SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Channel is a popular material used to create various metal structures and frame construction. The condition for the correct selection of profiles is selection by size, weight and determination of the required quantity. Gosstandart has developed requirements that channels must meet. Dimensions, weight, density and their ratio - all this includes the corresponding tables of a certain GOST. Descriptions of the most popular sizes are given in the article.

Channels are widely used in construction, industry, mechanical engineering and similar areas

Tables of channel sizes in accordance with GOST

A channel is a fairly popular rolled metal product made from different types of steel. The term itself is of German origin. The main distinguishing feature of the profile is the U-shaped cross-section of the product.

The production of channels is carried out on special equipment in accordance with established quality standards

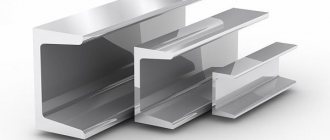

Special equipment is used for the manufacture of channels. Depending on the production method, hot-rolled or bent profiles are distinguished. According to the shape of the edges of the shelves, they can be parallel or have a certain slope inside. The classification is also based on a numerical value in the form of a number next to the corresponding marking. The numbers indicate the size, which is determined by the distance between the edges of the shelves on the outside.

The production of channels, like other rolled metal products, is regulated by the relevant GOST, which clearly states the basic requirements for this or that type of profile. All data is clearly presented in tables. For example, the regulatory document “Hot-rolled steel channels. Assortment" (GOST 8240 97) contains 7 such expanded tables.

Using the corresponding tabular data, you can determine the quality of the product by correlating its actual dimensions with those described in GOST. Ideally, the indicators should completely match, although sometimes metal products are made to order. Individual profiles are produced in small batches - for a specific project. The prices of custom-made channels differ from the cost of mass-produced products.

GOST standards clearly state all the requirements that a channel of one type or another must meet.

The standard height of the channels ranges from 50 to 400 mm, the width of the shelves - from 32 to 115 mm. The permissible error (compared to the specified standard dimensions) may be a maximum of 3 mm. The measured length of the channels corresponds to an indicator from 4 to 13 m.

Weight of channels, their markings and symbols

To designate different types of channels, special markings are used. The letter indicates the type of profile, characterizing the structural features and arrangement of the edges:

- “P” – indicates parallelism;

- “U” – indicates the presence of a slope on the edges;

- “E” – indicates efficiency;

- “L” – implies lightness;

- “C” indicates the special purpose of the profile.

Helpful advice! The numerical indicator next to the letter indicates the size of the product; it corresponds to the height given in the GOST table. It should be noted that channels are usually marked with numerical values in centimeters, and their height in the table is indicated in millimeters. Visually it looks like this: channel 8, channel weight 12 or channel dimensions 16P.

To determine the types of channels, as well as their characteristics, special symbols are used

In addition to the height of the product, other size indicators are also used. In the tables they have special designations:

- h is the profile height, which is the main quantity that determines the size of rolled metal products;

- b – indicates the width of the shelves;

- S – indicator of the thickness of the main wall;

- R – determines the radius of the rounded inner part of the shelf;

- t – indicates the thickness of the shelves;

- r is the value of the total radius of curvature of the shelves.

An important indicator in the choice of material (when designing construction) is the weight of the channel. Correct calculation of data allows you to accurately calculate the quantity of required products and, thus, save on their purchase. There are several methods for calculating the weight of a linear meter. They depend on the method of production of rolled products. For example, to determine the specific gravity of a hot-rolled channel, the indicators of the radii of internal curvature and flange curvature are taken into account.

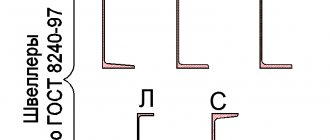

Drawing of a hot-rolled steel channel with a slope and parallel flanges

Channel

The assortment for hot-rolled channels is regulated by DSTU 3436–96 (GOST 8240–97). This standard establishes a range of hot-rolled steel channels for general and special purposes with a height of 50 to 400 mm and a flange width of 32 to 115 mm.

