Shaped metal products are, among other things, represented by 20P channel. The 20P channel owes its name to its external design - it resembles the letter “P”, the dimensions of which are 20 mm in length. Excellent technical characteristics support the ability of the part to withstand significant axial loads, with a clear advantage being bending performance.

That is why the 20P channel is ideal for installation in structures that are constantly in contact with aggressive elements and the environment. In fact, these can be unique buildings, buildings of the most bizarre shapes, the basis of which is precisely the product marked 20p. The strength of the part is ensured by special steel; there is no analogue of steel plates yet.

Advantages of channel 20P

During construction, the channel is very popular due to a number of advantages:

- the material meets the required strength indicators;

- provides significant rigidity, which makes it stand out among other frame-type metal products;

- shows fantastic results in relation to various types of deformation processes - does not react at all;

- resistant to external mechanical influences;

- If the part has through recesses, you will not have to use welding during installation, or involve additional equipment or professionals with special knowledge.

Buy a channel and work for your pleasure, quickly, smoothly and simply!

Features of hot-rolled channels of the 24th group

All channel products, regardless of the material used and production technology, have a similar appearance, which is significantly different from other rolled metal products. But if we look in more detail, significant differences can be found between different types of channels. If you know about these features, it will be more difficult to confuse different types of profiles, which is important both when selecting the necessary product and during its operation.

Number markings are placed only on hot-rolled channels. Moreover, it means not only belonging to a certain standard size, but also corresponds to a specific profile height reduced ten times - the distance between the outer edges of the profile flanges, which determines the width of its walls. Just by looking at the markings, you can calculate the height of the channel. In this case, the product designation contains the number 24, which means its height is 240 millimeters. For other channel products, the marking method is slightly different. Comprehensive information on a particular channel is contained in its GOST. One of the most common is GOST 8240.

How channel 20P is produced

To better understand what we are dealing with, let’s find out what the production of the frame of a product is, the dimensions of which are 20 mm in length. In this case we are talking about the letter “P”, but basics in the form of the letter “U” and other models are also used.

So, a channel is produced in one of 2 ways, it all depends on the technology adopted at the manufacturer’s plant:

- by hot rolling - special machine equipment is required;

- using profile mills.

In general, the production process looks like this:

- Rolls of metal are cut based on the width of the blocks.

- Then the rolls are distributed in special machines that ensure uninterrupted and constant movement of sheet metal, and bending involves fixing a section of a certain size.

- All that remains is to cut a piece of the required length.

Of course, production has been put on a conveyor belt, which shows good production of products in a short period of time.

Cold-drawn and hot-rolled channel 20P is considered the most durable. To obtain a high-quality shaped rolled product, it is enough to increase the volume of the carbon component and add manganese. This is the only way to achieve proportionality between the properties of strength and ductility.

Manufacturing process

Channel 20 is produced by hot rolling. The principle is this: raw materials undergo several stages of mechanical deformation in a special rolling mill. This complex is equipped with rotating shafts. Rolled products pass through these installations, successively changing their geometric shape to the required one. When setting up the mill, they are guided by the final dimensions of the channel; only the radii of curvature of the flanges on the inner sides of the product, the edges of the channel and the angle between their surfaces are not taken into account.

The fundamental difference from other technologies is the preheating of raw materials to high temperatures. More precise temperatures depend on the metal chosen. Different metals begin to change their state of aggregation at different temperatures. The metal is heated until it enters a state of increased plasticity; here the quality of the future channel is imparted, internal stresses in the material are removed, and the wear resistance of the working elements of the channel and the number of profiling stages are increased.

After heating, the raw material is rolled through the mill. A system of rotating shafts passes heated metal through itself, consistently changing its geometric parameters. By the end of processing, a standard channel comes out of the mill.

By increasing the temperature of the metal, it is possible to obtain a uniform structure inside, which increases resistance to various loads. Alternative methods for producing channels do not have this “trump card”. Preheating also eliminates future additional thermal operation to remove internal stresses. However, you have to pay for this method - hot-rolled 20P channel is more expensive than its alternatives, since heating the metal and using a rolling mill is expensive.

Specifications

Modern products, whose dimensions reach a length of 20 mm, require laying a step between the arms of 50-400 mm, and it is these indicators that determine in which building the 20p channel will be used.

