How to make a gearbox for a walk-behind tractor with your own hands

Making a gearbox for a walk-behind tractor with your own hands is a difficult and at the same time interesting task. This is one of the important mechanisms, without which the operation of garden equipment using a walk-behind tractor is unthinkable. Its main task is to reduce the speed of the drive shaft and at the same time increase or decrease the torque to the drive.

You can buy a transmission mechanism for your walk-behind tractor in a specialized store, but it is wiser to assemble the gearbox yourself, taking into account all the technical characteristics of the engine. This will be the best option, since when designing a mechanism for a specific power plant, an individual calculation is made, which will simplify the task of pairing it with the engine.

Manufacturing or selection of ready-made structures

With access to a wide range of components: a junkyard of old equipment or abandoned property of a repair shop, it is possible to manufacture a gearbox with an accurate selection of the gear ratio.

However, such a complex structural element requires serious metal processing equipment. You can select a housing of the appropriate size, drill holes for the shafts on the bearings, and assemble the structure no worse than the factory one.

However, experience shows that the selection of ready-made structures with minor modifications is much more effective. As an example, consider a homemade walk-behind tractor based on an engine from an IZH motorcycle.

A proprietary gearbox is used, with the ability to change speeds. The standard gear ratio is not enough, although a small sprocket on the output shaft of the gearbox, combined with a large sprocket from the drive wheel, already provides a good reduction in speed.

The shaft, installed in the bearing podium, is equipped with another small sprocket, which, using a second chain, transmits torque to the wheels. In turn, a large diameter star is installed on the drive axle.

The result is a design with two-stage rev reduction and solid torque. By using the motorcycle gearbox, you can select the required speed without using the throttle. The engine almost always runs at idle speed, which prolongs its service life.

No less popular is the use of a ready-made gearbox from the Ant scooter.

It is not necessary to use the entire wheeled platform; it is enough to install your rollers on the bridge. By using the gearbox from the selected power plant, you will get the optimal ratio of power and speed.

Video: modification of the gearbox of the Neva walk-behind tractor.

Gearbox manufacturing process

First, the parameters of the power plant are calculated. The crankshaft speed can be found in the technical specifications.

This is the first quantity required to perform the calculation. The value is not constant, with the addition of “gas” the number of revolutions increases. Basic value: idle speed +10% .

Next, the suspension axle revolutions are calculated . Knowing the size of the wheels, it will be possible to calculate the amount of run-out per revolution. The number of axis revolutions is calculated to ensure a comfortable speed - 3-5 km/h, which is the second value for design.

For example, idle speed +10% is 600 rpm. The required wheel axle speed for 3 km/h is 200 rpm. So, the gear ratio should be 3:1 . The rotation speed of the axis is reduced by three times in relation to the speed of the motor shaft, and the torque increases accordingly by three times. Gearbox types:

Final drive device

The design of the final drive is so simple that you can assemble it yourself. The basis of the mechanism is a gear that fits onto the splines of a standard drive. The second, driven gear rotates the wheel. To ensure that the direction of rotation does not change, intermediate (parasitic) gears are installed.

Typically the driven gear has more teeth than the drive gear. This allows you to increase the gear ratio and, if desired, equip the car with larger diameter tires.

The same principle applies to heavy tractor gearboxes such as T 170 or truck gearboxes, which are equipped with KamAZ or MAZ commercial vehicles. The only difference is that for tracked tractors and other equipment, the torque is transmitted not to the wheel hub, but to the track sprocket.

If necessary, repairs to the final drive can be done with your own hands. In most cases, to eliminate noise and vibration, it is enough to replace auxiliary elements: oil seals, floating seals, bearings, etc.

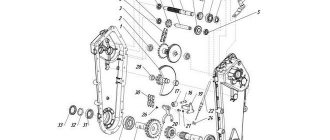

Diagram of a gearbox assembled from parts of a decommissioned car

This gearbox is assembled from parts of the main drive of the GAZ-69 vehicle. The bevel gears rotate from the drive sprocket, which is mounted on the shank. The torque is then redirected to one of the two driven gears, which rotate in bearings numbered 206 on the spline shaft. At the right time, the gear that engages with the reverse sleeve on the central spline of the shaft works. Then the cardan transmits the movement to the differential or the drive wheel of a mechanical vehicle.

