work and the seam turns out well. You should get a high-quality connection, and you will select the ratio of current strength and speed of movement experimentally. In this case, focus on the condition of the weld pool. It is your main indicator of quality.

Read about how to properly cook with inverter welding here.

Errors that may occur during welding

Now you know not only how to choose electrodes for inverter welding, but also how to connect them, what diameter you need them for this work, and how to select the current for each type of electrode and weld. Now let's talk a little about electrode holders.

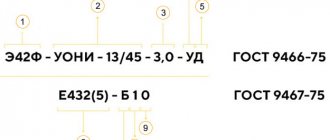

Purpose

The brand of the electrode, as a rule, encrypts its purpose. For example, product types:

- UONI - designed for welding parts at low temperatures;

- ANO-21 - for performing work with thin (up to 4 mm) parts operated under low pressure;

- MP-3S - for welding rolled parts and medium-carbon steels up to 20 mm thick;

- LEZ - for surfacing worn parts;

- inexpensive universal-use OZS-12 electrodes are recommended for welding carbon steels and are easy to use;

- rutile products of the ANO-4 grade are used for welding low-alloy and low-carbon steels; work on both direct and alternating currents; They cook metal contaminated with rust well, have a stable arc, and are easily cleaned of slag.

Experts distinguish between electrodes for welding, tacking, surfacing and cutting. Universal products are in great demand, saving a lot of time when performing various types of work.

Electrode holders

One of the welding cables has a holder into which the welding electrode is inserted. They are of two types:

- with a trigger key, the electrode is clamped in them automatically when the spring-loaded key is released, and released when you press it;

- threaded - the handle twists and unwinds, releasing or clamping the inserted electrode core.

Which one is better? It's up to you to decide, but if you accidentally press a key, you may drop the electrode while welding. Nothing bad happens, but it’s unpleasant...

When choosing an electrode holder, the main thing is to pay attention to the current strength for which it is designed. Choose according to the maximum parameter that is available for your welding machine.

How to connect the cable to a welding electrode holder with a threaded clamp is shown in the video.

The disadvantage of the clothespin holder is that over time, the spring that presses the electrode core weakens, and the contact deteriorates. I have to install a new one. Watch the video to see how to do this on a clothespin holder.

Connecting the welding electrode holder is easy. There is just one caveat: with frequent use, the welding cable gets chafed by its edge. You can, of course, shorten the cable and re-terminate it, but you don’t always want to cut off even 10-20 cm. To prevent this from happening, find a hose whose inner diameter is the same as or slightly smaller than the outer diameter of the welded cable. Cut a small piece of it - 15 centimeters - and cut it lengthwise. Now you can put it on the cable, pull it up and secure it there.