According to shape and size, channels are divided into:

- U - with a slope of the internal edges of the shelves;

- P - with parallel edges of the shelves;

- E - economical with parallel edges of shelves;

- L - light series with parallel edges of shelves;

- S - special.

Channel with a slope of the internal edges of the shelves - U series

The slope of the inner edges of the shelves of U series channels should be in the range from 4 to 10%.

Rice. 1. Channel with a slope of the internal edges of the shelves - series U according to DSTU 3436–96 (GOST 8240–97)

Legend: h—channel height; b - shelf width; S—wall thickness; R is the radius of the internal curvature of the shelves; t—thickness of the flange; r is the radius of curvature of the shelves.

Table 1. Dimensions and weight of channels with a slope of the internal edges of the shelves - series U according to DSTU 3436–96 (GOST 8240–97)

| U series channel number | Dimensions, mm | Weight 1 m, kg | Number of meters per ton, m | |||||

| h | b | S | t | R | r | |||

| no more | ||||||||

| 5U | 50 | 32 | 4,4 | 7 | 6 | 2,5 | 4,842 | 206,5 |

| 6.5U | 65 | 36 | 4,4 | 7,2 | 6 | 2,5 | 5,899 | 169,5 |

| 8U | 80 | 40 | 4,5 | 7,4 | 6,5 | 2,5 | 7,049 | 141,9 |

| 10U | 100 | 46 | 4,5 | 7,6 | 7 | 3 | 8,594 | 116,4 |

| 12U | 120 | 52 | 4,8 | 7,8 | 7,5 | 3 | 10,43 | 95,87 |

| 14U | 140 | 58 | 4,9 | 8,1 | 8 | 3 | 12,29 | 81,38 |

| 16U | 160 | 64 | 5 | 8,4 | 8,5 | 3,5 | 14,23 | 70,30 |

| 15аУ | 160 | 68 | 5 | 9 | 8,5 | 3,5 | 15,35 | 65,16 |

| 18U | 180 | 70 | 5,1 | 8,7 | 9 | 3,5 | 16,26 | 61,50 |

| 18аУ | 180 | 74 | 5,1 | 9,3 | 9 | 3,5 | 17,45 | 57,29 |

| 20U | 200 | 76 | 5,2 | 9 | 9,5 | 4 | 18,37 | 54,43 |

| 22U | 220 | 82 | 5,4 | 9,5 | 10 | 4 | 20,98 | 47,66 |

| 24U | 240 | 90 | 5,6 | 10 | 10,5 | 4 | 24,06 | 41,56 |

| 27U | 270 | 95 | 6 | 10,5 | 11 | 4,5 | 27,66 | 36,15 |

| 30U | 300 | 100 | 6,5 | 11 | 12 | 5 | 31,78 | 31,47 |

| 33U | 330 | 105 | 7 | 11,7 | 13 | 5 | 36,53 | 27,37 |

| 36U | 360 | 110 | 7,5 | 12,6 | 14 | 6 | 41,91 | 23,86 |

| 40U | 400 | 115 | 8 | 13,5 | 15 | 6 | 48,32 | 20,70 |

Note. The mass of 1 m of channel is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Channel with parallel flange edges - P series

Rice. 2. Channel with parallel flange edges - series P according to DSTU 3436–96 (GOST 8240–97)

Legend: h—channel height; b - shelf width; S—wall thickness; R—radius of internal curvature; t—thickness of the flange; r is the radius of curvature of the shelves.

Table 2. Dimensions and weight of channels with parallel flange edges - series P according to DSTU 3436–96 (GOST 8240–97)

| Series P channel number | Dimensions, mm | Weight 1 m, kg | Number of meters per ton, m | |||||

