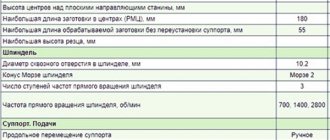

Channel 12 is a popular type of rolled product, having a U-shaped cross section and a wall height of 120 mm. According to the manufacturing method, a distinction is made between hot-rolled and bent profiles. The first is characterized by clear outer corners, increased strength due to slight thickening in the inner corners, possible surface defects and low dimensional accuracy. The second type of rolled products has rounded outer corners, the same width of the wall and flange, and acceptable surface quality, thanks to the correction of defects during bending on mills.

Classes E and L

The economical and lightweight series of shaped metal products are distinguished by wall thickness: it is less than the standard one. In grade 16p the parameter is (in mm):

- Economical - 4.7 (wall) and 8.4 (each shelf);

- Lungs - 3.4 (wall) and 5.3 (each shelf).

It is this characteristic that determines: the mass of one meter and the total weight of the beam, the quantity in one ton, the retail and wholesale price. Accordingly, the physical characteristics change: load resistance, strength, rigidity. The scope of application of beams, their durability, reliability, and, therefore, the quality of construction depend on these parameters.

Application

Channel grade 16 is intended for use in the construction industry. It is used in the construction of buildings and structures in earthquake-prone areas, as well as under constant vibration exposure during operation.

Main areas of application include:

- supporting parts of billboards;

- grillage of pile and pile-screw foundation;

- reinforcement of the underground part of the structure;

- marching and spiral staircases;

- frame buildings.

The product is used as a load-bearing, self-supporting and non-load-bearing element in the frame of buildings of various sizes.

If it is necessary to create the most reliable junction of several beams, the use of 16P is provided. Hot rolling provides strength and reliability under high loads and cold climates. The main material for the production of such a channel is steel with a low content of alloying components (09G2S).

Return to content

Bent channel 16: technical parameters and application

Bent channel is made from hot and cold rolled strips on roll forming mills in two ways:

- continuous – cutting into the required sections is carried out automatically on the bending line;

- piecewise – pre-cut blanks are subjected to profiling.

Differences between bent products and hot-rolled ones:

- lower strength characteristics;

- a richer assortment, the presence of not only equal-shelf, but also unequal-shelf products;

- rounded outer corners;

- higher dimensional accuracy due to correction of small surface defects during the bending process.

The range of bent equal-flange profile is regulated by GOST 8278-83, unequal-flange - GOST 8281-80.

Table of dimensions of equal-flange bent channel with a wall height of 160 mm - flange widths and wall thicknesses

| Shelf width, b, mm | Wall thickness, s, mm | Weight 1 m, kg | Shelf width, b, mm | Wall thickness, s, mm | Weight 1 m, kg |

| 40 | 2 | 3,65 | 60 | 6 | 12,14 |

| 40 | 3 | 5,38 | 70 | 4 | 8,95 |

| 40 | 5 | 8,71 | 80 | 2,5 | 6,11 |

| 50 | 2,5 | 4,92 | 80 | 3 | 7,26 |

| 50 | 4 | 7,7 | 80 | 4 | 9,58 |

| 50 | 5 | 9,49 | 80 | 5 | 11,85 |

| 50 | 6 | 11,2 | 80 | 6 | 14,02 |

| 60 | 2,5 | 5,31 | 100 | 3 | 8,28 |

| 60 | 3 | 6,32 | 100 | 6 | 15,91 |

| 60 | 4 | 8,32 | 120 | 6 | 17,79 |

| 60 | 5 | 10,28 | 160 | 6 | 21,56 |

Due to higher dimensional accuracy, bent profile products can be welded without chamfering. A channel obtained by bending is usually not used to create critical load-bearing structures that experience high loads. Typically, these metal products are used for:

- arrangement of frames for facing materials in ventilated facades;

- construction of internal partitions;

- production of heavy equipment.