Read also: Heating concrete with electrodes connection diagram

And the final important point for owners of walk-behind tractors or mini tractors. When purchasing a mechanism, price also plays an important role, because cheap units are mostly equipped with non-separable gearboxes. Such mechanisms are unreliable for long-term operation. If necessary, this gearbox cannot be repaired, disassembled or reassembled, or parts replaced. It is made of low quality metal, its parts are not gelled.

Expensive units are equipped with gearboxes that can be disassembled, which allows for gearbox maintenance and repairs. Like any other mechanical vehicle, it needs constant rechecking, repair, and updating, and the gearbox must be constantly inspected and monitored. From time to time it is necessary to carry out diagnostics of the mechanism to prevent breakdowns in the future.

When purchasing, it is more profitable to buy a more expensive gearbox, because it will serve you longer.

The pride of many summer residents is a homemade walk-behind tractor, assembled with their own hands from parts that have served their age. Installing an electric motor or a small gasoline motor from an old scooter or motorcycle onto a frame with wheels is not difficult even for a novice amateur mechanic. But what you have to think about is the gearbox for the walk-behind tractor.

Gears

By means of a gear engagement of two gears, rotation is transmitted from the engine shaft to the gearbox. Gears are cut on special gear cutting machines, so you should make a calculation and buy. The final placement of units and the quality of equipment operation depend on this choice. The number of teeth and gear diameter are two major factors in equipment design.

During installation, it is necessary to maintain the distance between the gears, protecting them from breakage. You should also ensure that the surfaces and teeth are lubricated with gear lubricant. It is poured to the level of the top of the gear, all other parts are lubricated by splashing oil as the gears rotate.

Types of gear units

The transmission of rotational motion from the motor shaft to the actuator shaft can be carried out by direct connection of the axes, if the speed and power of rotation of the engine are acceptable for operation, and the axes of the drive and driven shafts coincide. Such cases are extremely rare, and with several attachments for different purposes, direct transmission absolutely cannot be used. To match the speed and power of the drive and driven shafts, 4 types of mechanisms and their combinations are used. Main types of gears:

The worm gear is structurally limited by the speed-reducing function; the rest can be used in both downshifts and overdrives. In addition, such a gearbox always has a driven axis perpendicular to the drive shaft. This scheme is called an angular gearbox. In addition to the worm gear, you can change the direction of the axis using a spatial planetary mechanism. Belt and chain drives keep the driven axis parallel to the engine axis. In simple devices, reverse is possible only when the rotation of the engine changes.

Motoblocks use engines with a high number of revolutions per minute, which can be verified in the product data sheet. This means that you need to make a gearbox with your own hands to reduce the speed, and it is better to choose what type of homemade gearbox for a walk-behind tractor, knowing the characteristics of each type.

Belting

The pulley or belt that transmits rotation from shaft to shaft is familiar to every motorist who has looked under the hood of the engine compartment. The rotation speed reduction coefficient is determined by dividing the radius of the small driven wheel by the radius of the large driving wheel.

The advantages of belt gearboxes are their ease of manufacture and repair, and a wide variety of parts. And the disadvantages of the belt:

- belt stretching, decreased adhesion to the pulley due to temperature and wear;

- slippage during sudden increases in torque;

- short service life.

The shortcomings are compensated by using a spring-loaded roller that presses on the surface of the belt between the wheels, and by using a toothed belt on pulleys with transverse chamfers. Belt gearboxes require the drive and driven pulleys to be in the same plane; bending or twisting the belt will quickly lead to it breaking.

Chain type

The operating principle of a chain drive is similar to a belt drive, but sprockets are installed instead of pulleys, and the belt is replaced by a chain.

Such a homemade gearbox will not allow slipping, and under similar conditions it will work much longer. Just like a belt gearbox, a chain gearbox must have drive and driven sprockets in the same plane, and its gear ratio is calculated by the ratio of their teeth. The weight of this design is greater than that of a belt design, but it is safer to install it on powerful walk-behind tractors.

Unlike a belt drive, a chain drive requires caution or additional protective measures. If a rotating implement collides with a thick root in the soil, its drag force will be transferred to the motor, possibly damaging it. Until the engine fails or switches off, it will try to rotate with maximum power along with the frame around the driven axis of the gearbox. The greater the engine power, the stronger the tipping torque will be.

The gear ratio of a chain gearbox can be higher than that of a belt gearbox of the same size, since the drive sprocket, even having a small size, will not allow the chain to slip.