| h | b | S | t | R | r | |||

| no more | ||||||||

| 5P | 50 | 32 | 4,4 | 7 | 6 | 3,5 | 4,840 | 206,6 |

| 6.5P | 65 | 36 | 4,4 | 7,2 | 6 | 3,5 | 5,897 | 169,6 |

| 8P | 80 | 40 | 4,5 | 7,4 | 6,5 | 3,5 | 7,051 | 141,8 |

| 10P | 100 | 46 | 4,5 | 7,6 | 7 | 4 | 8,595 | 116,3 |

| 12P | 120 | 52 | 4,8 | 7,8 | 7,5 | 4,5 | 10,42 | 95,94 |

| 14P | 140 | 58 | 4,9 | 8,1 | 8 | 4,5 | 12,29 | 81,40 |

| 16P | 160 | 64 | 5 | 8,4 | 8,5 | 5 | 14,22 | 70,32 |

| 16aP | 160 | 68 | 5 | 9 | 8,5 | 5 | 15,34 | 65,18 |

| 18P | 180 | 70 | 5,1 | 8,7 | 9 | 5 | 16,26 | 61,50 |

| 18aP | 180 | 74 | 5,1 | 9,3 | 9 | 5 | 17,46 | 57,29 |

| 20P | 200 | 76 | 5,2 | 9 | 9,5 | 5,5 | 18,37 | 54,44 |

| 22P | 220 | 82 | 5,4 | 9,5 | 10 | 6 | 20,97 | 47,70 |

| 24P | 240 | 90 | 5,6 | 10 | 10,5 | 6 | 24,05 | 41,58 |

| 27P | 270 | 95 | 6 | 10,5 | 11 | 6,5 | 27,65 | 36,16 |

| 30P | 300 | 100 | 6,5 | 11 | 12 | 7 | 31,78 | 31,47 |

| 33P | 300 | 105 | 7 | 11,7 | 13 | 7,5 | 34,87 | 28,68 |

| 36P | 360 | 110 | 7,5 | 12,6 | 14 | 8,5 | 41,89 | 23,87 |

| 40P | 400 | 115 | 8 | 13,5 | 15 | 9 | 48,28 | 20,71 |

Note. The mass of 1 m of channel is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Economical channel – E series

Rice. 3. Economical channel - series E according to DSTU 3436–96 (GOST 8240–97)

Legend: h—channel height; b - shelf width; S—wall thickness; R—radius of internal curvature; t—thickness of the flange; r is the radius of curvature of the shelves.

Table 3. Dimensions and weight of economical channels - series E according to DSTU 3436–96 (GOST 8240–97)

| Series E channel number | Dimensions, mm | Weight m, kg | Number of meters per ton, m | |||||

| h | b | S | t | R | r | |||

| no more | ||||||||

| 5E | 50 | 32 | 4,2 | 7 | 6,5 | 2,5 | 4,79 | 207,3 |

| 6.5E | 65 | 36 | 4,2 | 7,2 | 6,5 | 2,5 | 5,82 | 170,7 |

| 8E | 80 | 40 | 4,2 | 7,4 | 7,5 | 2,5 | 6,92 | 143,6 |

| 10E | 100 | 46 | 4,2 | 7,6 | 9 | 3 | 8,47 | 117,3 |

| 12E | 120 | 52 | 4,5 | 7,8 | 9,5 | 3 | 10,24 | 96,81 |

| 14E | 140 | 58 | 4,6 | 8,1 | 10 | 3 | 12,15 | 82,29 |

| 16E | 160 | 64 | 4,7 | 8,4 | 11 | 3,5 | 14,01 | 70,97 |

| 18E | 180 | 70 | 4,8 | 8,7 | 11,5 | 3,5 | 16,01 | 62,14 |

| 20E | 200 | 76 | 4,9 | 9 | 12 | 4 | 18,07 | 55,03 |

| 22E | 220 | 82 | 5,1 | 9,5 | 13 | 4 | 20,69 | 48,09 |

| 24E | 240 | 90 | 5,3 | 10 | 13 | 4 | 23,69 | 42,02 |

| 27E | 270 | 95 | 5,8 | 10,5 | 13 | 4,5 | 27,37 | 36,37 |

| 30E | 300 | 100 | 6,3 | 11 | 13 | 5 | 31,35 | 31,74 |

| 33E | 330 | 105 | 6,9 | 11,7 | 13 | 5 | 36,14 | 27,49 |

| 36E | 360 | 110 | 7,4 | 12,6 | 14 | 6 | 41,53 | 23,95 |

| 40E | 400 | 115 | 7,9 | 13,5 | 15,5 | 6 | 47,97 | 20,75 |

Note. The mass of 1 m of channel is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Light channel – L series

Rice. 4. Light channel - L series according to DSTU 3436–96 (GOST 8240–97)

Legend: h—channel height; b - shelf width; S—wall thickness; R—radius of internal curvature; t—thickness of the flange; r is the radius of curvature of the shelves.

