Rolling is a process of bending metal under pressure, as a result of which the product acquires a cylindrical shape. This technology has been used for many centuries, and over the course of its existence it has improved significantly. New tools have appeared that facilitate the process of deformation of solid materials.

- Application area

- Characteristics of the rolling process

- Types of rolling machines

- Roller components

- Making sheet-bending equipment yourself

Application area

The sheet metal rolling process is a deformation method that is performed using a non-profiled rotating tool. This is a cold forming operation in which the metal takes the shape of a cone. After processing in this way, the structure of the workpiece becomes denser and its basic properties improve.

Metal deformation is used in many cases and for different materials. For example, rolling is a preparatory step for stamping the finished product. The same technology is used for primary processing of blanks.

This procedure can be applied not only to sheet metal, but also to pipes, rods and other profiles, products made from rubber compounds and plastics. It is important that the material is sufficiently ductile.

Metal rolling is often used to compact, compress and flatten workpieces, to give them a uniform gloss and thickness. The process can take place both in a cold state and in a heated state. It is possible to heat the rolls and change the speed of passage of the workpiece.

Today, metal rolling is carried out not only in production, but also at home, for which they use a special tool of the same name. In enterprises these are large machines with electric and hydraulic drives. Simple designs, often made by hand, are more suitable for repair shops.

The technological process of metal deformation using this method consists of several stages:

- Preparation of equipment - rollers.

- Rolling a bar or sheet.

- Intermediate annealing.

- Treatment of burrs and cracks.

- Final annealing and rolling.

The absence of burrs and cracks is one of the main conditions for high-quality rolling. Such defects can appear in the event of excessively strong compression of the bar by rollers or from uneven stress and annealing. Defects are identified and eliminated at the fourth stage of work after intermediate annealing. If this is not done and rolling continues, the cracks will increase.

Eliminate defects by rubbing cracks with a file and sawing off, biting off burrs. Then, in order to relieve stress from the metal, the workpiece is annealed and metal rolling continues. The resulting depressions are leveled.

This is interesting: Metal drill: types, markings, selection rules, manufacturers

Characteristics of the rolling process

The fundamental feature of sheet metal rolling is that the deformation process occurs over the entire contact surface . This slightly reduces productivity, but increases the durability of the rolling work rolls. The advantages of metal rolling include:

Reduced operating costs for tooling and equipment.- Increasing the service life of tools and machines.

- Effective use in single and small-scale production.

- Reducing losses from marriage.

- Low cost of a rolling machine compared to a hydraulic or mechanical press. The cost of its acquisition pays off within six months of active use.

During the rolling process, the operator can change the rate of metal deformation. With other forming and stamping operations this is not always possible.

Rolling a sheet of metal can be done in several ways:

- in the transverse direction of the workpiece feed;

- in the longitudinal direction;

- with screw feed.

The first option is used to obtain short pipes, the second - long ones.

The sheet rolling process is characterized by the following features:

Deformation is produced by torque, not force. The value of the torque depends on the conditions of contact friction, the diameter of the working rollers and the physical and mathematical characteristics of the material.- When performing an operation, the rolling speed does not affect energy costs; on the contrary, as the indicator increases, the working force of the process decreases.

- The friction between the rollers depends directly on the surface. Reduced roughness leads to reduced friction. Therefore, during continuous operation of rolling machines, it is necessary to periodically grind the surface of the equipment.

When rolling a steel product up to 6 mm thick, the original metal is processed in a cold state. If you are working with parts made of thick sheet material, preheating is used. In such cases, the rolling machine is installed near furnaces with a non-oxidizing heating system. Due to this, the formation of surface scale is reduced.

If hot-rolled sheet metal is deformed, the sheet is straightened before rolling. This is stipulated by the technical requirements of GOST.

Mechanism design and operating principle

The main part of both factory-made and self-made roller machines is considered to be a heavy bed, which acts as a base. It is usually made of cast iron or thick steel sheet. The machine body, which includes from two to nine rolls, is attached to this powerful frame.

In some devices, these rollers are also equipped with a special groove, which makes it possible to bend not only metal sheets, but also use them for rolling pipes and rods.

Rollers are:

- Metal polished.

- Rubberized.