Bent channels are made not only from “black” carbon steels, but also from corrosion-resistant steels. Stainless steel products are in demand in areas that require resistance to corrosion damage upon contact with aggressive environments and an attractive appearance. Uneven-flanged metal products are usually made to order.

Assortment

Depending on the method of production of the product, the length of the product is determined. Hot-rolled elements are produced with a length of 2-12 m, cold-formed elements - 3-12 m (obtained by continuous or piece bending). Continuous bending involves the use of a solid workpiece, and piece bending involves the use of individual elements with the required length.

The actual weight of products may differ slightly from the standard weight. The steel used for production has a density of 7850 kg/m3.

Return to content

Assortment of channel No. 16 and the standards by which it is produced

Channel 16 is manufactured only according to standard 8240. This GOST applies to hot-rolled steel channel products for special and general purposes, which, depending on the profile number, have a height in the range of 50–400 mm and a flange width of 32–115 mm.

Let us dwell on GOSTs, which are also used in the manufacture of channels of standard 8240. These GOSTs contain requirements for the quality of manufacturing of metal products and their technical characteristics, namely: strength and other properties, as well as classification according to them; a list of steel grades used for production, indicating their chemical composition; other parameters of finished products. Depending on the conditions of use, as well as the purpose of the metal product (in this case, a channel), they are guided by one of the following standards:

- GOST 19281-89 – applies to all types of rolled metal products made from steel alloys with increased strength (means low-alloy steels);

- GOST 535-2005 - for long and shaped products for both general and special purposes, made of carbon steels of ordinary quality;

- GOST R 52927-2015 – applies to rolled products produced from alloys of increased, high and normal strength and intended for the construction of berths, pontoons, ships (river and sea), oil and gas platforms and other welded structures;

- GOST 27772-88 – applies to various metal products made of carbon and low-alloy alloys intended for steel building structures with welded and other connections;

- GOST R 55374-2012 – for some types of hot-rolled steel, including shaped steel, intended for use in bridge construction and made of alloyed structural alloys.

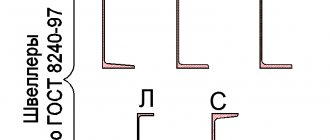

According to standard 8240, all products manufactured according to it are divided into several types. The first, but not the main division is the shape of the shelves. The latter on the channel can be:

- With an inclined edge on the inner side of the channel.

- With parallel edges.

Channel with an inclined edge

The main division - according to the shape and geometric dimensions of the cross section - into a series of hot-rolled channel profiles:

- U - products with shelves of 1 type;

- P – channels with 2 types of shelves;

- E – economical profiles with 2 types of shelves;

- L – light series channels with 2 types of shelves;

- C – special profiles with shelves of 1 type.

In addition, channel 16, like a number of other products (of other standard sizes) of the 8240 standard, in the U, P and S series is represented not by one, but by several types. This means that there are profiles of the main standard size and additional ones. The last ones from the same series, with the same wall height, are designated in the same way. But they differ from the main standard size by being more massive. That is, they have thicker walls, wider shelves and may have larger radii of curvature on the edges of the latter. Channels of these additional standard sizes are classified as reinforced. Letter indices are added to their markings: “a” for the first additional standard size and “b” for the second, more powerful one.

Channel No. 16 has only one (first) additional standard size in the U, P and S series. Thus, in accordance with GOST 8240, the assortment of this product consists of 8 items. These are profiles: 16U, 16aU, 16P, 16aP, 16E, 16L, 16S and 16Sa.