Table 4. Dimensions and weight of light channels - L series according to DSTU 3436–96 (GOST 8240–97)

| Series L channel number | Dimensions, mm | Weight 1 m, kg | Number of meters per ton, m | |||||

| h | b | S | t | R | r | |||

| no more | ||||||||

| 12L | 120 | 30 | 3 | 4,8 | 7 | 0 | 5,026 | 199,0 |

| 14L | 140 | 32 | 3,2 | 5,6 | 7 | 0 | 6,214 | 160,9 |

| 16L | 160 | 35 | 3,4 | 5,3 | 8 | 0 | 7,115 | 140,5 |

| 18L | 180 | 40 | 3,6 | 5,6 | 8 | 0 | 8,503 | 117,6 |

| 20L | 200 | 45 | 3,8 | 6 | 9 | 0 | 10,12 | 98,81 |

| 22L | 220 | 50 | 4 | 6,4 | 10 | 0 | 11,87 | 84,27 |

| 24L | 240 | 55 | 4,2 | 6,8 | 10 | 0 | 13,67 | 73,14 |

| 27L | 270 | 60 | 4,5 | 7,3 | 11 | 0 | 16,31 | 61,33 |

| 30L | 300 | 65 | 4,8 | 7,8 | 11 | 0 | 19,08 | 52,40 |

Note. The mass of 1 m of channel is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Special channel – series C (corresponds to GOST 19425–74)

Rice. 5. Special channel - series C according to DSTU 3436–96 (GOST 8240–97)

Legend: h—channel height; b - shelf width; S—wall thickness; R—radius of internal curvature; t—thickness of the flange; r is the radius of curvature of the shelves.

Table 5. Dimensions and weight of special channels - series C according to DSTU 3436–96 (GOST 8240–97)

| Series C channel number | Dimensions, mm | Shelf slope, % | Weight 1 m, kg | Number of meters per ton | |||||