The technological capabilities of a roller mill are determined by its design features, in particular:

- sheet metal width;

- the diameters of the rollers, on which the radius of the part being manufactured directly depends;

- the thickness of the metal itself;

- distance between shafts (maximum measured);

- production of cone-shaped elements.

In addition to the above, there are many more factors that determine the performance of rolling machines and the ease of use.

Pipes are produced quite simply on a rolling machine:

- First of all, the prepared metal sheet is clamped with a special handle between the shafts (middle and outer);

- After this, using the third roller, the workpiece is pressed against it;

- Then the specialist starts the electric motor, or rotates the rollers with his own hands.

The whole process of work consists in the fact that the metal sheet, passing at a designated speed through the shafts, is bent under the required shafts.

To make pipes from a gutter with your own hands, it will be enough to purchase a roller machine for manual work. But the need for this type of purchase will disappear if you make such a device with your own hands.

Types of rolling machines

The equipment used for rolling is simple and versatile , so you can make it yourself for home use. Production workshops are equipped with serial models of rollers, which are presented in a wide range on the market today.

All machines, depending on the number of rolls, are divided into four-, three- and two-roll. Three-rollers can be symmetrical or asymmetrical. Four-roll machines have an additional shaft, which simplifies the rolling process. All elements are securely interconnected, which minimizes the likelihood of sheet material slipping and increases processing speed.

According to the type of drive used, rollers are:

- hydraulic;

- manual;

- electric.

Manually driven rollers are very simple in design. Such a device does not require additional power to operate and has the following advantages:

- reliability;

- compactness and mobility;

- low cost;

- ease of maintenance and operation.

The disadvantages of this type of equipment include:

- impossibility of using metal products more than 2 mm thick when rolling;

- low productivity;

- bending a sheet blank will require significant physical effort.

Electrically driven machines are more efficient. They can be used to process sheet metal products of considerable thickness.

Hydraulically driven rollers are the most powerful. This type of device is characterized by large dimensions. As a rule, such equipment is installed at industrial enterprises.

Roller components

There are two types of rolling equipment:

- machines with a pressure roller, most often located in the middle;

- installations with tools placed eccentrically.

The first type is used for rolling thick metal. The second option is used when workpieces are deformed by no more than 2.5 mm.

In the equipment under consideration, a significant difference is the relative arrangement of the rolls: symmetrical or asymmetrical. Asymmetric machines are more versatile. They are used not only for rolling cylinders, but also for a variety of edge designs.

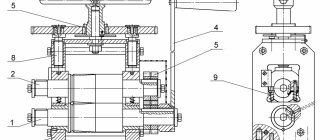

In practice, a scheme with three symmetrically located rolls is more often used, since it is more technologically advanced during maintenance. This type of rolling machine with external drive has the following components:

electric motor;- clinometer transmission or gearbox;

- a shaft with a main roll placed on it;

- side stands with bearing assemblies: rolling bearings are used in high-speed rollers, and sliding bearings are used for equipment power;

- two driven bottom rolls;

- bed with two support posts;

- protective casing for receiving semi-finished products during machine operation;

- roller control system.

The technological parameters of the equipment are adjusted by changing the gap between the rolls. In manual models this is done using a screw or ratchet mechanism, in automatic machines - programmatically.

Rollers: operating principle

The key working mechanism of the device is a rotating cylinder through which hot sheets of metal are passed and bent. Rolling machines can be equipped with cylinders from 2 to 5 pieces , but three-roll and four-roll products are most often used. The parts are bent through the action of the third rear shaft, and the fixing radius depends on the distance between the upper and rear shaft.

Sometimes metal rollers break and require replacement. When working with iron, the machine must be constantly heated, and the layers of iron after the rollers go into the furnace, they are heated there, and then pumped again. After that they go back to the machine.

After roller processing, the cross-section of the metal is reduced and it becomes longer under the influence of high metal temperature and degree of pressure.

To obtain a cylindrical product, the rear shaft must be adjusted parallel to the front one, and to make a cone, the rear shaft must be set at an angle relative to the front one.

There are roller models that can be used to process metal directly on the table, but they are not very functional. Working with them can be simplified using fasteners . The cost of rollers depends on their dimensions. And if you decide to make the machine yourself, you will save a lot.