Specifications

The main characteristics of the product include:

| Characteristics and dimensions of channel 16 | 16U/ 16aU | 16P/ 16aP | 16E | 16L | 16С/ 16Са |

| Steel density, kg/m3 | 7850 | ||||

| Cross-sectional area, cm2 | 18,1/19,5 | 18,1/19,5 | 17,85 | 9,04 | 21,95/25,15 |

| Height, mm | 160 | ||||

| Wall thickness, mm | 5 | 5 | 4,7 | 3,4 | 6,5/8,5 |

| Shelf thickness, mm | 8,4/9 | 8,4/9 | 8,4 | 5,3 | 10 |

| Shelf width, mm | 64/68 | 64/68 | 64 | 35 | 63/65 |

| Radius of internal rounding, mm | 8,5 | 8,5 | 11 | 8 | 10 |

| Radius of external rounding, mm | 3,5 | 5 | 3,5 | — | 5 |

| Channel weight 16, kg/m | 14,2/15,3 | 14,2/15,3 | 14,01 | 7,1 | 17,53/19,74 |

The painting area of the element is 40.5 m2/t, and the rolled length is 4-12 m. Depending on the type of channel, its main characteristics will differ.

Return to content

Price

The price of hot-rolled channel 16 GOST 8240-97 depends on the following parameters:

- Measure of length;

- Price of one meter;

- Weight of one profile;

- Method and terms of delivery.

The price of a wholesale batch depends on how many products are contained in 1 ton and what the remainder is (there is a smaller beam in each batch, since division does not lead to a whole number). In the Moscow region, the price per ton or per meter for channel grade 16 starts from the following values:

- With parallel shelves: from 29,800 rub/t with a length of 9 m; from 26680 rub/ton (material - galvanized steel), length 12 m;

- With a slope of the internal walls of the shelves: from 23,400 rubles/ton (1 product has a length of 12 m), from 24,400 rubles/ton with a product length of 9 m;

- Price per 1 linear meter with a hot-rolled channel length of 12 m: from 615 rubles.

Varieties

Several types of channels are produced using hot rolling (in accordance with GOST 8240-97):

- With a slope of the internal edges of the shelves of 6-10%. The designation of such an element contains the letter “U”. The scope of application may differ, special purpose is marked “C”, reinforced beams – “a”. In the latter case, the width and thickness of the shelf are greater compared to standard elements.

- Channel 16p has parallel shelves. Additionally, the indices “L” and “E” can be entered, which indicate low weight (light) and efficiency. They have reduced dimensions of walls and shelves, but their height is 16 cm.

Bent rolled products are characterized by rounded corners and equal-thick walls and flanges. Equal flange elements are manufactured according to GOST 8278-83, and unequal flange elements - according to GOST 8281-80. By bending you can create more types of channels than by hot rolling. Bent products are characterized by high surface quality and dimensional accuracy. This is due to the absence of temperature effects that cause shrinkage, as well as the manufacturability of the process.

Return to content

Table with dimensions of channels with parallel flange edges.

| Series P channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5P | 50 | 32 | 4.4 | 7.0 | 6.0 | 3.5 | 6.16 | 4.84 | 22.8 | 9.1 | 1.92 | 5.61 | 5.95 | 2.99 | 0.98 | 1.21 |

| 6.5P | 65 | 36 | 4.4 | 7.2 | 6.0 | 3.5 | 7.51 | 5.90 | 48.8 | 15.0 | 2.55 | 9.02 | 9.35 | 4.06 | 1.12 | 1.29 |

| 8P | 80 | 40 | 4.5 | 7.4 | 6.5 | 3.5 | 8.98 | 7.05 | 89.8 | 22.5 | 3.16 | 13.30 | 13.90 | 5.31 | 1.24 | 1.38 |

| 10P | 100 | 46 | 4.5 | 7.6 | 7.0 | 4.0 | 10.90 | 8.59 | 175.0 | 34.9 | 3.99 | 20.50 | 22.60 | 7.37 | 1.44 | 1.53 |

| 12P | 120 | 52 | 4.8 | 7.8 | 7.5 | 4.5 | 13.30 | 10.40 | 305.0 | 50.8 | 4.79 | 29.70 | 34.90 | 9.84 | 1.62 | 1.66 |

| 14P | 140 | 58 | 4.9 | 8.1 | 8.0 | 4.5 | 15.60 | 12.30 | 493.0 | 70.4 | 5.61 | 40.90 | 51.50 | 12.90 | 1.81 | 1.82 |

| 16P | 160 | 64 | 5.0 | 8.4 | 8.5 | 5.0 | 18.10 | 14.20 | 750.0 | 93.8 | 6.44 | 54.30 | 72.80 | 16.40 | 2.00 | 1.97 |

| 16aP | 160 | 68 | 5.0 | 9.0 | 8.5 | 5.0 | 19.50 | 15.30 | 827.0 | 103.0 | 6.51 | 59.50 | 90.50 | 19.60 | 2.15 | 2.19 |