| h | b | S | t | R | r | ||||

| no more | |||||||||

| 8C | 80 | 45 | 5,5 | 9 | 9 | 1,5 | 6 | 9,248 | 108,1 |

| 14C | 140 | 58 | 6 | 9,5 | 9,5 | 4,75 | – | 14,54 | 68,80 |

| 14Ca | 140 | 60 | 8 | 9,5 | 9,5 | 5 | 10 | 16,70 | 59,89 |

| 16C | 160 | 63 | 6,5 | 10 | 10 | 5 | – | 17,24 | 58,00 |

| 16Ca | 160 | 65 | 8,5 | 10 | 10 | 5 | – | 19,75 | 50,63 |

| 18C | 180 | 68 | 7 | 10,5 | 10,5 | 5,3 | – | 20,17 | 49,57 |

| 18Ca | 180 | 70 | 9 | 10,5 | 10,5 | 5,3 | – | 23,00 | 43,48 |

| 18Sat | 180 | 100 | 8 | 10,5 | 10,5 | 5 | 6 | 26,70 | 37,45 |

| 20C | 200 | 73 | 7 | 11 | 11 | 5,5 | 10 | 22,60 | 44,25 |

| 20Ca | 200 | 75 | 9 | 11 | 11 | 5,5 | 10 | 25,74 | 38,85 |

| 20Sat | 200 | 100 | 8 | 11 | 11 | 5,5 | 6 | 28,69 | 34,85 |

| 24C | 240 | 85 | 9,5 | 14 | 14 | 7 | – | 34,90 | 28,66 |

| 26C | 260 | 65 | 10 | 16 | 15 | 3 | – | 34,82 | 28,72 |

| 26Ca | 260 | 90 | 10 | 15 | 15 | 7,5 | 8 | 39,67 | 25,21 |

| 30C * | 300 | 85 | 7,5 | 13,5 | 13,5 | 7 | 10 | 34,40 | 29,07 |

| 30Ca | 300 | 87 | 9,5 | 13,5 | 13,5 | 7 | 10 | 39,11 | 25,57 |

| 30Sat | 300 | 89 | 11,5 | 13,5 | 13,5 | 7 | 10 | 43,82 | 22,82 |

Note. The mass of 1 m of channel is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value. * - The geometric dimensions of the 30C channel according to GOST 8240–97 differ from the dimensions of the 30C channel according to GOST 19425–74.

Channels are manufactured in lengths from 2 to 12 m. It is allowed to manufacture channels longer than 12 m by agreement between the consumer and the manufacturer. By length, channels are divided into:

- measured length;

- measured and unmeasured lengths in an amount of no more than 5% of the batch weight;

- multiple measured length;

- multiple measured lengths from unmeasured lengths in an amount of no more than 5% of the batch weight;

- unmeasured length;

- limited length within unmeasured.

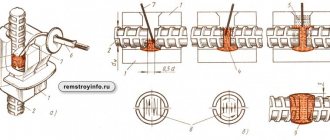

Rice. 6. Maximum deviations of channel dimensions

Table 6. Limit deviations of parameters

| Parameter | Parameter value range | Limit deviations |

| Height, h | Up to 80 incl. | ±1,5 |

| From 80 to 200 incl. | ±2,0 | |

| From 200 to 400 incl. | ±3,0 | |

| Shelf width, b | Up to 40 incl. | ±1,5 |

| From 40 to 89 incl. | ±2,0 | |

| From 89 | ±3,0 | |

| Shelf thickness, t | Up to 10 incl. | –0,5 |

| From 10 to 11 inclusive. | –0,8 | |

| From 11 | –1,0 | |

| Flange skew, ∆, with flange width (b), no more | Up to 95 incl. | 1,0 |

| From 95 | 0.015b | |

| Wall deflection, f, along the height (h) of the profile section, no more | Up to 100 incl. | 0,5 |

| From 100 to 200 incl. | 1,0 | |

| From 200 to 400 incl. | 1,5 |

Maximum mass deviations should not exceed ±4% for a batch and ±6% for an individual channel. Weight deviation is the difference between the actual weight as delivered and the theoretical weight calculated from the tables.

The dimensions and geometric shape of the channel are controlled at a distance of at least 500 mm from the end. The height of the channel is controlled in the plane of the wall, the thickness of the wall is controlled at the end of the profile.

The standard establishes maximum deviations along the length of channels of measured and multiple measured lengths. They must not exceed:

- with a length from 2 to 8 m inclusive. — up to + 40 mm;

- with a length over 8 m - up to + [40+5•(L–8)] mm, but not more than 100 mm, where L is the length of the channel in meters.

The miter cut that occurs when cutting a channel should not take the length of the channels beyond the maximum deviations along the length. The length of an individual channel is defined by the standard as the longest length of a conditionally cut rod with ends perpendicular to the longitudinal axis. The curvature of the channel in the horizontal and vertical planes should not exceed 0.2% of the length, by agreement between the manufacturer and the consumer - up to 0.15% of the length.

When calculating the mass of a batch, half the sum of the maximum deviations along the length of the channels in the batch is added to the total length of a batch of channels in meters or a multiple measure of length.

Determining the weight and price of a channel per meter: table of sizes, cost of profiles

Complex calculations of specific gravity, in addition to mathematical skills, also require updating the school course in physics and geometry. Therefore, it is better to use ready-made calculations given in special tables, or use an online calculator. To do this, just enter the necessary data and get an accurate result.

The cost of channels is determined in accordance with linear meters. The price formation is influenced by the profile height, which determines the product number, as well as the grade of steel from which the product is made. For example, a channel made from low-alloy steel will cost an order of magnitude more than similar products made from carbon steel. This is due to the fact that the first type of raw material has increased strength characteristics.