The functions of modern rolling machines, home-made and factory-made, three-roll and four-roll, are as follows:

- the ability to bend pipes up to 160 degrees;

- working with metal pipes;

- deformation of pipes regardless of their diameter.

This is interesting: Do-it-yourself manual edge bender: drawings, types of machine

Features of machines for metal

Without a rolling machine, it is impossible to shape sheet metal into a cylindrical shape, and pipe rollers help create a drainage system . Machines with forging cylinders are needed for cold bending of metal blanks; also, thanks to rollers, you can process:

- plastic;

- ductile metal;

- rubber compounds.

You need to choose one or another machine depending on the thickness of the metal:

- Twin-roll rollers include two parallel shafts, the upper one has a small cross-section and is made of high-strength steel, and the lower one has a large cross-section and is made of rubber-coated steel. Depending on the pressure force of the pipe, its outlet diameter is selected;

- three-rollers can be symmetrical or asymmetrical ; they are often used in the production of ventilation, round gutters and radius parts. In addition, three-roll rollers are used when processing products made of copper, iron, steel, zinc, etc.;

- four-roll designs are equipped with an additional roll at the bottom to simplify the rolling process.

The most common rollers are three-roll and four-roll. Thus, three-rollers have the following distinctive properties:

- a sheet whose width is less than 6 mm will slip between the shafts;

- the sheet rolling speed should be a maximum of 5 m per minute;

- it is difficult to operate the machine due to the lack of exact coordinates of the metal clamping point;

- affordable price.

But four-roll rollers have the following characteristics:

- the rollers are securely coupled and the risk of sheet slipping is minimized;

- rolling speed can exceed 6 m per minute;

- the work process is fully automated;

- the price is high.

About symmetry.

Two different types of roller machines are available: symmetrical and asymmetrical. When purchasing, you should pay special attention to this. When working on a symmetrical rolling machine, the sheet is pre-bent on only one side, while on asymmetrical machines, pre-bending is required on both sides, but alternately. For processing thick sheets of metal, symmetrical ones are used. If the processing of the product is not of high complexity, it is more practical to purchase an asymmetric one. The cost of such a machine will be much lower. And this will not affect the quality of the processed material in any way.

The article was prepared based on materials from the website www.x-profil.ru and thanks to consultations with employees of X-Profil LLC, for which the editors express gratitude and recommend the company for cooperation to all interested parties! The best consultants are at your service, ready to answer any question you may have. They will provide detailed and high-quality information on each of the proposed options, if necessary. The choice of new rollers is an acquisition for many years, and the right choice also guarantees the efficiency of the enterprise and the reduction of unplanned costs.

Purpose of rollers

Electromechanical rollers are a mechanism based on the principle of rotation, designed for cold processing of various sheet alloys and metals. Roller machines are used in the installation of sanitary, engineering, ventilation systems, for the production of various forms from rolled metal for the engineering, aviation, and chemical industries:

- cone-shaped parts;

- cylinder-shaped parts;

- folding edges;

- parts in the form of arcs;

- leveling flat workpieces.

The radius of curvature of the workpiece depends on the material and thickness of the sheet:

- for low-carbon steels - 1.2 thicknesses;

- for aluminum alloys - up to 5.

To bend soft steel and thin sheets, manual roller models are successfully used.

Types of sheet metal rollers

Sheet-leveling machines for working with metal workpieces can be different, the scope of their application depends on the technical characteristics and the range of tasks expected to be solved:

- the dimensions and diameter of the shafts depend on the type of structure, depending on this the radius of the possible bend will change;

- the length of the shafts determines the width of the workpiece that can be worked with at one time;

- the drive determines the thickness of the products suitable for processing.

Much will depend on the design features of the machines.

For example, when working with products of unusual shapes, the ability of the working shafts to change position is directly affected. So two identical machines from the same company can be diametrically different.

Machines are divided among themselves depending on technological capabilities and technical characteristics. Machines for working with metal can be divided into several main categories:

- two-roll;

- three-roll;

- four-roll.

The first type is the simplest. Their design is based on two working shafts and a rigid frame; the shafts are located parallel to each other. The one on top is always half the size. It is preferable to use steel as a material for it.