| 18P | 180 | 70 | 5.1 | 8.7 | 9.0 | 5.0 | 20.70 | 16.30 | 1090.0 | 121.0 | 7.26 | 70.00 | 100.00 | 20.60 | 2.20 | 2.14 |

| 18aP | 180 | 74 | 5.1 | 9.3 | 9.0 | 5.0 | 22.20 | 17.40 | 1200.0 | 133.0 | 7.34 | 76.30 | 123.00 | 24.30 | 2.35 | 2.36 |

| 20P | 200 | 76 | 5.2 | 9.0 | 9.5 | 5.5 | 23.40 | 18.40 | 1530.0 | 153.0 | 8.08 | 88.00 | 134.00 | 25.20 | 2.39 | 2.30 |

| 22P | 220 | 82 | 5.4 | 9.5 | 10.0 | 6.0 | 26.70 | 21.00 | 2120.0 | 193.0 | 8.90 | 111.00 | 178.00 | 31.00 | 2.58 | 2.47 |

| 24P | 240 | 90 | 5.6 | 10.0 | 10.5 | 6.0 | 30.60 | 24.00 | 2910.0 | 243.0 | 9.75 | 139.00 | 248.00 | 39.50 | 2.85 | 2.72 |

| 27P | 270 | 95 | 6.0 | 10.5 | 11.0 | 6.5 | 35.20 | 27.70 | 4180.0 | 310.0 | 10.90 | 178.00 | 314.00 | 46.70 | 2.99 | 2.78 |

| 30P | 300 | 100 | 6.5 | 11.0 | 12.0 | 7.0 | 40.50 | 31.80 | 5830.0 | 389.0 | 12.00 | 224.00 | 393.00 | 54.80 | 3.12 | 2.83 |

| 33P | 330 | 105 | 7.0 | 11.7 | 13.0 | 7.5 | 46.50 | 36.50 | 8010.0 | 486.0 | 13.10 | 281.00 | 491.00 | 64.60 | 3.25 | 2.90 |

| 36P | 360 | 110 | 7.5 | 12.6 | 14.0 | 8.5 | 53.40 | 41.90 | 10850.0 | 603.0 | 14.30 | 350.00 | 611.00 | 76.30 | 3.38 | 2.99 |

| 40P | 400 | 115 | 8.0 | 13.5 | 15.0 | 9.0 | 61.50 | 48.30 | 15260.0 | 763.0 | 15.80 | 445.00 | 760.00 | 89.90 | 3.51 | 3.05 |

For channels of the U and P series there is a size that is not subject to control - this is the maximum deviation in wall thickness.

Prices for channel 16 in Moscow

Attention! The prices given here for channel 16 should be understood as indicative only. In many cases, prices are actually negotiable and may depend on delivery and other delivery conditions, as well as lot sizes. In retail trade, goods can be sold at a price per piece.

To review prices for channel 16, the largest electronic trading platforms were used: “Price Pulse” and “Tiu.ru”. For an objective analysis, offers with prices from the categories “by rating”, “cheap” and “expensive” were taken. Here are prices per kilogram (usually for retail and small wholesale) and per ton. It should be noted that the lowest prices are usually offered for large quantities of channel bars.