The current average prices for channels on the Russian rolled metal market are shown in the table:

| Channel number | Weight per linear meter, kg | Length in ton, m | Price per linear meter, rub. |

| 5 | 4,8 | 207 | 200 |

| 6,5 | 5,9 | 169 | 240 |

| 8 | 7,1 | 142 | 265 |

| 10 | 8,6 | 115 | 350 |

| 12 | 10,4 | 97 | 420 |

| 14 | 12,3 | 82 | 480 |

| 16 | 14,2 | 71 | 520 |

| 18 | 16,3 | 60 | 600 |

| 20 | 18,4 | 55 | 760 |

| 22 | 21,0 | 48 | 870 |

| 24 | 24,0 | 42 | 1020 |

| 27 | 27,7 | 35 | 1150 |

| 30 | 31,8 | 32 | 1400 |

| 40 | 48,3 | 21 | 4250 |

Above is a general table. In order to have an idea about each type of channel, its individual features, sizes and characteristics, it is worth getting to know each type in more detail. Below, as an example, we will consider the most popular types and sizes of channels that are in high demand and widely used.

Aluminum channels

Using a steel channel is not always advisable. Firstly, it still has a very large mass, and secondly, carbon steel rusts, and in order to prevent this from happening, it has to be painted.

In cases where the strength of steel is not required to strengthen the structure, aluminum products are used. Aluminum channel is much lighter than steel, so it is indispensable in aircraft construction. It is often used in interior design of residential premises and retail spaces. Modern automotive industry also cannot do without it.

Characteristics of channel 10: dimensions, weight, cost

The range of channel 10, as a fairly popular rolled metal product, is quite wide. The characteristics of its varieties and types are regulated by GOST No. 8240, developed back in 1989. The properties of products include the parameters of shelves and walls, in particular their height and width, and also the radii of curvature of channels marked 10U are taken into account.

Channel 10 has three subtypes with corresponding markings:

- U – a profile in which the internal shelves are made with a slope;

- P – channel, where the edges of the flanges are parallel;

- E - economical products with parallel placement of shelves.

Helpful advice! Each type of channel has its own designation, for example, 10P, 10U or 10E. The corresponding values are contained in a separate table. Despite the same numerical data, these are different types of products.

The range of channels includes products of various sizes and configurations

The most used in various industries is, due to its size, the 10P channel. It is widely used in individual construction for the construction of load-bearing structures. The number 10 in the marking, in fact, indicates its height, equal to 100 mm, and the letter P indicates the type of profile, while emphasizing the parallel arrangement of the shelves. This type of channel has the following parameters:

- width is 46 mm;

- wall thickness – 4.5 mm;

- shelf thickness – 7.6 mm;

- radius of curvature – 7 mm;

- The radius of curvature at the edge of the shelf is 4 mm.

To determine the weight of channel 10, it is necessary to know the cross-sectional area. This figure corresponds to 10.9 cm². This type of channel is produced in lengths from 4 to 12 m. Longer products are made to order. The weight of 1 meter of channel 10 with a steel density of 7.85 g/cm³, according to calculations, is 8.59 kg. The error in the indicated mass values may be 3-5%. The average price of channel 10 per meter is 356 rubles.

Channels are made by hot-rolled, cold-rolled and by bending metal sheets

The usual way to calculate the load on a channel

To make the calculation you need to do the following:

- First, collect the entire load that will be directed to the beam - normative and calculated, and at the same time already multiplied by the safety factor for the loads.

- The result obtained must be multiplied by the pitch of the beams (in this case this applies to channels).

- Next, you need to calculate the maximum bending moment. The formula is as follows: M max will be equal to the design load multiplied by the length of the channel (but squared) unit of measurement kNm.

- Then proceed to calculate the required moment of resistance of the beam. The formula is as follows: Wtr will be equal to Mmax, which is multiplied by the operating conditions coefficients and everything must be divided by the product 1c equal to 1.12 (this is a coefficient for taking into account plastic deformations).