The workpiece is pressed by the lower shaft and scrolled, which gives the product the desired shape. The possibilities of bending metal are formed depending on the nature of the rotation of the shafts, which is why two identical machines can differ from each other in terms of efficiency. The machine is adjusted mechanically, so the radius of the product can be set in advance.

More often, such a machine processes cylindrical structures rather than conical ones.

The second type can be divided into symmetrical and asymmetrical. The work involves the principle of rolling a workpiece sheet around one of the shafts, which is the main one in the design.

Electromechanical machines with three shafts are sometimes called power machines; they are more massive in design and have a higher tensile strength, unlike a manual drive. Such equipment can be used to manufacture products on an industrial scale. For home workshops, such designs are suitable for processing copper or aluminum up to 4 mm thick.

Four-roll rolling machines are designed with one more shaft at the very bottom, which makes bending the metal easier. This is the type of machine most often used for industrial processing. Here, the thickness of the blanks can reach 75 mm, the shape can be simple or geometrically complex - both can be accurately reproduced in the same way.

Numerical control facilitates the setting and adjustment of certain parameters during the production process of the product.

This is a professional tool for working with metal in every way.

Types of roller machines

There are three types of roller machines, two-roller, three-roller, and four-roller.

1.Two-roll.

Designed to work with materials up to 3 mm thick. They have the most attractive price. Suitable for small private industries.

2. Three-roll

The thickness of the processed sheet of material is up to 10 mm. Operated hydraulically, electrically or manually. They are the more common of those presented here.

Four-roll

For their tasks, the best and most productive ones roll metal with a thickness of over 10 mm. They have the highest price, but are worth the money. The most high-performance and reliable.

Equipment used

The equipment used for rolling is distinguished not only by its versatility, but also by its simplicity of design, so it is not difficult to make it yourself. Of course, homemade rolling machines are optimal for home use, and to equip a production workshop, where the load on such equipment is quite large, it is best to purchase serial models of rollers, which are presented in a wide variety on the modern market.

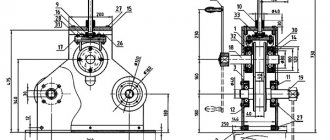

Both serial and home-made models of machines with which rolling is carried out work on the principle of rolling sheet material around the main roll located on top. Side rollers also take part in this process, which can be moved, thereby adjusting the diameter of the formed shell.

The rollers of this machine are rotated manually, and the approach of the upper roller is done using two handles

Important characteristics of rollers are the radius of their working elements - the rollers, as well as the greatest thickness and width of the workpiece. The radius of the rolls, in particular, influences such a parameter as the minimum bending radius of the workpiece. The larger the diameter of the rolls, the correspondingly greater the value of the minimum bending radius of the sheet metal workpiece. The value of the minimum bending radius is also influenced by the thickness of the sheet itself. As a rule, for rollers, the minimum bending radius of a sheet stock should be 5-10 times its thickness.

Taking into account the high loads that rolls experience during operation, only high-strength steel is used for their manufacture, which can significantly improve their performance characteristics. Based on the number of working elements, two-, three- and four-roll machines are distinguished, with the last two types being the most popular.

Main differences between 3 and 4 roll machines

3-roll sheet bending rollers, the working elements of which can be arranged symmetrically and asymmetrically, although they have a reasonable price, have the following disadvantages:

- low rolling speed (no more than 5 m/min);

- the difficulty of processing workpieces less than 6 mm thick, which can simply slip between the rolls;

- lack of exact coordinates at the clamping point of the workpiece.

The rollers on which an additional fourth shaft is installed are free from all such shortcomings. Due to reliable clamping, the metal sheet blank does not slip between the rollers during processing. This ensures a high rolling speed of 6 m/min or more.

The machine with 4 rolls is capable of producing, in addition to cylindrical, oval and polycentric workpieces

Rollers of this type are usually equipped with automated control systems, which has a positive effect not only on their productivity, but also on the accuracy of the processing performed. The big and, perhaps, the only disadvantage of such a device is its high cost.

Classification of machines

According to the bending method, rollers are:

- segmental, where the pipes are bent under the action of one pulling segment;

- mandrels, which deform thin-walled pipes;

- spring. Thanks to the presence of a spring, the plastic bends without deformation;

- crossbow, which are designed for pipes of one diameter or another.

