When constructing or renovating a private house, structures made from plasterboard sheets are often used. Depending on the initial conditions and final goals, they can be mounted on structures made of various materials, and one of the possible and most commonly used options is a frame structure made of metal profiles.

Metal profiles for plasterboard can be used when installing structures of various types and purposes. In private housing construction, plasterboard profiles are usually used for the following purposes:

- forming frames for suspended ceilings;

- wall cladding;

- construction of double-sided partitions;

- arrangement of niches for compartment doors.

There is a wide range of metal profiles of various types and sizes on the building materials market, shown in Table 1.

Table 1. Types and designation of metal profiles for plasterboard structures

| Designation | Name |

| Mon (UW) | guide profile |

| PS (CW) | rack profile |

| PP (CD) | ceiling profile |

| PNP (UD) | ceiling guide profile |

| PA | arched profile |

| U.A. | reinforced profile |

| U | Y-shaped profile with flanges |

| Elastic tire | |

| PU | corner profile |

| PM | beacon profile |

The metal profile for plasterboard is made from rolled galvanized steel 0.4-0.7 mm thick by rolling through a profile bending machine, which forms stiffening ribs and perforates mounting holes simultaneously giving the product the required shape, and the zinc coating provides long-term protection of the product from corrosion.

PN (UW) – guide profile

It has a U-shape and is used in the frames of partitions and cladding as a guide element or a jumper device paired with a rack profile, in compliance with the appropriate standard sizes (the same back width).

Table 2. Guide profile dimensions

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Standard product length, m |

| Mon (UW) – 50×40 | 0,4 – 0,6 | 50 | 40 | 2,6; 3,0; 4,0 |

| Mon (UW) – 65×40 | 65 | |||

| Mon (UW) – 75×40 | 75 | |||

| Mon (UW) – 100×40 | 100 |

For greater convenience and ease of installation, some manufacturers can make the back perforated for future attachment points.

Basic principles

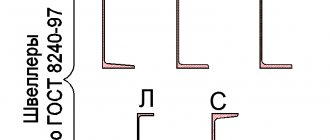

According to GOST No. 8240-97, the product range includes all-metal profiles with a wide range of possible parameters. With this variety on offer, it is quite difficult to make a choice: which brand is most suitable for its purposes. Of course, manufacturing companies take this nuance into account. Product marking is used to designate channels, and according to it, a complete picture is given of the characteristics and dimensions of U-shaped rolled products.

Marking “U” - inclined edges

According to GOST number 8240-97, the following markers are distinguished: 1) numbers, 2) letters. The numbers that come first in the designations “tell” about the distance between the shelves. The letter determines what type a particular product is.

- The internal edges of the shelves are inclined - the letter “U”. They are used mainly for high-strength structures in construction and mechanical engineering;

- The edges run parallel - “P”;

- Economical channels – letter “E”. Can be used for all kinds of frames;

- Light plan - “L” - in lightweight structures of various types;

- Special purpose - “C” - for frames and structures of a special nature.

If you need to find out the remaining parameters and profile sizes of a specific brand taken from the assortment, the tables where they are indicated will help (shown below - tables numbered 1-5). The selection of brands, as a rule, is carried out depending on the loads for which the structure made of channels and other material is intended.

Channel "P"

According to GOST 8240-97, the geometric characteristics and dimensions of the P (parallel edges of the shelves) and U (slope of the internal edges of the shelves) series are practically the same. Their main difference is only in the radius of curvature. The key parameters in markings are width and height. Additional designations for the tables below:

- I—moment of inertia;

- W is the moment of resistance;

- i is the radius of gyration.

Channel with sloped edges (U)

Table 1

With parallel edges

Table 2

Economical profiles

Table 3

Light profile series

Table 4

Special channels

Table 5

Deviation limits

According to GOST No. 8240-97, metal U-shaped profiles may have permissible deviations in their design. We offer information in the following table.

Table 6

Theoretical weight

Table 7

PS (CW) – rack profile

It has the shape of a square letter “C” and is used as vertical posts for plasterboard partitions and wall cladding. Mounted in pairs with a PN profile of the appropriate size (same back width). The choice of dimensions should be made based on the width of the structure (affects the width of the backrest) and its height (the length of the profile from floor to ceiling without joints).