This will give you the required section cm cubic. In this case, it is necessary to assume that the channel number is greater than the required section moment. All data is taken according to GOST.

Main parameters of channel 12: dimensions, weight and cost

A metal product called channel 12 with parallel flanges has a body thickness of 7.8 mm and a wall thickness of 4.8 mm. Such products are produced in lengths from 2 to 12 m. Longer copies can be made to order. The popularity of this type of profile is due to its positive qualities, contained in the optimal ratio of weight, strength and relatively low cost.

Profiles made of low-alloy steel are subject to operation at high temperatures and under conditions of increased exposure to chemicals. Also, the products have excellent resistance to compression and bending, but at the same time have poor resistance to torsion.

The weight of 1 meter of channel 12 can be found using the table above or using an online calculator. The price of the product depends on this parameter. According to the table, the weight of channel 12 per 1 meter is 10.4 kg.

Channel 12 - drawing with dimensions according to GOST

Like channels of other sizes, this type of product has additional markings with different characteristics. The most popular is the 12P channel, which has parallel flanges with edges without slope.

The dimensions of the 12P channel are given below:

- width – 52 mm;

- linear meter weight – 10.40 kg;

- length in ton – 95.94 m.

The channel with mark 12 also has other series. For example, 12L is a rolled metal product with dimensions of 120x30 mm, characterized by inclined shelves. The weight of 1 m of such a profile is 5.02 kg, and the footage of 1 ton is 199 m.

Helpful advice! The marking of the channel 12C indicates its special purpose, 12E - an economical series of products with shelves without slope. Their size is standard - 120x52 mm, and their weight is slightly lower - 10.24 kg. Accordingly, a ton of material contains almost 97 m.

Together with the digital value indicating the width of the profile, a letter is placed indicating the structural features of the material

Channel 14 variations: dimensions, weight, scope of application

U-shaped products marked 14, due to their high strength characteristics, are widely used in strengthening reinforced concrete products, used for reinforcing metal structures, as well as in various construction and restoration works. This type of product has its own series:

- 14P is a channel produced by the hot-rolled method and has a general purpose. It is produced in accordance with GOST 8240-97.

- 14U is a special-purpose profile that is widely used in mechanical engineering.

- Bent steel channel with equal flanges is produced using specialized machines.

- A bent steel profile with unequal flanges is produced using roll forming equipment.

Channel 14, like other types of rolled metal, can be either with parallel flanges (marked “P”) or with inclined flanges (marked “U”). Both series have common characteristics:

- height – 140 mm;

- width – 58 mm;

- shelf thickness – 8.1 mm;

- wall thickness – 4.9 mm;

- weight of 1 meter of channel 14 – 12.3 kg;

- There are 81.3 m of product in 1 ton.

Channel 14 - cross-sectional diagram with symbols

It should be noted that the weight of channel 14 is strictly regulated by the requirements of a certain GOST. The maximum error cannot exceed 4.5% of the weight of all purchased products. Channels of this type are produced in lengths from 2 to 12 m. The cost of products depends on the series.

Differences between hot rolled and bent channels

The reason for the differences between them lies in the production method itself. The hot-rolled profile is stronger and can be used to strengthen objects subject to particularly heavy loads. However, it also has its shortcomings, which, in principle, are a continuation of their advantages.

It is enough to look at a photo of a channel, both one and another type, in order to make sure that hot-rolled products have clearer edges and clearly defined angles. They are more durable, but when installing them, it is almost impossible to use welding. They do not weld well to each other and to other metal parts.

Thus, everything is far from clear. It seems that a more powerful channel is always preferable, because, compared to a bent one, it is capable of withstanding generally prohibitive loads, but not everything is so simple, and, despite its higher strength characteristics, it is not always preferable.

Features of channel 16: dimensions, weight and cost

Channel 16 is widely used for strengthening large-sized structures such as bridges, supports, as well as when pouring the foundations of high-rise buildings. The technical features of a special series of rolled metal products provide for its use in mechanical engineering, carriage building and shipbuilding.