Prices for "Tiu"

Rating section:

- 25 rub/kg. Channel 30 U

- RUB 26,638/ton

Cheap category:

- 20.70 rub/kg

- RUB 20,500/ton

Road section e:

- RUB 38,720/ton

Table with dimensions of channels for economical shelves with parallel edges.

| Series E channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5E | 50 | 32 | 4.2 | 7.0 | 6.5 | 2.5 | 6.10 | 4.79 | 22.9 | 9.17 | 1.94 | 5.62 | 6.02 | 3.05 | 0.993 | 1.23 |

| 6.5E | 65 | 36 | 4.2 | 7.2 | 6.5 | 2.5 | 7.41 | 5.82 | 48.9 | 15.05 | 2.57 | 9.02 | 9.42 | 4.13 | 1.127 | 1.32 |

| 8E | 80 | 40 | 4.2 | 7.4 | 7.5 | 2.5 | 8.82 | 6.92 | 90.0 | 22.50 | 3.19 | 13.31 | 13.93 | 5.38 | 1.257 | 1.41 |

| 10E | 100 | 46 | 4.2 | 7.6 | 9.0 | 3.0 | 10.79 | 8.47 | 175.9 | 35.17 | 4.04 | 20.55 | 22.68 | 7.47 | 1.450 | 1.56 |

| 12E | 120 | 52 | 4.5 | 7.8 | 9.5 | 3.0 | 13.09 | 10.24 | 307.0 | 51.17 | 4.84 | 29.75 | 35.12 | 10.03 | 1.638 | 1.70 |

| 14E | 140 | 58 | 4.6 | 8.1 | 10.0 | 3.0 | 15.41 | 12.15 | 495.7 | 70.81 | 5.67 | 40.96 | 51.76 | 13.13 | 1.833 | 1.86 |

| 16E | 160 | 64 | 4.7 | 8.4 | 11.0 | 3.5 | 17.85 | 14.01 | 755.5 | 94.43 | 6.50 | 54.41 | 73.17 | 16.70 | 2.024 | 2.02 |

| 18E | 180 | 70 | 4.8 | 8.7 | 11.5 | 3.5 | 20.40 | 16.01 | 1097.9 | 121.99 | 7.34 | 70.05 | 100.51 | 20.87 | 2.219 | 2.18 |

| 20E | 200 | 76 | 4.9 | 9.0 | 12.0 | 4.0 | 23.02 | 18.07 | 1537.1 | 153.71 | 8.17 | 88.03 | 134.07 | 25.54 | 2.413 | 2.35 |

| 22E | 220 | 82 | 5.1 | 9.5 | 13.0 | 4.0 | 26.36 | 20.69 | 2134.2 | 194.02 | 9.00 | 111.00 | 179.05 | 31.54 | 2.606 | 2.52 |

| 24E | 240 | 90 | 5.3 | 10.0 | 13.0 | 4.0 | 30.19 | 23.69 | 2927.0 | 243.92 | 9.85 | 139.08 | 249.03 | 40.07 | 2.872 | 2.78 |

| 27E | 270 | 95 | 5.8 | 10.5 | 13.0 | 4.5 | 34.87 | 27.37 | 4200.2 | 311.12 | 10.97 | 178.25 | 316.24 | 47.43 | 3.011 | 2.83 |

| 30E | 300 | 100 | 6.3 | 11.0 | 13.0 | 5.0 | 39.94 | 31.35 | 5837.1 | 389.14 | 12.09 | 224.00 | 395.57 | 55.58 | 3.147 | 2.88 |

| 33E | 330 | 105 | 6.9 | 11.7 | 13.0 | 5.0 | 46.15 | 36.14 | 8021.8 | 488.17 | 13.18 | 281.23 | 497.02 | 65.78 | 3.282 | 2.94 |

| 36E | 360 | 110 | 7.4 | 12.6 | 14.0 | 6.0 | 52.90 | 41.53 | 10864.5 | 603.58 | 14.33 | 350.05 | 618.92 | 77.76 | 3.420 | 3.04 |

| 40E | 400 | 115 | 7.9 | 13.5 | 15.5 | 6.0 | 61.11 | 47.97 | 15307.9 | 765.40 | 15.83 | 445.41 | 770.89 | 91.80 | 3.552 | 3.10 |

The dimensions of the economical channel (E series) are controlled according to GOST 8240-97 (the data in the tables corresponds).