Table 3. Rack profile dimensions

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Standard product length, m |

| PS (CW) – 50×50 | 0,4 – 0,6 | 50 | 50 | 2,6; 3,0; 4,0 |

| PS (CW) – 65×50 | 65 | |||

| PS (CW) – 75×50 | 75 | |||

| PS (CW) – 100×50 | 100 |

The back may have holes for utilities, and the shelves may be embossed with stripes or dots for centering the screws when screwing in and marking when installing gypsum boards (depending on the manufacturer).

Galvanized steel profiles: order from professionals!

Judging by the offers on the Internet, dozens of large and medium-sized enterprises are engaged in the production of galvanized steel profiles in Moscow.

And if you take into account the proposals of small ones, the bill will easily exceed a hundred. Of course, in such a huge list of offers you can find the most budget options. But will the quality meet your expectations in this case? If the profile is not made professionally, several serious mistakes can be made. The most critical is at the design stage, when the thickness of the workpieces is incorrectly calculated and their use becomes dangerous. When working on primitive equipment, there is a risk of damaging the galvanized layer: in the future, pockets of corrosion will inevitably appear in these areas. Errors in setting up the machine can lead to distortion of the profile shape. And if cut into strips incorrectly during the preparatory stage, the edge of the future product may acquire uneven edges.

Only professionals can produce galvanized steel profiles. Trust us - and you will be completely satisfied with the quality of our products.

PP (CD) – ceiling profile

It is used for installation of suspended ceiling frames and wall cladding. The shelves and back of this profile have longitudinal embossing in the form of three stripes to center the screws and increase rigidity. Fastening to supporting structures is done using hangers, for installation of which the edges of the ceiling profile are bent inward. Installation is carried out in tandem with the ceiling guide profile.

Table 4. Ceiling profile dimensions

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Standard product length, m |

| PP (CD) – 60×27 | 0,4 – 0,6 | 60 | 27 | 2,6; 3,0; 4,0 |

Production technologies

There are cold-rolled (bent) and hot-rolled technologies for the production of these products. In the first case, the channel is obtained by cold profiling from appropriate blanks. In the second - using hot rolled profiles.

Also, U-shaped channels are different in their design. For example, there are products with parallel edges of shelves (brand P) and with inclined edges (brand U). Regardless of the options used, the range of profiles determines their low weight and excellent rigidity. It is these properties that make it possible to use channels of different sizes for the manufacture of structures with increased loads for construction and other purposes. Among the advantages of profiles is the ability to withstand bending, as well as various types of loads: for example, rupture or compression.

PNP (UD) – ceiling guide profile

Serves as a guide and holding support for the PP ceiling profile both when installing suspended ceilings from gypsum plasterboard, and when covering walls with plasterboard sheets. Mounted in tandem with a ceiling profile.

Table 5. Dimensions of the ceiling guide profile

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Standard product length, m |

| PNP (UD) – 28×27 | 0,4 – 0,6 | 28 | 27 | 3,0 |

For convenience, some manufacturers can produce a ceiling guide profile with holes in the back for future mounting points.

Production of bent profiles

The popularity of galvanized bent profiles is due to several reasons:

- the material is moisture and temperature resistant. You can work with it not only in dry and warm weather, but all year round. Therefore, for the production of galvanized steel profiles there is no such thing as seasonality;

- the lightness of the products greatly simplifies installation. Even during the construction of large objects, heavy equipment is used to a minimum;

- low labor costs reduce the cost of work, and therefore reduce prices for the customer.

PA(CD) – arched profile

Used to make structures with radial bends. It is made on the basis of a PP profile with the formation of flat sections 150 mm long at both ends. When making an arched profile from a ceiling yourself, you need to cut the shelves of the product into sectors, and then bend them in the desired direction with the required radius.

Table 6. Dimensions of the arched profile

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Standard product length, m | Minimum bending radius, mm |

| PA(CD) – 60×27 convex (external) | 0,4 – 0,6 | 60 | 27 | 2,6; 3,0; 4,0 | 1000 |

| PA(CD) – 60×27 konkav (internal) | 500 |

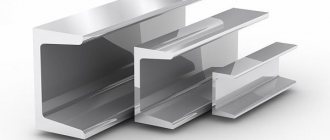

Main settings

Roughly speaking, a channel is an all-metal profile with a U-shaped section of shelves (in appearance it resembles the letter of the same name - hence the name). It can be made of different types of steel and stainless steel. This rental product differs in dimensions and dimensions (all information is in the special tables below), and in its technological characteristics and parameters: height, width, thickness, shelf inclination, as well as resistance and inertia, and some other data. The height of the product is greater than its width, as a rule, one and a half times or more (up to 3.5). And the cross-sectional shape of the channel provides a high level of structural rigidity. This type of rolled metal is also used in the construction of buildings, structures of various sizes, as well as in mechanical engineering, as a rule, for the manufacture of metal structures. The product is used as a load-bearing element of floors and frames of various structures. In addition, some brands are used in automobile and carriage construction, as well as for decorative purposes. To understand all this in detail, let’s carefully read the materials below.