- Manual . Such machines are the most convenient and practical; they do not need to be connected to the network. Clamps and feed rollers with a chain drive are attached to their main frame. Manual profile machines are durable, reliable, compact, easy to adjust and have an affordable price. Manual rollers have a subcategory for jewelry; they are used for rolling and rolling jewelry blanks;

- Hydraulic . Hydraulically driven devices with high power, which are characterized by high performance. Their disadvantage is their dimensions; you cannot easily move such a unit with your own hands;

- Electrical . High productivity is achieved through the operation of an electric motor, although the principle of operation of the machine is no different from a manual one. Most often they are used on an industrial scale, since such rollers have a considerable price.

If you purchase or make a machine with your own hands for small household needs, then it is desirable that it have the following characteristics:

- mobility and light weight;

- compactness;

- economical in terms of energy consumption, since a powerful device can damage home wiring.

Types of rolling machines

Large-sized roller machines are often used in industrial production. Small workshops are quite content with devices for manual work.

Roller machines are divided into:

- Mechanical. They are very easy to use and also have a low cost. This mechanism consists of three rollers that must be rotated manually. Gears transmit movement from the handle to the actuator. A mechanical roller machine cannot bend cone-shaped parts. They are most often used in small workshops and private workshops to produce parts from very thin metal sheets.

- Electromechanical. This type of rolling machine is more productive due to the additional presence of an electric drive, which rotates the actuator. The presence of this element allows you to process metal sheets with greater thickness and significantly reduce the time required to complete the work. For a roller device with an electric motor, a brake is required.

Principle of operation

Roll processing is an intermediate step between metal cutting and profiling. The operation of the rollers is based on the principle of cold rolling a sheet of metal around the upper roller. The diameter of the future product depends on the position of the rollers relative to each other.

The technologist developing the manufacturing of a part faces the following questions:

- Is it possible to make a part from sheet material of certain parameters using existing rollers;

- what is the minimum radius to which a sheet can be bent;

- how to adjust the upper roller to obtain a workpiece with the desired bending diameter.

The main types of movement used in the design are roller rotation (reverse and forward), lateral movement and lifting.

Before rolling, the surface of the sheet is leveled by rolling. After which the rollers are adjusted using mechanical devices, accurately setting their position.

Sheet metal is pulled through rollers and bent, creating blanks in the form of cylinders or round clamps. The lower or upper roller can rotate. The actuating instruments move in a vertical plane and rotate in both directions.

To bend the metal into a cone shape, one of the edges of the sheet is slowed down using a special warping device.

Although metal bending seems like a simple task, only qualified personnel are allowed to do it. Modern rollers can quickly be adjusted to new product models, reducing production costs.

When and where are roller machines used?

For the mass production of parts made of iron or steel, very expensive, large-sized modern equipment is used. It is mandatory to ensure uninterrupted production of large batches of blanks during the following operations:

- piercing of forged workpiece

- welding

- pressing

- rolling

- reduction

- and many others

This is not a complete list of very expensive techniques that are used in large factories. Thanks to the huge batches of products produced, this is completely justified. What is the solution if the production is small-scale (small plant, small workshop)? If you need, for example, a small batch of non-standard parts (pipes or cones). It is necessary to install manual rolling. Today even owners of small sites can afford it and not be afraid that the purchase will not pay for itself.

Operating principle of a metal rolling machine

The main component of the machine equipment is the cast frame. It can be steel or cast iron. A special deformation mechanism is installed on the frame, which consists of 3-4 rollers. Three-rollers are usually used. Two rollers do not move; the third roller rotates during operation.

In addition, the movable shafts can move vertically.

The roller is fixed on top of the frame according to a scheme that allows you to quickly remove it if necessary or quickly adjust it for the production of pipes with different cross-sections. This structural element is adjusted using a single thumbscrew.

The metal rolling machine has a long service life

If the work rollers have grooves , you can bend them:

- Pipes;

- Rods;

- Thick wire.

Manual metal bending equipment traditionally has 3 rollers, but there is a type of pipe bender with 4 rollers. But hydraulic machines are always created with 4 rolls.

Making pipes on any unit is quite simple:

- Clamping the sheet with a special handle on the machine equipment between the shaft in the middle and at the edge.

- Pressing the workpiece with the third roller.