Related article:

Assortment of channels: the ratio of characteristics as a guarantee of reliability. Types, markings and characteristics of U-shaped rolled metal products. Requirements according to GOST, Gosstandart tables. Weight and dimensions of channels.

The main feature is the slope of the edges in the middle of the products, which gives increased bending strength and torsional stability. This product type has three series:

- 16P - used in installation work due to ease of installation;

- 16U – is resistant to vertical loads, which suggests its use in areas with increased seismic activity;

- 16L - due to its low weight, it is used for the construction of monolithic structures and in shipbuilding.

Depending on the design, channels have different purposes

All products comply with specific GOST:

- 8240-97 – hot-rolled channels;

- 8278-83 – cold-formed channels with equal flanges;

- 8281-80 – bent with unequal flanges.

The standard dimensions of channel 16 correspond to the following values:

- height – 160 mm;

- shelf width – 64 mm;

- wall thickness – 5 mm;

- shelf thickness – 8.4 mm.

The weight of channel 16 corresponds to 14.2 kg. There are about 70 m of rolled products in one ton. These indicators directly proportionally affect the pricing of steel profiles. For example, the average price of channel 16 per meter is 520 rubles. Products are produced in lengths from 2 to 12 m.

Helpful advice! The length of the product affects the ease of its transportation. That is why it is not practiced to produce channels longer than 12 m. At the same time, this is the length that is most popular, and special vehicle platforms are designed just for it.

The length of the channel can be different and most often starts from 2 m

Bent channel assortment

The bent channel is distinguished by precise geometric dimensions and uniform wall thickness. This is explained by the fact that roll forming equipment serves not only to give the required profile, but also to correct some defects in the workpiece. The range of equal-shelf products is determined by GOST 8278-83. Depending on the material used to manufacture these metal products, the standard wall height varies:

- carbon boiling and semi-calm steel – 25-410 mm;

- quiet carbon and low-alloy – 25-310 mm.

Weight, price, dimensions of channel 20: all the necessary information about the profile

Channel 20 belongs to the category of universal rolled metal products made from hot-rolled steel. It is used in almost all industries - not only in the construction of load-bearing structures, but also for the construction of bridges, in the automotive and carriage industries, as well as in heavy engineering. The production of products is regulated by several GOSTs, according to which technical characteristics and permissible deviations from the norm are established.

Channel 20 has three main types that meet certain Gosstandart requirements:

- general use and special purpose - GOST 8240-97;

- special for the automotive industry - GOST 19425-74;

- special for carriage building - GOST 5267.1-90.

All these types of rolled products are characterized by common parameters, such as the height, width of the flanges and the weight of the channel 20. It should be noted that the profile can be either equal flange or with inclined flange edges. The dimensional characteristics of profile 20 are as follows:

- height – 200 mm;

- shelf width – 76 mm;

- wall thickness – 52 mm;

- Shelf thickness – 9 mm.

Channel 20 is most in demand in construction for the construction of supporting structures

The weight of different types of channel may vary slightly. For example, for a 20P channel the weight of 1 meter is 18.4 kg. Series P channel 20 is most in demand in the construction market. It is used both for the construction of frames and for the construction of bridges, the creation of large machine tools, as well as for other purposes. According to GOST 8240-89 for hot-rolled and GOST 8278-83 for bent channels, profiles are made with lengths from 4 to 12 m.

Size gradation

Thus, channel No. 8, that is, a product with a height of 8 centimeters, is often used in the construction of residential multi-storey buildings and production workshops.

The material for their manufacture is carbon steel, which makes them reliable welded structures. Channel No. 0 is used in machine tool and mechanical engineering, in the construction of load-bearing supports of bridges.

Channel number 12 is intended for use in the same branches of human activity as the previous two; it differs from them only in a higher level of strength. In the construction of the most critical production facilities, channels number 14 are used. In addition, they can be used in the construction of residential buildings and other similar facilities.

Channel number 20 is used to strengthen structures experiencing increased loads. Bent channel is widely used in construction, mechanical engineering and in general wherever increased strength of structures is required. However, despite the high efficiency of the bent channel, its hot-rolled counterpart looks much more efficient.