In terms of cost, ease of assembly, and prevalence of parts, a chain drive is not inferior to a belt drive.

Using gears

A walk-behind tractor with a gear reducer is more reliable and durable than one with a chain or belt drive. Gear structures are installed on factory products, and not only on walk-behind tractors. The units are small in size as a result of combining two gears with different diameters on one axis. For a walk-behind tractor, for example, a gearbox from an Ant scooter is perfect. But you can make your own using gears from motor vehicle gearboxes.

Types of gearboxes

These devices differ in the type of torque transmission.

- Worm gearboxes. The transmission system of these devices contains a worm gear, which allows not only to significantly reduce the speed of the working shaft, but also to change the direction of rotation. The gearbox shaft at the output of the device is usually located at right angles to the input shaft. This feature of worm devices allows the engine to be placed most compactly together with the torque-transmitting mechanism. The gear ratio of this type of gearbox can be up to 1 to 100 or more;

- Gear reducers. Gear mechanisms for torque transformation are often used in units in which it is necessary to implement a different gear ratio between the input and output shafts. A gearbox of this type can be made with one transmission mechanism, or using several gears with a significant gear ratio. The teeth in such devices can have different shapes, but the quality of processing of such parts must be the highest;

- Hydraulic gearboxes. Such devices are installed between the pump and hydraulic mechanisms. A hydraulic gearbox is used for the same purpose as mechanical ones - to reduce the transmitted energy or rotational speed;

- Geared motor. This system is also used for torque transformation and is a gearbox and motor combined in one housing. The most common are gearmotors operating on electric traction. In this case, it is possible to significantly reduce the size of the gearbox and increase the efficiency of the device;

- Planetary gearboxes. The transmission system and planetary type gearbox circuit is a type of gear mechanism, but due to the originality of the applied method of transmitting torque, it can be considered a separate type. Such mechanisms are compact and very reliable in operation, but require precise calculations during production. The teeth of planetary gearboxes must be tightly meshed with each other, but easily set in motion.

The working parts of gearboxes must be lubricated to reduce the coefficient of friction and power loss. The method of applying lubricants depends on the type of gearbox and the power of the transmitted energy. If the transmission system does not operate at high rotation speeds, then a single application of lubricant to the working surfaces during the entire service life is sufficient. For powerful devices, a special system of forced supply of lubricating fluid is used, followed by cooling and cleaning.

Non-separable products, as a rule, operate at low power levels and in those areas where the device is not required to operate in harsh conditions. Gearboxes that are used to transform large capacities are located in a casing of a collapsible design, which allows, if necessary, to carry out scheduled or emergency repairs and adjustments of the mechanism.

The gear housing can be made of various materials. The selection of material depends on the operating conditions and power of the device. The gearbox for low-power household devices can be made of high-strength plastic or aluminum alloy.

How is the tilt and turn mechanism of a plastic window adjusted?

According to most users, a tilt-and-turn window is one of the most convenient to use, since they have the ability to open the sash in two planes: horizontal - the main one and vertical - in ventilation mode.

In order for a PVC window with a tilt-and-turn mechanism (TIM) to work reliably for the entire required period, it requires periodic maintenance and adjustment.

These mandatory operations are prescribed by the manufacturer and can be performed by the owner independently or with the involvement of a specialized organization. It is important, when making adjustments, to take into account that such structures, as a rule, have multi-season operating modes: winter and summer, which implies different settings of the trunnion positions.

When is tuning required?

The manufacturer of the structure clearly prescribes the frequency of adjustment of the scissors and awnings for each PVC window design.

Such actions must be carried out by the owner or contractor in the following cases :

- after completion of installation work when installing a new PVC window;

- after replacing the glass, which could lead to a failure in the fitting settings;

- every six months, when switching to “summer” or “winter” operating modes;

- if the sash begins to function poorly;

- if the window begins to blow out and is covered with condensation;

- The window sash does not open.

If the user discovers that the PVC window has begun to function poorly immediately after installation by the contractor, the problem cannot be corrected by adjustment, since in this case the source of the problem is considered to be poor-quality installation work. Therefore, the customer must immediately contact the installation company to correct malfunctions.

The latest swing-out models include the following structural components :

- group of loops;

- scissors;

- window handle;

- set providing angular transmission;

- constipation;

- a blocker that prevents incorrect opening;

- microlift;

- set of strike plates.