UA – reinforced profile

Used to form the frame of reinforced suspended ceilings. It can also be used as part of structures for fastening door and window frames, wall decoration, for placing wiring and communication lines, as well as installing partitions with special requirements and increased height. It is distinguished by increased metal thickness in the product and increased shelf height.

Table 7. Reinforced profile dimensions

| Product marking | Metal thickness, mm | Back width, mm | Shelf height, mm | Number of rows of notches in the back, pcs. | Standard product length, m |

| UA – 50×40×2 | 2,0 | 50 | 40 | 1 | 2,6; 3,0; 4,0 |

| UA – 75×40×2 | 75 | 2 | |||

| UA – 100×40×2 | 100 | ||||

| UA – 125×40×2 | 125 | ||||

| UA – 150×40×2 | 150 |

Profile production

For the manufacture of galvanized steel profiles, rolled sheet metal is used, which, after cutting and bending, is transformed into plates.

Thanks to the acquired stiffening ribs, these products are highly durable and can withstand a large weight load. It is no coincidence that they become elements of structures that are fundamentally different in purpose: from bridges and overpasses to garden greenhouses. A bent profile is a “fighter of the invisible front”: its main function is to hold the structure, form its frame, and not be visible. Therefore, after installation, this structural element is “hidden” under sheathing made of plasterboard, metal and other materials. If a large profile is used in construction, a small one is suitable for repair and finishing work.

U-shaped profile with flanges

Used for installation of ceilings, partitions, attics, and wall cladding. The U-shaped profile is used in cases where it is necessary to reduce the installation distance to a minimum when attaching plasterboard sheets.

Table 8. U-profile dimensions

| product name | Metal thickness, mm | Back width, mm | Product height, mm | Standard product length, m |

| U-shaped profile with flanges | 0,6 | 98 | 15 | 4,0 |

Steel and aluminum U-shaped profile: what it is like and where it is used

Frame made of U-shaped profile for installing a plasterboard partition

Of the entire range of profile products, aluminum channel (aluminum U-shaped profile) today is perhaps the most widely used. Wherever it is used: in mechanical engineering, furniture production, glazing systems and the production of windows and doors.

One of the main areas of its application is construction, where the U-profile can be present both as a decorative element and as part of the load-bearing components of the structure. True, these nodes should be either completely unloaded or moderately loaded. At high load levels, alloys or U-shaped steel profile GOST 11474-76 are used.

Next, we will talk about the main types of profiles that have a cross-section in the shape of the letter “U”, and to broaden your horizons on this topic, we will offer a video in this article: “U-shaped steel profile: dimensions.”

What you need to know about the material

Since the scope of application of the material is so wide, it is clear that its size range should be no less wide. And the methods for producing a profile are different, since each industry has its own requirements for its characteristics.

Profile for furniture

A furniture profile is made from metal blanks using one of three technologies: casting, stamping or corner profiling. This can be steel, which then has to be coated with a layer of zinc, but aluminum is more often used, which is still more reliable in terms of corrosion resistance.

In addition, it has less weight and is better amenable to mechanical processing. To improve the appearance, finished aluminum U-shaped profiles are surface painted or the products are subjected to an anodizing process.

Note: U-profiles for furniture are also made from PVC - so to speak, a budget option.

Perforated U-shaped galvanized steel profile Aluminum profile 16 mm U-shaped U-profile PVC U-shaped aluminum profile 6 mm used for MDF panels

Having a variety of sizes, the U-shaped aluminum profile can be used not only for the end decoration of furniture facades, but also be present as a component of its frame. They are often framed with elements made of wood, glass, and plastic.