- Rotate the roll manually or start the engine.

Passing through the rollers at a certain speed, the metal workpiece bends at the required angles. To build pipes or gutters at home, you need to use a manual unit. By and large, there is no need to even purchase it (although their price is low), since you can assemble a homemade machine and use it to strengthen the profile pipe.

Operating principle of roller machines

Roller machines of various modifications mostly have a similar design, the difference is only in some individual design components. So, these machines consist of a pair of sections that operate in parallel and are separated by a longitudinal partition. Each section contains rollers, a feeding mechanism, a dump-dump device, an automatic machine based on a hydraulic (mechanical) principle of operation, a device that removes the product and a drive.

The automatic control drives the power mechanism through a flat-belt type transmission from the roller hub, while the roller rotates at a certain considerable speed. The roller intended for dosing is driven by a gear transmission from the distributing roller. There must be a gap between the distribution roller and the damper, which can be adjusted manually using the steering wheel. The valve opens and closes automatically. The rollers rotate at high speed in directions that are opposite to each other.

It is important for flour mills, as well as some cereal factories, to purchase roller machines (for feed and grain). The cost of such equipment will cost from 250 thousand rubles to half a million. But since grain grinding is the leading technological operation in production of this type, it is impossible to do without them. Roller machines will provide an efficient grinding process, which generally increases the level of economic performance of the enterprise.

Review of modern models

"VET-1500" is one of the most popular inexpensive models of machine tools. Such machines have a wide operating range; there are various options for ready-made designs on the market. For a home workshop, in the early stages, twin-roll hydraulic machines are suitable; they will more than allow you to implement a wide range of amateur and professional tasks at home.

The weight and dimensions of such a machine are minimal, which gives another advantage in favor of purchasing this device for the home.

Another brand worth checking out is DEGstm. This is a foreign company producing machine tools of a wide variety of calibers, which has already established itself with high-quality products. For example, their four-roll hydraulic machines can process workpieces up to and including 3,100 mm in length and 680 mm in diameter.

For three-roll machines with electromechanical or manual drive, you can safely contact Metal Master. In fact, the modern market provides users with a huge amount of equipment, so with the right approach, everyone can choose what suits them.

A simple option for making rollers yourself

Analyzing the simplicity of the design and operation of the roller machine, many mistakenly believe that assembling this device with one’s own hands is not difficult. This is not entirely true. All this because most of the necessary components will need to be turned out yourself. If the master has basic skills in turning, you can safely try to assemble a hand-pulled rolling machine at home.

For this purpose you will need:

- Metal pins of different diameters.

- Channel.

- Bearings.

- Bulgarian.

- Welder.

- Shafts.

- Lathe device.

Next will follow the actual process of assembling the roller machine:

- The channel is needed in order to weld a frame from it - a platform for the future rolling machine.

- The frame for the roller device is made in the shape of the letter “P” and also from a channel. Next, reinforcement stops are welded to it, which are responsible for the stand of the pressure shaft.

- After this, it is necessary to make three shafts, mount them on bearings and secure them to the corners, inserted into the base.

- The position of the shaft will be changed using a threaded pin secured at the bottom with a washer.

- The shaft on top should turn freely on bearings.

The parameters of the part to be processed will depend on the length of the machine shafts. The dimensions of the distance between the shafts from below are adjusted manually.

Recommendations for assembling rollers for the machine yourself:

- Cracks and scratches should not be allowed to appear on the metal profile;

- The platform should not be stretched or compressed at the point where the greatest stress is placed on the structural component;

- Do not deform the elements before starting work.

With this manual rolling device, in addition to metal sheets, you can also bend pipes.

Video: manual tabletop rolling machine.

Roller specifications

When designing homemade manual three-roll rollers, it is necessary to take into account the required operational and technical qualities. The characteristics of a suitable factory model can be taken as a basis for analysis. But at the same time, its parameters must be adapted to the actual characteristics of the homemade design.

First of all, the dimensions of the machine are taken into account. They depend on the length of the shafts and affect the maximum width of the processed sheets. It must be remembered that a manual mechanism will be used as a drive, which must be done with your own hands. Therefore, usually the working width of the shaft does not exceed 1.2 m. The weight of the homemade structure will only affect the possibility of its transportation.