When operating a PVC window, experts distinguish between primary and current adjustment of a rotary-mechanical type.

Primary

The primary one is carried out after completion of installation and construction work when installing PVC windows.

During primary regulation, the POM is checked:

- completeness of opening/closing of the sash in horizontal and vertical positions;

- operation of the handle on the sash: when closing the window, the handle should be directed vertically downwards, when turning 90 degrees, the handle is moved horizontally, in this position the sash opens;

- turning to the top position - the sash opens vertically in ventilation mode;

- check the tightness of its clamping to the frame and the operation of the seals;

- check the operation of additional elements, for example, anti-burglary mechanisms.

When checking and adjusting all components and modes of the tilt and turn mechanism, you need to ensure that all manipulations are carried out without the use of effort - as smoothly and tightly as possible.

Current

Current POM regulation is carried out at least 2 times a year at the beginning of the warm and cold seasons. At this time, the mode of use of the unit is switched to winter and summer.

Before changing the operating mode of opening the sash, the entire fittings and insulation are thoroughly washed from dust and lubricated with silicone grease . After changing the position of the trunnions, check the tightness of the sash with maximum pressure for winter mode and minimum for summer mode and, if necessary, make adjustments.

What exactly needs to be regulated?

Before making adjustments to the POM, you need to know its design. This mechanism is divided into 2 parts: the upper one, which the craftsmen call “Scissors” and the lower one, which is responsible for the upper movement of the sash. The upper adjustment occurs with a slight shift to the left and right, and the lower adjustment is adjusted by shifting up and down.

The balancing process begins with the upper part of the POM, then adjusts the lower part. To do this, you will need to open the sash, find the upper part of the mechanism and there is a small adjustment hole on it that fits a hex key.

In certain cases, adjusting the POM is not able to solve the problem of a poorly functioning sash, since the failure may be caused by a defect in the mechanism itself. In this case, you need to invite specialists who installed such a block, especially if the window is still under warranty.

What tools are needed?

To adjust the POM, the contractor will need to have a standard set for adjusting PVC windows , which includes:

- electric screwdriver for working with screw connections;

- bits for a screwdriver;

- pliers;

- hex key No. 4, which is used directly for the adjustment operation; it can be purchased at any furniture store, since it is used for assembling furniture;

- two screwdrivers - flat and Phillips, for adjusting some components of the tilt-and-turn mechanism;

- silicone grease for fittings.

Step-by-step instructions for setting it up yourself

After the performer carefully inspects the external condition of the rotating mechanism, cleans it of dust and lubricates it with silicone grease, they begin the adjustment process :

- Adjustment starts from the top.

- Open the sash, inspect the mechanism, find a small adjustment hole suitable for a 4 mm hex key.

- Insert the adjusting key into the hole, unscrew the bolt secured there, completely freeing the upper part of the mechanism.

- Find a small aluminum strip to which the window is attached to the mechanism, and fix it in a slightly different position to the side or lower if the window, for example, rubs from above.

- Make sure that the adjustment is correct, lightly cover the sash and make sure that it fits into the frame as evenly and easily as possible.

- The mechanism is attached to the window in the reverse order.

- Make sure that the window is aligned correctly, the final adjustment can only be made using the lower adjustment, it is important not to overdo it with the adjustment by moving the rail too far.

- Move to the bottom of the mechanism.

- On the lower mechanism, the protective coating in the form of a cap is removed by ordinary removal.

- They find a specially made turnkey tube.

- The key is lowered into the tube with the long side and gradually begins to unscrew.

- Next, the setting process is similar to the upper mechanism.

Differences in technology for the rotary mechanism

Such differences, when making adjustments, are associated with the different design of the mechanisms of PVC windows; in the rotary version, hinges are installed on the sash. The adjustment process is aimed at adjusting the elements of the window structure, which are responsible for the vertical position of the sash.

Start balancing from the bottom loop . Perhaps it weakened during use or was over-tightened during the autumn-winter cold period. In the case when the hinge is very slack, the sash is lifted up, and in the case when it is pressed strongly, the hinge must be loosened.

During the adjustment process, the sash should be level, the process should take place with the window closed.

Possible errors and difficulties

The process of adjusting the POM window is not complicated; all home craftsmen can do it, if they have the necessary tools and consumables.

However, in practice, performers often make mistakes that can have very negative consequences, which can disrupt the overall setup of the fittings, as a result of which the window sash will not open.