Table with dimensions of light series channels with parallel flange edges.

| Series L channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0cm | ||||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | i0 cm | |||||||||

| 12L | 120 | 30 | 3.0 | 4.8 | 7 | – | 6.39 | 5.02 | 135.26 | 22.54 | 4.60 | 13.43 | 5.02 | 2.24 | 0.89 | 0.76 |

| 14L | 140 | 32 | 3.2 | 5.6 | 7 | – | 7.57 | 5.94 | 212.94 | 30.42 | 5.31 | 18.23 | 6.55 | 2.70 | 0.93 | 0.78 |

| 16L | 160 | 35 | 3.4 | 5.3 | 8 | – | 9.04 | 7.10 | 331.96 | 41.49 | 6.06 | 24.84 | 9.23 | 3.46 | 1.01 | 0.83 |

| 18L | 180 | 40 | 3.6 | 5.6 | 8 | – | 10.81 | 8.49 | 503.87 | 55.98 | 6.83 | 33.49 | 14.64 | 4.10 | 1.16 | 0.94 |

| 20L | 200 | 45 | 3.8 | 6.0 | 9 | – | 12.89 | 10.12 | 748.17 | 74.82 | 7.62 | 44.59 | 22.37 | 6.51 | 1.32 | 1.06 |

| 22L | 220 | 50 | 4.0 | 6.4 | 10 | – | 15.11 | 11.86 | 1070.97 | 97.36 | 8.42 | 57.82 | 32.85 | 8.61 | 1.47 | 1.19 |

| 24L | 240 | 55 | 4.2 | 6.8 | 10 | – | 17.41 | 13.66 | 1476.39 | 123.03 | 9.21 | 72.90 | 46.25 | 11.04 | 1.63 | 1.31 |

| 27L | 270 | 60 | 4.5 | 7.3 | 11 | – | 20.77 | 16.30 | 2218.16 | 164.31 | 10.33 | 97.48 | 65.10 | 14.17 | 1.77 | 1.40 |

| 30L | 300 | 65 | 4.8 | 7.8 | 11 | – | 24.30 | 19.07 | 3186.74 | 212.45 | 11.45 | 126.24 | 89.08 | 17.84 | 1.91 | 1.51 |

Series L channels must have a wall deflection size of no more than 0.15s.

Table with sizes of special channels.

| Series C channel number | h | b | s | t | R | r | Shelf slope % | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | |||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | ix cm | Iy cm4 | Wy cm3 | Iy cm | ||||||||||

| 8C | 80 | 45 | 5.5 | 9.0 | 9.0 | 1.5 | 6 | 11.80 | 9.26 | 115.82 | 28.95 | 3.13 | 22.24 | 7.63 | 1.38 | 1.57 |

| 14C | 140 | 58 | 6.0 | 9.5 | 9.5 | 4.75 | – | 18.51 | 14.53 | 563.70 | 80.50 | 5.52 | 53.20 | 13.01 | 1.70 | 1.71 |

| 14Ca | 140 | 60 | 8.0 | 9.5 | 9.5 | 5.0 | 10 | 21.30 | 16.72 | 609.10 | 87.01 | 5.35 | 61.02 | 14.09 | 1.69 | 1.67 |

| 16C | 160 | 63 | 6.5 | 10.0 | 10.0 | 5.0 | – | 21.95 | 17.53 | 866.20 | 108.30 | 6.28 | 73.30 | 16.30 | 1.83 | 1.80 |

| 16Ca | 160 | 65 | 8.5 | 10.0 | 10.0 | 5.0 | – | 25.15 | 19.74 | 934.50 | 116.80 | 6.10 | 83.40 | 17.55 | 1.82 | 1.75 |