In addition to these indicators, it is necessary to take into account the following parameters that manual three-roll rollers must have:

- diameter of working shafts. This indicator affects the maximum possible radius of curvature of the processed material;

- degree of distance between the upper shaft and the lower guides;

- distance between the lower shafts;

- material supply speed.

When choosing a specific model of three-roll sheet bending rollers, you should accurately calculate the rigidity of the structure. Despite the fact that the pressure is mainly exerted on the shafts, the frame also experiences certain mechanical loads. Therefore, the choice of manufacturing materials and design of this machine model must be approached with special care.

The presence of three shafts in the design is optimal. When installing additional components, the degree of load on the manual drive mechanism increases, which is extremely undesirable for home-made models.

Classification of rollers by drive type

- manual;

- electrical;

- hydraulic.

The simplest in design are manually driven rollers; it is these that home craftsmen most often assemble with their own hands for their own needs.

On simple three-roll rollers, clamping the workpiece, rotating the shafts and forming the bend radius is done manually

Significant advantages of such a device, which does not require any additional power for its operation, are:

- compactness and, accordingly, high mobility;

- reliability;

- ease of operation and maintenance;

- low cost (especially if the rollers are assembled by yourself).

Among the disadvantages of machines of this type, it should be noted:

- low productivity;

- the impossibility, especially in the case of home-made machines, to roll products made of sheet metal of large thickness (more than 2 mm);

- the need to apply significant physical effort to bend steel sheets.

Electromechanical double-sided rollers with program control

Machines equipped with an electric drive are more productive and efficient in operation. Of course, their cost, even if they are made by hand, is higher than the price of hand rollers, but they allow processing sheet products of considerable thickness.

The most powerful are the hydraulically driven rollers. The capabilities of such machines, which are distinguished by their large dimensions, make it possible to successfully roll sheet metal blanks of even very significant thickness. Devices of this type are usually installed in industrial enterprises, where high demands are placed on the power, reliability and functionality of the equipment.

Industrial rollers with hydraulic drive

Main types of rollers and their purpose

Rolling machines in the modern world are very often found in many enterprises producing metal products. You can easily make such a device at home with your own hands. Using this mechanism, a specialist can make parts of various shapes from a metal sheet - cylindrical, oval or conical.

This task is performed using shafts through which a sheet of metal passes. Rolling is a term denoting the name of the operation that solves these problems. With the help of roller machines, the process of manufacturing pipes, arc-shaped devices, chimney pipes, drains and much more takes place.

Rolling devices, which are now produced on an industrial scale, are capable of processing sheets of various types of steel, as well as copper, aluminum, brass, and cast iron.

There are three categories of rolling devices:

- Manual machine for rolling sheet metal. This type of device is manufactured in two versions: floor-mounted (when the flaring machine is installed on a stand), and desktop (when the unit is mounted on a workbench). To work on this type of manual rolling machine, you will have to put in a lot of physical effort, although the undoubted advantage is ease of operation and a very simple design, which allows you to preserve the reliability of the device for a long period of time.

- Electromechanical rolling machine. A device of this type has a gearbox in its components. It allows you to significantly increase the efficiency of such a unit. An electromechanical machine is used in industrial production to process metal sheets and to slightly change the configuration of rolled pipe.

- Roller machine with hydraulic drive. This type of machine is one of the most powerful and is very often used in enterprises of various fields. Compared to manual and electromechanical machines, it has many more working mechanisms in its design. These devices make the device more powerful. This type of equipment can bend even the thickest metal sheets (up to 8mm) without any problems.

Advantages of manual rollers:

- compactness of the device;

- low weight;

- good mobility;

- electrical efficiency;

- relatively low cost.

How to use?

Before starting work, it is worth conducting a trial stage . Bending the workpiece is generally easy. To do this, the metal sheet is placed on the lower rollers and pressed by the upper one. The workpiece should be fixed without problems; most often, editing of the structure is required here: if the product is not pressed tightly enough, it can be damaged. Then all that remains is to try to rotate the handle and check the result of your work.

With manually driven machines made by yourself, everything is extremely simple. All defects are visible at the very beginning of work, so if necessary, the breakdown can be easily corrected. The main thing is not to rush and follow the instructions or the selected drawing.

For information on how to make homemade rollers, see below.