The most common mistakes when performing regulatory measures include:

- Wrong choice of setting area, start balancing from the bottom of the tilt and turn mechanism, and it is necessary - from the top.

- The preset cleaning of the mechanism from dust and dirt and lubrication for smooth operation of the elements have not been carried out.

- Strong extension of the aluminum sash strip.

- The process of general adjustment of the operation of the fittings in the adjustment field has not been completed.

How much does the service cost?

Despite the fact that the process of adjusting the tilt-and-turn mechanism of a window sash is not complicated, many owners, especially of expensive window units, prefer to invite specialists for this work. Often such balancing is carried out as part of other operations, for example, when preparing a window for operation in a certain season of the year.

The cost of services for such work depends on the window model, modification of the installed tilt-and-turn mechanism and the area where services are provided; in Moscow and St. Petersburg these prices are usually 15-20% higher.

Prices for certain types of work on setting up POM windows:

- Profile cleaning - 250 rub. per p.m.

- Sealing - 500 rub.

- Adjusting the opening sash - 350 rubles.

- Adjustment of the swing-out flap - 850 rubles.

- Replacement of POM - 1230 rub.

- Replacement of seals with labor and material - 150 rub./l.m.

- Lubricating window fittings - 300 rubles.

- Binding accessories - 1800 rub.

- Repair work on the folding mechanism - 1260 rubles.

- Repair work on fittings - from 1400 rubles.

- Visit of a specialist - from 300 rubles.

Conclusion

A comprehensive PVC window system, which can operate both by opening and tilting for ventilation, is today considered the most effective and is preferable when choosing a design.

In order for the tilt-and-turn mechanisms to work accurately and the window to perform its energy-efficient functions, adjustment operations must be carried out periodically - the first when installing the window unit, and the current ones 2 times a year, before the start of the summer and winter climatic seasons.

Why use a bevel gear?

A mower is being made for a mini tractor; there is a need to change the direction of the drive shaft by 90 degrees, i.e. you need a bevel gear. Or no reduction at all, or with a slight reduction. What common things can it be used for? It won't work with a grinder. The rear axle of the Ural motorcycle lowers greatly. Maybe agricultural machinery has something like this as standard? Does anyone have experience in manufacturing such gearboxes using automotive differential gears?

I saw something similar on a combine harvester, on this thing in front)) well, where are the knives. The combine in the village is some kind of ancient, either Neva or xs. in general, look for angular gears, they are available in the factory version

off: and here the oil tank builders crawled

Well, if you install a bevel gear with a large reduction, and then increase the speed.

I already thought. but as in the joke: this back and forth annoys me. I would like to avoid unnecessary details... this has already happened a couple of times, you get wiser and wiser, and then you come across a simple solution. Unfortunately, a person’s horizons are not limitless. Right now I’m already thinking about making a turn from two cardans with an intermediate support.

Please note: Original ideas for flower beds made from tires

90 degrees and cardans, well, I don’t know, will they work normally?

turns out 2 at 45 degrees

I saw such a gearbox with a slight reduction in an agricultural machine for sorting potatoes

2Dred Did you decide to come up with a mower for a Lambordini?

On 40s, a drive pulley with an angular gearbox is placed on the rear PTO. In teeth 22-12, if I'm not mistaken..

Yes, my phacelia is blooming, so in a couple of weeks I will need to mow it. Last year, two days of three hours each with a lawn mower did not inspire me; my hand then went numb and did not come off for a month, but this year the area sown has increased.

I tried to find a standard one from the 40, but either the working unit is sold assembled, or it is no longer a gearbox. and the trash...

It turned out that the Ural chainsaw supposedly has an angular gearbox... can anyone explain anything about this? I know where many of these saws are lying without engines.

“Friendship”, “Ural” Electron”, Angular gearbox, gear ratio - 1:2 (I also know where many of these saws are. In the topic “Friendship saw”. There are a lot of them!)

Yes, not supposedly, but it really is worth it, but the gear ratio is about 13

And if you look at the gearboxes of outboard motors? There are so many of them lying around everywhere now. Not very step-down (and if you turn it on the other way around, then step-up), in addition to reverse

there is a gear ratio of approximately 1.5

I’m already thinking about “putting the reduction gear in reverse.” I can only take power from the camshaft, and starting occurs through it, i.e. revolutions from 500 to 1500. For a rotary mower, judging by the characteristics of factory mowers, speeds from 2500 and above are needed. so a 1:3 gearbox will be fine. What do you think about using flanges from a household concrete mixer in a mower? the shape of the disc, there is a seat for the bearing, the diameter is about 500 mm, the price tag is humane and is always available in spare parts.