Channel 20P has the following physical properties:

- height – 20 mm;

- depth – 76 mm;

- cross section - 23.4 square meters. mm;

- radius 1 and radius 2 – 9.5 and 5.5 mm.

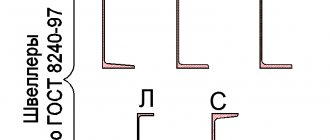

The letter marking, in turn, determines the following features of the channel:

- “U” – fixes the angle of inclination for the internal parts of the shelves;

- “P” – shelves are located parallel to each other;

- “L” - the part is similar to the “P” design, but avoids too precise shapes;

- “E” is the most economical option “P”;

- “C” is a special sample (most often made to order).

One way or another, the technical properties of metal parts are described in the norms and regulations of GOST, where the dimensions and parameters of each type of product are indicated. During the development of products, GOST was changed and supplemented several times, so today the modification of devices has the best characteristics, established by trial and error, taken from the own experience of leading builders, engineers and designers.

Types of channel 20, main characteristics

GOST 8240-97 regulates the production of several types of hot-rolled products with a U-shaped cross section. Hot-rolled channel 20 is sold in lengths of 2-12 m. On request, the length can be longer.

- With a slope of the inner edges of the shelves . The markings indicate the height of the shelf in centimeters and the letter “U”. The products are used in frame construction, to strengthen the foundation, construct trusses, arched ceilings, construct small architectural forms, and create load-bearing metal structures for various purposes.

- With parallel edges of shelves . The designation contains the letter “P”. Like the U series products, it is used in construction. Products with parallel inner edges of the shelves are convenient in cases where a tight fit along the inner part of the section is necessary.

- Economical series (E) with parallel shelf edges . The wall thickness is less than the wall thickness of P series metal products.

- With parallel edges of light series shelves (L) . The 20 L channel is characterized by a reduced shelf length, shelf and wall thickness, and therefore a smaller cross-sectional area, weight of 1 m, and load-bearing capacity, compared to the P series. The product is in demand in structures not intended to withstand significant forces.

- With a slope of the internal edges of the special series shelves (C) - 20C, 20Ca, 20Sb. Metal products with indices “a” and “b” have a more powerful cross-section compared to rolled products 20C.

Equal-flange bent channel 20, produced in accordance with GOST 8278-83, can have flanges with a width of 50, 80, 100, 180 mm, and a wall thickness of 3, 4, 5, 6 mm. It is made from hot-rolled roll blanks. Unequal bent products are produced in accordance with GOST 8281-80. The standard provides for shelves with a width of 50 and 30 mm, wall thickness - 4 mm.

To increase corrosion resistance, metal products made from “black” carbon steels are coated with a protective zinc layer.

Areas of application of the channel

We have already found out the dimensions of the channel with the letter “P” with a height of 20 mm, now it’s time to decide on the weight of the element of the building structure, and it is rather large - 18 kg of metal is required for 1 m. Therefore, the product is used in the construction of monolithic, significant structures:

- it may be an industrial building where operation with a static load is expected;

- when arranging residential complexes;

- creation of machine-building and metallurgical workshops.

Hot rolled channel 24 P length 12 m

Rolled metal → Products → Channel → Hot-rolled channel GOST 8240-89 → Hot-rolled channel 24 P length 12 m

Height (h), mm: 240 Shelf width (b), mm: 90 Wall thickness (s), mm: 5.6 Shelf thickness (t), mm: Length: 12 m Weight 1 m, kg: 24 Meters per ton: 41.7 GOST: GOST 8240-89

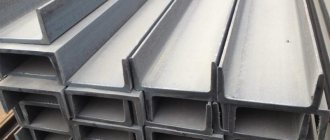

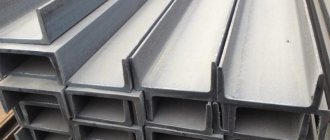

The hot-rolled channel is a steel profile with a U-shaped section. The hot-rolled channel supplied meets all the requirements of GOST 8240-89.

The following types of hot-rolled channels are produced:

- with a slope of the internal edges of the shelves (U): 5; 6.5; 8; 10; 12; 14; 16; 16a; 18; 18a; 20; 22; 24; 27; thirty; 40.

- with parallel edges of shelves (P): 5P; 6.5P; 8P; 10P; 12P; 14P; 16aP; 18P; 18aP; 20P; 22P; 24P; 27P; PDO; 40P.