| 18C | 180 | 68 | 7.0 | 10.5 | 10.5 | 5.3 | – | 25.70 | 20.20 | 1272.00 | 141.00 | 7.04 | 98.50 | 20.10 | 1.96 | 1.88 |

| 18Ca | 180 | 70 | 9.0 | 10.5 | 10.5 | 5.3 | – | 29.30 | 23.00 | 1370.00 | 152.00 | 6.84 | 111.00 | 21.30 | 1.95 | 1.84 |

| 18Sat | 180 | 100 | 8.0 | 10.5 | 10.5 | 5.0 | 6 | 34.04 | 26.72 | 1791.01 | 199.00 | 7.25 | 305.48 | 43.58 | 3.00 | 2.99 |

| 20C | 200 | 73 | 7.0 | 11.0 | 11.0 | 5.5 | 10 | 28.83 | 22.63 | 1780.37 | 178.04 | 7.86 | 128.04 | 24.19 | 2.11 | 2.02 |

| 20Ca | 200 | 75 | 9.0 | 11.0 | 11.0 | 5.5 | 10 | 32.83 | 25.77 | 1913.71 | 191.37 | 7.64 | 143.63 | 25.88 | 2.09 | 1.95 |

| 20Sat | 200 | 100 | 8.0 | 11.0 | 11.0 | 5.5 | 6 | 36.58 | 28.71 | 2360.88 | 236.09 | 8.03 | 327.23 | 46.30 | 2.99 | 2.93 |

| 24C | 240 | 85 | 9.5 | 14.0 | 14.0 | 7.0 | – | 44.46 | 34.90 | 3841.35 | 320.11 | 9.29 | 268.89 | 43.70 | 2.46 | 2.35 |

| 26C | 260 | 65 | 10.0 | 16.0 | 15.0 | 3.0 | – | 44.09 | 34.61 | 4088.00 | 314.50 | 9.63 | 1115.60 | 171.60 | 5.03 | 3.91 |

| 26Ca | 260 | 90 | 10.0 | 15.0 | 15.0 | 7.5 | 8 | 50.60 | 39.72 | 5130.83 | 394.68 | 10.07 | 343.15 | 52.62 | 2.60 | 2.48 |

| 30C | 300 | 85 | 7.5 | 13.5 | 13.5 | 7.0 | 10 | 43.88 | 34.44 | 6045.43 | 403.03 | 11.74 | 260.74 | 41.41 | 2.44 | 2.20 |

| 30Ca | 300 | 87 | 9.5 | 13.5 | 13.5 | 7.0 | 10 | 49.88 | 39.15 | 6495.43 | 433.03 | 11.41 | 288.78 | 43.93 | 2.41 | 2.13 |

| 30Sat | 300 | 89 | 11.5 | 13.5 | 13.5 | 7.0 | 10 | 55.88 | 43.86 | 6945.43 | 463.03 | 11.15 | 315.35 | 46.29 | 2.38 | 2.09 |

Series C channels are hot-rolled steel channels, which come in general and special purposes and can have the following dimensions: height 50 - 400 mm, shelf width 32 - 15 mm. The dimensions of the C series channel are controlled according to GOST 8240-97.

Maximum deviations of parameters (channel sizes) in the table.

| Parameter | Parameter value range | Maximum deviation |

| Height h | Up to 80 | ±1.5 |

| Over 80 to 200 | ±2.0 | |

| Over 200 to 400 | ±3.0 | |

| Shelf width b | Up to 40 | ±1.5 |

| Over 40 to 89 | ±2.0 | |

| Over 89 | ±3.0 | |

| Shelf thickness t | To 10 | -0.5 |

| Over 10 to 11 | -0.8 | |

| Over 11 | -1.0 | |

| Wall thickness s | Up to 5.1 | ±0.5 |

| Over 5.1 to 6.0 | ±0.6 | |

| Over 6.0 | ±0.7 | |

| Warp of shelf D with shelf width b, no more | Up to 95 | 1.0 |

| Over 95 | 0.015b | |

| Wall deflection ƒ along the height h of the profile section, no more | Up to 100 | 0.5 |

| Over 100 to 200 | 1.0 | |

| Over 200 to 400 | 1.5 |