Judge for yourself how aesthetically pleasing it looks from the photo:

U-shaped aluminum profile 10 mm used to decorate the ends of drawers in the kitchen Framing the countertop on the kitchen unit with an 8 mm profile U-shaped aluminum profile for 16 mm chipboard in cabinet design Aluminum U-shaped edging profile 16 mm used for glass in sliding partitions Aluminum profile U-shaped end for furniture facades Aluminum profile U-shaped 10*10*10*1 mm in the design of a tabletop

Mounting profiles

Just as in furniture production, along with products made from aluminum and its alloys, galvanized steel U-shaped profiles are widely used. It all depends on the specific purpose. Let's talk first about the aluminum version.

Made of aluminum

Such profiles are manufactured according to several standards:

- For translucent structures (glass partitions, polycarbonate, windows and doors - according to GOST 22233*2001. Manufacturing method - hot pressing;

- Technical conditions for the production of other mounting profiles, produced by the same pressing, are presented in GOST 8617, which has been in force since 1981;

- The range of profiles with a U-shaped cross-section is determined by GOST 13623*90. It includes products of various sizes, with a minimum shelf height of 3 mm and a maximum of 275 mm. There are more than three hundred species in total.

Note: The standards do not limit the scope of use of aluminum channel. Where to apply each specific option is decided by designers and product manufacturers, who confirm certain decisions with calculations.

The U-shaped mounting profile, made of aluminum or its alloys, is used both in everyday life for minor repairs and in the construction of pavilions, greenhouses, installation of partitions, glazed facades.

U-shaped profile for composite panels and glass on the facade Mounting U-profile for greenhouses Office partition made of aluminum and glass Such cornices are usually made of AD31 alloy

- Even though the aluminum version is more expensive than the galvanized U-profile, it is often preferred for various reasons. One of these reasons is that, compared to steel, aluminum has very low electrical conductivity and does not accumulate static electricity.

- In addition, structures assembled from aluminum profiles are most often installed without welding. This allows them to be disassembled and transported to another facility, which is very valuable for temporary structures.

- The most important thing is that aluminum does not require corrosion protection, which is why in the construction industry it is mainly used in decorative structures and finishing coatings. Thanks to this metal, the product or structure retains its original appearance throughout its entire service life.

- Where the frame is hidden by cladding, steel profile-P is often used. Its price is lower, and then, steel has higher strength characteristics and can withstand greater loads.

- However, for those areas of use where the properties of the metal still require aluminum, the latter is strengthened by adding magnesium, silicon, and some other components, resulting in very strong alloys. Suffice it to say that some of them can be forged - however, it is unlikely that even craftsmen do it with their own hands.

Types and classification of aluminum alloys

Aluminum in its pure form is rarely used anywhere, at least in residential construction. The most commonly used alloy is AD 31, from which all these profiles for glazing, edging, cornices, etc. are made.

The remaining alloys, which have very high levels of corrosion, low- and high-temperature resistance, are used in industries such as shipbuilding, aviation, medical equipment and others.

Made from galvanized steel

As mentioned above, along with an aluminum profile, an equal-flange bent U-shaped profile made of galvanized steel is used in construction. It is produced in accordance with GOST 8278 * 83, which sets out both the technical conditions and the assortment, in which the smallest profile has shelf and back dimensions of 25 * 26 mm, and the largest 310 * 100 mm.

- Depending on the size and purpose, channels can be made either from cold-rolled steel or from strips (hot-rolled sheets).

- The most popular products, which everyone is accustomed to positioning as a U-shaped profile for plasterboard, are made from carbon or low-alloy steel, which, with sufficiently high strength, is easy to process.

Steel profile can be easily cut with scissors

- Structural profiles are protected against corrosion by galvanizing. If rolled metal must meet certain aesthetic requirements, its surface can be painted or polished.

Perforated

To reduce metal consumption in construction, products used for the installation of various load-bearing structures, which usually have a fairly thick wall, are perforated in production.

- U-shaped perforated profile is used for assembling support subsystems for heavy equipment, shelving, metal cabinets, frames for greenhouses or other light buildings.

Galvanized profile with three-sided perforation Galvanized perforated U-shaped profile: frame for a future cabinet Suspension of trays from the ceiling on a perforated profile

- The U-shaped perforated mounting profile is also used for installation of engineering systems. Trays for laying cables are made from it, in which, thanks to perforation, condensation does not form, and which, thanks to it, weigh very little.

- For example, a U-shaped perforated profile 32*20*3000 mm, which is used for hanging the above-mentioned trays, is in great demand. Since the profile is fixed on studs with nuts, the perforation also creates a certain convenience for making fastenings.