Here's the device, we'll torture it...

A mower is being made for a mini tractor,

show me what you came up with, maybe we can help you with advice

Yes, I rarely ever make things up, so I decided to stupidly steal the design of an MTZ or forty mower, i.e. a tire made of a channel, on top of it are three flanges of a concrete mixer, we sculpt 3 knives from spring steel onto them, the drive is first with a cardan based on the Ural motorcycle joints through an angular step-up gearbox and then with a motorcycle chain on the sprockets of the flanges, all three are one chain, so the axles of the flanges are not on a straight line, but in a triangle, well, you’ll also have to attach a spring-loaded tensioner. All. The problem is not to invent, the problem is to adapt various standard crap in order to at least bother with a lathe and milling machine. and so that it would be cheap, i.e. crap not from Lexus, it was right now I can throw in a little drawing

How to make a homemade mini tractor

The simplest option to make a mini tractor with your own hands is to remake a used walk-behind tractor. It contains almost everything you need for construction:

- engine;

- clutch;

- Transmission;

- tractor wheels with axle shafts.

The frame from the walk-behind tractor can be used as a fragment of the frame of a mini tractor. There are mounts for the engine and gearbox. Assembly must be done in the following sequence:

- Weld a frame with all fastening units from rolled metal.

- Install the rear and front axles.

- Secure the engine and transmission elements.

- Assemble the steering.

- Secure the fuel tank, driver's seat, and protective covers.

- Weld a device for installing attachments.

- Conduct electrical equipment and install lighting fixtures.

You can take it as a basis. A powerful frame is not required to remake it. A square pipe with a cross section of 100 mm is sufficient. On one side the cultivator itself is attached, and on the other, a steering control with a pedal assembly is installed. The gas and clutch control cables are connected to the pedals. A driver's seat is installed in the middle of the structure. The towbar is welded in the rear part.

Equipment

The converter can be collapsible or non-dismountable. As a rule, budget modifications of walk-behind tractors are equipped with the latter option. Their difference is in less expensive parts that cannot be replaced. If it breaks, you will have to replace the entire gearbox. Manufacturers determine the service life of such models from one to two seasons, no more, provided that the device is used correctly.

More expensive equipment is equipped with a collapsible gearbox, which can be repaired by replacing failed components. Therefore, the service life increases significantly.

The converter package includes the following items.

- Frame . Depending on the type of gearbox, it may be dismountable or not.

- Rotor shaft , which provides torque.

- Gears of different sizes.

- Chain or belt depending on the type of gearbox.

- With chain transmission, movement is carried out using sprockets - toothed disks .

- With a belt drive, the mechanism is equipped with pulleys onto which the belt is placed.

- Bearings . Since all the parts rotate, it is necessary to reduce friction and ensure that the elements rotate freely. The bearing is designed to cope with this task.

All parts are located inside the case. In addition to the standard set of components, elements for lubricating bearings, for example, an oil pump or a cooling device, can be added inside the device.

Main types, their purpose

A gearbox is equipment that allows the use of an engine in the design of various units. Rotation from the motor is transmitted to the car wheel and boat propeller. In this case, the force increases, with a decrease in the rotation of the motor shaft.

In the household, walk-behind tractors and cultivators are most often used. According to their design features, they can be installed:

- Gear mechanism. Bevel or cylindrical gears are pressed onto the drive shafts. This design allows them to be used in direct transmission of rotation from the engine. Can be used as an angular gearbox for a walk-behind tractor, while the design uses a bevel gear.

- The device is gear-worm. Most often installed with a vertical engine crankshaft. A gear with a certain number of teeth and a worm screw with a certain thread pitch is a schematic description of the type of device. The main feature is the transmission of rotation of the engine shaft at a right angle.

- Chain device. The shafts are equipped with toothed sprockets. They are wearing a special chain, with the help of which torque is transmitted from the motor. For good performance, the chain is tensioned using a tensioner roller.

- Belt device. Rotation is transmitted using belts. Pulleys with grooves for belts are pressed onto the shafts, and the belt is tensioned using a tension screw.

To make a homemade bevel gear, you need to know its operating principle and how to make them at home.