Hot-rolled steel channel GOST 8240-89 for both general and special purposes is produced in lengths from 4 to 12 m, height 50-400 mm, shelf width 32-115 mm.

Hot-rolled steel channel is used in the construction and repair of bridges, long-span trusses, in columns, and in roof purlins. In addition to construction, hot-rolled channels are widely used in various industries, for example, in mechanical engineering, machine tool building and road construction.

Hot-rolled steel channel is made from cold-rolled, hot-rolled, carbon, high-quality structural and low-alloy steel.

| Name | Price | Availability |

| Hot rolled channel 24 P length 12 m | specify | In stock |

Dimensions, weight and number of meters per ton of hot-rolled channel

| Name | h | b | s | t | Weight 1 m, kg | Meters per ton |

| Hot rolled channel 5 P length 6m, 11.7m | 50 | 32 | 4,4 | 7 | 4,84 | 206,6 |

| Hot-rolled channel 5 P n/a | 50 | 32 | 4,4 | 7 | 4,84 | 206,6 |

| Hot rolled channel 6.5 P length 6 m, 11.7 m | 65 | 36 | 4,4 | 7,2 | 5,9 | 169,5 |

| Hot-rolled channel 6.5 P n/a | 65 | 36 | 4,4 | 7,2 | 5,9 | 169,5 |

| Hot rolled channel 8 U length 6m, 11.7m | 80 | 40 | 4,5 | 7,4 | 7,05 | 141,8 |

| Hot rolled channel 8 U n/a | 80 | 40 | 4,5 | 7,4 | 7,05 | 141,8 |

| Hot rolled channel 10 P length 6m, 11.7m | 100 | 46 | 4,5 | 7,6 | 8,59 | 116,4 |

| Hot-rolled channel 10 P n/a | 100 | 46 | 4,5 | 7,6 | 8,59 | 116,4 |

| Hot rolled channel 12 U length 12m | 120 | 52 | 4,8 | 7,8 | 10,4 | 96,2 |

| Hot rolled channel 12 P length 6m, 12m | 120 | 52 | 4,8 | 7,8 | 10,4 | 96,2 |

| Hot rolled channel 14 U length 12 m | 140 | 58 | 4,9 | 8,1 | 12,3 | 81,3 |

| Hot rolled channel 14 P length 12 m | 140 | 58 | 4,9 | 8,1 | 12,3 | 81,3 |

| Hot rolled channel 16 U length 12 m | 160 | 64 | 5 | 8,4 | 14,2 | 70,4 |

| Hot rolled channel 16 P length 12 m | 160 | 64 | 5 | 8,4 | 14,2 | 70,4 |

| Hot rolled channel 18 U length 12 m | 180 | 70 | 5,1 | 8,7 | 16,3 | 61,3 |

| Hot rolled channel 18 P length 12 m | 180 | 70 | 5,1 | 8,7 | 16,3 | 61,3 |

| Hot rolled channel 20 U length 12 m | 200 | 76 | 5,2 | 9 | 18,4 | 54,3 |

| Hot rolled channel 20 P length 12 m | 200 | 76 | 5,2 | 9 | 18,4 | 54,3 |

| Hot rolled channel 22 U length 12m | 220 | 82 | 5,4 | 9,5 | 21 | 47,6 |

| Hot rolled channel 22 P length 12 m | 220 | 82 | 5,4 | 9,5 | 21 | 47,6 |

| Hot rolled channel 24 U length 12 m | 240 | 90 | 5,6 | 10 | 24 | 41,7 |

| Hot rolled channel 24 P length 12 m | 240 | 90 | 5,6 | 10 | 24 | 41,7 |

| Hot rolled channel 27 U length 12m | 270 | 95 | 6 | 10,5 | 27,7 | 36,1 |

| Hot rolled channel 27 P length 12 m | 270 | 95 | 6 | 10,5 | 27,7 | 36,1 |

| Hot rolled channel 30 U length 12 m | 300 | 100 | 6,5 | 11 | 31,8 | 31,4 |

| Hot rolled channel 30 P length 12 m | 300 | 100 | 6,5 | 11 | 31,8 | 31,4 |

| Hot rolled channel 40 U length 11.5 m | 400 | 115 | 8 | 13,5 | 48,3 | 20,7 |