- Depending on the purpose of the profile, it can be completely perforated, or have holes only on the shelves. An example of this is the U-profile 60*40*3000*2.0 mm presented below, which is precisely used for hanging communications.

U-shaped profile 60*40 mm

Thin-walled

Thin-walled profiles, which are mainly used for installing suspended ceiling systems, constructing lightweight enclosing and decorative structures, are already practically weightless, so there is no need to perforate them. These include a galvanized U-shaped profile for plasterboard, the dimensions of which are maximally oriented towards the convenience of installing the frame and covering it with sheet material.

Profiles for installing a frame under plasterboard Guide and rack profile Frame for a suspended ceiling Galvanized U-shaped profile 50*50 mm from Knauf Frame for covering the base with panels Options for end and cross connections of the U-profile

However, this type of rolled metal can be used not only for installing a frame under drywall. It is universal - in general, all types of panels can be mounted on a steel sheathing: from plastic lengths and lining to façade siding and porcelain stoneware.

Plasterboard covering on a metal frame Installation of lining on a metal frame Facade cladding on a metal frame

Another thing is that in each specific case, the metal perforated U-shaped profile has its own parameters, adapted to the dimensions of the cladding elements.

The main role here is played not so much by the length of the product, but by the width of the shelves and back. The more loads the frame has to withstand, the larger the cross-sectional dimensions of the profile should be.

Here the regulations are already set by the instructions of the manufacturer of the facing material.

Elastic tire

An elastic tire is used when installing gypsum boards in the space between the ceiling and the roof structure, with a small installation height, when installing cladding on wooden slats or brickwork.

Table 9. Elastic tire dimensions

| product name | Metal thickness, mm | Back width, mm | Product height, mm | Standard product length, m |

| Elastic tire | 0,6 | 60 | 4,0 |

PU – corner profile

It is designed to protect the outer corners of plasterboard partitions and cladding, and the plaster layer from mechanical damage. The profile has an acute angle (85°) and perforation along the entire length of each shelf. Putty penetrates into the holes of the shelves, which ensures strong adhesion to the surface of the corner. Made from galvanized steel or aluminum.

Table 10. Corner profile dimensions

| Product marking | Metal thickness, mm | Shelf width, mm | Material | Standard product length, m |

| PU20×20 | 0,22 – 0,25 | 20 | aluminum | 2,5; 3,0 |

| PU25×25 | 0,4 | 25 | Cink Steel | |

| PU30×30 | 0,4 | 30 | ||

| 0,5 | ||||

| PU35×35 | 0,5 | 35 |

Production of U-shaped profiles - Metalworker's Handbook

The development of modern metallurgy and the introduction of cost-effective technologies have made the widespread use of various metal profiles in a wide variety of areas of human activity.

Modern methods of computer planning and metalworking make it possible to develop and produce a wide variety of profiles. These are U, J and C profiles, as well as racks, struts, and spacers. In addition, various holders, frames, frames, as well as inserts, shells, brackets.

Be sure to have various supports, stiffening ribs, and railings. Accordingly, rails with purlins and much more.

All of them are united by the relatively small thickness of the metal in relation to the length and cross-sectional profile, which can be very diverse.

Assortment by material

U-profile metal, as a rule, is made of steel or aluminum. In this case we can highlight:

- cold-rolled steel “08 ps”, “08 kp”, “08-Yu”;

- hot-rolled steel “St 3ps”, “St 3 sp”, “09G2S”, “S235”, “S245”, “S255”, “S275”, “S345”, “10 HSND”;

- aluminum;

- galvanized steel according to GOST 14918–94, GOST R 52246–2004 rolled grade 350 with first class zinc coating (275 g);

- stainless steel “12Х18Н9Т”, “12Х18Н9Б”, “12Х18Н10Т”, “12Х18Н10Б”.

The choice of brand of manufacturing material depends on the purpose and operating environment. In most cases, in handicraft production it is enough to know the geometric parameters of the profile and what type of metal it is made from (black or stainless). In addition, it can be aluminum or galvanized steel.

In principle, the variety of metal or various alloys used for the production of profiles is very large, especially when it comes to special-purpose profiles. Thus, aluminum profiles are simply irreplaceable in the manufacture of window frames and partitions, and are often used in the design of premises for various design projects.

And also in their production various coatings in the form of primers, paints and enamels can be used. Recently, polymer coatings have been frequently used.