Types of gearboxes

The design of any converting device for a walk-behind tractor (gearbox) consists of a set of motion-transmitting shafts or gears of different diameters, enclosed in a durable housing.

Converting devices are divided into several types according to the type of transmission:

- chain;

- belt;

- gear;

- worm (gear-worm);

- combined systems.

For chain-type gearboxes, rotation transmission is provided using a chain and sprockets of different sizes, which are installed on rotary shafts. The operating principle of a belt mechanism is similar to a chain mechanism, but instead of sprockets and a chain, pulleys and a belt are used.

Inside the housing of the gear reducer there are shafts with gears mounted on them, having straight or oblique teeth. Gears transmit rotation from the engine to moving parts. Bevel gears are used in angular mechanisms for heavy walk-behind tractors.

Self-manufacturing of the gearbox - simple about the complex

Each of the listed types of converters has its own disadvantages. Therefore, in order to repair the walk-behind tractor gearbox as rarely as possible, some farmers prefer to equip their equipment with homemade converters. A self-made structure often turns out to be of higher quality and more reliable. To work you will need:

- Phillips and flathead screwdrivers;

- Hacksaw for working with metal;

- Pliers;

- Vise;

- Welding machine.

First you need to weld the body. For this you can use stainless steel plates. Gears and shafts will also be needed for the job. You can “borrow” them from the Druzhba chainsaw. In this case, you will need to drill a hole inside one of the tool shafts. On the opposite side of the gearbox it is necessary to install a second shaft, and after it - bearings and a cage. The output shaft of the device is attached to a pulley. After this, the finished device should be placed in the previously welded housing and machine oil should be poured inside.

The made converter is connected according to the same principle as the standard gearbox. As you do this, pay attention to the position of each gear. The elements should not be skewed, and their teeth should have perfectly straight ends without kinks or other deformations.

Finally, you will need to test the converter. We advise you not to load it immediately after creation. To begin, stretch the wound-up walk-behind tractor along the ground - let the elements of the converter connect and establish interaction. Only after this can the equipment be used for its intended purpose.

Do-it-yourself winch with manual or electric drive

Helical gearbox: overview of types and operating principle

The drill body already contains a planetary gearbox of approximately 3:1. A very powerful machine. Do it yourself - with your own hands" - a site of interesting homemade products made from scrap materials and items at home.

Today there are different types of devices on sale, but many car owners make a winch with their own hands. It is impossible to make a winch without a gearbox. Motorists use the most unusual gearboxes, for example, a trolleybus door opening mechanism.

When choosing a starter, preference should be given to models with a planetary gearbox. Each master develops and implements his own designs. The winch can be made by hand using the following technology. After installing the drum, a gearbox is attached to its axis. An adapter necessary for mounting the starter is installed in the upper part of the gearbox.

For installation, you first need to place the winch at the mounting location and make markings. If the car gets stuck deeply, you can attach a winch and pull the car out of the quagmire.

Anyone who can confidently work with a welding machine, an angle grinder, and, if necessary, can even use a lathe, can make interesting homemade products from a chainsaw with their own hands. This chainsaw moped is equipped with a gearbox with a gear ratio of 18:1 and a CVT transmission, which allows you to comfortably move on it at the speed of a regular bicycle.

Since the ice auger operates at low speeds, to adapt the chainsaw motor, it is connected to the auger through a reduction worm gear. It consists of a frame, an engine with a gear reducer, a control panel, a generator and connecting electrical cables. Detail 2.JPG please help, the differential housing rotates, which rotates two satellites, one of which transmits rotation to the engine, and the second satellite is connected to a worm gear.

If the gearbox has helical gears or a worm gear, then an axial load is transmitted to the shaft (and, accordingly, the bearings). Sometimes there is also distortion of the walls in a two-stage gearbox. Sometimes a purchased, working gearbox installed on a model suddenly fails, and an attempt to turn its shaft by hand often leads nowhere.

It may seem that a gearbox for a walk-behind tractor is a complex technical device and can only be manufactured in a factory setting. However, many of our farmers have homemade gearboxes for walk-behind tractors. The most important part of the unit is the drive. When there is a need to buy a gearbox, you need to know that its further operation and even functionality depends on the quality of this particular unit.

The gearbox transmits and appropriately converts torque, the conductors of which are mechanical transmissions. You can literally make a device from junk items, you just need to understand the principle of how the design works.